ASTM E422-99

(Test Method)Standard Test Method for Measuring Heat Flux Using a Water-Cooled Calorimeter

Standard Test Method for Measuring Heat Flux Using a Water-Cooled Calorimeter

SCOPE

1.1 This test method covers the measurement of a steady heat flux to a given water-cooled surface by means of a system energy balance.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E422–99

Standard Test Method for

Measuring Heat Flux Using a Water-Cooled Calorimeter

This standard is issued under the fixed designation E422; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope state of the boundary layer are outside the scope of this test

method. It should be noted that recombination effects at low

1.1 This test method covers the measurement of a steady

pressurescancauseseriousdiscrepanciesinheatfluxmeasure-

heat flux to a given water-cooled surface by means of a system

ments (such as discussed in Ref (1)) depending upon the

energy balance.

surface material on the calorimeter.

1.2 This standard does not purport to address all of the

3.3 For the particular control volume cited, the energy

safety concerns, if any, associated with its use. It is the

balance can be written as follows:

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

E 5 @mC ~DT 2DT !#/A (1)

CAL p 0 1

bility of regulatory limitations prior to use.

where:

−2

2. Referenced Documents E 5 energy flux transferred to calorimeter face, W·m

CAL

−1

m 5 mass flow rate of coolant water, kg·s

2.1 ASTM Standards:

−1 −1

C 5 water specific heat, J·kg ·K ,

p

E235 Specification for Thermocouples, Sheathed, Type K,

DT 5 T — T calorimeter water bulk temperature rise

2 0 0 0

2 1

for Nuclear or for Other High-Reliability Applications

during operation, K,

DT 5 T — T 5calorimeter water apparent bulk tem-

1 2 1

3. Summary of Test Method

perature rise before operation, K,

3.1 A measure of the heat flux to a given water-cooled

T 5 water exhaust bulk temperature during operation,

surface is based upon the following measurements: (1)the

K,

water mass flow rate and (2)the temperature rise of coolant

T 5 water inlet bulk temperature during operation, K,

water. The heat flux is determined numerically by multiplying

T 5 water exhaust bulk temperature before operation,

the water coolant flow rate by the specific heat and rise in

K,

temperature of the water and dividing this value by the surface

T 5 water inlet bulk temperature before operation, K,

area across which heat has been transferred.

and

3.2 The apparatus for measuring heat flux by the energy-

A 5 sensing surface area of calorimeter, m .

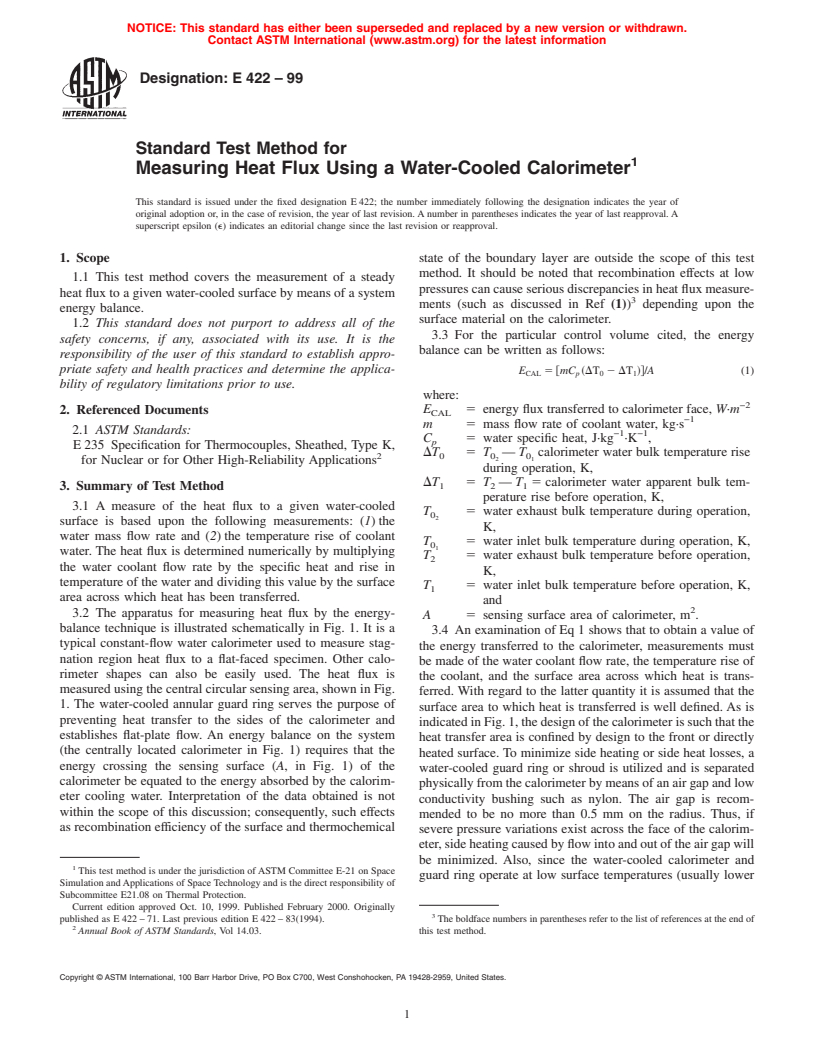

balance technique is illustrated schematically in Fig. 1. It is a

3.4 An examination of Eq 1 shows that to obtain a value of

typical constant-flow water calorimeter used to measure stag-

the energy transferred to the calorimeter, measurements must

nation region heat flux to a flat-faced specimen. Other calo-

be made of the water coolant flow rate, the temperature rise of

rimeter shapes can also be easily used. The heat flux is

the coolant, and the surface area across which heat is trans-

measured using the central circular sensing area, shown in Fig.

ferred. With regard to the latter quantity it is assumed that the

1. The water-cooled annular guard ring serves the purpose of

surface area to which heat is transferred is well defined. As is

preventing heat transfer to the sides of the calorimeter and

indicatedinFig.1,thedesignofthecalorimeterissuchthatthe

establishes flat-plate flow. An energy balance on the system

heat transfer area is confined by design to the front or directly

(the centrally located calorimeter in Fig. 1) requires that the

heated surface. To minimize side heating or side heat losses, a

energy crossing the sensing surface (A, in Fig. 1) of the

water-cooled guard ring or shroud is utilized and is separated

calorimeter be equated to the energy absorbed by the calorim-

physicallyfromthecalorimeterbymeansofanairgapandlow

eter cooling water. Interpretation of the data obtained is not

conductivity bushing such as nylon. The air gap is recom-

within the scope of this discussion; consequently, such effects

mended to be no more than 0.5 mm on the radius. Thus, if

as recombination efficiency of the surface and thermochemical

severe pressure variations exist across the face of the calorim-

eter,sideheatingcausedbyflowintoandoutoftheairgapwill

be minimized. Also, since the water-cooled calorimeter and

This test method is under the jurisdiction ofASTM Committee E-21 on Space

guard ring operate at low surface temperatures (usually lower

Simulation andApplications of SpaceTechnology and is the direct responsibility of

Subcommittee E21.08 on Thermal Protection.

Current edition approved Oct. 10, 1999. Published February 2000. Originally

published as E422–71. Last previous edition E422–83(1994). Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

Annual Book of ASTM Standards, Vol 14.03. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E422

FIG. 1 Steady-State Water-Cooled Calorimeter.

than 100°C) heat losses across the gap by radiant interchange water-cooled calorimeters be used (rather than one large unit).

are negligible and consequently no special calorimeter surface These shall be located across the heated surface such that a

gap finishes are necessary. Depending upon the size of the heat-flux distribution can be described. With this, a more

calorimeter surface, large variations in heat flux may exist detailed heat-flux measurement can be applied to the specimen

across the face of the calorimeter. Consequently, the measured test and more information can be deduced from the test.

heat flux represents an average heat flux over the surface area

5. Apparatus

of the water-cooled calorimeter. The water-cooled calorimeter

can be used to measure heat-flux levels over a range from 10

5.1 General—The apparatus shall consist of a water-cooled

2 2

kW/m to 60 MW/m .

calorimeter and the necessary instrumentation to measure the

heat transferred to the calorimeter.Although the recommended

4. Significance and Use

instrumentation accuracies are state-of-the-art values, more

4.1 The purpose of this test method is to measure the heat rugged and higher accuracy instrumentation may be required

fluxtoawater-cooledsurfaceforpurposesofcalibrationofthe for high pressure and high heat-flux applications.Anumber of

thermal environment into which test specimens are placed for materials can be used to fabricate the calorimeter, but OFHC

evaluation. If the calorimeter and holder size, shape, and (oxygen free high conductivity) copper is often preferred

surface finish are identical to that of the test specimen, the because of its superior thermal properties.

measured heat flux to the calorimeter is presumed to be the 5.2 Coolant Flow Measurement—The water flow rate to

sameasthattothesample’sheatedsurface.Themeasuredheat each component of the calorimeter shall be chosen to cool the

flux is one of the important parameters for correlating the apparatus adequately and to ensure accurately measurable rise

behavior of materials. inwatertemperature.Theerrorinwaterflowratemeasurement

4.2 The water-cooled calorimeter is one of several calorim- shall be not more than 62%. Suitable equipment that can be

eterconceptsusedtomeasureheatflux.Theprimedrawbackis used is listed in Ref (2) and includes turbine flowmeters,

its long response time, that is, the time required to achieve variableareaflowmeters,etc.Caremustbeexercisedintheuse

steady-stateoperation.Tocalculateenergyaddedtothecoolant of all these devices. In particular, it is recommended that

water, accurate measurements of the rise in coolant tempera- appropriate filters be placed in all water inlet lines to prevent

ture are needed, all energy losses should be minimized, and particles or unnecessary deposits from being carried to the

steady-state conditions must exist both in the thermal environ- water-coolingpassages,pipe,andmeterwalls.Waterflowrates

ment and fluid flow of the calorimeter. and pressure shall be adjusted to ensure that no bubbles are

4.3 Regardless of the source of energy input to the water- formed (no boiling). If practical, the water flowmeters shall be

cooled calorimeter surface (radiative

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.