ASTM F2936-12(2018)e1

(Specification)Standard Specification for Chocks, Ship Mooring, Cast Steel

Standard Specification for Chocks, Ship Mooring, Cast Steel

ABSTRACT

This specification covers the principal dimensions and materials of closed chocks for installation on ships used for mooring. It specifies the classification of chocks, their dimension requirements, and strength requirements. It also demonstrates the proper horizontal and vertical loading for Type A and Type B chocks.

SCOPE

1.1 This specification covers the principal dimensions and materials of closed chocks for installation on ships used for mooring.

1.2 Chocks can be used with either wire rope or fiber and synthetic ropes.

1.3 Chocks are for mounting directly on a deck, seat (foundation), or for mounting in a bulwark.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2936 − 12 (Reapproved 2018) An American National Standard

Standard Specification for

Chocks, Ship Mooring, Cast Steel

This standard is issued under the fixed designation F2936; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Keywords section was editorially added in March 2018.

1. Scope 3.1.2 closed chock—a metal flared ring-like fitting mounted

on a ship, through which mooring lines pass to moor a ship.

1.1 This specification covers the principal dimensions and

3.1.3 mooring ring or pipe—a chock mounted in the bul-

materials of closed chocks for installation on ships used for

wark and conforming to Type II and IV.

mooring.

3.1.4 rope contact area—that part of the fitting in contact

1.2 Chocks can be used with either wire rope or fiber and

with the mooring line in normal mooring operations.

synthetic ropes.

1.3 Chocks are for mounting directly on a deck, seat

4. Classification

(foundation), or for mounting in a bulwark.

4.1 The size of the chocks will be identified by the nominal

1.4 The values stated in SI units are to be regarded as

size “L” and “H” of the opening as shown in Table 1 and Table

standard. No other units of measurement are included in this

2.

standard.

4.2 Chocks are furnished in types as follows:

1.5 This international standard was developed in accor-

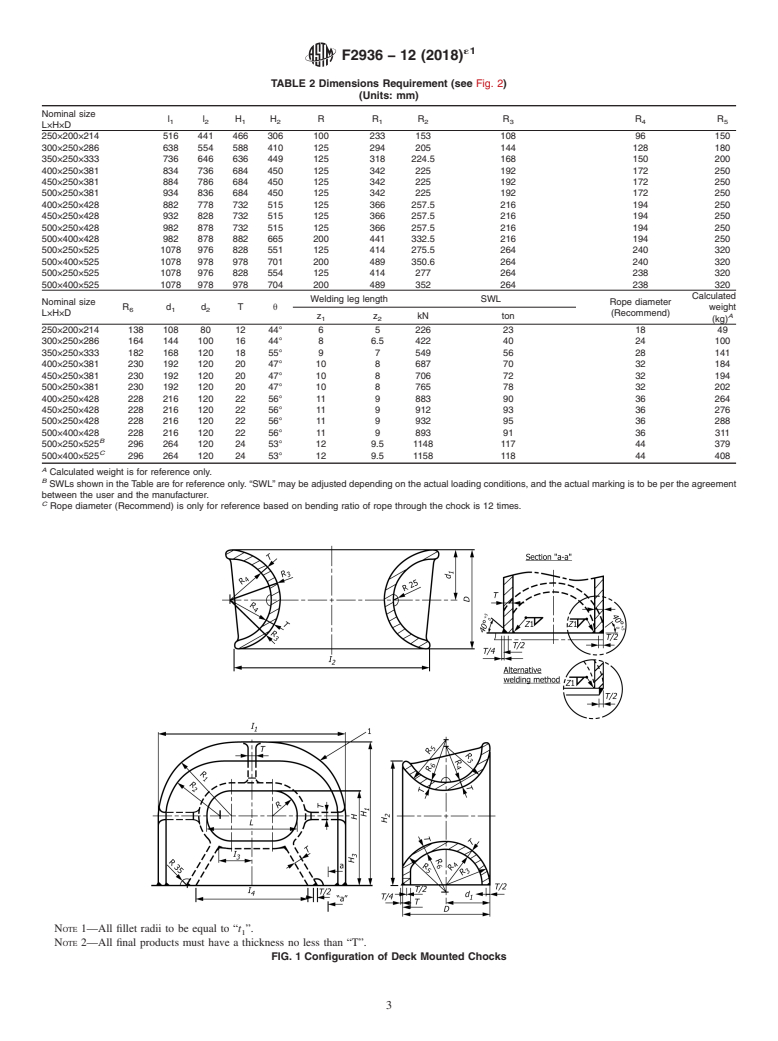

4.2.1 Type I—Deck mounted as shown in Fig. 1 and

dance with internationally recognized principles on standard-

conforming to all dimensions in Table 1.

ization established in the Decision on Principles for the

4.2.2 Type II—Bulwark mounted as shown in Fig. 2 and

Development of International Standards, Guides and Recom-

conforming to all dimensions in Table 2.

mendations issued by the World Trade Organization Technical

4.2.3 Type III—Deck mounted, conforming only to dimen-

Barriers to Trade (TBT) Committee.

sions “L” and “H” of Table 1 and is of adequate strength to at

least meet 7.2 requirement and the requirements of Sections 6

2. Referenced Documents

to 10.

2.1 ASTM Standards:

4.2.4 Type IV—Bulwark mounted, conforming only to di-

A27/A27M Specification for Steel Castings, Carbon, for

mensions “L” and “H” of Table 2 and is of adequate strength

General Application

to at least meet 7.2 requirement and the requirements of

2.2 ANSI Standards:

Sections 6 to 10.

B 46.1 Surface Texture

4.3 Chocks shall be furnished in either of the following

grades:

3. Terminology

4.3.1 Grade 1—Surface finish shall be in the as cast

3.1 Definitions of Terms Specific to This Standard:

condition.

3.1.1 bulwark—a structural enclosure along the edge of the

4.3.2 Grade 2—Surface finish in way of rope contact shall

ship to serve as a rail.

be in accordance with 8.2.

5. Ordering Information

This specification is under the jurisdiction of ASTM Committee F25 on Ships

5.1 Orders for chocks under this specification shall include

and Marine Technology and is the direct responsibility of Subcommittee F25.01 on

Structures. this standard, date, and the following:

Current edition approved March 1, 2018. Published April 2018. Originally

5.1.1 Descriptive information (size, material, etc.) of moor-

approved in 2012. Last previous edition approved in 2012 as F2936 – 12.

ing lines,

DOI:10.1520/F2936-12R18E01.

5.1.2 Quantity (number) of chocks required,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.3 Size (opening, L × H),

Standards volume information, refer to the standard’s Document Summary page on

5.1.4 Type and grade,

the ASTM website.

3 5.1.5 Primer and coating, if any (see 8.3), and

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. 5.1.6 Marking.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2936 − 12 (2018)

TABLE 1 Dimension Requirements (see Fig. 1)

(Units: mm)

Nominal size

l l l l H H H R R R R

1 2 3 4 1 2 3 1 2 3

L×H×D

250×200×214 488 453 76 265 427 368 108 100 219 160 108

300×250×286 614 565 89 330 551 481 144 125 282 212 144

350×250×333 716 660 114 403 601 525 168 125 308 232 168

400×250×381 820 754 139 475 652 553 192 125 335 236 192

450×250×381 870 804 164 524 652 553 192 125 335 236 192

500×250×381 920 854 189 574 652 553 192 125 335 236 192

400×250×428 870 796 139 500 701 609 216 125 360 268 216

450×250×428 920 846 164 550 701 609 216 125 360 268 216

500×250×428 970 896 189 600 701 609 216 125 360 268 216

500×400×428 970 896 176 600 851 759 216 200 435 343 216

A

500×250×525 1068 1000 190 652 798 675 264 125 409 286 264

A

500×400×525 1068 1000 193 652 948 825 264 200 484 361 264

B

500×250×525 1074 1000 176 652 801 680 264 125 412 291 264

B

500×400×525 1074 1000 179 652 951 830 264 200 487 366 264

Welding leg Rope

Nominal size SWL Calculated

R R R d T length diameter

4 5 6 1 C

L×H×D weight (kg)

z kN ton (Recommend)

250×200×214 86 150 128 108 22 6 226 23 18 73

300×250×286 118 180 154 144 26 6.5 422 40 24 142

350×250×333 138 200 170 168 30 7.5 549 56 28 222

400×250×381 156 250 214 192 36 9 687 70 32 310

450×250×381 156 250 214 192 36 9 706 72 32 322

500×250×381 156 250 214 192 36 9 765 78 32 337

400×250×428 178 250 212 216 38 9.5 883 90 36 434

450×250×428 178 250 212 216 38 9.5 912 93 36 452

500×250×428 178 250 212 216 38 9.5 932 95 36 472

500×400×428 178 250 212 216 38 9.5 893 91 36 528

A

500×250×525 224 320 280 264 40 10 1148 117 44 657

A

500×400×525 224 320 280 264 40 10 1158 118 44 724

B

500×250×525 218 320 274 264 46 11.5 1413 144 44 753

B

500×400×525 218 320 274 264 46 11.5 1383 141 44 825

A

SWLs shown in the Table are for reference only. “SWL” may be adjusted depending on the actual loading conditions, and the actual marking is to be per the agreement

between the user and the manufacturer.

B

Rope diameter (Recommend) is only for reference based on bending ratio of rope through the chock is 12 times.

C

Calculated weight is for reference only.

6. Materials and Manufacture loadings were considered individually; both loadings were not

considered simultaneously.

6.1 Material shall be cast steel in accordance with Specifi-

7.1.1 Case 1—Horizontal loading (see Fig. 3).

cation A27/A27M, Grade 60–30.

7.1.2 Case 2—Vertical loading (see Figs. 4-6).

6.2 For Types III and IV the manufacturer shall certify that

7.2 The combined stress is limited to 85 % of the yield

strength of the chock will at least meet 7.2 requirement, and

stress of the material.

that it is suitable for the mooring lines specified in the ordering

information.

8. Workmanship, Finish, and Appearance

6.3 Casting shall be smooth, fine grain, and free of cracks,

8.1 Casting shall be sand, grit, or shot blasted to a gray

hot tears, and blow holes, detrimental to end use. Defects

metal finish to remove all loose scale. All mold flashing shall

having an area larger than 25 by 25 mm and a depth of more

be removed and radii shall be fair so as to present an even

than 10 % of the thickness in way thereof will be cause for

surface.

rejection. Smaller defects in way of rope contact shall be

8.2 The surface of Grade 2 chocks

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F2936 − 12 F2936 − 12 (Reapproved 2018) An American National Standard

Standard Specification for

Chocks, Ship Mooring, Cast Steel

This standard is issued under the fixed designation F2936; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Keywords section was editorially added in March 2018.

1. Scope

1.1 This specification covers the principal dimensions and materials of closed chocks for installation on ships used for mooring.

1.2 Chocks can be used with either wire rope or fiber and synthetic ropes.

1.3 Chocks are for mounting directly on a deck, seat (foundation), or for mounting in a bulwark.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A27/A27M Specification for Steel Castings, Carbon, for General Application

2.2 ANSI Standard:Standards:

B 46.1 Surface Texture

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bulwark—a structural enclosure along the edge of the ship to serve as a rail.

3.1.2 closed chock—a metal flared ring-like fitting mounted on a ship, through which mooring lines pass to moor a ship.

3.1.3 mooring ring or pipe—a chock mounted in the bulwark and conforming to Type II and IV.

3.1.4 rope contact area—that part of the fitting in contact with the mooring line in normal mooring operations.

4. Classification

4.1 The size of the chocks will be identified by the nominal size “L” and “H” of the opening as shown in Table 1 and Table

2.

4.2 Chocks are furnished in types as follows:

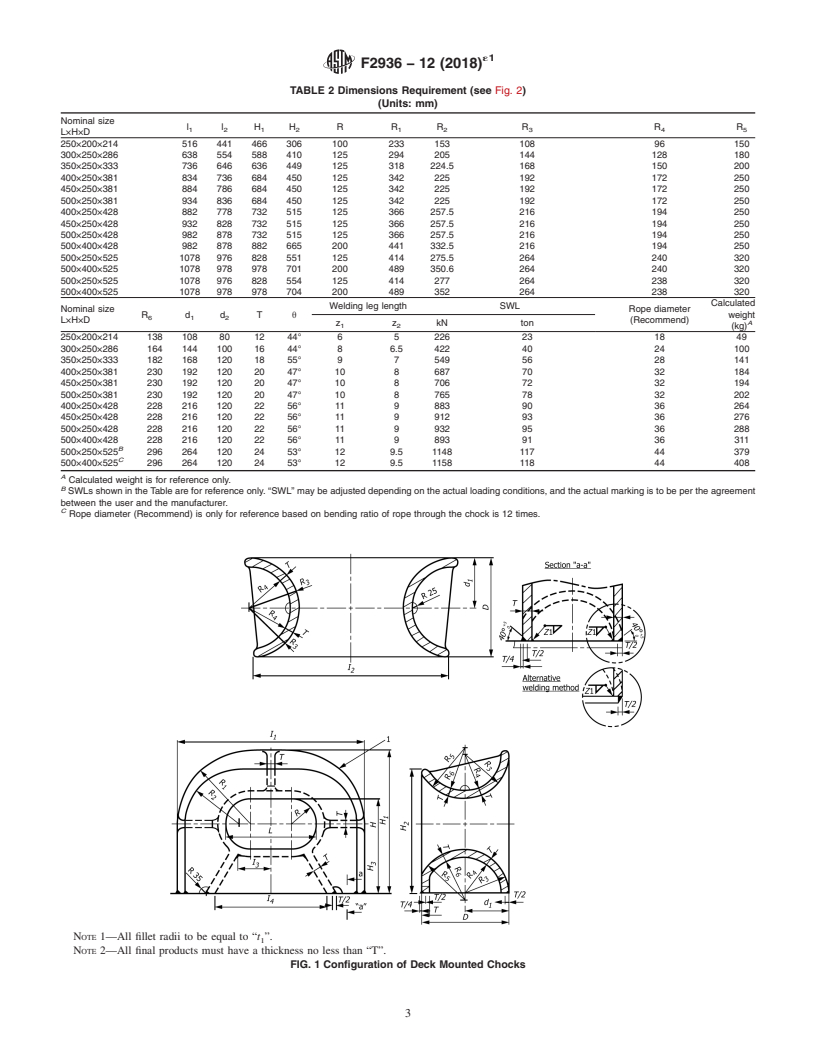

4.2.1 Type I—Deck mounted as shown in Fig. 1 and conforming to all dimensions in Table 1.

4.2.2 Type II—Bulwark mounted as shown in Fig. 2 and conforming to all dimensions in Table 2.

4.2.3 Type III—Deck mounted, conforming only to dimensions “L” and “H” of Table 1 and is of adequate strength to at least

meet 7.2 requirement and the requirements of Sections 6 to 10.

4.2.4 Type IV—Bulwark mounted, conforming only to dimensions “L” and “H” of Table 2 and is of adequate strength to at least

meet 7.2 requirement and the requirements of Sections 6 to 10.

4.3 Chocks shall be furnished in either of the following grades:

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.01 on

Structures.

Current edition approved Jan. 1, 2012March 1, 2018. Published February 2012April 2018. DOI: 10.1520/F2936-12.Originally approved in 2012. Last previous edition

approved in 2012 as F2936 – 12. DOI:10.1520/F2936-12R18E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2936 − 12 (2018)

TABLE 1 Dimension Requirements (see Fig. 1)

(Units: mm)

Nominal size

l l l l H H H R R R R

1 2 3 4 1 2 3 1 2 3

L×H×D

250×200×214 488 453 76 265 427 368 108 100 219 160 108

300×250×286 614 565 89 330 551 481 144 125 282 212 144

350×250×333 716 660 114 403 601 525 168 125 308 232 168

400×250×381 820 754 139 475 652 553 192 125 335 236 192

450×250×381 870 804 164 524 652 553 192 125 335 236 192

500×250×381 920 854 189 574 652 553 192 125 335 236 192

400×250×428 870 796 139 500 701 609 216 125 360 268 216

450×250×428 920 846 164 550 701 609 216 125 360 268 216

500×250×428 970 896 189 600 701 609 216 125 360 268 216

500×400×428 970 896 176 600 851 759 216 200 435 343 216

A

500×250×525 1068 1000 190 652 798 675 264 125 409 286 264

A

500×400×525 1068 1000 193 652 948 825 264 200 484 361 264

B

500×250×525 1074 1000 176 652 801 680 264 125 412 291 264

B

500×400×525 1 074 1 000 179 652 951 830 264 200 487 366 264

B

500×400×525 1074 1000 179 652 951 830 264 200 487 366 264

Welding leg Rope

Nominal size SWL Calculated

R R R d T length diameter

4 5 6 1 C

L×H×D weight (kg)

z kN ton (Recommend)

250×200×214 86 150 128 108 22 6 226 23 18 73

300×250×286 118 180 154 144 26 6.5 422 40 24 142

350×250×333 138 200 170 168 30 7.5 549 56 28 222

400×250×381 156 250 214 192 36 9 687 70 32 310

450×250×381 156 250 214 192 36 9 706 72 32 322

500×250×381 156 250 214 192 36 9 765 78 32 337

400×250×428 178 250 212 216 38 9.5 883 90 36 434

450×250×428 178 250 212 216 38 9.5 912 93 36 452

500×250×428 178 250 212 216 38 9.5 932 95 36 472

500×400×428 178 250 212 216 38 9.5 893 91 36 528

A

500×250×525 224 320 280 264 40 10 1148 117 44 657

A

500×400×525 224 320 280 264 40 10 1158 118 44 724

B

500×250×525 218 320 274 264 46 11.5 1413 144 44 753

B

500×400×525 218 320 274 264 46 11.5 1383 141 44 825

A

SWLs shown in the Table are for reference only. “SWL” may be adjusted depending on the actual loading conditions, and the actual marking is to be per the agreement

between the user and the manufacturer.

B

Rope diameter (Recommend) is only for reference based on bending ratio of rope through the chock is 12 times.

C

Calculated weight is for reference only.

4.3.1 Grade 1—Surface finish shall be in the as cast condition.

4.3.2 Grade 2—Surface finish in way of rope contact shall be in accordance with 8.2.

5. Ordering Information

5.1 Orders for chocks under this specification shall include this standard, date, and the following:

5.1.1 Descriptive information (size, material, etc.) of mooring lines,

5.1.2 Quantity (number) of chocks required,

5.1.3 Size (opening, L × H),

5.1.4 Type and grade,

5.1.5 Primer and coating, if any (see 8.3), and

5.1.6 Marking.

6. Materials and Manufacture

6.1 Material shall be cast steel in accordance with Specification A27/A27M, Grade 60-30.60–30.

6.2 For Types III and IV the manufacturer shall certify that strength of the chock will at least meet 7.2 requirement, and that

it is suitable for the mooring lines specified in the ordering information.

6.3 Casting shall be smooth, fine grain, and free of cracks, hot tears, and blow holes, detrimental to end use. Defects having

an area larger than 25 by 25 mm and a depth of more than 10 % of the thickness in way thereof will be cause for rejection. Smaller

defects in way of rope contact shall be welded and finished smooth. Where applicable, welding shall be in accordance with code

requirements, such as ABS, AWS, and so on, and may require post weld heat treatment (PWHT).

6.4 All excess material, vents, and gates shall be removed and finished smooth to match the surrounding surface.

6.5 Limber or drain holes shall be 25 mm in diameter and provided in webs and brackets to prevent water entrapment.

6.6 Type I shall be in accordance with Fig. 1 and Table 1.

6.7 Type II shall be in accordance with Fig. 2 and Table 2.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.