ASTM A811-15(2022)

(Specification)Standard Specification for Soft Magnetic Iron Parts Fabricated by Powder Metallurgy Techniques

Standard Specification for Soft Magnetic Iron Parts Fabricated by Powder Metallurgy Techniques

ABSTRACT

This specification covers soft magnetic iron parts fabricated by pressing and sintering of iron powder. The specification does not cover parts produced by metal injection molding. Parts produced to this specification shall have a minimum sintered density of 6.6 g/cm3 (6600 kg/m3) in the magnetically critical section of the part. Chemical requirements for the sintered part are given. Three grades distinguished by the measured maximum value of coercive field strength are defined. Apart from the required measurements of sintered density, chemical composition and coercive field strength, information on magnetic aging and its detection is given. Appendices containing magnetic and mechanical property data for a variety of sintering conditions are provided.

SCOPE

1.1 This specification covers parts produced from iron powder metallurgy materials.

1.2 This specification deals with powder metallurgy parts in the sintered or annealed condition. Should the sintered parts be subjected to any secondary operation that causes mechanical strain, such as machining or sizing, they should be resintered or annealed.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to customary (cgs-emu and inch-pound) units, which are provided for information only, and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A811 −15 (Reapproved 2022)

Standard Specification for

Soft Magnetic Iron Parts Fabricated by Powder Metallurgy

Techniques

This standard is issued under the fixed designation A811; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A596/A596M Test Method for Direct-Current Magnetic

PropertiesofMaterialsUsingthePointbyPoint(Ballistic)

1.1 This specification covers parts produced from iron

Method and Ring Specimens

powder metallurgy materials.

A773/A773M Test Method for Direct Current Magnetic

1.2 This specification deals with powder metallurgy parts in

Properties of Low Coercivity Magnetic Materials Using

the sintered or annealed condition. Should the sintered parts be

Hysteresigraphs

subjected to any secondary operation that causes mechanical

B962 Test Methods for Density of Compacted or Sintered

strain,suchasmachiningorsizing,theyshouldberesinteredor

Powder Metallurgy (PM) Products Using Archimedes’

annealed.

Principle

E1019 Test Methods for Determination of Carbon, Sulfur,

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses are mathematical Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

Alloys by Various Combustion and Inert Gas Fusion

conversions to customary (cgs-emu and inch-pound) units,

which are provided for information only, and are not consid- Techniques

ered standard.

3. Terminology

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1 The terms and symbols used in this specification are

responsibility of the user of this standard to establish appro- defined in Terminology A340.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 4. Ordering Information

1.5 This international standard was developed in accor-

4.1 Purchase orders for parts conforming to this specifica-

dance with internationally recognized principles on standard-

tion shall include the following information:

ization established in the Decision on Principles for the

4.1.1 Reference to this specification and year of issue/

Development of International Standards, Guides and Recom-

revision,

mendations issued by the World Trade Organization Technical

4.1.2 Reference to an applicable part drawing,

Barriers to Trade (TBT) Committee.

4.1.3 Quantity required,

4.1.4 Acritical cross section of the part shall be defined and

2. Referenced Documents

so indicated on the applicable part drawing.The location of the

2.1 ASTM Standards: critical section is by mutual agreement between the user and

the producer (6.2),

A34/A34M Practice for Sampling and Procurement Testing

of Magnetic Materials 4.1.5 Magnetic property requirements if they are other than

stated in Table 1,

A340 Terminology of Symbols and Definitions Relating to

Magnetic Testing 4.1.6 Whethercertificationofchemicalanalysisormagnetic

property evaluation is required (Sections 5 and 7),

4.1.7 Marking and packaging requirements (Section 12),

and

This specification is under the jurisdiction of ASTM Committee A06 on

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on 4.1.8 Exceptions to this specification or special require-

Material Specifications.

ments such as functional testing as mutually agreed upon

Current edition approved Oct. 1, 2022. Published November 2022. Originally

between the producer and the user.

approved in 1983. Last previous edition approved in 2015 as A811 – 15. DOI:

10.1520/A0811-15R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Chemical Composition

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 The chemical composition of the parts shall conform to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the requirements prescribed in Table 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A811−15 (2022)

TABLE 1 Maximum Coercive Field Strength Requirements

7.5 Coercive Field Strength Requirements—Three grades,

Grade Coercive Field Strength defined by coercive field strength, are stipulated by this

1 140 A/m (1.8 Oe) specification and are listed in Table 1. The coercive field

2 160 A/m (2.0 Oe)

strength requirement for Grade 3 was developed from an

3 180 A/m (2.3 Oe)

interlaboratory study. The values for Grades 1 and 2 are based

on a literature review and are believed to reflect the current

industry capabilities.

TABLE 2 Chemical Requirements (weight percent)

Element % 7.6 Magnetic Aging—Nitrogen introduced during sintering

can cause time-dependent degradation of magnetic properties.

Carbon, max 0.03

Oxygen, max 0.10

Therefore, when requested by the user, the producer shall test

Nitrogen, max 0.01

for aging. To determine the susceptibility of the parts to aging,

A

Others 0.50, max

B

Iron balance thetestring(s)shouldbeheatedinairforeither100 hat150 °C

A

6 5 °C or 600 h at 100 °C 6 5 °C and the coercive field

Others refers to trace elements which are to be regarded as incidental and not

deliberate additions.

strength remeasured. A change in coercive field strength of

B

Iron is the balance by difference. Quantitative analysis of this element is not

10 % or more of the original value is evidence that aging has

required.

occurred.

7.7 Since magnetic properties are strongly affected by

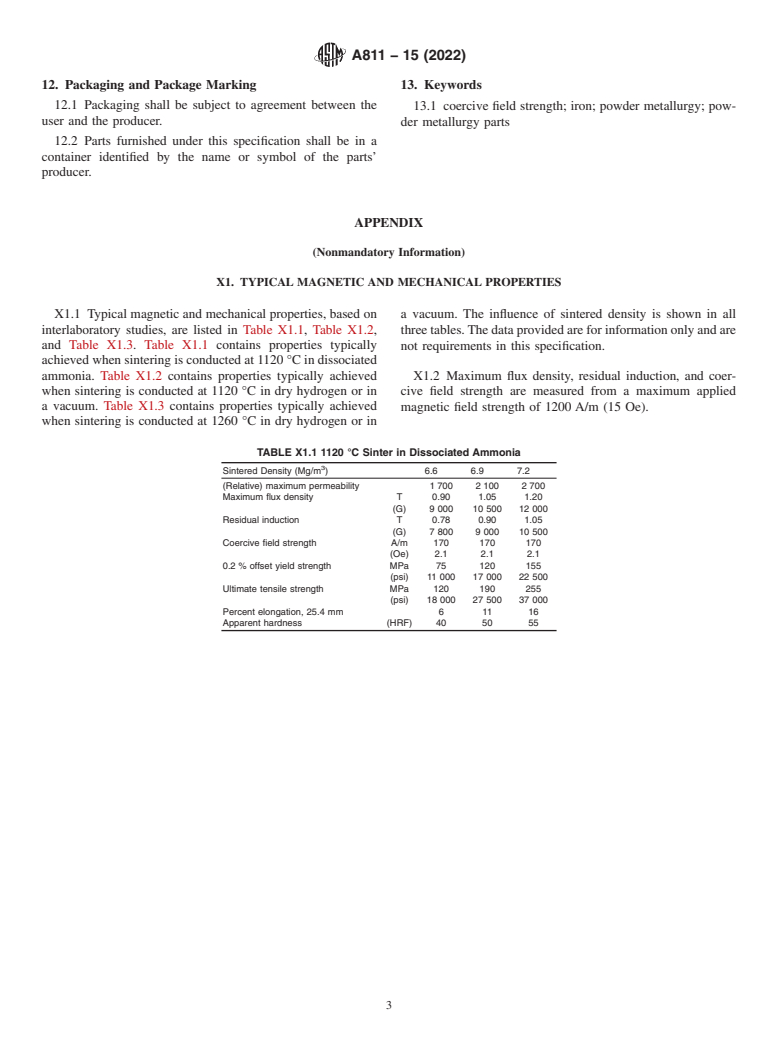

processconditions,refertoAppendixX1fortypicalvaluesand

explanatory notes.

5.2 Determination of metallic constituents shall be by a

method acceptable to both the producer and the user. Analysis

8. Workmanship, Finish, and Appearance

of carbon, oxygen, sulfur, and nitrogen shall be done in

8.1 The parts shall be uniform in composition and uniform

accordance with Test Methods E1019.

in density within critical sections.

6. Sintered Density Requirements 8.2 If parts are sectioned or fractured, there shall be no

readily recognizable defects.

6.1 Magnetic and residual induction of powder metallurgy

parts strongly depend on density. The density of powder

9. Sampling

metallurgy parts is determined by the compressibility of the

powder, the compacting pressure, and sintering practice

9.1 A lot shall consist of parts of the same form and

(temperature, time, and atmosphere).

dimensions, produced from a single mixed powder batch and

from an unchanged process, without d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.