ASTM C240-97(2003)

(Test Method)Standard Test Methods of Testing Cellular Glass Insulation Block

Standard Test Methods of Testing Cellular Glass Insulation Block

SIGNIFICANCE AND USE

From a general standpoint, these test methods outline the particular points which have to be taken into account when applying ASTM standard test methods to the case of cellular glass insulating block.

SCOPE

1.1 These test methods cover the testing of cellular glass insulation block for density, water absorption, compressive strength, flexural strength at ambient temperature; preparation for chemical analysis; and thermal conductivity measurements.

1.2 The values stated in SI are generally to be regarded as the standard. The SI dimensions are to be used for material supplied in metric sizes. The inch dimensions are to be used for material supplied in inch sizes.

1.3 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C240–97 (Reapproved 2003)

Standard Test Methods of

Testing Cellular Glass Insulation Block

This standard is issued under the fixed designation C240; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ISO Standard:

ISO 3951 Sampling Procedure and Charts for Inspection by

1.1 These test methods cover the testing of cellular glass

Variables for Percent Nonconforming

insulation block for density, water absorption, compressive

2.3 Military Standard:

strength, flexural strength at ambient temperature; preparation

MIL-I-24244 Specification Insulation Materials with Spe-

forchemicalanalysis;andthermalconductivitymeasurements.

cial Corrosion, Chloride, and Fluoride Requirements

1.2 The values stated in SI are generally to be regarded as

2.4 Other Standard:

the standard. The SI dimensions are to be used for material

NRC 1.36 Nonmetallic Thermal Insulation for Austenitic

suppliedinmetricsizes.Theinchdimensionsaretobeusedfor

Stainless Steel

material supplied in inch sizes.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions—Terminology C168 shall be considered as

responsibility of the user of this standard to establish appro-

applying to the terms considered in these test methods.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Significance and Use

4.1 From a general standpoint, these test methods outline

2. Referenced Documents

the particular points which have to be taken into account when

2.1 ASTM Standards:

applying ASTM standard test methods to the case of cellular

C165 Test Method for Measuring Compressive Properties

glass insulating block.

of Thermal Insulations

C168 Terminology Relating to Thermal Insulation

5. Test Methods

C177 Test Method for Steady-State Heat Flux Measure-

5.1 General Sample Preparation—All tests have to be run

ments and Thermal Transmission Properties by Means of

2 on dry specimens. In case of need, the sample must be

the Guarded-Hot-Plate Apparatus

unpacked and stored in a dry place in such a way that all

C203 Test Methods for Breaking Load and Flexural Prop-

2 surfaces are exposed to the ambient air for at least one day

erties of Block-Type Thermal Insulation

before testing.

C303 Test Method for Dimensions and Density of Pre-

2 5.2 Density—DeterminethedensityinaccordancewithTest

formed Block and Broad-Type Thermal Insulation

Method C303. Preferably, the density shall be measured on a

C390 Practice for Sampling andAcceptance of Preformed

2 full block, 450 by 600 mm (18 by 24 in.) by full thickness.

Thermal Insulation Lots

5.2.1 Itshouldbenotedthatdensityisinterestingassuchfor

C518 Test Method for Steady-State Thermal Transmission

2 calculation of insulated equipment load and because it has

Properties by Means of the Heat Flow Meter Apparatus

some influence on the other important properties of cellular

C871 Test Methods for Chemical Analysis of Thermal

glass. But it should not be considered in itself as a criterion for

Insulation Materials for Leachable Chloride, Fluoride,

2 acceptance in the case of cellular glass.

Silicate, and Sodium Ions

5.3 Water Absorption:

D 226 Specification for Asphalt-Saturated Organic Felt

Used in Roofing and Waterproofing

These test methods are under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on Available from American National Standards Institute, 25 W. 43nd St., 4th

Mechanical Properties. Floor, New York, NY 10036.

Current edition approved April 10, 2003. Published July 2003. Originally Available from Standardization Documents Order Desk, Bldg. 4, Section D,

approved in 1950. Last previous edition approved in 1997 as C 240–97. 700 Robbins Ave., Philadelphia, PA 19111-5094.

2 6

Annual Book of ASTM Standards, Vol 04.06. Available from Director of Regulatory Standards, USAtomic Energy Commis-

Annual Book of ASTM Standards, Vol 04.04. sion, Washington, DC 20545.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C240–97 (2003)

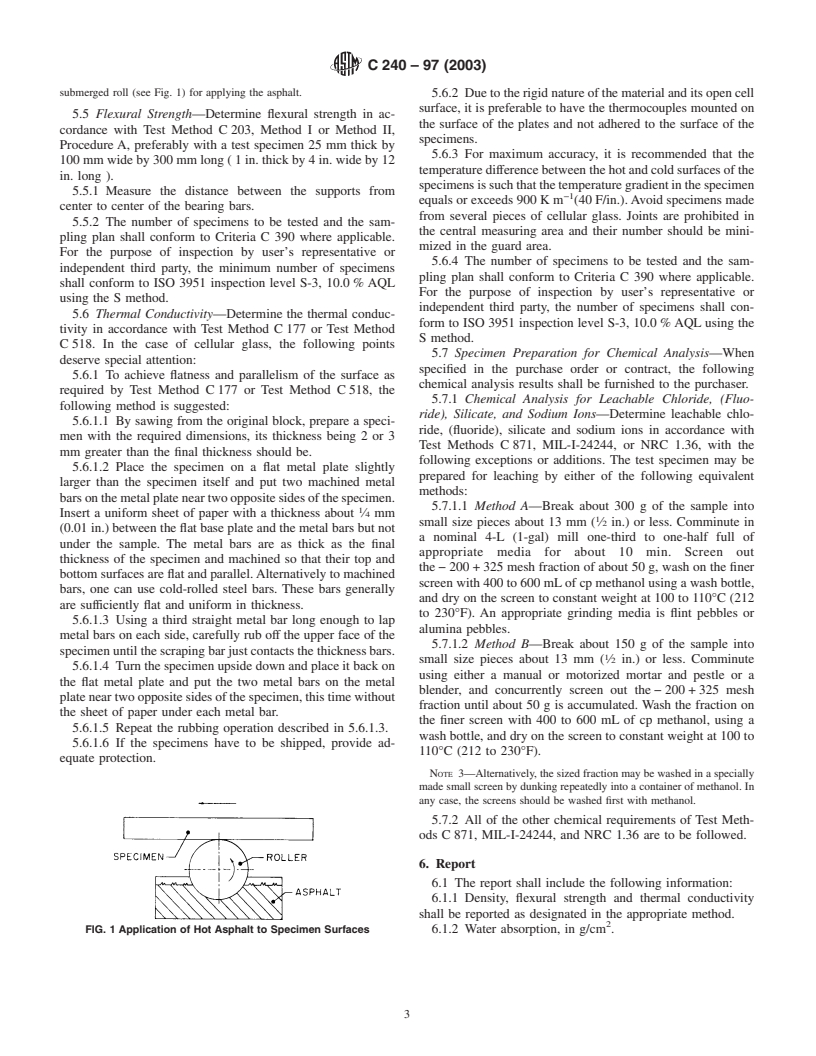

5.3.1 Scope—This test method covers the determination of 5.4 Compressive Strength—Determine the compressive

water absorption of cellular glass insulating blocks by measur- strength in accordance with Test Method C165 Procedure A,

ing the amount of water retained as a result of complete with the following test parameters and specimen preparation

immersion for a prescribed time interval. Surface blotting is techniques:

used to correct for the water absorbed on the cut surface cells. 5.4.1 Each of the two parallel bearing surfaces of the

5.3.2 Significance and Use—This test method provides a specimens shall be plane. If necessary, rub them on a suitable

means of measuring the water absorption of cellular glass abrasive surface to produce the required flat surface.

insulating blocks under isothermal conditions as a result of 5.4.2 The test specimens shall preferably be one half block

direct immersion in liquid water. It is intended for use in 300 by 450 mm (12 by 18 in.) by nominal received thickness.

product evaluation and quality control. Alternates include a quadrant 225 by 300 mm (9 by 12 in.) or

5.3.3 Equipment and Materials: afullblock450by600mm(18by24in.)bynominalreceived

5.3.3.1 Balance, with about 1500 g capacity and at least 0.1 thickness.Aquadrant specimen shall be taken from any one of

g sensitivity. four equal area quadrants of the preformed block. The mini-

5.3.3.2 Immersion Tank, equipped with inert specimen sup- mum acceptable specimen size is 200 by 200 mm (8 by 8 in.).

ports and top surface weights such as stainless steel. The report shall include the specimen size.

5.3.3.3 Synthetic Sponge, at least 100 by 180 by 40 mm (4 5.4.3 Capbothbearingsurfacesofthespecimensasfollows:

by 7 by 1.5 in.). Sponges found acceptable to use include Coat one surface with molten Type III or Type IV asphalt

cellulosic sponges and fine-pored absorbent synthetic plastic (preheated to 177,+28,−14°C (350,+50,−25°F)), com-

sponges. pletely filling the surface cells with a small excess. Such a

2 2

5.3.3.4 Test Room, with temperature of 21 6 3°C (70 6 coatingapplicationrateisapproximately1.0kg/m (0.20lb/ft )

5°F) and relative humidity of 50 6 10%. 6 25%. Immediately press the hot coated block onto a precut

5.3.3.5 Distilled Water. pieceoffeltorpaperlayingonaflatsurface.Thisistoprevent

5.3.4 Procedure: the asphalt surface from sticking to the compression platten

5.3.4.1 Carefully measure the thickness, width, and length during the test. A lightweight kraft paper is suitable, although

to the nearest 1 mm of a cellular glass block, preferably 50 by traditionally a Type 1 roofing felt paper, commonly called a

300 by 450 mm (2 by 12 by 18 in.) and calculate the volume No. 15 asphalt felt, per Specification D226 has been used.

and exposed surface area.

NOTE 1—A hot asphalt capping is used to simulate field applied

5.3.4.2 Weigh the specimen to the nearest 0.1 g (W ), then

systems, which require a high load bearing insulation product, ranging

submerge it horizontally under 25 mm (1 in.) of water

from roof applications to cryogenic storage tank base applications.

maintained at 21 6 3°C (70 6 5°F). Inert top surface weights

Uncapped material or different cappings will give different values.

are required to keep it submerged.After submerging it for 2 h,

Properlycappedsurfacesshouldbeapproximatelyplaneand

set the specimen on end on a damp cotton bath towel to drain

parallel. Set the specimens on edge, exposing both capped

for 10 min.After the 10 min, remove the excess surface water

surfaces to room temperature for a minimum of 15 min to

byhandwithadampspongefor1minperlargefaceand1min

allow the asphalt to harden before testing.

for the four sides. Wring out the sponge before and once in

5.4.4 The number of specimens to be tested and the sam-

between for each face and pass at least two times on each

pling plan shall conform to Criteria C 390 where applicable.

surface.Bloteachfaceofthespecimenequallybycompressing

For the purpose of inspection by user’s representative or

the sponge by at least 10% of its thickness. Weigh the

independent third party, the number of specimens shall con-

specimen immediately (W ) to the nearest 0.1 g.

form to ISO 3951 inspection level S-4, 10.0%AQL using the

5.3.5 Calculation of Results—Calculate the weight of water

S method.

absorbed(W − W )andexpressitasafunctionoftheexterior

2 1

5.4.5 Compress the specimen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.