ASTM D6693/D6693M-04(2015)e1

(Test Method)Standard Test Method for Determining Tensile Properties of Nonreinforced Polyethylene and Nonreinforced Flexible Polypropylene Geomembranes

Standard Test Method for Determining Tensile Properties of Nonreinforced Polyethylene and Nonreinforced Flexible Polypropylene Geomembranes

SIGNIFICANCE AND USE

4.1 This test method is designed to produce tensile property data for the control and specification of nonreinforced polyethylene and flexible nonreinforced polypropylene geomembranes. These data are also useful for qualitative characterization and for research and development. It may be necessary to modify this procedure for use in testing certain materials as recommended by the material specifications. Therefore, it is advisable to refer to that material's specification before using this test method. Table 1 in Classification D4000 lists the ASTM materials standards that currently exist.

4.2 Tensile properties may vary with specimen preparation, test speed, and environment of testing. Consequently, where precise comparative results are desired, these factors must be carefully monitored and controlled.

4.2.1 It is realized that a material cannot be tested without also testing the method of preparation of that material. Hence, when comparative tests of materials are desired, the care must be exercised to ensure that all samples are prepared in exactly the same way, unless the test is to include the effects of sample preparation. Similarly, for referee purposes or comparisons within any given series of specimens, care must be taken to secure the maximum degree of uniformity in details of preparation, treatment, and handling.

Note 2: Tensile properties may provide useful data for plastics engineering design purposes. However, because of the high degree of sensitivity exhibited by many plastics to rate of straining and environmental conditions, data obtained by this test method cannot be considered valid for applications involving load-time scales or environments widely different from those of this test method. In cases of such dissimilarity, no reliable estimation of the limit of usefulness can be made for most plastics. This sensitivity to rate of straining and environment necessitates testing over a broad load-time scale and range of environmental conditions...

SCOPE

1.1 This test method covers the determination of the tensile properties of nonreinforced geomembranes in the form of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, and machine speed.

1.2 This test method can be used for testing materials thickness between 0.25 mm [0.010 in.] and 6.3 mm [0.25 in.].

Note 1: This test method is not intended to cover precise physical procedures. The constant rate of crosshead movement of this test lacks accuracy from a theoretical standpoint. A wide difference may exist between the rate of crosshead movement and the rate of strain of the specimen indicating that the testing speeds specified may disguise important effects or characteristics of these materials in the plastic state. Further, it is realized that variations in the thicknesses of test specimens, as permitted by this test method, produce variations in the surface-volume ratios of such specimens, and that these variations may influence the test results. Hence, where directly comparable results are desired, all samples should be of equal thickness. Special additional tests should be used where more precise physical data are needed.

1.3 Test data obtained by this test method are relevant and may be appropriate for use in engineering design with consideration of test conditions as compared with in-service conditions.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the appli...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6693/D6693M − 04 (Reapproved 2015)

Standard Test Method for

Determining Tensile Properties of Nonreinforced

Polyethylene and Nonreinforced Flexible Polypropylene

Geomembranes

This standard is issued under the fixed designation D6693/D6693M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Designation was changed to dual and units information was corrected editorially in June 2015.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers the determination of the tensile

properties of nonreinforced geomembranes in the form of

2. Referenced Documents

standard dumbbell-shaped test specimens when tested under

2.1 ASTM Standards:

defined conditions of pretreatment, temperature, and machine

D638 Test Method for Tensile Properties of Plastics

speed.

D4000 Classification System for Specifying Plastic Materi-

1.2 This test method can be used for testing materials

als

thickness between 0.25 mm [0.010 in.] and 6.3 mm [0.25 in.].

D4439 Terminology for Geosynthetics

NOTE 1—This test method is not intended to cover precise physical D5199 Test Method for Measuring the Nominal Thickness

procedures. The constant rate of crosshead movement of this test lacks

of Geosynthetics

accuracy from a theoretical standpoint. A wide difference may exist

D5994/D5994M Test Method for Measuring CoreThickness

between the rate of crosshead movement and the rate of strain of the

of Textured Geomembranes

specimen indicating that the testing speeds specified may disguise

E4 Practices for Force Verification of Testing Machines

important effects or characteristics of these materials in the plastic state.

Further, it is realized that variations in the thicknesses of test specimens, E691 Practice for Conducting an Interlaboratory Study to

as permitted by this test method, produce variations in the surface-volume

Determine the Precision of a Test Method

ratios of such specimens, and that these variations may influence the test

results. Hence, where directly comparable results are desired, all samples

3. Terminology

shouldbeofequalthickness.Specialadditionaltestsshouldbeusedwhere

more precise physical data are needed.

3.1 Definitions—Definitions of terms applying to this test

method appear in Terminology D4439.

1.3 Test data obtained by this test method are relevant and

may be appropriate for use in engineering design with consid-

4. Significance and Use

eration of test conditions as compared with in-service condi-

4.1 This test method is designed to produce tensile property

tions.

data for the control and specification of nonreinforced poly-

1.4 The values stated in either SI units or inch-pound units

ethylene and flexible nonreinforced polypropylene geomem-

are to be regarded separately as standard. The values stated in

branes. These data are also useful for qualitative characteriza-

each system may not be exact equivalents; therefore, each

tion and for research and development. It may be necessary to

system shall be used independently of the other. Combining

modify this procedure for use in testing certain materials as

values from the two systems may result in non-conformance

recommended by the material specifications. Therefore, it is

with the standard.

advisable to refer to that material’s specification before using

1.5 This standard does not purport to address all of the

this test method. Table 1 in Classification D4000 lists the

safety concerns, if any, associated with its use. It is the

ASTM materials standards that currently exist.

responsibility of the user of this standard to establish appro-

4.2 Tensile properties may vary with specimen preparation,

test speed, and environment of testing. Consequently, where

This test method is under the jurisdiction of ASTM Committee D35 on

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.10onGeomem-

branes. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2015. Published June 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2001. Last previous edition approved in 2010 as D6693–04(2010). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D6693_D6693M-04R15E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6693/D6693M − 04 (2015)

precise comparative results are desired, these factors must be Other techniques that have been found useful, particularly with

carefully monitored and controlled. smooth-faced grips, are abrading that portion of the surface of

4.2.1 It is realized that a material cannot be tested without the specimen that will be in the grips, and interposing thin

also testing the method of preparation of that material. Hence, pieces of abrasive cloth, abrasive paper, plastic, or rubber-

when comparative tests of materials are desired, the care must coated fabric, commonly called hospital sheeting, between the

be exercised to ensure that all samples are prepared in exactly specimen and the grip surface. No. 80 double-sided abrasive

the same way, unless the test is to include the effects of sample paper has been found effective in many cases. An open-mesh

preparation. Similarly, for referee purposes or comparisons fabric, in which the threads are coated with abrasive, has also

within any given series of specimens, care must be taken to been effective. Reducing the cross-sectional area of the speci-

secure the maximum degree of uniformity in details of men may also be effective. The use of special types of grips is

preparation, treatment, and handling. sometimes necessary to eliminate slippage and breakage in the

grips.

NOTE 2—Tensile properties may provide useful data for plastics

5.1.4 Drive Mechanism—A drive mechanism for imparting

engineering design purposes. However, because of the high degree of

to the movable member a uniform, controlled velocity with

sensitivity exhibited by many plastics to rate of straining and environ-

mental conditions, data obtained by this test method cannot be considered

respect to the stationary member, with this velocity to be

valid for applications involving load-time scales or environments widely

regulated as specified in Section 9.

different from those of this test method. In cases of such dissimilarity, no

5.1.5 Load Indicator—A suitable load-indicating mecha-

reliableestimationofthelimitofusefulnesscanbemadeformostplastics.

nism capable of showing the total tensile load carried by the

This sensitivity to rate of straining and environment necessitates testing

over a broad load-time scale and range of environmental conditions if test specimen when held by the grips. This mechanism shall be

tensile properties are to suffice for engineering design purposes.

essentially free of inertia lag at the specified rate of testing and

shall indicate the load with an accuracy of 61 % of the

5. Apparatus

indicated value, or better. The accuracy of the testing machine

5.1 Testing Machine—A testing machine of the constant-

shall be verified in accordance with Practices E4.

rate-of-crosshead-movement type and comprising essentially

NOTE 3—Experience has shown that many testing machines now in use

the following:

are incapable of maintaining accuracy for as long as the periods between

5.1.1 Fixed Member—A fixed or essentially stationary

inspection recommended in Practices E4. Hence, it is recommended that

member carrying one grip.

each machine be studied individually and verified as often as may be

found necessary. It frequently will be necessary to perform this function

5.1.2 Movable Member—A movable member carrying a

daily.

second grip.

5.1.3 Grips—Grips for holding the test specimen between

6. Test Specimens

the fixed member and the movable member of the test

6.1 Sheet, Plate, and Molded Plastics:

apparatus can be either a fixed or self-aligning type.

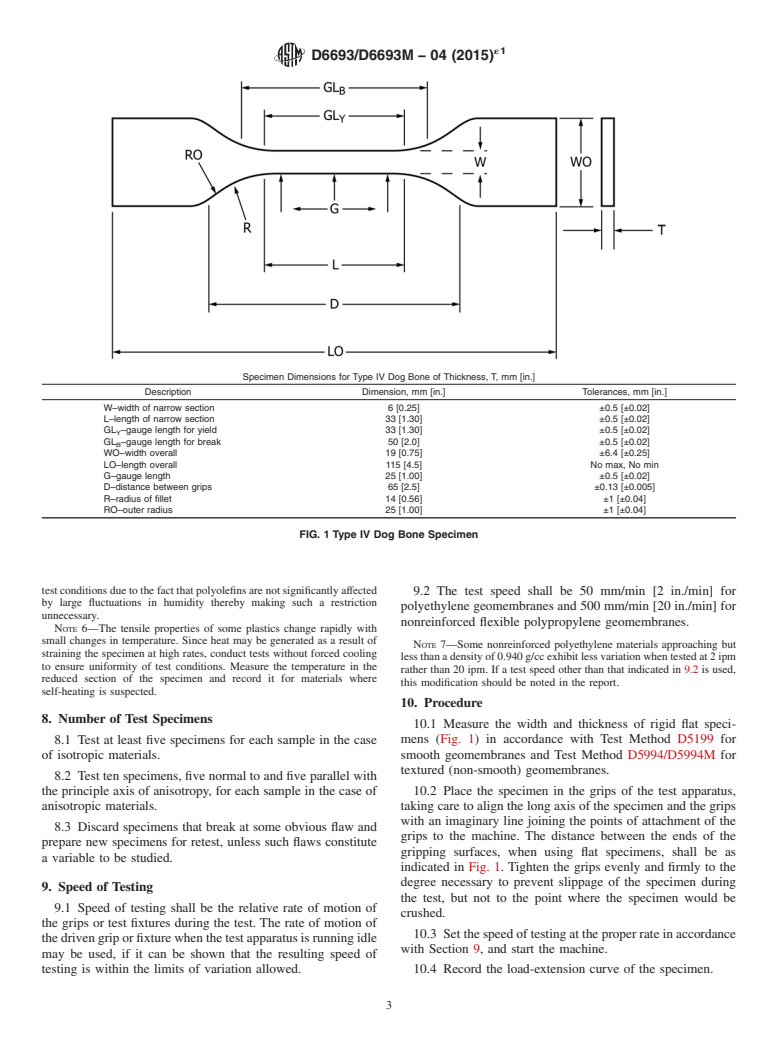

6.1.1 The test specimens shall conform to the dimensions

5.1.3.1 Fixed grips are rigidly attached to the fixed and

shown in Fig. 1. This specimen geometry was adopted from

movable members of the test apparatus. Extreme care should

Test Method D638 and is therefore equivalent to Type IV of

be taken when this type of grip is used to ensure that the test

said standard.

specimen is inserted and clamped so that the long axis of the

6.1.2 Test specimens shall be prepared by die cutting from

test specimen coincides with the direction of pull through the

materials in sheet, plate, slab, or similar form.

centerline of the grip assembly.

5.1.3.2 Self-aligning grips are attached to the fixed and

6.2 All surfaces of the specimen shall be free of visible

movable members of the test apparatus. This type of grip

flaws, scratches, or imperfections. If the specimen exhibits

assembly is such that they will move freely into alignment as

such markings, it should be discarded and replaced. If these

soon as any load is applied as long as the long axis of the test

flaws or imperfections are present in the new specimen, the die

specimen will coincide with the direction of the applied pull

should be inspected for flaws.

through the centerline of the grip assembly. The specimens

NOTE 4—Negative effects from imperfections on the edge of the

should be aligned as perfectly as possible with the direction of

specimens can severely impact the results of this test and should therefore

pull so that no rotary motion will occur in the grips thereby

be carefully monitored. In cases of dispute over the results, inspection of

inducing slippage; there is a limit to the amount of misalign-

the die and specimen preparation should take place.

ment self-aligning grips will accommodate.

7. Conditioning

5.1.3.3 The test specimen shall be held in such a way that

slippage relative to the grips is prevented as much as possible.

7.1 Conditioning—Specimens should be tested once the

Grip surfaces that are deeply scored or serrated with a pattern

material has reached temperature equilibrium. The time re-

similar to those of a coarse single-cut file, serrations about

quired to reach a temperature equilibrium may vary according

2.4 mm [0.09 in.] apart and about 1.6 mm [0.06 in.] deep, have

to the manufacturing process, material type, and material

been found satisfactory for most thermoplastics. Finer serra-

thickness.

tions have been found to be more satisfactory for harder

7.2 Test Conditions—Conduct tests in the Standard Labora-

plastics, such as the thermosetting materials. The serrations

t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6693 − 04 (Reapproved 2010) D6693/D6693M − 04 (Reapproved 2015)

Standard Test Method for

Determining Tensile Properties of Nonreinforced

Polyethylene and Nonreinforced Flexible Polypropylene

Geomembranes

This standard is issued under the fixed designation D6693;D6693/D6693M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Designation was changed to dual and units information was corrected editorially in June 2015.

1. Scope

1.1 This test method covers the determination of the tensile properties of nonreinforced geomembranes in the form of standard

dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, and machine speed.

1.2 This test method can be used for testing materials thickness between 0.25 mm (0.010 in.)[0.010 in.] and 6.3 mm (0.25

in.).[0.25 in.].

NOTE 1—This test method is not intended to cover precise physical procedures. The constant rate of crosshead movement of this test lacks accuracy

from a theoretical standpoint. A wide difference may exist between the rate of crosshead movement and the rate of strain of the specimen indicating that

the testing speeds specified may disguise important effects or characteristics of these materials in the plastic state. Further, it is realized that variations

in the thicknesses of test specimens, as permitted by this test method, produce variations in the surface-volume ratios of such specimens, and that these

variations may influence the test results. Hence, where directly comparable results are desired, all samples should be of equal thickness. Special additional

tests should be used where more precise physical data are needed.

1.3 Test data obtained by this test method are relevant and may be appropriate for use in engineering design with consideration

of test conditions as compared with in-service conditions.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. The values given in

parentheses are for information only.stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D4000 Classification System for Specifying Plastic Materials

D4439 Terminology for Geosynthetics

D5199 Test Method for Measuring the Nominal Thickness of Geosynthetics

D5994D5994/D5994M Test Method for Measuring Core Thickness of Textured Geomembranes

E4 Practices for Force Verification of Testing Machines

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—Definitions of terms applying to this test method appear in Terminology D4439.

This test method is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved March 1, 2010May 1, 2015. Published April 2010June 2015. Originally approved in 2001. Last previous edition approved in 20042010 as

D6963D6693–04(2010).–04. DOI: 10.1520/D6693-04R10.10.1520/D6693_D6693M-04R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6693/D6693M − 04 (2015)

4. Significance and Use

4.1 This test method is designed to produce tensile property data for the control and specification of nonreinforced polyethylene

and flexible nonreinforced polypropylene geomembranes. These data are also useful for qualitative characterization and for

research and development. It may be necessary to modify this procedure for use in testing certain materials as recommended by

the material specifications. Therefore, it is advisable to refer to that material’s specification before using this test method. Table 1

in Classification D4000 lists the ASTM materials standards that currently exist.

4.2 Tensile properties may vary with specimen preparation, test speed, and environment of testing. Consequently, where precise

comparative results are desired, these factors must be carefully monitored and controlled.

4.2.1 It is realized that a material cannot be tested without also testing the method of preparation of that material. Hence, when

comparative tests of materials are desired, the care must be exercised to ensure that all samples are prepared in exactly the same

way, unless the test is to include the effects of sample preparation. Similarly, for referee purposes or comparisons within any given

series of specimens, care must be taken to secure the maximum degree of uniformity in details of preparation, treatment, and

handling.

NOTE 2—Tensile properties may provide useful data for plastics engineering design purposes. However, because of the high degree of sensitivity

exhibited by many plastics to rate of straining and environmental conditions, data obtained by this test method cannot be considered valid for applications

involving load-time scales or environments widely different from those of this test method. In cases of such dissimilarity, no reliable estimation of the

limit of usefulness can be made for most plastics. This sensitivity to rate of straining and environment necessitates testing over a broad load-time scale

and range of environmental conditions if tensile properties are to suffice for engineering design purposes.

5. Apparatus

5.1 Testing Machine—A testing machine of the constant-rate-of-crosshead-movement type and comprising essentially the

following:

5.1.1 Fixed Member—A fixed or essentially stationary member carrying one grip.

5.1.2 Movable Member—A movable member carrying a second grip.

5.1.3 Grips—Grips for holding the test specimen between the fixed member and the movable member of the test apparatus can

be either a fixed or self-aligning type.

5.1.3.1 Fixed grips are rigidly attached to the fixed and movable members of the test apparatus. Extreme care should be taken

when this type of grip is used to ensure that the test specimen is inserted and clamped so that the long axis of the test specimen

coincides with the direction of pull through the centerline of the grip assembly.

5.1.3.2 Self-aligning grips are attached to the fixed and movable members of the test apparatus. This type of grip assembly is

such that they will move freely into alignment as soon as any load is applied as long as the long axis of the test specimen will

coincide with the direction of the applied pull through the centerline of the grip assembly. The specimens should be aligned as

perfectly as possible with the direction of pull so that no rotary motion will occur in the grips thereby inducing slippage; there is

a limit to the amount of misalignment self-aligning grips will accommodate.

5.1.3.3 The test specimen shall be held in such a way that slippage relative to the grips is prevented as much as possible. Grip

surfaces that are deeply scored or serrated with a pattern similar to those of a coarse single-cut file, serrations about 2.4 mm (0.09

in.)[0.09 in.] apart and about 1.6 mm (0.06 in.)[0.06 in.] deep, have been found satisfactory for most thermoplastics. Finer

serrations have been found to be more satisfactory for harder plastics, such as the thermosetting materials. The serrations should

be kept clean and sharp. Breaking in the grips may occur at times, even when deep serrations or abraded specimen surfaces are

used; other techniques must be used in these cases. Other techniques that have been found useful, particularly with smooth-faced

grips, are abrading that portion of the surface of the specimen that will be in the grips, and interposing thin pieces of abrasive cloth,

abrasive paper, plastic, or rubber-coated fabric, commonly called hospital sheeting, between the specimen and the grip surface. No.

80 double-sided abrasive paper has been found effective in many cases. An open-mesh fabric, in which the threads are coated with

abrasive, has also been effective. Reducing the cross-sectional area of the specimen may also be effective. The use of special types

of grips is sometimes necessary to eliminate slippage and breakage in the grips.

5.1.4 Drive Mechanism—A drive mechanism for imparting to the movable member a uniform, controlled velocity with respect

to the stationary member, with this velocity to be regulated as specified in Section 9.

5.1.5 Load Indicator—A suitable load-indicating mechanism capable of showing the total tensile load carried by the test

specimen when held by the grips. This mechanism shall be essentially free of inertia lag at the specified rate of testing and shall

indicate the load with an accuracy of 61 % of the indicated value, or better. The accuracy of the testing machine shall be verified

in accordance with Practices E4.

NOTE 3—Experience has shown that many testing machines now in use are incapable of maintaining accuracy for as long as the periods between

inspection recommended in Practices E4. Hence, it is recommended that each machine be studied individually and verified as often as may be found

necessary. It frequently will be necessary to perform this function daily.

6. Test Specimens

6.1 Sheet, Plate, and Molded Plastics:

´1

D6693/D6693M − 04 (2015)

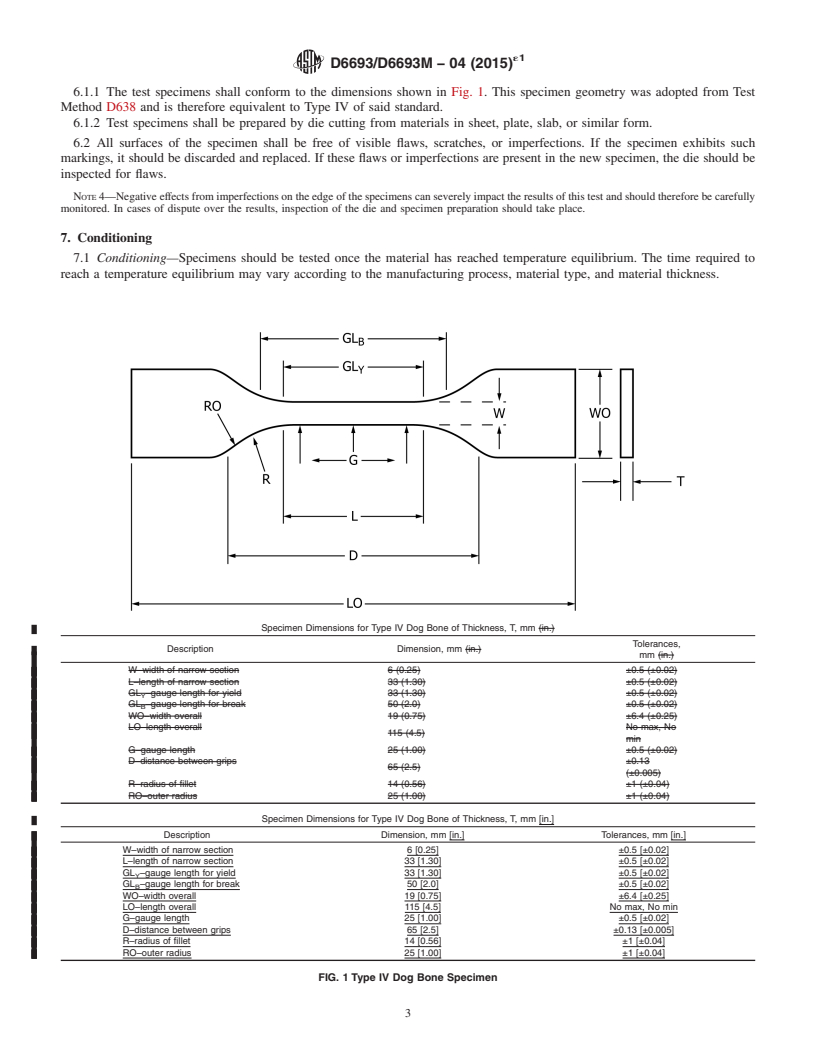

6.1.1 The test specimens shall conform to the dimensions shown in Fig. 1. This specimen geometry was adopted from Test

Method D638 and is therefore equivalent to Type IV of said standard.

6.1.2 Test specimens shall be prepared by die cutting from materials in sheet, plate, slab, or similar form.

6.2 All surfaces of the specimen shall be free of visible flaws, scratches, or imperfections. If the specimen exhibits such

markings, it should be discarded and replaced. If these flaws or imperfections are present in the new specimen, the die should be

inspected for flaws.

NOTE 4—Negative effects from imperfections on the edge of the specimens can severely impact the results of this test and should therefore be carefully

monitored. In cases of dispute over the results, inspection of the die and specimen preparation should take place.

7. Conditioning

7.1 Conditioning—Specimens should be tested once the material has reached temperature equilibrium. The time required to

reach a temperature equilibrium may vary according to the manufacturing process, material type, and material thickness.

Specimen Dimensions for Type IV Dog Bone of Thickness, T, mm (in.)

Tolerances,

Description Dimension, mm (in.)

mm (in.)

W–width of narrow section 6 (0.25) ±0.5 (±0.02)

L–length of narrow section 33 (1.30) ±0.5 (±0.02)

GL –gauge length for yield 33 (1.30) ±0.5 (±0.02)

Y

GL –gauge length for break 50 (2.0) ±0.5 (±0.02)

B

WO–width overall 19 (0.75) ±6.4 (±0.25)

LO–length overall No max, No

115 (4.5)

min

G–gauge length 25 (1.00) ±0.5 (±0.02)

D–distance between grips ±0.13

65 (2.5)

(±0.005)

R–radius of fillet 14 (0.56) ±1 (±0.04)

RO–outer radius 25 (1.00) ±1 (±0.04)

Specimen Dimensions for Type IV Dog Bone of Thickness, T, mm [in.]

Description Dimension, mm [in.] Tolerances, mm [in.]

W–width of narrow section 6 [0.25] ±0.5 [±0.02]

L–length of narrow section 33 [1.30] ±0.5 [±0.02]

GL –gauge length for yield 33 [1.30] ±0.5 [±0.02]

Y

GL –gauge length for break 50 [2.0] ±0.5 [±0.02]

B

WO–width overall 19 [0.75] ±6.4 [±0.25]

LO–length overall 115 [4.5] No max, No min

G–gauge length 25 [1.00] ±0.5 [±0.02]

D–distance between grips 65 [2.5] ±0.13 [±0.005]

R–radius of fillet 14 [0.56] ±1 [±0.04]

RO–outer radius 25 [1.00] ±1 [±0.04]

FIG. 1 Type IV Dog Bone Specimen

´1

D6693/D6693M − 04 (2015)

7.2 Test Conditions—Conduct tests in the Standard Laboratory Atmosphere of 21 6 2°C (69.8[69.8 6 3.6°F)3.6°F] unless

otherwise specified in the test methods.

NOTE 5—A humidity requirement has intentionally been left out of the test conditions due to the fact that polyolefins are not significantly affected by

large fluctuations in humidity thereby making such a restriction unnecessary.

NOTE 6—The tensile properties of some plastics change rapidly with small changes in temperature. Since heat may be generated as a result of straining

the specimen at high rates, conduct tests without forced cooling to ensure uniformity of test conditions. Measure the temperature in the reduced section

of the specimen and record it for materials where self-heating is suspected.

8. Number of Test Specimens

8.1 Test at least five specimens for each sample in the case of isotropic materials.

8.2 Test ten specimens, five normal to and five parallel with the principle axis of anisotropy, for each sample in the case of

anisotropic materials.

8.3 Discard specimens that break at some obvious flaw and prepare new specimens for retest, unless such flaws constitute a

variable to be studied.

9. Speed of Testing

9.1 Speed of testing shall be the relative rate of motion of the grips or test fixtures during the test. The rate of motion of the

driven grip or fixture when the test apparatus is running idle may be used, if it can be shown that the resulting speed of testing

is within the limits of variation allowed.

9.2 The test speed shall be 50 mm/min (2 in./min)[2 in./min] for polyethylene geomembranes and 500 mm/min (20 in./min)[20

in./min] for nonreinforced flexible polypropylene geomembranes.

NOTE 7—Some nonreinforced polyethylene materials approaching but less than a density of 0.940 g/cc exhibit less variation when tested at 2 ipm rather

than 20 ipm. If a test speed other than that indicated in 9.2 is used, this modification should be noted in the report.

10. Procedure

10.1 Measure the width and thickness of rigid flat specimens (Fig.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.