ASTM B352/B352M-17

(Specification)Standard Specification for Zirconium and Zirconium Alloy Sheet, Strip, and Plate for Nuclear Application

Standard Specification for Zirconium and Zirconium Alloy Sheet, Strip, and Plate for Nuclear Application

ABSTRACT

This specification covers hot- and cold-rolled zirconium and zirconium alloy sheet, strip, and plate.

SCOPE

1.1 This specification covers hot- and cold-rolled zirconium and zirconium alloy sheet, strip, and plate.

1.2 One unalloyed and three alloys for use in nuclear applications are described.

1.3 The products covered in this specification include the following forms and sizes:

1.3.1 Sheet, 24 in. [600 mm] or more in width; under 0.187 in. [4.8 mm) in thickness,

1.3.2 Strip, less than 24 in. [600 mm] in width; under 0.187 in. [4.8 mm] in thickness, and

1.3.3 Plate, over 10 in. [250 mm] in width; 0.187 in. [4.8 mm] and over in thickness.

Note 1: Material over 0.187 in. [4.8 mm] in thickness and less than 10 in. [250 mm] wide is covered as bar in Specification B351/B351M.

1.4 Unless a single unit is used, for example corrosion mass gain in mg/dm2, the values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. SI values cannot be mixed with inch-pound values.

1.5 The following precautionary caveat pertains only to the test method portions of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B352/B352M −17

Standard Specification for

Zirconium and Zirconium Alloy Sheet, Strip, and Plate for

1

Nuclear Application

This standard is issued under the fixed designation B352/B352M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This specification covers hot- and cold-rolled zirconium

2.1 ASTM Standards:

and zirconium alloy sheet, strip, and plate. B350/B350M Specification for Zirconium and Zirconium

Alloy Ingots for Nuclear Application

1.2 One unalloyed and three alloys for use in nuclear

B351/B351M Specification for Hot-Rolled and Cold-

applications are described.

Finished Zirconium and Zirconium Alloy Bars, Rod, and

1.3 The products covered in this specification include the

Wire for Nuclear Application

following forms and sizes:

E8/E8M Test Methods for Tension Testing of Metallic Ma-

1.3.1 Sheet, 24 in. [600 mm] or more in width; under 0.187

terials

in. [4.8 mm) in thickness,

E21 TestMethodsforElevatedTemperatureTensionTestsof

1.3.2 Strip, less than 24 in. [600 mm] in width; under 0.187

Metallic Materials

in. [4.8 mm] in thickness, and

E29 Practice for Using Significant Digits in Test Data to

1.3.3 Plate, over 10 in. [250 mm] in width; 0.187 in. [4.8

Determine Conformance with Specifications

mm] and over in thickness.

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

Contact Testing

NOTE 1—Material over 0.187 in. [4.8 mm] in thickness and less than 10

in. [250 mm] wide is covered as bar in Specification B351/B351M.

E1001 Practice for Detection and Evaluation of Discontinui-

ties by the Immersed Pulse-Echo Ultrasonic Method

1.4 Unless a single unit is used, for example corrosion mass

2

Using Longitudinal Waves

gain in mg/dm , the values stated in either inch-pound or SI

G2/G2M Test Method for Corrosion Testing of Products of

units are to be regarded separately as standard. The values

Zirconium, Hafnium, and Their Alloys in Water at 680°F

stated in each system are not exact equivalents; therefore each

(360°C) or in Steam at 750°F (400°C)

system must be used independently of the other. SI values

cannot be mixed with inch-pound values.

3. Terminology

1.5 The following precautionary caveat pertains only to the

test method portions of this specification. This standard does 3.1 Definitions of Terms Specific to This Standard:

not purport to address all of the safety concerns, if any, 3.1.1 annealed, n—denotes material that exhibits a recrys-

associated with its use. It is the responsibility of the user of this tallized grain structure.

standard to establish appropriate safety and health practices

3.2 Lot Definition:

and determine the applicability of regulatory limitations prior

3.2.1 Sheet, strip, and plate products (single definition,

to use.

common to nuclear and non-nuclear standards), n—a lot shall

1.6 This international standard was developed in accor-

consist of a material of the same size, shape, condition, and

dance with internationally recognized principles on standard-

finish produced from the same ingot or powder blend by the

ization established in the Decision on Principles for the

same reduction schedule and the same heat treatment param-

Development of International Standards, Guides and Recom-

eters. Unless otherwise agreed between manufacturer and

mendations issued by the World Trade Organization Technical

purchaser, a lot shall be limited to the product of an 8 h period

Barriers to Trade (TBT) Committee.

for final continuous anneal, or to a single furnace load for final

batch anneal.

1

This specification is under the jurisdiction of ASTM B10 on Reactive and

Refractory Metals and Alloys and is the direct responsibility of B10.02 on

2

Zirconium and Hafnium. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2017. Published May 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1960. Last previous edition approved in 2016 as B352/B352M – 11 Standards volume information, refer to the standard’s Document Summary page on

(2016). DOI: 10.1520/B0352_B0352M-17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

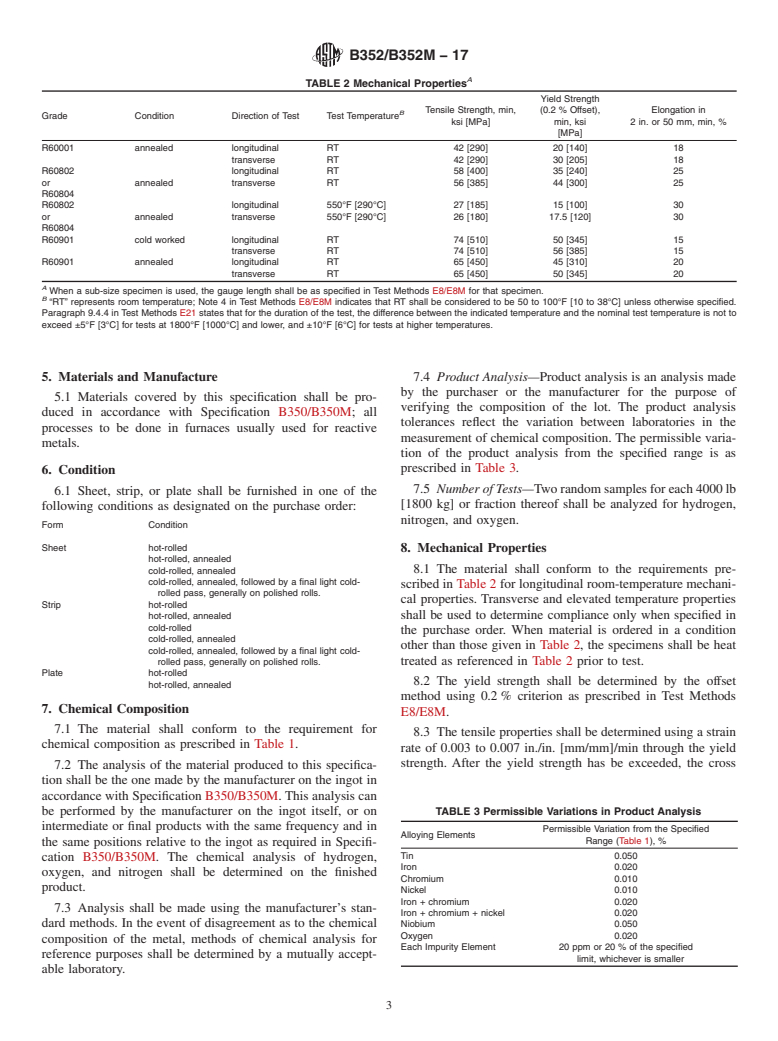

B352/B352M−17

NOTE 2—Atypical ordering description is as follows: _ 5000 lb reactor

4. Ordering Information

grade zirconium alloy, cold-rolled, vacuum annealed strip, 4.750 by 0.065

4.1 Purchase orders for material under this specification

by 72 in., ASTM Specification B352/B352M - 11, Grade R60804.

sho

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B352/B352M − 11 (Reapproved 2016) B352/B352M − 17

Standard Specification for

Zirconium and Zirconium Alloy Sheet, Strip, and Plate for

1

Nuclear Application

This standard is issued under the fixed designation B352/B352M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers hot- and cold-rolled zirconium and zirconium alloy sheet, strip, and plate.

1.2 One unalloyed and three alloys for use in nuclear applications are described.

1.3 The products covered in this specification include the following forms and sizes:

1.3.1 Sheet, 24 in. [600 mm] or more in width; under 0.187 in. [4.8 mm) in thickness,

1.3.2 Strip, less than 24 in. [600 mm] in width; under 0.187 in. [4.8 mm] in thickness, and

1.3.3 Plate, over 10 in. [250 mm] in width; 0.187 in. [4.8 mm] and over in thickness.

NOTE 1—Material over 0.187 in. [4.8 mm] in thickness and less than 10 in. [250 mm] wide is covered as bar in Specification B351/B351M.

2

1.4 Unless a single unit is used, for example corrosion mass gain in mg/dm , the values stated in either inch-pound or SI units

are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must

be used independently of the other. SI values cannot be mixed with inch-pound values.

1.5 The following precautionary caveat pertains only to the test method portions of this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B350/B350M Specification for Zirconium and Zirconium Alloy Ingots for Nuclear Application

B351/B351M Specification for Hot-Rolled and Cold-Finished Zirconium and Zirconium Alloy Bars, Rod, and Wire for Nuclear

Application

E8/E8M Test Methods for Tension Testing of Metallic Materials

E21 Test Methods for Elevated Temperature Tension Tests of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Contact Testing

E1001 Practice for Detection and Evaluation of Discontinuities by the Immersed Pulse-Echo Ultrasonic Method Using

Longitudinal Waves

G2/G2M Test Method for Corrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F (360°C)

or in Steam at 750°F (400°C)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 annealed, n—denotes material that exhibits a recrystallized grain structure.

1

This specification is under the jurisdiction of ASTM B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of B10.02 on Zirconium and

Hafnium.

Current edition approved Oct. 1, 2016May 1, 2017. Published October 2016May 2017. Originally approved in 1960. Last previous edition approved in 20112016 as

B352/B352M – 11.B352/B352M – 11 (2016). DOI: 10.1520/B0352_B0352M-11R16.10.1520/B0352_B0352M-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

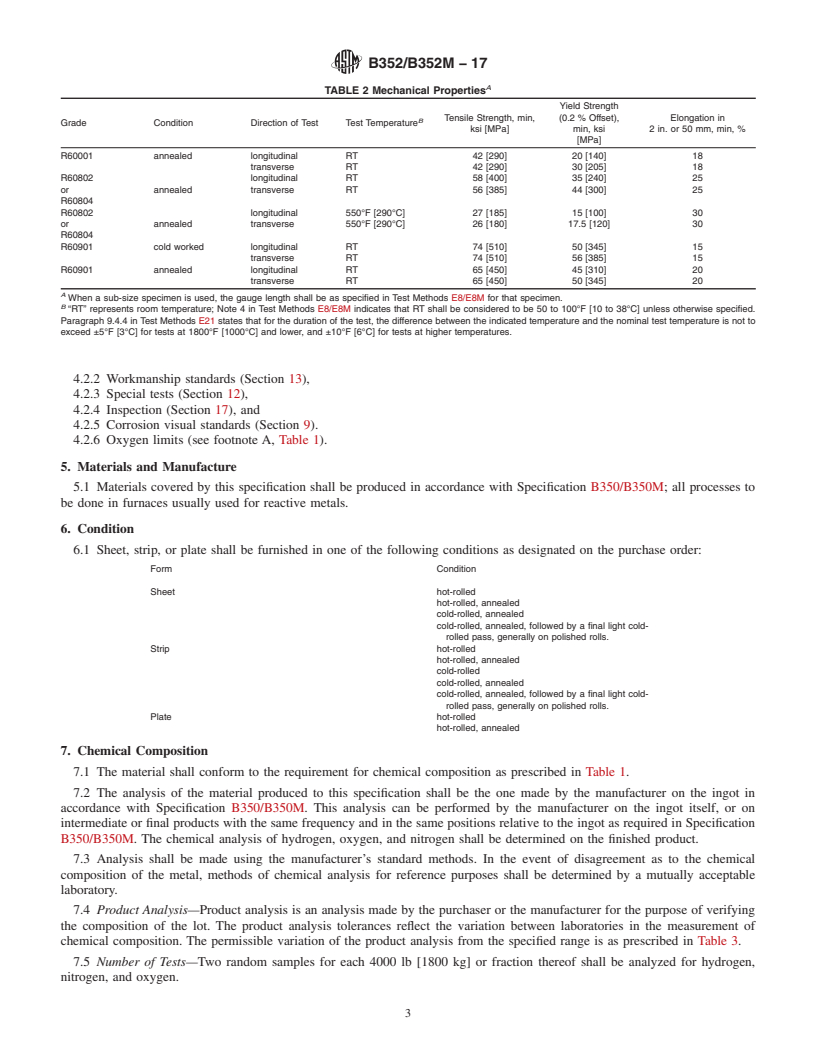

B352/B352M − 17

3.2 Lot Definition:

3.2.1 Sheet, strip, and plate products (single definition, common to nuclear and non-nuclear standards), n—a lot shall consist

of a material of the same size, shape, condition, and finish produced from the same ingot or powder blend by the same reduction

schedule and the same heat treatment parameters. Unless otherwise agreed between manufacturer and purchaser, a lot shall be

limited to the product of a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.