ASTM D3997/D3997M-16

(Practice)Standard Practice for Preparing Coke Samples for Microscopical Analysis by Reflected Light

Standard Practice for Preparing Coke Samples for Microscopical Analysis by Reflected Light

SIGNIFICANCE AND USE

5.1 Briquettes and blocks of coke prepared in accordance with the laboratory procedures of this practice will have flat, scratch-free surfaces suitable for examination with a microscope using reflected light illumination. The polished surface of the samples prepared using this practice will contain particles representative of the original gross sample. Polished blocks of coke will preserve the porosity and undisturbed distributions of carbon forms required in the production of sequences of stitched and tiled image mosaics. Such images are required for microscopic porosity measurement.

5.2 Samples prepared by this practice are used for microscopical determination of the textural components in coke (see Test Method D5061) and the measurement of coke reflectance.

SCOPE

1.1 This practice covers laboratory procedures for the preparation of granular and lump coke into briquette and block samples for examination with a reflected light microscope. The samples prepared are used for examination and identification of the components in coke and the measurement of the reflectance of coke.

Note 1: Sieve size is identified by its standard designation in Specification E11. The alternative designation given in parentheses is for information only and does not represent a different standard sieve size

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3997/D3997M −16

Standard Practice for

Preparing Coke Samples for Microscopical Analysis by

1

Reflected Light

This standard is issued under the fixed designation D3997/D3997M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions:

1.1 This practice covers laboratory procedures for the

preparation of granular and lump coke into briquette and block 3.1.1 For additional definitions of terms used in this

practice, refer to Terminology D121.

samplesforexaminationwithareflectedlightmicroscope.The

samplespreparedareusedforexaminationandidentificationof 3.1.2 block, n—piece of sectioned lump coke or coke

drillcore embedded in sample binder.

thecomponentsincokeandthemeasurementofthereflectance

of coke.

3.1.3 briquette, n—cylindrical block composed of granu-

lated coal or coke particles compressed and embedded with an

NOTE 1—Sieve size is identified by its standard designation in Speci-

fication E11. The alternative designation given in parentheses is for epoxy binder.

information only and does not represent a different standard sieve size

4. Summary of Practice

1.2 Units—The values stated in either SI units or inch-

4.1 Arepresentativesampleiscrushedtoaspecifiedparticle

pound units are to be regarded separately as standard. The

size, oven-dried or after air-drying, mixed with a binder, and

values stated in each system may not be exact equivalents;

formed into a block specimen referred to as a “briquette.”

therefore,eachsystemshallbeusedindependentlyoftheother.

Combining values from the two systems may result in non-

4.2 Alternatively, a sectioned lump of coke, or coke drill

conformance with the standard.

core, oven-dried or after air-drying, is embedded in a suitable

1.3 This standard does not purport to address all of the binder and formed into a block specimen referred to as a

safety concerns, if any, associated with its use. It is the “block.”

responsibility of the user of this standard to establish appro-

4.3 The briquette or block is then polished to a flat,

priate safety and health practices and determine the applica-

scratch-free surface for microscopical examination under re-

bility of regulatory limitations prior to use.

flected light.

2. Referenced Documents

5. Significance and Use

2

2.1 ASTM Standards: 5.1 Briquettes and blocks of coke prepared in accordance

with the laboratory procedures of this practice will have flat,

D121Terminology of Coal and Coke

D346 Practice for Collection and Preparation of Coke scratch-free surfaces suitable for examination with a micro-

scope using reflected light illumination. The polished surface

Samples for Laboratory Analysis

D5061Test Method for Microscopical Determination of the of the samples prepared using this practice will contain

particles representative of the original gross sample. Polished

Textural Components of Metallurgical Coke

E11Specification forWovenWireTest Sieve Cloth andTest blocks of coke will preserve the porosity and undisturbed

Sieves distributions of carbon forms required in the production of

sequencesofstitchedandtiledimagemosaics.Suchimagesare

required for microscopic porosity measurement.

1

This practice is under the jurisdiction of ASTM Committee D05 on Coal and 5.2 Samples prepared by this practice are used for micro-

Coke and is the direct responsibility of Subcommittee D05.28 on Petrographic

scopical determination of the textural components in coke (see

Analysis of Coal and Coke.

Test Method D5061) and the measurement of coke reflectance.

Current edition approved Oct. 1, 2016. Published October 2016. Originally

approved in 1992. Last previous edition approved in 2009 as D3997–97(2009).

6. Apparatus

DOI: 10.1520/D3997_D3997M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Grinder, Pulverizer, Mill, or Jaw Crusher, or other

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

suitable equipment for final crushing of the sample to pass a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 2.36-mm (No. 8) U.S. Standard Sieve.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

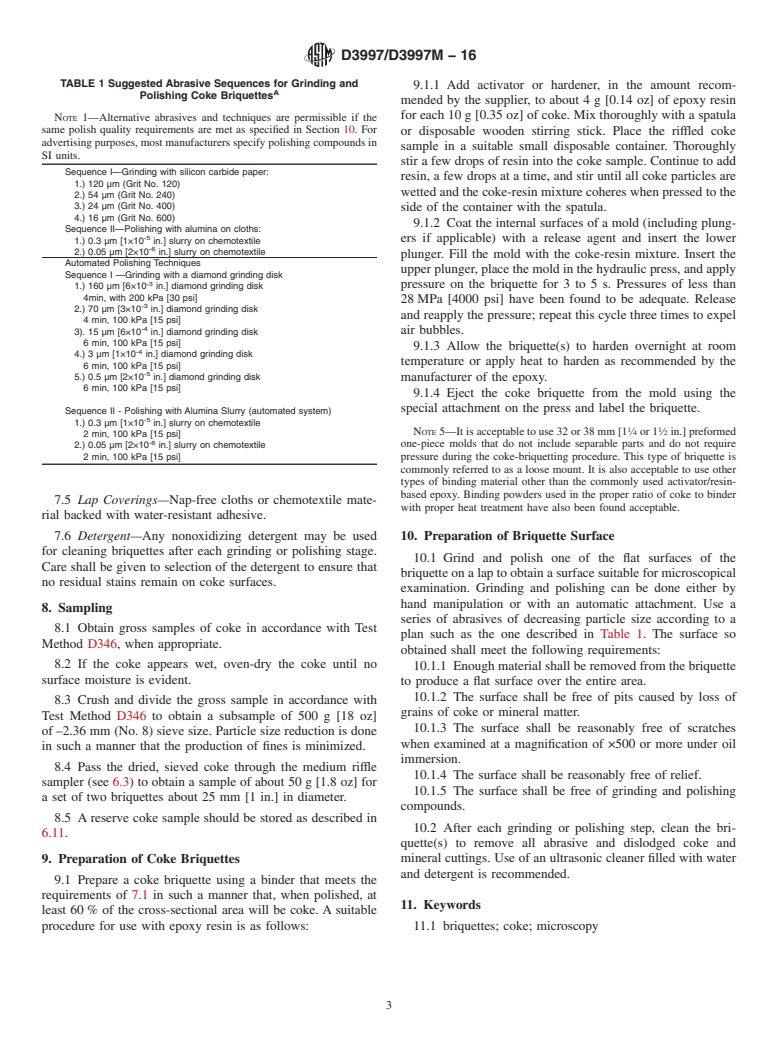

D3997/D3997M−16

6.2 Coarse Riffle Sampler, with at least twelve divisions of 6.8 Hydraulic Press, capable of producing a pressure up to

1

not less than 12.7 mm

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3997/D3997M − 97 (Reapproved 2009) D3997/D3997M − 16

Standard Practice for

Preparing Coke Samples for Microscopical Analysis by

1

Reflected Light

This standard is issued under the fixed designation D3997/D3997M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers laboratory procedures for the preparation of granular samples of coke and lump coke into briquette and

block samples for examination with a reflected light microscope. The samples prepared are used for identifyingexamination and

quantifying identification of the textural components in coke. This practice does not apply to the preparation components in coke

and the measurement of the reflectance of coke.

NOTE 1—Sieve size is identified by its standard designation in Specification E11. The alternative designation given in parentheses is for information

only and does not represent a different standard sieve sizeof oriented lump specimens of coke for structural analysis.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D121 Terminology of Coal and Coke

D346 Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

D5061 Test Method for Microscopical Determination of the Textural Components of Metallurgical Coke

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Terminology

3.1 Definitions:

3.1.1 For additional definitions of terms used in this practice, refer to Terminology D121.

3.1.2 block, n—piece of sectioned lump coke or coke drillcore embedded in sample binder.

3.1.3 briquette, n—a cylindrical block composed of granulated coal or coke particles compressed and embedded with an epoxy

binder.

4. Summary of Practice

4.1 A representative sample is crushed to a specified particle size, oven-dried, oven-dried or after air-drying, mixed with a

binder, and formed into a block specimen referred to as a briquette. The briquette is then polished to a flat, scratch-free surface

for microscopical examination under reflected light.“briquette.”

4.2 Alternatively, a sectioned lump of coke, or coke drill core, oven-dried or after air-drying, is embedded in a suitable binder

and formed into a block specimen referred to as a “block.”

4.3 The briquette or block is then polished to a flat, scratch-free surface for microscopical examination under reflected light.

1

This practice is under the jurisdiction of ASTM Committee D05 on Coal and Coke and is the direct responsibility of Subcommittee D05.28 on Petrographic Analysis

of Coal and Coke.

Current edition approved Sept. 1, 2009Oct. 1, 2016. Published March 2010October 2016. Originally approved in 1992. Last previous edition approved in 20042009 as

D3997 – 97(2004).(2009). DOI: 10.1520/D3997_D3997M-97R09.10.1520/D3997_D3997M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3997/D3997M − 16

5. Significance and Use

5.1 Briquettes and blocks of granular coke prepared in accordance with the laboratory procedures of this practice will have flat,

scratch-free surfaces suitable for examination with a microscope using reflected light illumination. The polished surface of

briquettes the samples prepared using this practice will contain particles representative of the original gross sample. Polished

blocks of coke will preserve the porosity and undisturbed distributions of carbon forms required in the production of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.