ASTM B401-99

(Specification)Standard Specification for Compact Round Concentric-Lay-Stranded Aluminum Conductors, Steel-Reinforced (ACSR/COMP)

Standard Specification for Compact Round Concentric-Lay-Stranded Aluminum Conductors, Steel-Reinforced (ACSR/COMP)

SCOPE

1.1 This specification covers compact round concentric-lay-stranded conductors made from aluminum 1350-H19 (extra hard) wires and round zinc-coated, aluminum-coated, or aluminum-clad steel core wires usually used in overhead lines. These conductors shall be constructed with one steel core wire surrounded by one or more layers of helically-laid compacted or otherwise shaped aluminum wires (Explanatory Notes 1 and 2).

1.2 Compact ACSR covered by this specification has five types of steel core wire which are designated by abbreviations as follows (Explanatory Note 2).

1.2.1 ACSR/GA/COMP -Compact ACSR using Class A zinc-coated steel wire,

1.2.2 ACSR/GB/COMP -Compact ACSR using Class B zinc-coated steel wire,

1.2.3 ACSR/GC/COMP -Compact ACSR using Class C zinc-coated steel wire,

1.2.4 ACSR/AZ/COMP -Compact ACSR using aluminum-coated (aluminized) steel wire, and

1.2.5 ACSR/AW/COMP -Compact ACSR using aluminum-clad steel wire.

1.3 The SI values of density and resistivity are to be regarded as standard. For all other properties the inch-pound values are to be regarded as standard and the SI units may be approximate. Note 1-Prior to 1975, aluminum 1350 was designated as EC aluminum. Note 2-The aluminum and temper designations conform to ANSI H35.1. Aluminum 1350 corresponds to Unified Numbering System A91350 in accordance with Practice E527.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 401 – 99

Standard Specification for

Compact Round Concentric-Lay-Stranded Aluminum

Conductors, Steel-Reinforced (ACSR/COMP)

This standard is issued under the fixed designation B 401; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 230 Specification for Aluminum 1350-H19 Wire for Elec-

trical Purposes

1.1 This specification covers compact round concentric-lay-

B 232 Specification for Concentric-Lay-Stranded Alumi-

stranded conductors made from aluminum 1350-H19 (extra

num Conductors, Coated Steel Reinforced (ACSR)

hard) wires and round zinc-coated, aluminum-coated, or

B 263 Test Method for Determination of Cross-Sectional

aluminum-clad steel core wires usually used in overhead lines.

Area of Stranded Conductors

These conductors shall be constructed with one steel core wire

B 341 Specification for Aluminum-Coated (Aluminized)

surrounded by one or more layers of helically-laid compacted

Steel Core Wire for Aluminum Conductors, Steel-

or otherwise shaped aluminum wires (Explanatory Note 1 and

Reinforced (ACSR/AZ)

Note 2).

B 354 Terminology Relating to Uninsulated Metallic Elec-

1.2 Compact ACSR covered by this specification has five

trical Conductors

types of steel core wire which are designated by abbreviations

B 498 Specification for Zinc-Coated (Galvanized) Steel

as follows (Explanatory Note 2).

Core Wire for Aluminum Conductors, Steel Reinforced

1.2.1 ACSR/GA/COMP—Compact ACSR using Class A

(ACSR)

zinc-coated steel wire,

B 502 Specification for Aluminum-Clad Steel Core Wire for

1.2.2 ACSR/GB/COMP—Compact ACSR using Class B

Aluminum Conductors, Aluminum-Clad Steel Reinforced

zinc-coated steel wire,

B 802 Specification for Zinc-5 % Aluminum-Mischmetal

1.2.3 ACSR/GC/COMP—Compact ACSR using Class C

Alloy-Coated Steel Core Wire for Aluminum Conductors,

zinc-coated steel wire,

Steel Reinforced (ACSR)

1.2.4 ACSR/AZ/COMP—Compact ACSR using aluminum-

E 29 Practice for Using Significant Digits in Test Data to

coated (aluminized) steel wire, and

Determine Conformance with Specifications

1.2.5 ACSR/AW/COMP—Compact ACSR using aluminum-

E 527 Practice for Numbering Metals and Alloys (UNS)

clad steel wire.

2.3 Other Documents:

1.3 The SI values of density and resistivity are to be

ANSI H35.1, American National Standard Alloy and Tem-

regarded as standard. For all other properties the inch-pound

per Designation Systems For Aluminum

values are to be regarded as standard and the SI units may be

NBS Handbook 100—Copper Wire Tables of the National

approximate.

Bureau of Standards

NOTE 1—Prior to 1975, aluminum 1350 was designated as EC alumi-

num.

3. Ordering Information

NOTE 2—The aluminum and temper designations conform to ANSI

3.1 Orders for material under this specification shall include

H35.1. Aluminum 1350 corresponds to Unified Numbering System

the following information:

A91350 in accordance with Practice E 527.

3.1.1 Quantity of each size and stranding (Table 1),

2. Referenced Documents

3.1.2 Conductor size: circular-mil area or AWG (Section 6,

and Table 1),

2.1 The following documents of the issue in effect on date

3.1.3 Steel wire coating or aluminum-clad (see 11.3),

of material purchase form a part of this specification to the

3.1.4 Special tension test, if required (see 15.3),

extent referenced herein.

2.2 ASTM Standards:

Annual Book of ASTM Standards, Vol 02.03.

Annual Book of ASTM Standards, Vol 14.02.

1 4

This specification is under the jurisdiction of ASTM Committee B-1 on Annual Book of ASTM Standards, Vol 01.01.

Electrical Conductors, and is the direct responsibility of Subcommittee B01.07 on Available from the American National Standards Institute, 11 West 42nd St.,

Conductors of Light Metals. 13th Floor, New York, NY 10018.

Current edition approved April 10, 1999. Published June 1999. Originally Available from the National Technical Information Service, 5285 Port Royal

published as B 401 – 63 T. Last previous edition B 401 – 92. Rd., Springfield, VA 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 401

TABLE 1 Construction Requirements for Compact Round Concentric-Lay-Stranded Aluminum Conductors, Steel Reinforced

Required Construction Nominal Mass for Conductors With:

Compact

Conductor Size Steel Wire Aluminum-Clad

Number of

Conductor Coated Steel Core Wire

(Aluminum Wires) Diameter Steel Core Wire

Aluminum

Diameter

Wires

cmil mm AWG in. mm in. mm lb/1000 ft kg/km lb/1000 ft kg/km

336 400 170.5 . 18 0.1367 3.472 0.628 15.95 364.8 542.8 357.2 531.5

266 800 135.2 . 18 0.1217 3.091 0.559 14.20 289.1 430.2 283.1 421.3

211 600 107.2 0000 6 0.1878 4.770 0.517 13.13 290.8 432.7 276.5 411.5

167 800 85.03 000 6 0.1672 4.247 0.461 11.71 230.5 343.0 219.2 326.1

133 100 67.44 00 6 0.1489 3.782 0.410 10.41 182.8 272.0 173.8 258.7

105 600 53.51 0 6 0.1327 3.371 0.365 9.27 145.2 216.0 138.1 205.4

83 690 42.41 1 6 0.1181 3.000 0.326 8.28 115.0 171.1 109.4 162.7

66 360 33.62 2 7 0.1299 3.299 0.298 7.57 106.6 158.7 99.8 148.5

66 360 33.62 2 6 0.1052 2.672 0.290 7.37 91.2 135.8 86.8 129.1

52 620 26.66 3 6 0.0937 2.380 0.258 6.55 72.4 107.7 68.8 102.4

41 740 21.15 4 7 0.1029 2.614 0.236 5.99 67.0 99.6 62.7 93.3

41 740 21.15 4 6 0.0834 2.118 0.229 5.82 57.3 85.3 54.5 81.1

26 240 13.30 6 6 0.0661 1.679 0.182 4.62 36.0 53.6 . .

3.1.5 Place of inspection (Section 16), and 7. Rated Strength of Conductor

3.1.6 Packaging and Package Marking (Section 17).

7.1 The rated strength of a completed conductor shall be

taken as the aggregate strength of the aluminum and steel

4. Joints

components, calculated as follows: The strength contribution

of the aluminum wires shall be taken as the percentage,

4.1 Electric-butt welds, electric-butt, cold-upset welds, or

according to the number of layers of aluminum wires, indicated

cold-pressure welds in the individual round-drawn or shaped

in Table 2, of the sum of the strengths of the 1350-H19 wires,

aluminum wires may be made during the stranding process. No

calculated on the basis of the nominal wire diameter for the

weld shall occur within 50 ft (15 m) of a weld in the same wire

corresponding noncompacted construction given in Specifica-

or in any other wire of the completed conductor.

tion B 232 and the appropriate specified minimum average

4.2 There shall be no joints of any kind made in the finished

tensile strength given in Specification B 230. The strength

coated, or aluminum-clad steel wires.

contribution of the steel core shall be taken as 96 % of the

strength of the steel wire calculated from its specified nominal

5. Lay

diameter and the appropriate specified minimum stress at 1 %

5.1 The preferred lay of the aluminum wires of aluminum

extension given in Specification B 341, B 498, B 502, or

conductors, steel-reinforced, having a single wire steel core

B 802, whichever is applicable.

and one layer of aluminum wires is 14 times the outside

7.2 Rated strength and breaking strength values shall be

diameter of the conductor but the lay shall be not less than 13

rounded to three significant figures, in the final value only, in

nor more than 16 times that diameter.

accordance with Practice E 29.

5.2 The preferred lay of the outside layer of aluminum wires

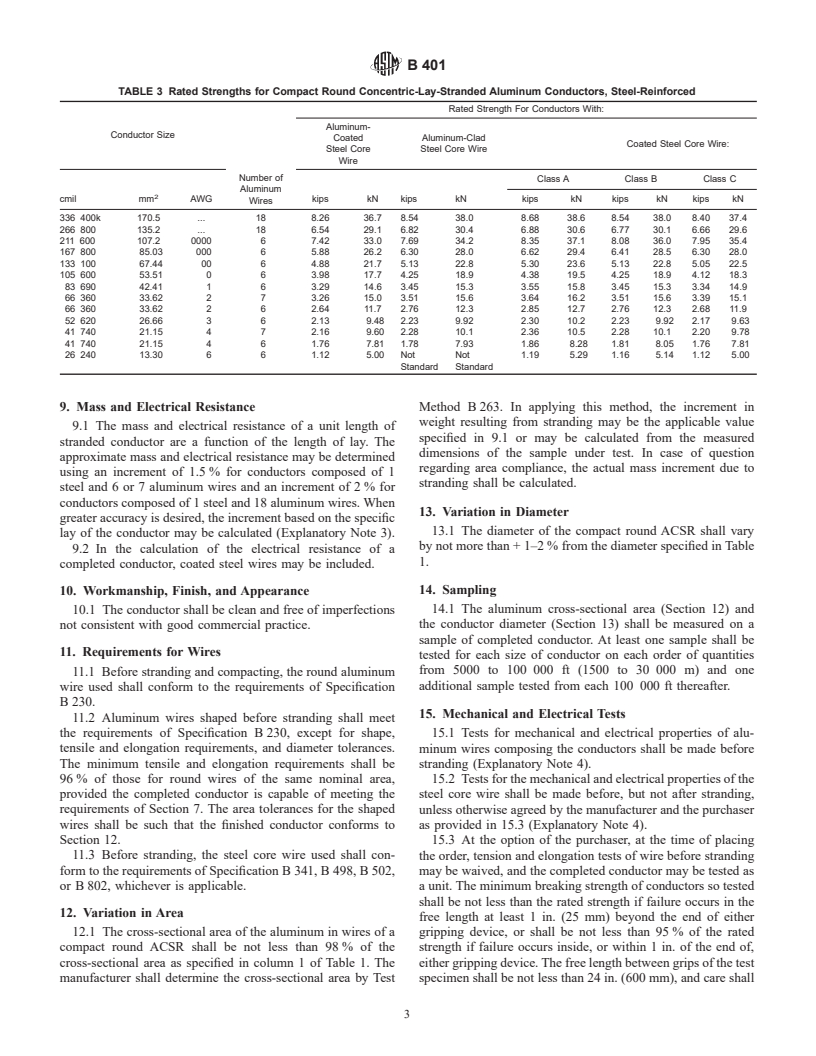

7.3 Rated strength of conductors are given in Table 3.

of aluminum conductors, steel-reinforced, having multiple

layers of aluminum wires is 12 times the outside diameter of

8. Density

the conductor but the lay shall be not less than 11 nor more

8.1 For the purpose of calculating mass, mass per unit

than 14 times that diameter.

length, cross sections, etc., the density of aluminum 1350 shall

5.3 The preferred lay of the layer immediately beneath the 3 3

be taken as 2705 kg/m (0.0975 lb/in. ) at 20°C.

outside layer of aluminum wires of aluminum conductors,

8.2 For the purpose of calculating mass, mass per unit

steel-reinforced, having multiple layers of aluminum wires is

length, cross sections, etc., the density of coated steel wire shall

14 times the outside diameter of such layer but the lay shall be 3 3

be taken as 7780 kg/m (0.281 lb/in. ) at 20°C.

not less than 11 nor more than 17.5 times that diameter.

8.3 For the purpose of calculating mass, mass per unit

5.4 The direction of lay of the outside layer of aluminum

length, cross sections, etc., the density of aluminum-clad steel

3 3

wires shall be right hand.

wire shall be taken as 6590 kg/m (0.2381 lb/in. ) at 20°C.

5.5 The direction of lay shall be reversed in successive

layers.

TABLE 2 Strength Rating Factors

Stranding Rating Factor, %

6. Construction

Number of Wires Number of Layers

Aluminum Steel

Aluminum Steel Aluminum Steel

6.1 The diameter of the steel core wire, the number of

A

61 1 96 96

aluminum wires, the aluminum cross-sectional area, the diam-

A

71 1 96 96

A

eter and weight of the compact round concentric-lay-stranded

18 1 2 93 96

aluminum conductors, steel-reinforced, shall be as shown in A

Central steel wire only: the 96 % Rating Factor is applied to the single steel

Table 1. wire core in the event it contains a weld (made prior to drawing).

B 401

TABLE 3 Rated Strengths for Compact Round Concentric-Lay-Stranded Aluminum Conductors, Steel-Reinforced

Rated Strength For Conductors With:

Aluminum-

Conductor Size

Coated Aluminum-Clad

Coated Steel Core Wire:

Steel Core

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.