ASTM A773/A773M-01(2009)

(Test Method)Standard Test Method for dc Magnetic Properties of Materials Using Ring and Permeameter Procedures with dc Electronic Hysteresigraphs

Standard Test Method for dc Magnetic Properties of Materials Using Ring and Permeameter Procedures with dc Electronic Hysteresigraphs

SIGNIFICANCE AND USE

Hysteresigraph testing permits more rapid and efficient collection of dc hysteresis (B-H loop) data as compared to the point by point ballistic Test Methods A 341/A 341M and A 596/A 596M. The accuracy and precision of testing is comparable to the ballistic methods. Hysteresigraphs are particularly desirable for testing of semihard and hard magnetic materials where either the entire second quadrant (demagnetization curve) or entire hysteresis loop is of primary concern.

Provided the test specimen is representative of the bulk sample or lot, this test method is well suited for design, specification acceptance, service evaluation and research and development.

SCOPE

1.1 This test method provides dc hysteresigraph procedures (B-H loop methods) for the determination of basic magnetic properties of materials in the form of ring, toroidal, link, double-lapped Epstein cores, or other standard shapes that may be cut, stamped, machined, or ground from cast, compacted, sintered, forged, or rolled materials. It includes tests for normal induction and hysteresis taken under conditions of continuous sweep magnetization. Rate of sweep may be varied, either manually or automatically at different portions of the curves during tracing. Total elapsed time for tracing a hysteresis loop is commonly 10 to 120 s per loop.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A773/A773M − 01(Reapproved 2009)

Standard Test Method for

dc Magnetic Properties of Materials Using Ring and

Permeameter Procedures with dc Electronic

1

Hysteresigraphs

This standard is issued under the fixed designationA773/A773M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A343/A343MTest Method for Alternating-Current Mag-

netic Properties of Materials at Power Frequencies Using

1.1 This test method provides dc hysteresigraph procedures

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

(B-H loop methods) for the determination of basic magnetic

stein Test Frame

properties of materials in the form of ring, toroidal, link,

A596/A596MTest Method for Direct-Current Magnetic

double-lappedEpsteincores,orotherstandardshapesthatmay

Properties of Materials Using the Ballistic Method and

be cut, stamped, machined, or ground from cast, compacted,

Ring Specimens

sintered,forged,orrolledmaterials.Itincludestestsfornormal

2.2 Other:

induction and hysteresis taken under conditions of continuous

IEC Publication 404-4:Magnetic Materials—Part 4: Meth-

sweep magnetization. Rate of sweep may be varied, either

odsofMeasurementofdcMagneticPropertiesofIronand

manually or automatically at different portions of the curves

3

Steel (1995)

during tracing. Total elapsed time for tracing a hysteresis loop

is commonly 10 to 120 s per loop.

3. Summary of Test Method

1.2 The values stated in either SI units or inch-pound units

3.1 Asinmakingmostmagneticmeasurements,aspecimen

are to be regarded separately as standard. The values stated in

is wound with an exciting winding (the primary) and a search

each system may not be exact equivalents; therefore, each

coil(thesecondary)formeasuringthechangeinflux.Whenan

system shall be used independently of the other. Combining

exciting current, I, is applied to the primary winding, a

values from the two systems may result in non-conformance

magnetic field, H, is produced in the coil, and this in turn

with the standard.

produces magnetic flux φ in the specimen. In uniform speci-

1.3 This standard does not purport to address all of the

mens that do not contain air gaps, such as ring samples, all of

safety concerns, if any, associated with its use. It is the

the exciting current is used to magnetize the specimen, and H

responsibility of the user of this standard to establish appro-

is proportional to I in accordance with the following equation:

priate safety and health practices and determine the applica-

H 5 KI (1)

bility of regulatory limitations prior to use.

where:

2. Referenced Documents

H = magnetic field strength, Oe [A/m];

2

2.1 ASTM Standards:

I = current in the exciting coil A; and

A34/A34MPractice for Sampling and Procurement Testing

K = constantdeterminedbythenumberofprimaryturnsthe

of Magnetic Materials

magnetic path length of the specimen and system of

A341/A341MTest Method for Direct Current Magnetic

units.

Properties of Materials Using D-C Permeameters and the

3.1.1 The magnetic flux may be determined by integration

Ballistic Test Methods

of the instantaneous electromotive force that is induced in the

secondary coil when the flux is increased or decreased by a

1

This test method is under the jurisdiction of ASTM Committee A06 on

varying H. The instantaneous voltage, e, is equal to:

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

dφ

Methods.

1

e52NK (2)

Current edition approved May 1, 2009. Published August 2009. Originally

dt

approved in 1980. Last previous edition approved in 2001 as A773/A773M–01.

or

DOI: 10.1520/A0773_A0773M-01R09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 25 W. 43rd St., 4th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A773/A773M − 01 (2009)

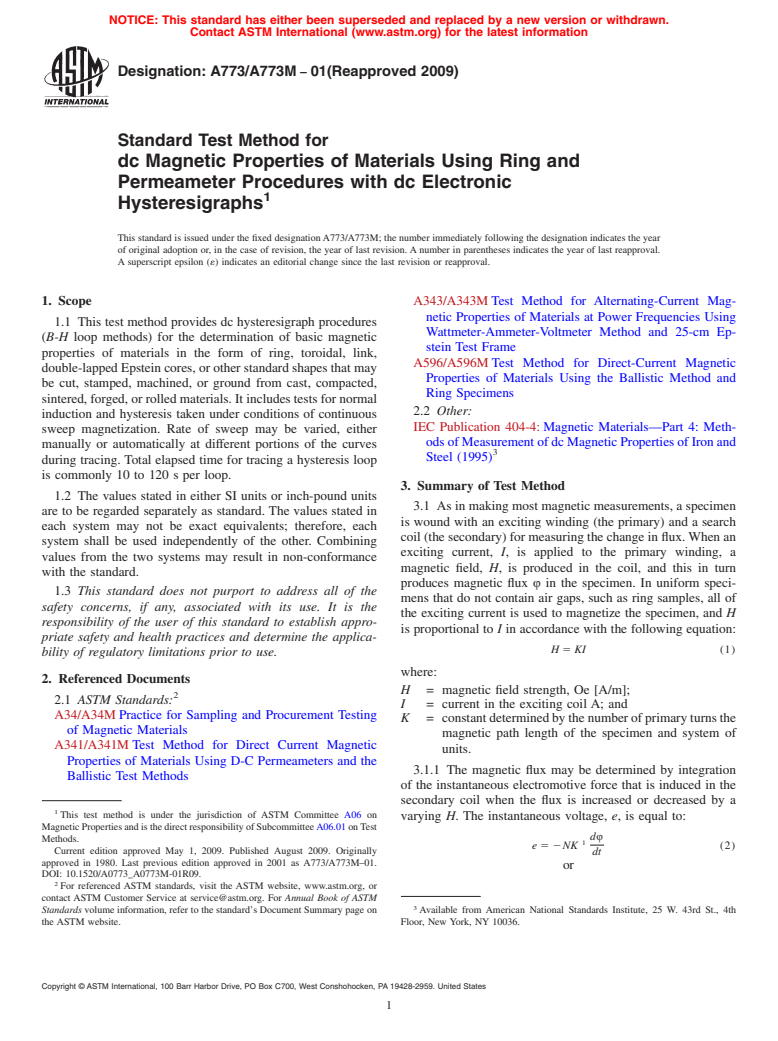

FIG. 1 Block Diagram of Ring Test Apparatus

1

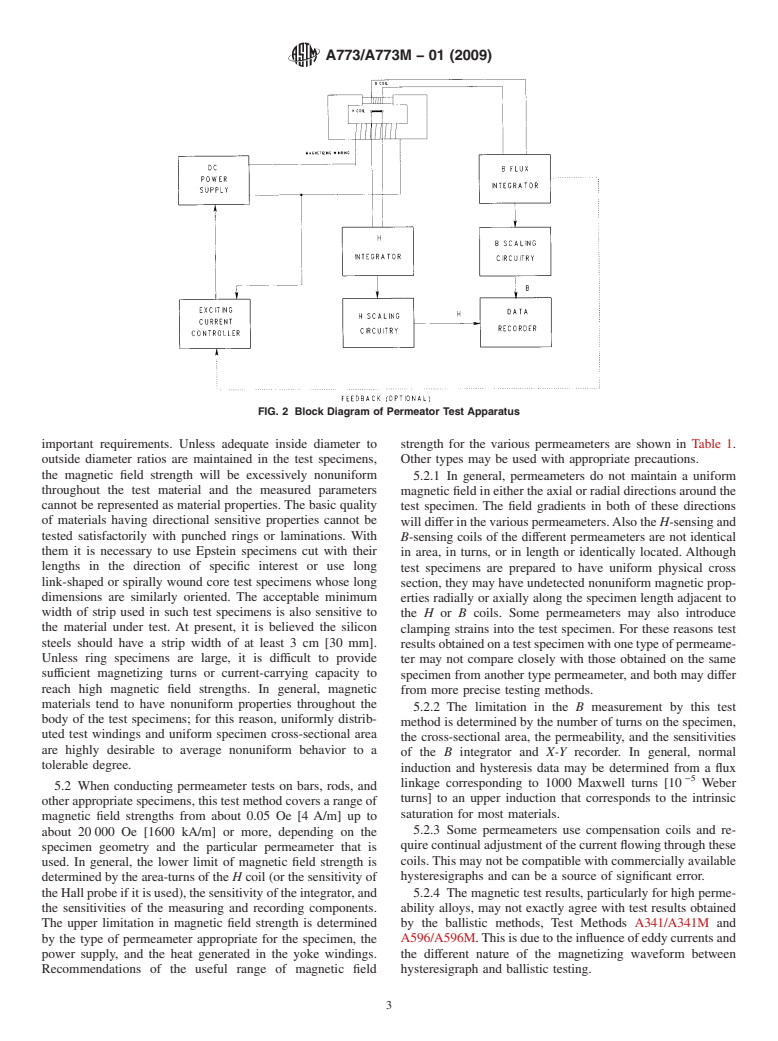

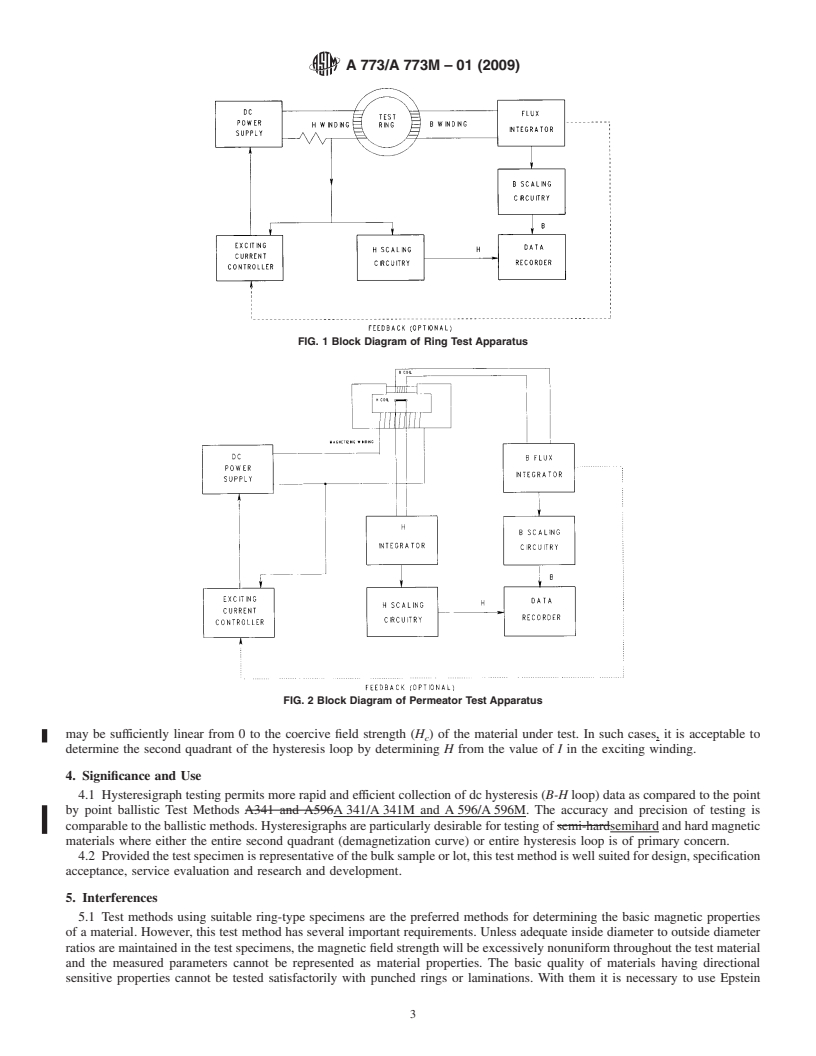

3.1.3 In the testing of hard magnetic materials, or soft

φ5 edt

*

K N magnetic materials in the form of wire, bars or rods, it is

1

usually necessary to use a permeameter. This is shown in the

where:

block diagram of Fig. 2. When using permeameters, the value

dt = time differential,

of H in the gap is generally not proportional to I that flows

N = number of turns, and

through the exciting coil of the yoke. In these cases, the

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: A 773/A 773M – 01 (Reapproved 2009)

Designation:A 773/A 773M–96

Standard Test Method for

dc Magnetic Properties of Materials Using Ring and

Permeameter Procedures with dc Electronic

1

Hysteresigraphs

ThisstandardisissuedunderthefixeddesignationA773/A773M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides dc hysteresigraph procedures (B-H loop methods) for the determination of basic magnetic

properties of materials in the form of ring, toroidal, link, double-lapped Epstein cores, or other standard shapes that may be cut,

stamped, machined, or ground from cast, compacted, sintered, forged, or rolled materials. It includes tests for normal induction

and hysteresis taken under conditions of continuous sweep magnetization. Rate of sweep may be varied, either manually or

automatically at different portions of the curves during tracing. Total elapsed time for tracing a hysteresis loop is commonly 10

to 120 s per loop.

1.2The values stated in either customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard.

Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each

system shall be used independently of the other. Combining values from the systems may result in nonconformance with this test

method.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing of Magnetic MaterialsMaterials

A341/A341M TestMethodforDirect-CurrentMagneticPropertiesofMaterialsUsingdcD-CPermeametersandtheBallistic

2

Test Methods Methods

A343/A343M Test Method for Alternating-Current Magnetic Properties of Materials at Power Frequencies Using the

2

Wattmeter-Ammeter-Voltmeter Method and 25-cm Epstein Frame Test Frame

A596/A596M Test Method for Direct-Current Magnetic Properties of Materials Using the Ballistic Method and Ring

2

Specimens Specimens

2.2 Other:

IEC Publication 404-4: Magnetic Materials—Part 4: Methods of Measurement of dc Magnetic Properties of Iron and Steel

3

(1995)

3. Summary of Test Method

3.1 As in making most magnetic measurements, a specimen is wound with an exciting winding (the primary) and a search coil

(the secondary) for measuring the change in flux.When an exciting current, I, is applied to the primary winding, a magnetic field,

H, is produced in the coil, and this in turn produces magnetic flux f in the specimen. In uniform specimens that do not contain

1

ThistestmethodisunderthejurisdictionofASTMCommitteeA-6A06onMagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTestMethods.

Current edition approved Dec. 10, 1996. Published March 1997. Originally published as A773–80. Last previous edition A773–91.

Current edition approved May 1, 2009. Published August 2009. Originally approved in 1980. Last previous edition approved in 2001 as A773/A773M–01.

2

Annual Book of ASTM Standards, Vol 03.04.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute, 1125 W. 42nd43rd St., 13th4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A773/A773M–01 (2009)

airgaps,suchasringsamples,alloftheexcitingcurrentisusedtomagnetizethespecimen,andHisproportionaltoIinaccordance

with the following equation:

H 5 KI

(1)

where:

H = magnetic field strength, Oe [A/m], [A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.