ASTM A773/A773M-01(2009)

(Test Method)Standard Test Method for dc Magnetic Properties of Materials Using Ring and Permeameter Procedures with dc Electronic Hysteresigraphs

Standard Test Method for dc Magnetic Properties of Materials Using Ring and Permeameter Procedures with dc Electronic Hysteresigraphs

SIGNIFICANCE AND USE

Hysteresigraph testing permits more rapid and efficient collection of dc hysteresis (B-H loop) data as compared to the point by point ballistic Test Methods A 341/A 341M and A 596/A 596M. The accuracy and precision of testing is comparable to the ballistic methods. Hysteresigraphs are particularly desirable for testing of semihard and hard magnetic materials where either the entire second quadrant (demagnetization curve) or entire hysteresis loop is of primary concern.

Provided the test specimen is representative of the bulk sample or lot, this test method is well suited for design, specification acceptance, service evaluation and research and development.

SCOPE

1.1 This test method provides dc hysteresigraph procedures (B-H loop methods) for the determination of basic magnetic properties of materials in the form of ring, toroidal, link, double-lapped Epstein cores, or other standard shapes that may be cut, stamped, machined, or ground from cast, compacted, sintered, forged, or rolled materials. It includes tests for normal induction and hysteresis taken under conditions of continuous sweep magnetization. Rate of sweep may be varied, either manually or automatically at different portions of the curves during tracing. Total elapsed time for tracing a hysteresis loop is commonly 10 to 120 s per loop.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A773/A773M − 01(Reapproved 2009)

Standard Test Method for

dc Magnetic Properties of Materials Using Ring and

Permeameter Procedures with dc Electronic

Hysteresigraphs

This standard is issued under the fixed designationA773/A773M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A343/A343MTest Method for Alternating-Current Mag-

netic Properties of Materials at Power Frequencies Using

1.1 This test method provides dc hysteresigraph procedures

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

(B-H loop methods) for the determination of basic magnetic

stein Test Frame

properties of materials in the form of ring, toroidal, link,

A596/A596MTest Method for Direct-Current Magnetic

double-lappedEpsteincores,orotherstandardshapesthatmay

Properties of Materials Using the Ballistic Method and

be cut, stamped, machined, or ground from cast, compacted,

Ring Specimens

sintered,forged,orrolledmaterials.Itincludestestsfornormal

2.2 Other:

induction and hysteresis taken under conditions of continuous

IEC Publication 404-4:Magnetic Materials—Part 4: Meth-

sweep magnetization. Rate of sweep may be varied, either

odsofMeasurementofdcMagneticPropertiesofIronand

manually or automatically at different portions of the curves

Steel (1995)

during tracing. Total elapsed time for tracing a hysteresis loop

is commonly 10 to 120 s per loop.

3. Summary of Test Method

1.2 The values stated in either SI units or inch-pound units

3.1 Asinmakingmostmagneticmeasurements,aspecimen

are to be regarded separately as standard. The values stated in

is wound with an exciting winding (the primary) and a search

each system may not be exact equivalents; therefore, each

coil(thesecondary)formeasuringthechangeinflux.Whenan

system shall be used independently of the other. Combining

exciting current, I, is applied to the primary winding, a

values from the two systems may result in non-conformance

magnetic field, H, is produced in the coil, and this in turn

with the standard.

produces magnetic flux φ in the specimen. In uniform speci-

1.3 This standard does not purport to address all of the

mens that do not contain air gaps, such as ring samples, all of

safety concerns, if any, associated with its use. It is the

the exciting current is used to magnetize the specimen, and H

responsibility of the user of this standard to establish appro-

is proportional to I in accordance with the following equation:

priate safety and health practices and determine the applica-

H 5 KI (1)

bility of regulatory limitations prior to use.

where:

2. Referenced Documents

H = magnetic field strength, Oe [A/m];

2.1 ASTM Standards:

I = current in the exciting coil A; and

A34/A34MPractice for Sampling and Procurement Testing

K = constantdeterminedbythenumberofprimaryturnsthe

of Magnetic Materials

magnetic path length of the specimen and system of

A341/A341MTest Method for Direct Current Magnetic

units.

Properties of Materials Using D-C Permeameters and the

3.1.1 The magnetic flux may be determined by integration

Ballistic Test Methods

of the instantaneous electromotive force that is induced in the

secondary coil when the flux is increased or decreased by a

This test method is under the jurisdiction of ASTM Committee A06 on

varying H. The instantaneous voltage, e, is equal to:

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

dφ

Methods.

e52NK (2)

Current edition approved May 1, 2009. Published August 2009. Originally

dt

approved in 1980. Last previous edition approved in 2001 as A773/A773M–01.

or

DOI: 10.1520/A0773_A0773M-01R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 25 W. 43rd St., 4th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A773/A773M − 01 (2009)

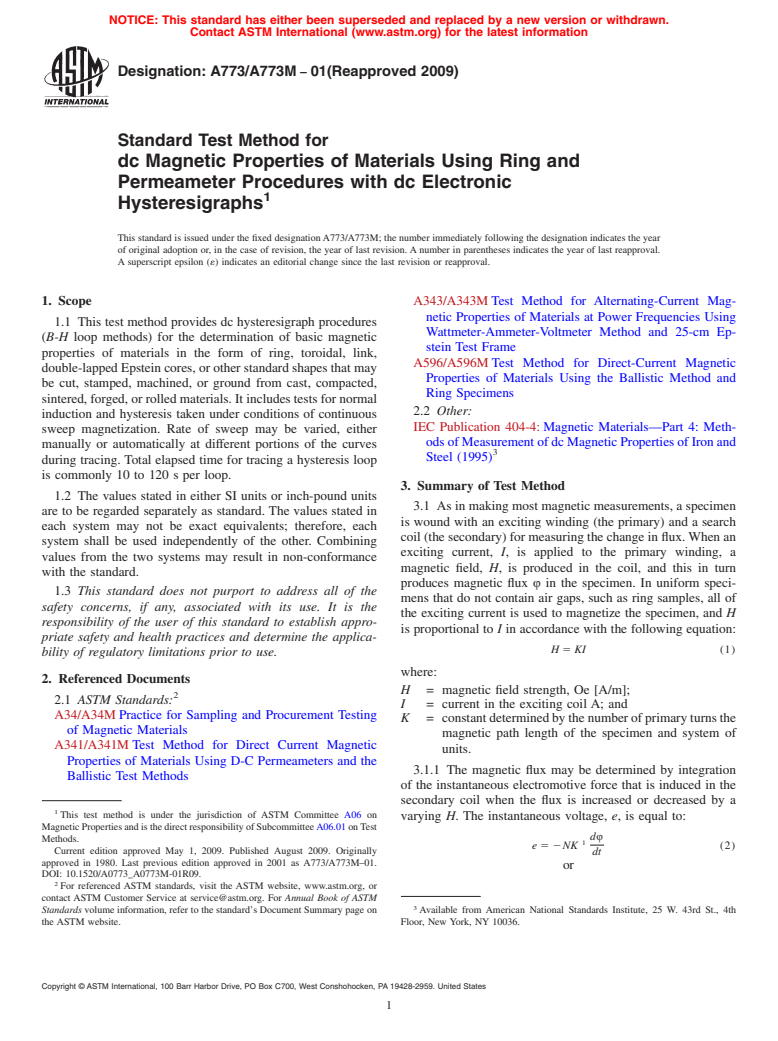

FIG. 1 Block Diagram of Ring Test Apparatus

3.1.3 In the testing of hard magnetic materials, or soft

φ5 edt

*

K N magnetic materials in the form of wire, bars or rods, it is

usually necessary to use a permeameter. This is shown in the

where:

block diagram of Fig. 2. When using permeameters, the value

dt = time differential,

of H in the gap is generally not proportional to I that flows

N = number of turns, and

through the exciting coil of the yoke. In these cases, the value

−8

K =10 for cgs-emu system, or K =1 for SI system.

1 1

of H is determined by integration of the electromotive force

thatisinducedinan Hcoil(orChattockpotentiometer)orfrom

The flux φ can be obtained if ∫edt can be determined. This

the signal developed by a Hall probe which is placed near the

can be accomplished by several means, as described in ASTM

specimen. When using an H coil, the determination of H is

STP 526. (1) The most common method uses an electronic

accomplished with an H integrator in exactly the same manner

integrator consisting of a high-gain dc amplifier with resistive-

asthatusedtodeterminefluxwiththe Bintegratordescribedin

capacitive feedback. The relationship to ∫ edt is:

3.1. When using a Hall sensor, the H values are determined

from the voltage output which is proportional to H. In some

E5 edt (3)

*

cases, the H versus I relationship may be sufficiently linear

RC

from 0 to the coercive field strength (H ) of the material under

c

where:

test. In such cases, it is acceptable to determine the second

E = output voltage, V;

quadrant of the hysteresis loop by determining H from the

R = input resistance of the integrator in the secondary

value of I in the exciting winding.

circuit, Ω; and

C = the feedback capacitance, F.

4. Significance and Use

By combining the two equations:

4.1 Hysteresigraph testing permits more rapid and efficient

ERC φNK collection of dc hysteresis (B-H loop) data as compared to the

φ5 or E5 (4)

point by point ballistic Test Methods A341/A341M and A596/

K N RC

A596M.Theaccuracyandprecisionoftestingiscomparableto

If the voltage, E, is applied to the Y axis of an X-Y recorder,

the ballistic methods. Hysteresigraphs are particularly desir-

the Y deflection of the pen is proportional to the flux, φ.

ablefortestingofsemihardandhardmagneticmaterialswhere

3.1.2 Measurements of magnetic field strength and flux by

either the entire second quadrant (demagnetization curve) or

thehysteresigraphmethodisillustratedintheblockdiagramof

entire hysteresis loop is of primary concern.

Fig. 1. The system consists of a magnetizing power source, an

4.2 Provided the test specimen is representative of the bulk

exciting current controller, an electronic flux integrator, and a

sample or lot, this test method is well suited for design,

data recorder. As exciting current is applied to the coil, a

specification acceptance, service evaluation and research and

voltage proportional to I is produced across the shunt resistor

development.

whichisconnectedinserieswiththeprimarycoil.Thisvoltage

determines the value of H.

5. Interferences

5.1 Test methods using suitable ring-type specimens are the

preferred methods for determining the basic magnetic proper-

The boldface numbers in parentheses refer to a list of references at the end of

this standard. ties of a material. However, this test method has several

A773/A773M − 01 (2009)

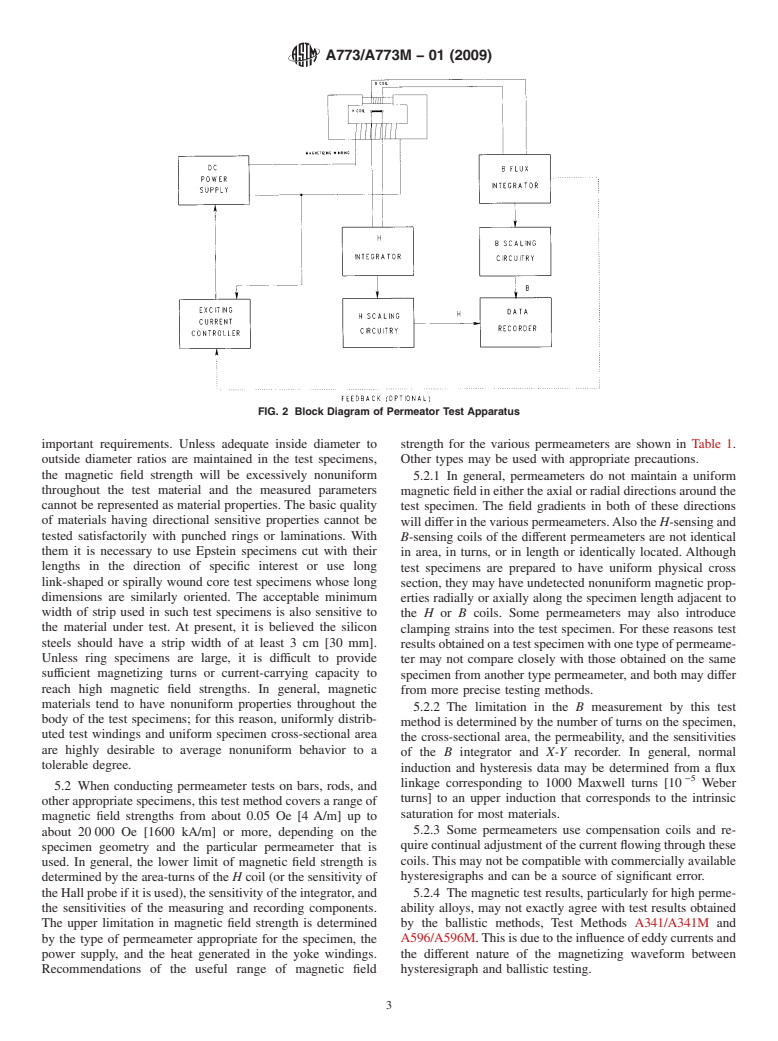

FIG. 2 Block Diagram of Permeator Test Apparatus

important requirements. Unless adequate inside diameter to strength for the various permeameters are shown in Table 1.

outside diameter ratios are maintained in the test specimens, Other types may be used with appropriate precautions.

the magnetic field strength will be excessively nonuniform

5.2.1 In general, permeameters do not maintain a uniform

throughout the test material and the measured parameters

magneticfieldineithertheaxialorradialdirectionsaroundthe

cannot be represented as material properties. The basic quality

test specimen. The field gradients in both of these directions

of materials having directional sensitive properties cannot be

willdifferinthevariouspermeameters.Alsothe H-sensingand

tested satisfactorily with punched rings or laminations. With

B-sensing coils of the different permeameters are not identical

them it is necessary to use Epstein specimens cut with their

in area, in turns, or in length or identically located. Although

lengths in the direction of specific interest or use long

test specimens are prepared to have uniform physical cross

link-shaped or spirally wound core test specimens whose long

section, they may have undetected nonuniform magnetic prop-

dimensions are similarly oriented. The acceptable minimum

erties radially or axially along the specimen length adjacent to

width of strip used in such test specimens is also sensitive to

the H or B coils. Some permeameters may also introduce

the material under test. At present, it is believed the silicon

clamping strains into the test specimen. For these reasons test

steels should have a strip width of at least 3 cm [30 mm].

resultsobtainedonatestspecimenwithonetypeofpermeame-

Unless ring specimens are large, it is difficult to provide

ter may not compare closely with those obtained on the same

sufficient magnetizing turns or current-carrying capacity to

specimen from another type permeameter, and both may differ

reach high magnetic field strengths. In general, magnetic

from more precise testing methods.

materials tend to have nonuniform properties throughout the

5.2.2 The limitation in the B measurement by this test

body of the test specimens; for this reason, uniformly distrib-

method is determined by the number of turns on the specimen,

uted test windings and uniform specimen cross-sectional area

the cross-sectional area, the permeability, and the sensitivities

are highly desirable to average nonuniform behavior to a

of the B integrator and X-Y recorder. In general, normal

tolerable degree.

induction and hysteresis data may be determined from a flux

−5

linkage corresponding to 1000 Maxwell turns [10 Weber

5.2 When conducting permeameter tests on bars, rods, and

turns] to an upper induction that corresponds to the intrinsic

otherappropriatespecimens,thistestmethodcoversarangeof

saturation for most materials.

magnetic field strengths from about 0.05 Oe [4 A/m] up to

5.2.3 Some permeameters use compensation coils and re-

about 20000 Oe [1600 kA/m] or more, depending on the

quirecontinualadjustmentofthecurrentflowingthroughthese

specimen geometry and the particular permeameter that is

coils.Thismaynotbecompatiblewithcommerciallyavailable

used. In general, the lower limit of magnetic field strength is

hysteresigraphs and can be a source of significant error.

determined by the area-turns of the H coil (or the sensitivity of

theHallprobeifitisused),thesensitivityoftheintegrator,and 5.2.4 The magnetic test results, particularly for high perme-

the sensitivities of the measuring and recording components. ability alloys, may not exactly agree with test results obtained

The upper limitation in magnetic field strength is determined by the ballistic methods, Test Methods A341/A341M and

by the type of permeameter appropriate for the specimen, the A596/A596M.Thisisduetotheinfluenceofeddycurrentsand

power supply, and the heat generated in the yoke windings. the different nature of the magnetizing waveform between

Recommendations of the useful range of magnetic field hysteresigraph and ballistic testing.

A773/A773M − 01 (2009)

TABLE 1 Permeameters Recommended for Use With

7. Test Specimens for Ring-Type Measurements

Hysteresigraphs

7.1 The specifications in 7.2-7.8 cover the general case for

NOTE 1—Other permeameters may be suitable for use with dc hyster-

specimens in which magnetic field strength is proportional to

esigraphswhereappropriatemodificationsaremade.RefertoTestMethod

the exciting current, that is, H= kI.

A341/A341M for other permeameters.

7.2 When the test specimen represents a test lot of material,

Permeameter Magnetic Field Strength Range H Measurement

Device

its selection shall conform to the requirements of Practice

Oe kA/m

A34/A34M or of an individual specification.

Babbit (2, 3) 40/100 3.2/8 current, H coil

Fahy Simplex (4-6) 0.1/300 0.008/24 H coil

7.3 To qualify as a test specimen suitable for evaluation of

Fahy Simplex Super 100/2500 8/200 H coil

H Adapter (6)

material properties, the effective ratio of mean diameter to

IEC Type A 12/2500 1/200 H coil, Hall probe

radialwidthshallbenotlessthan10to1(oraninsidediameter

IEC Type B 12/620 1/50 H coil

to outside diameter ratio not less than 0.82). When the test

Isthmus (6, 7) 100/20 000 + 8/1600 + H coil, Hall probe

specimen has smaller ratios than the above requirements, the

test data should not be represented as material properties but

should be called core properties because of nonuniform flux

distribution.

6. Apparatus

7.4 When link, oval-shaped, or rectangular test specimen

forms are used, the requirements of 7.3 apply to the end or

6.1 The apparatus shall consist of as many of the compo-

corner sections where flux crowding occurs. When straight-

nents described in 6.2-6.6 as required to perform the tests.

sided test specimens are very long relative to the length of the

6.1.1 All apparatus used in this test method shall be cali-

corner or end sections, they are suitable for basic material

brated against known standards to ensure the accuracy limits

properties evaluation with relatively unoriented materials,

given below.

provided the uncertainty in determination of true-path (effec-

6.2 Balance or Scales: tive) length is less than 1% of the total path length.When this

uncertainty in path length (shortest or longest relative to the

6.2.1 The balance or scales used to weigh the test specimen

mean-path length) exceeds 1%, the test values should be

shall be capable of weighing to an accuracy of 0.2%.

reported as core properties and not basic material properties.

6.2.2 Themicrometerordimensionalmeasuringscalesused

to determine specimen dimensions for calculation of cross-

7.5 The test specimen may be constructed of solid, lami-

sectional area shall be capable of measuring to an accuracy of

nated, or strip materials and in any of the shapes described in

at least 0.1%.

1.1.

7.6 Test specimen cores made from strip may be laminated,

6.3 Magnetizing Power Source—The power source may

range from simple batteries

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: A 773/A 773M – 01 (Reapproved 2009)

Designation:A 773/A 773M–96

Standard Test Method for

dc Magnetic Properties of Materials Using Ring and

Permeameter Procedures with dc Electronic

Hysteresigraphs

ThisstandardisissuedunderthefixeddesignationA773/A773M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides dc hysteresigraph procedures (B-H loop methods) for the determination of basic magnetic

properties of materials in the form of ring, toroidal, link, double-lapped Epstein cores, or other standard shapes that may be cut,

stamped, machined, or ground from cast, compacted, sintered, forged, or rolled materials. It includes tests for normal induction

and hysteresis taken under conditions of continuous sweep magnetization. Rate of sweep may be varied, either manually or

automatically at different portions of the curves during tracing. Total elapsed time for tracing a hysteresis loop is commonly 10

to 120 s per loop.

1.2The values stated in either customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard.

Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each

system shall be used independently of the other. Combining values from the systems may result in nonconformance with this test

method.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing of Magnetic MaterialsMaterials

A341/A341M TestMethodforDirect-CurrentMagneticPropertiesofMaterialsUsingdcD-CPermeametersandtheBallistic

Test Methods Methods

A343/A343M Test Method for Alternating-Current Magnetic Properties of Materials at Power Frequencies Using the

Wattmeter-Ammeter-Voltmeter Method and 25-cm Epstein Frame Test Frame

A596/A596M Test Method for Direct-Current Magnetic Properties of Materials Using the Ballistic Method and Ring

Specimens Specimens

2.2 Other:

IEC Publication 404-4: Magnetic Materials—Part 4: Methods of Measurement of dc Magnetic Properties of Iron and Steel

(1995)

3. Summary of Test Method

3.1 As in making most magnetic measurements, a specimen is wound with an exciting winding (the primary) and a search coil

(the secondary) for measuring the change in flux.When an exciting current, I, is applied to the primary winding, a magnetic field,

H, is produced in the coil, and this in turn produces magnetic flux f in the specimen. In uniform specimens that do not contain

ThistestmethodisunderthejurisdictionofASTMCommitteeA-6A06onMagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTestMethods.

Current edition approved Dec. 10, 1996. Published March 1997. Originally published as A773–80. Last previous edition A773–91.

Current edition approved May 1, 2009. Published August 2009. Originally approved in 1980. Last previous edition approved in 2001 as A773/A773M–01.

Annual Book of ASTM Standards, Vol 03.04.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute, 1125 W. 42nd43rd St., 13th4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A773/A773M–01 (2009)

airgaps,suchasringsamples,alloftheexcitingcurrentisusedtomagnetizethespecimen,andHisproportionaltoIinaccordance

with the following equation:

H 5 KI

(1)

where:

H = magnetic field strength, Oe [A/m], [A/m];

I = current in the exciting coil A,A; and

K = constant determined by the number of primary turns the magnetic path length of the specimen and system of units.

3.1.1 The magnetic flux may be determined by integration of the instantaneous electromotive force that is induced in the

secondary coil when the flux is increased or decreased by a varying H. The instantaneous voltage, e, is equal to:

df

e52NK

dt

(2)

or

f5 edt

*

K N

where:

dt = time differential,

N = number of turns, and

−8

K =10 for cgs-emu system, or K =1 for SI system.

1 1

The flux f can be obtained if |Mi *edt can be determined. This can be accomplished by several means, as described in ASTM

STP 526. (1) The most common method utilizesuses an electronic integrator consisting of a high-gain dc amplifier with

resistive-capacitive feedback. The relationship to |Mi * edt is:

E 5 edt

*

RC

(3)

where:

E = output voltage, V,;

R = input resistance of the integrator in the secondary circuit, V,V; and

C = the feedback capacitance, F.

By combining the two equations:

ERC

f5 or E

K N

fNK

RC

(4)

ERC

f5 or E

K N

fNK

RC

(4)

If the voltage, E, is applied to the Y axis of an X-Y recorder, the Y deflection of the pen is proportional to the flux, f.

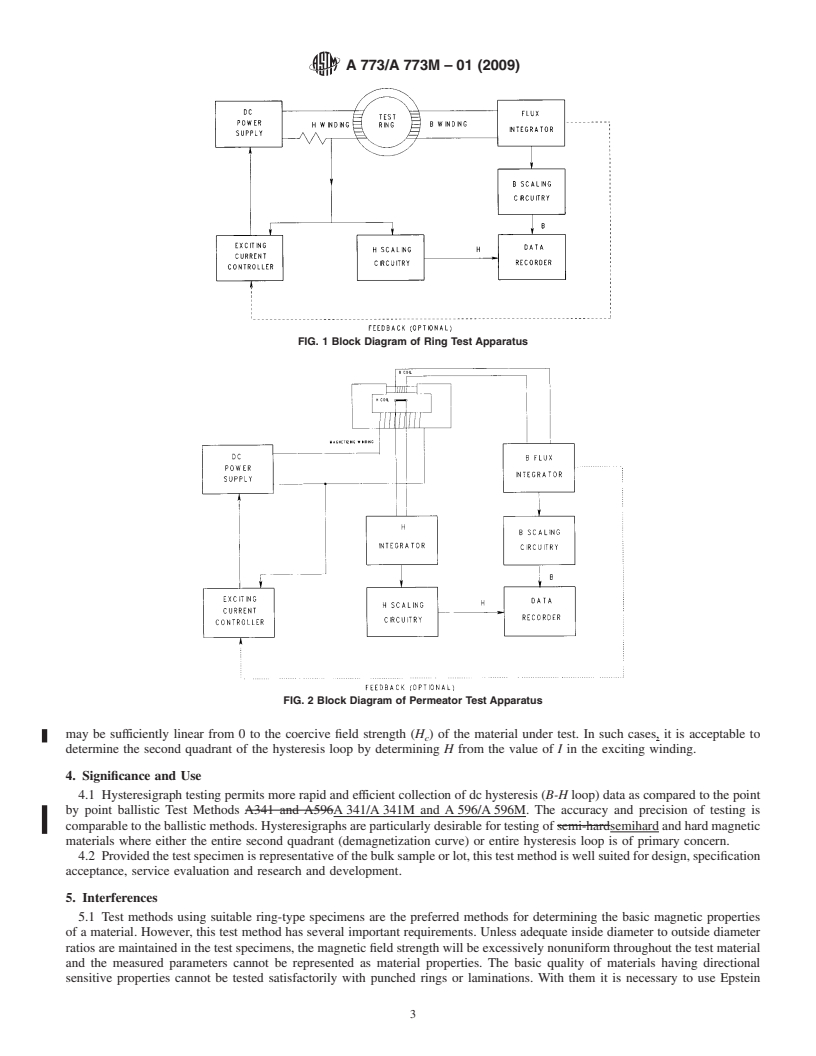

3.1.2 Measurements of magnetic field strength and flux by the hysteresigraph method is illustrated in the block diagram of Fig.

1. The system consists of a magnetizing power source, an exciting current controller, an electronic flux integrator, and a data

recorder. As exciting current is applied to the coil, a voltage proportional to I is produced across the shunt resistor which is

connected in series with the primary coil. This voltage determines the value of H.

3.1.3 Inthetestingofhardmagneticmaterials,orsoftmagneticmaterialsintheformofwire,barsorrods,itisusuallynecessary

to use a permeameter. This is shown in the block diagram of Fig. 2. When using permeameters, the value of H in the gap is

generally not proportional to I that flows through the exciting coil of the yoke. In these cases, the value of H is determined by

integration of the electromotive force that is induced in an H -coilcoil (or Chattock potentiometer) or from the signal developed

by a Hall probe which is placed near the specimen. When using an H -coil,coil, the determination of H is accomplished with an

H integrator in exactly the same manner as that used to determine flux with the B integrator described in 3.1. When using a Hall

sensor, the H values are determined from the voltage output which is proportional to H. In some cases, the H versus I relationship

The boldface numbers in parentheses refer to thea list of references at the end of this test method.standard.

A773/A773M–01 (2009)

FIG. 1 Block Diagram of Ring Test Apparatus

FIG. 2 Block Diagram of Permeator Test Apparatus

may be sufficiently linear from 0 to the coercive field strength (H ) of the material under test. In such cases, it is acceptable to

c

determine the second quadrant of the hysteresis loop by determining H from the value of I in the exciting winding.

4. Significance and Use

4.1 Hysteresigraph testing permits more rapid and efficient collection of dc hysteresis (B-H loop) data as compared to the point

by point ballistic Test Methods A341 and A596A341/A341M and A596/A596M. The accuracy and precision of testing is

comparabletotheballisticmethods.Hysteresigraphsareparticularlydesirablefortestingofsemi-hardsemihardandhardmagnetic

materials where either the entire second quadrant (demagnetization curve) or entire hysteresis loop is of primary concern.

4.2 Providedthetestspecimenisrepresentativeofthebulksampleorlot,thistestmethodiswellsuitedfordesign,specification

acceptance, service evaluation and research and development.

5. Interferences

5.1 Test methods using suitable ring-type specimens are the preferred methods for determining the basic magnetic properties

of a material. However, this test method has several important requirements. Unless adequate inside diameter to outside diameter

ratiosaremaintainedinthetestspecimens,themagneticfieldstrengthwillbeexcessivelynonuniformthroughoutthetestmaterial

and the measured parameters cannot be represented as material properties. The basic quality of materials having directional

sensitive properties cannot be tested satisfactorily with punched rings or laminations. With them it is necessary to use Epstein

A773/A773M–01 (2009)

specimens cut with their lengths in the direction of specific interest or use long link-shaped or spirally wound core test specimens

whoselongdimensionsaresimilarlyoriented.Theacceptableminimumwidthofstripusedinsuchtestspecimensisalsosensitive

to the material under test. At present, it is believed the silicon steels should have a strip width of at least 3 cm [30 mm]. Unless

ring specimens are large, it is difficult to provide sufficient magnetizing turns or current-carrying capacity to reach high magnetic

field strengths. In general, magnetic materials tend to have nonuniform properties throughout the body of the test specimens; for

this reason, uniformly distributed test windings and uniform specimen cross-sectional area are highly desirable to average

nonuniform behavior to a tolerable degree.

5.2 When conducting permeameter tests on bars, rods, and other appropriate specimens, this test method covers a range of

magnetic field strengths from about 0.05 Oe [4 A/m] up to about 20000 Oe [1600 kA/m] or more, depending on the specimen

geometryandtheparticularpermeameterthatisemployed.used.Ingeneral,thelowerlimitofmagneticfieldstrengthisdetermined

bythearea-turnsofthe Hcoil(orthesensitivityoftheHallprobeifitisused),thesensitivityoftheintegrator,andthesensitivities

of the measuring and recording components. The upper limitation in magnetic field strength is determined by the type of

permeameter appropriate for the specimen, the power supply, and the heat generated in the yoke windings. Recommendations of

the useful range of magnetic field strength for the various permeameters are shown in Table 1. Other types may be used with

appropriate precautions.

5.2.1 In general, permeameters do not maintain a uniform magnetic field in either the axial or radial directions around the test

specimen.Thefieldgradientsinbothofthesedirectionswilldifferinthevariouspermeameters.Alsothe H-sensingand B-sensing

coils of the different permeameters are not identical in area, in turns, or in length or identically located.Although test specimens

are prepared to have uniform physical cross section, they may have undetected nonuniform magnetic properties radially or axially

along the specimen length adjacent to the H or B coils. Some permeameters may also introduce clamping strains into the test

specimen. For these reasons test results obtained on a test specimen with one type of permeameter may not compare closely with

those obtained on the same specimen from another type permeameter, and both may differ from more precise testing methods.

5.2.2 The limitation in the B measurement by this test method is determined by the number of turns on the specimen, the

cross-sectional area, the permeability, and the sensitivities of the B integrator and X-Y recorder. In general, normal induction and

−5

hysteresis data may be determined from a flux linkage corresponding to 1000 Maxwell- turns [10 Weber turns] to an upper

induction that corresponds to the intrinsic saturation for most materials.

5.2.3 Some permeameters utilizeuse compensation coils and require continual adjustment of the current flowing through these

coils. This may not be compatible with commercially available hysteresigraphs and can be a source of significant error.

5.2.4 Themagnetictestresults,particularlyforhighpermeabilityalloys,maynotexactlyagreewithtestresultsobtainedbythe

ballistic methods, Test MethodsA341 andA596A341/A341M andA596/A596M. This is due to the influence of eddy currents

and the different nature of the magnetizing waveform between hysteresigraph and ballistic testing.

6. Apparatus

6.1 The apparatus shall consist of as many of the components described in 6.2 through 6.6 6.2-6.6 as required to perform the

tests.

6.1.1 All apparatus used in this test method shall be calibrated against known standards to ensure the accuracy limits given

below.

6.2 Balance or Scales:

6.2.1 The balance or scales used to weigh the test specimen shall be capable of weighing to an accuracy of 0.2%.

TABLE 1 Permeameters Recommended for Use With

Hysteresigraphs

NOTE 1—Other permeameters may be suitable for use with dc hyster-

esigraphswhereappropriatemodificationsaremade.RefertoTestMethod

A341/A341M for other permeameters.

Permeameter Magnetic Field Strength Range H Measurement

Device

Oe kA/m

Babbit (2, 3) 40/100 3.2/8 current, H- coil

Babbit (2, 3) 40/100 3.2/8 current, H coil

Fahy Simplex (4,5,6) 0.1/300 0.008/24 H- coil

Fahy Simplex (4-6) 0.1/300 0.008/24 H coil

Fahy Simplex Super 100/2500 8/200 H- coil

H Adapter (6)

Fahy Simplex Super 100/2500 8/200 H coil

H Adapter (6)

IEC Type A 12/2500 1/200 H- coil, Hall probe

IEC Type A 12/2500 1/200 H coil, Hall probe

IEC Type B 12/620 1/50 H- coil

IEC Type B 12/620 1/50 H coil

Isthmus (6, 7) 100/20 000 + 8/1600 + H- coil, Hall probe

Isthmus (6, 7) 100/20 000 + 8/1600 + H coil, Hall probe

A773/A773M–01 (2009)

6.2.2 The micrometer or dimensional measuring scales used to determine specimen dimensions for calculation of cross-

sectional area shall be capable of measuring to an accuracy of at least 0.1%.

6.3 Magnetizing Power Source—The power source may range from simple batteries to sophisticated regulated, low-ripple,

protected, programmable types. It shall have sufficient capacity to produce the maximum currents required for magnetization of

the specimen under test.

6.4 Exciting Current Controller—Instantaneousvalueofmagnetizingcurrent,anditsrateofchange,maybecontrolledentirely

manually by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.