ASTM D3632-98

(Test Method)Standard Test Method for Accelerated Aging of Adhesive Joints by the Oxygen-Pressure Method

Standard Test Method for Accelerated Aging of Adhesive Joints by the Oxygen-Pressure Method

SCOPE

1.1 This test method describes how to estimate the relative resistance to deterioration of adhesive films and adhesive-bonded joints placed in a high-pressure oxygen environment. The instructions include both wood-to-wood and wood-to-metal joints as well as free film of adhesive. The effects of chemicals such as fire retardants, preservatives, or wood extractives, can be evaluated by using materials containing these chemicals for adherends.

1.2 1 This test method is primarily intended for elastomer-based construction adhesives, but is also applicable to other types of adhesives that may be susceptible to oxygen degradation. This accelerated test does not correlate exactly with the natural aging of the adhesive because of the varied conditions of natural aging and the absence of factors such as moisture and stress. The results of this accelerated test are only comparative and must be evaluated against the performance of bonded joints whose natural and accelerated aging characteristics are known.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3632 – 98

Standard Test Method for

Accelerated Aging of Adhesive Joints by the Oxygen-

Pressure Method

This standard is issued under the fixed designation D 3632; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 907 Terminology of Adhesives

D 2339 Test Method for Strength Properties of Adhesives in

1.1 This test method describes how to estimate the relative

Two-Ply Wood Construction in Shear by Tension Loading

resistance to deterioration of adhesive films and adhesive-

bonded joints placed in a high-pressure oxygen environment.

3. Terminology

The instructions include both wood-to-wood and wood-to-

3.1 Definitions—Many definitions in this test method are

metal joints as well as free film of adhesive. The effects of

defined in Terminology D 907.

chemicals such as fire retardants, preservatives, or wood

extractives, can be evaluated by using materials containing

4. Summary of Test Method

these chemicals for adherends.

4.1 This test method entails subjecting specimens with

1.2 This test method is primarily intended for elastomer-

known physical properties to a controlled aging environment

based construction adhesives, but is also applicable to other

for specific time periods, then observing the physical properties

types of adhesives that may be susceptible to oxygen degrada-

again and noting any changes. The controlled environment

tion. This accelerated test does not correlate exactly with the

consists of elevated temperature (70°C) (158°F) and oxygen at

natural aging of the adhesive because of the varied conditions

elevated pressure 2.07 MPa (300 psi).

of natural aging and the absence of factors such as moisture

4.2 Three types of test specimens are offered. The party

and stress. The results of this accelerated test are only

requesting the adhesive evaluation will choose the type of

comparative and must be evaluated against the performance of

specimen to be used.

bonded joints whose natural and accelerated aging character-

Physical Property

istics are known.

Specimen Type Configuration

Tested

1.3 This standard does not purport to address all of the

A wood-to-wood lap shear strength

safety concerns, if any, associated with its use. It is the B wood-to-metal lap shear strength

C unsupported film flexibility

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.3 Three different oxygen-pressure aging exposures are

bility of regulatory limitations prior to use.

offered. Use any exposure with any of the above specimens.

The party requesting the adhesive evaluation will choose the

2. Referenced Documents

exposure to which the specimens are subjected.

2.1 ASTM Standards:

4.3.1 Constant exposure for 500 h with a single test of the

D 143 Methods of Testing Small Clear Specimens of Tim-

physical property at the end of 500 h.

ber

4.3.2 Constant exposure for 1000 h with a single test of the

D 454 Test Method for Rubber Deterioration by Heat and

physical property at the end of 1000 h.

Air Pressure

4.3.3 Constant exposure for up to 1000 h with a series of

D 572 Test Method for Rubber—Deterioration by Heat and

tests of the physical property after 200, 400, 600, 800, and

Oxygen

1000 h.

D 573 Test Method for Rubber—Deterioration in an Air

5. Significance and Use

Oven

5.1 This test method is useful to the adhesive manufacturer

1 in research and development or in manufacturing control. The

This test method is under the jurisdiction of ASTM Committee D-14 on

results are also used for specification acceptance or as a guide

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

Adhesives.

in adhesive selection.

Current edition approved June 10, 1998. Published March 1999. Originally

{1

published as D 3632 – 77. Last previous edition D 3632–77(1990) .

Annual Book of ASTM Standards, Vol 04.10.

3 4

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 15.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3632

5.2 The provisions for testing bonded specimens as well as 6.1.1.4 Use a thermostat to control automatically the tem-

free films are made for two purposes. First, it is possible for an perature of the heating medium.

interaction to occur between oxygen and chemicals or degra-

6.1.1.5 Record the temperature automatically throughout

dation products that may affect the degradation of the bonded

the test period. If the pressure chamber is completely im-

joints strength. Second, some increase in strength due to

mersed, use the temperature of the heating medium as the

oxidative crosslinking may not be detrimental in a bonded

temperature of the pressure chamber. Place the sensing element

assembly and in fact may be beneficial. Adhesives of this

close to the temperature-measuring device but not touching the

behavior are not satisfactorily tested by a film flexibility test.

pressure chamber. If the pressure chamber is not completely

5.3 Some users of this test method will be most interested in

immersed in the heating medium, place the sensing element in

the performance of the bonded joint; some will be most a thermometer well that extends into the pressure chamber. Fill

interested in the performance of the adhesive. In the latter case,

the thermometer well with enough water to cover the element

it is important to note that the true variance (error mean square)

so that heat will transfer easily. If a comparison has been made

of the strength of the adhesive may be obscured when the

and it has been confirmed that the temperature of the oxygen

tested control specimens or the tested aged specimens show

within the chamber is the same as the temperature of the

wood failure.

heating medium, it is permissible to take the temperature in the

5.4 Conflict of Procedure—If the procedures of this test heating medium instead of in the thermometer well. When

method conflict with those of detailed product specifications or using air as the heating medium, check the temperature in

manufacturer’s use instructions for a particular material, then various parts of the oven to determine that the oven is heating

use the latter. evenly. In any case, verify the recorded temperature by

checking with a temperature-indicating device whose sensing

6. Apparatus element is directly exposed to the oxygen within the pressure

chamber.

6.1 Oxygen-Pressure Vessel—The specifications for the

6.1.1.6 Maintain positive, rapid, and complete circulation of

oxygen-pressure vessel described in 6.1.1.1 through 6.1.1.8 are

the heating medium so as to ensure accurate, uniform heating.

the same as those described in Test Method D 572. Adequate

6.1.1.7 The pressure chamber should have a reliable safety

safety provisions are important when heating oxidizable or-

valve or rupture diaphragm set for release at 3.448 MPa (500

ganic materials in oxygen, since the rate of reaction may

psi) pressure.

become very rapid and very high pressures may develop.

Heating these materials is especially dangerous when a large

6.1.1.8 Do not expose any copper or brass parts to the

surface area is exposed. If the same equipment is used for the atmosphere nor use them in the pressure chamber or the tubing

oxygen-pressure test as for the air-pressure heat test (Test

or valves leading to it.

Method D 454), be careful and check to see that the thermo-

6.2 Testing Machine for Lap Shear Strength Tests—The

static controls are set properly because the specimens may

testing machine specifications described in 6.2.1 are the same

react with oxygen very rapidly at the temperature of the

as those described in Test Method D 2339.

air-pressure heat test. Fluids acceptable as heating media for

6.2.1 Use a testing machine capable of maintaining a

one test may be hazardous when used for the other test.

constant rate of loading of 42 to 74 N/s (600 to 1000 lbf/min)

6.1.1 Use an oxygen-pressure chamber consisting of a metal

or a constant rate of crosshead travel of 0.020 mm/s (0.050

vessel designed to retain an internal atmosphere of oxygen gas

in./min) 6 25 %. Use a testing machine with suitable grips and

under pressure, with provisions for placing specimens within it

jaws so that the specimen can be gripped tightly and held in

and for subjecting the entire chamber to controlled uniform

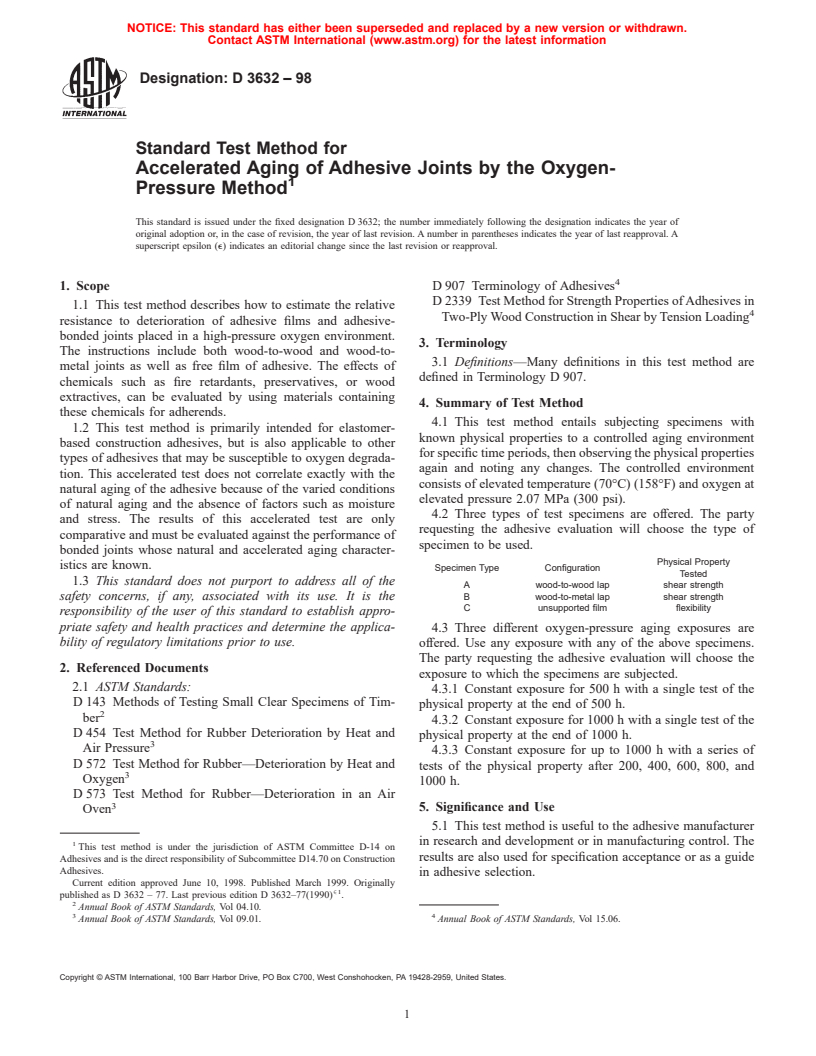

alignment as the load is applied. Fig. 1 shows grips and jaws

temperature. Because of the superior temperature control and

that have been found satisfactory. Place the testing machine in

heat transfer, a metal vessel completely immersed in a liquid

an atmosphere that will not noticeably alter the moisture

medium is recommended for referee tests. Ensure that the

content of the specimens developed under the conditions

apparatus conforms to the following requirements:

prescribed in 10.2.

6.1.1.1 The chamber can be any size; however, it must be

6.3 Air Curing and Drying Oven—Except for some modi-

large enough so that the specimens can be hung within it

fication, the oven specifications described (in 6.3.1 through

vertically, without crowding them, letting them touch each

6.3.9) are the same as those described in Test Method D 573.

other, or letting them touch the sides of the chamber.

6.3.1 Use an oven whose interior size is (minimum) 0.40 m

6.1.1.2 The source of heat is optional, but a location outside

3 3 3

(1 ft ) to (maximum) 1.33 m (36 ft ) or any equivalent

of the aging chamber itself is required.

volume.

6.1.1.3 The heating medium is optional. Water, air, or other

6.3.2 Suspend the specimens vertically without letting them

fluids that will not ignite when oxygen is present may be used.

touch each other or the sides of the oven.

Water has an advantage because it transfers heat rapidly and is

6.3.3 The temperature variation in various parts of the oven

noncombustible. When using air for the heating medium,

shall not be allowed to exceed 2°C (4°F).

thoroughly circulate the heated air by mechanically agitating it,

6.3.4 For the heating medium, use air circulated within the

and use baffles as needed to prevent local overheating and dead

chamber at atmospheric pressure.

spots. Do not use oils or other combustible fluids as heating

media for this test because they are extremely hazardous when 6.3.5 Any source of air may be used, if it is located in the air

oxygen is present. supply outside of the chamber itself.

D 3632

8. Sampling

8.1 Sampling Method—When several test specimen panels

are made or films cast and groups of individual specimens are

aged for different time intervals, mix all the specimens in a box

and draw at random from the box for assignment to a given

group.

8.2 Sample Size—Use at least five test specimens to deter-

mine the original physical properties of each sample. Also use

five or more specimens of the same material for each exposure

period of the test. But for purposes of statistical analyses

described in a later section, the number of specimens in the

control group and in each aged group should be the same. The

user may increase the number of specimens in each group in

response to the size of the property change to be detected, the

degree of confidence desired, and the test result variability.

This subject is further considered in Annex A1.

9. Test Specimens

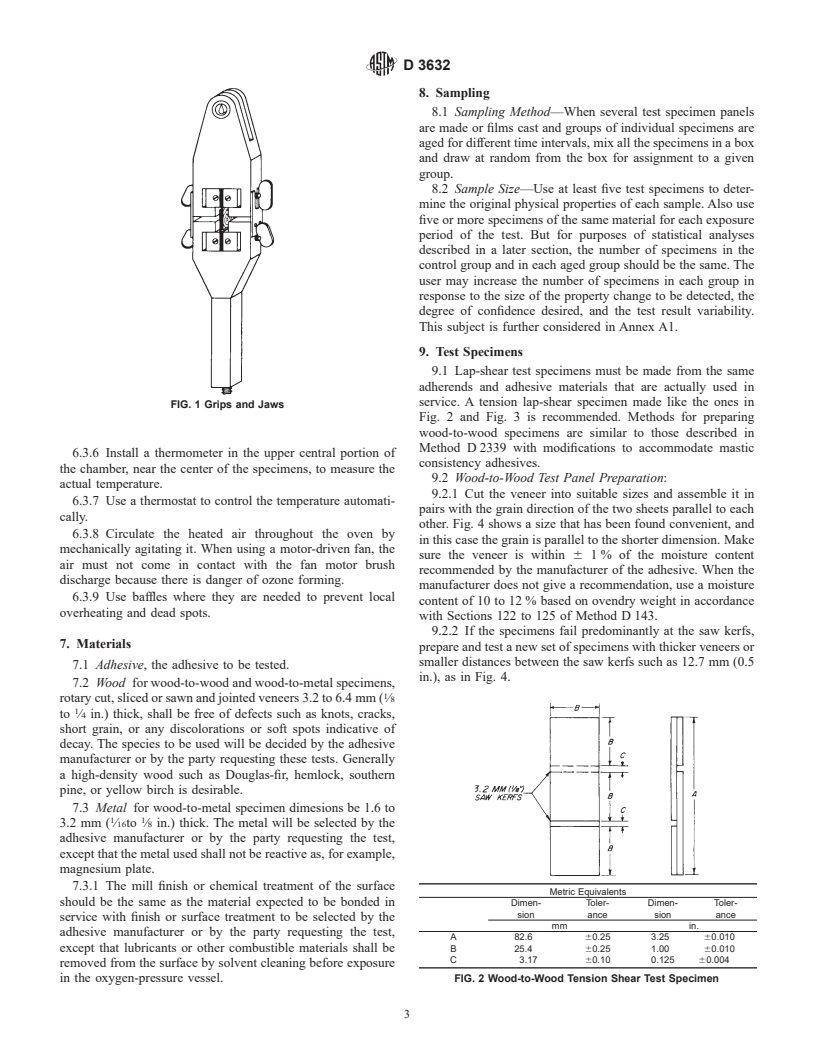

9.1 Lap-shear test specimens must be made from the same

adherends and adhesive materials that are actually used in

service. A tension lap-shear specimen made like the ones in

FIG. 1 Grips and Jaws

Fig. 2 and Fig. 3 is recommended. Methods for preparing

wood-to-wood specimens are similar to those described in

Method D 2339 with modifications to accommodate mastic

6.3.6 Install a thermometer in the upper central portion of

consistency adhesives.

the chamber, near the center of the specimens, to measure the

9.2 Wood-to-Wood Test Panel Preparation:

actual temperature.

9.2.1 Cut the veneer into suitable sizes and assemble it in

6.3.7 Use a thermostat to control the temperature automati-

pairs with the grain direction of the two sheets parallel to each

cally.

other. Fig. 4 shows a size that has been found convenient, and

6.3.8 Circulate the heated air throughout the oven by

in this case the grain is parallel to the shorter dimension. Make

mechanically agitating it. When using a motor-driven fan, the

sure the veneer is within 6 1 % of the moisture content

air must not come in contact with the fan motor brush

recommended by the manufacturer of the adhesive. When the

discharge because there is danger of ozone forming.

manufacturer does not give a recommendation, use a moisture

6.3.9 Use baffles where they are needed to prevent local

content of 10 to 12 % based on ovendry weight in accordance

overheating and dead spots.

with Sections 122 to 125 of Method D 143.

9.2.2 If the specimens fail predominantly at the saw kerfs,

7. Materials

prepare and test a new set of specimens with thicker veneers or

smaller distances between the saw kerfs such as 12.7 mm (0.5

7.1 Adhesive, the adhesive to be tested.

in.), as in Fig. 4.

7.2 Wood for wood-to-wood and wood-to-metal specimens,

rotary cut, sliced or sawn and jointed veneers 3.2 to 6.4 mm ( ⁄8

to ⁄4 in.) thick, shall be free of defects such as knots, cracks,

short grain, or any discolorations or soft spots indicative of

decay. The species to be used will be decided by the adhesive

manufacturer or by the party requesting these tests. Generally

a high-density wood such as Douglas-fir, hemlock, southern

pine, or yellow birch is desirable.

7.3 Metal for wood-to-metal specimen dimesions be 1.6 to

1 1

3.2 mm ( ⁄16to ⁄8 in.) thick. The metal will be selected by the

adhesive manufacturer or by the party requesting the test,

except that the metal used shall not be reactive as, for example,

magnesium plate.

7.3.1 The mill finish or chemical treatment of the surface

Metric Equivalents

should be the same as the material expected to be bonded in Dimen- Toler- Dimen- Toler-

sion ance sion ance

service with finish or surface treatment to be selected by the

mm in.

adhesive manufacturer or by the party requesting the test,

A 82.6 60.25 3.25 60.010

except that lubricants or other combustible materials shall be B 25.4 60.25 1.00 60.010

C 3.17 60.10 0.125 60.004

removed from the surface by solvent cleaning before exposure

in the oxygen-pressure vessel. FIG. 2 Wood-to-Wood Tension Shear Test Specimen

D 3632

(140°F) for 12 h. These recommendations are not intended to

override any

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.