ASTM D6344-98(2003)

(Test Method)Standard Test Method for Concentrated Impacts to Transport Packages

Standard Test Method for Concentrated Impacts to Transport Packages

SCOPE

1.1 This test method covers procedures and equipment for testing complete filled transport packages for resistance against concentrated low-level impacts typical of those encountered in the distribution environment. The test is most appropriate for packages such as thin fluted/lighter grade corrugated boxes or stretch-wrapped packaging.

1.2 The test result is a pass/fail determination, based on acceptance criteria previously established, and a record of the energy dissipated by the complete filled transport package during a low level concentrated impact.

Note 1—This test method discusses the conduct of the test from a prescribed height that either meets or does not meet specific acceptance criteria. It may be possible to conduct this type of testing using modified procedures that provide a numerical response. These might include an incremental test where the drop height (or mass) is increased until a specific failure occurs or an up-and-down or staircase procedure used to find the average height to failure.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6344 – 98 (Reapproved 2003)

Standard Test Method for

Concentrated Impacts to Transport Packages

This standard is issued under the fixed designation D 6344; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers procedures and equipment for 3.1 Definitions—General definitions for the packaging and

testing complete filled transport packages for resistance against distribution environments are found in Terminology D 996.

concentrated low-level impacts typical of those encountered in 3.2 Definitions of Terms Specific to This Standard:

the distribution environment. The test is most appropriate for 3.2.1 acceptance criteria—the acceptable condition of

packages such as thin fluted/lighter grade corrugated boxes or package and contents that must be met after the shipping

stretch-wrapped packaging. container has been tested.

1.2 The test result is a pass/fail determination, based on

4. Significance and Use

acceptance criteria previously established, and a record of the

energy dissipated by the complete filled transport package 4.1 This test method is intended to evaluate the ability of

packaging to resist the force of concentrated impacts from

during a low level concentrated impact.

outside sources, such as those encountered in various modes of

NOTE 1—This test method discusses the conduct of the test from a

transportation and handling. These impacts may be inflicted by

prescribed height that either meets or does not meet specific acceptance

adjacent freight jostling against the package in a carrier

criteria. It may be possible to conduct this type of testing using modified

vehicle, by accidental bumps against other freight when loaded

procedures that provide a numerical response. These might include an

incremental test where the drop height (or mass) is increased until a

or unloaded from vehicles, by packages bumping against one

specific failure occurs or an up-and-down or staircase procedure used to

another during sorting on conveyors or chutes, or many other

find the average height to failure.

circumstances.

1.3 This standard does not purport to address all of the 4.2 This test method is intended to determine the ability of

safety concerns, if any, associated with its use. It is the packaging to protect contents from such impacts, and to

responsibility of the user of this standard to establish appro- evaluate if there is sufficient clearance or support or both

priate safety and health practices and determine the applica- between the package wall and its contents.

bility of regulatory limitations prior to use.

5. Apparatus

2. Referenced Documents

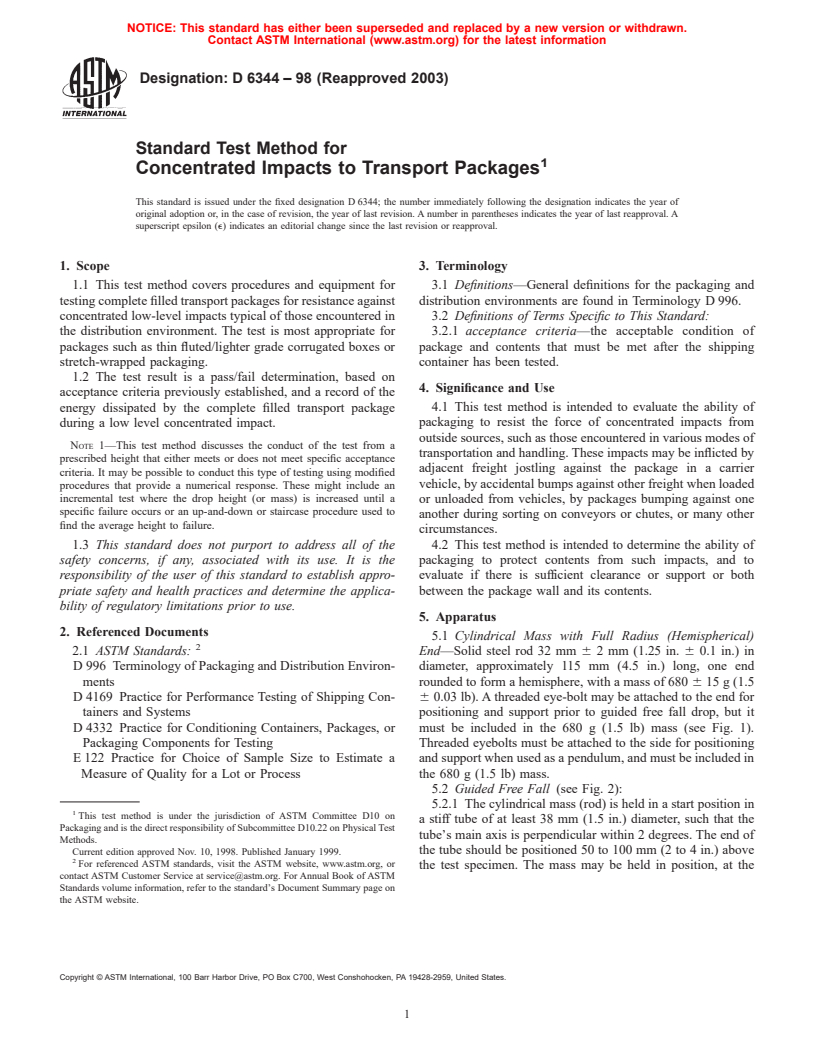

5.1 Cylindrical Mass with Full Radius (Hemispherical)

2.1 ASTM Standards: End—Solid steel rod 32 mm 6 2 mm (1.25 in. 6 0.1 in.) in

D 996 Terminology of Packaging and Distribution Environ- diameter, approximately 115 mm (4.5 in.) long, one end

ments rounded to form a hemisphere, with a mass of 680 6 15 g (1.5

D 4169 Practice for Performance Testing of Shipping Con- 6 0.03 lb). A threaded eye-bolt may be attached to the end for

tainers and Systems positioning and support prior to guided free fall drop, but it

D 4332 Practice for Conditioning Containers, Packages, or must be included in the 680 g (1.5 lb) mass (see Fig. 1).

Packaging Components for Testing Threaded eyebolts must be attached to the side for positioning

E 122 Practice for Choice of Sample Size to Estimate a and support when used as a pendulum, and must be included in

Measure of Quality for a Lot or Process the 680 g (1.5 lb) mass.

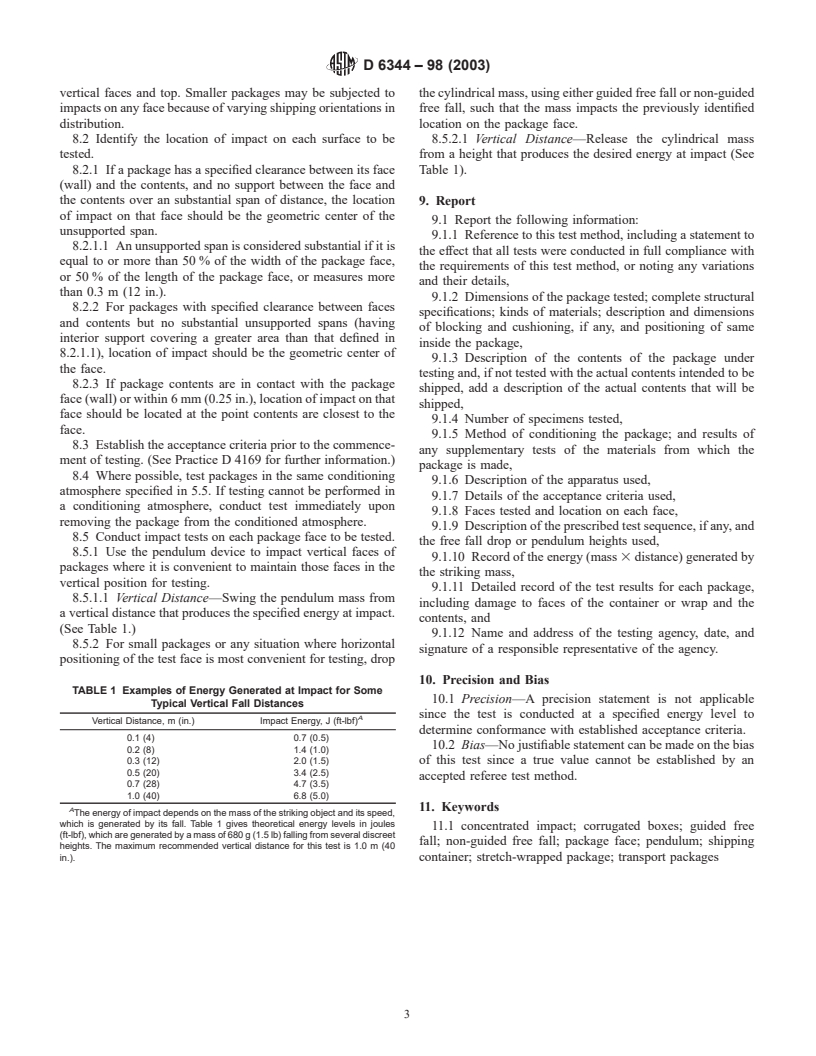

5.2 Guided Free Fall (see Fig. 2):

5.2.1 The cylindrical mass (rod) is held in a start position in

This test method is under the jurisdiction of ASTM Committee D10 on

a stiff tube of at least 38 mm (1.5 in.) diameter, such that the

Packaging and is the direct responsibility of Subcommittee D10.22 on Physical Test

tube’s main axis is perpendicular within 2 degrees. The end of

Methods.

the tube should be positioned 50 to 100 mm (2 to 4 in.) above

Current edition approved Nov. 10, 1998. Published January 1999.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the test specimen. The mass may be held in position, at the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6344 – 98 (2003)

FIG. 1 Cylindrical Mass (steel rod)

FIG. 3 Pendulum

10 mm (0.4 in.) of the desired point of impact. The test surface

must be perpendicular to the direction of the falling mass.

5.4.2 The test specimen must be braced securely so it does

not move when impacted.

5.5 Conditioning Apparatus—Adequate facilities shall be

provided for conditioning test specimens at the proper humid-

ity and temperature prior to testing.

5.5.1 It is recommended that atmospheres for conditioning

be selected from those given in Practice D 4332. Unless

otherwise specified, fiberboard or paperboard containers shall

be conditioned in accordance with the preconditioning and

FIG. 2 Guided Free Fall

standard conditioning atmospheres specified in Practice

D 4332.

specified vertical distance, with either a string from the top of

6. Sampling

the tube, or by a support pin placed through the side of the tube.

6.1 The test specimens and number of samples shall be

5.2.2 The mass is allowed to fall freely when released to

chosen to permit an adequate determination of representative

strike the test specimen with its rounded end. The free falling

performance. Practice E 122 is recommended.

rod must strike the test surface within 10 mm (0.4 in.) of the

desired point of impact. The test surface must be perpendicular

7. Test Specimen

to the direction of the falling mass.

5.3 Non-guided Free Fall:

7.1 It is preferable to prepare the package with the actual

5.3.1 If greater precision of impact velocity is desired, the contents for which it was designed (see Note 2). Close the

cylindrical mass (rod) may be dropped without guidance of a

package in the same manner that will be used in preparing it for

tube. Means of suspending the mass and its release must be shipment.

such that accuracy of positioning (drop height and impact

NOTE 2—Where the use of actual goods is not feasible because of

point) are not affected.

excessive cost or danger, a dummy load simulating the goods may be used,

5.3.2 The free falling rod must strike the test surface within

provided the dummy load has the same exterior surfaces as the actual

10 mm (0.4 in.) of the desired p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.