ASTM D5034-08

(Test Method)Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

SIGNIFICANCE AND USE

The grab test procedure in this test method for the determination of breaking force and elongation is considered satisfactory for acceptance testing of commercial shipments of most woven or nonwoven textile fabrics, and the modified grab test procedure is considered satisfactory for acceptance testing of commercial shipments of most woven textile fabrics, since the procedures have been used extensively in the trade for acceptance testing.

In case of disagreement arising from differences in reported test values when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens which are as homogeneous as possible and which are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student's t-test for unpaired data and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected, or the purchaser and the supplier must agree to interpret future test results in light of the known bias.

This test method is not recommended for knitted fabrics because of their high stretch.

Some modification of technique may be necessary for any fabric having a strength in excess of 200-N/cm (1140-lb/in.) width. Special precautionary measures are provided for use when necessary for strong fabrics.

All of the procedures are applicable for testing fabrics either conditioned or wet.

Comparison of results from tensile testing machines operating on different principles is not recommended. When different types of machines are used for comparison testi...

SCOPE

1.1 This test method covers the grab and modified grab test procedures for determining the breaking strength and elongation of most textile fabrics. Provisions are made for wet testing.

1.1.1 The grab test procedure is applicable to woven, nonwoven, and felted fabrics, while the modified grab test procedure is used primarily for woven fabrics.

1.2 This test method is not recommended for glass fabrics, or for knitted fabrics and other textile fabrics which have high stretch (more than 11 %).

Note 1—For the determination of the breaking force and elongation of textile fabrics using the raveled strip test procedure and the cut strip test procedure, refer to Test Method D 5035.

1.3 This test method provides the values in both inch-pound units and SI units. Inch-pound units is the technically correct name for the customary units used in the United States. SI units is the technically correct name for the system of metric units known as the International System of Units. The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining in any way.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5034 – 08

Standard Test Method for

Breaking Strength and Elongation of Textile Fabrics (Grab

1

Test)

This standard is issued under the fixed designation D 5034; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D 123 Terminology Relating to Textiles

3

D 629 Test Methods for Quantitative Analysis of Textiles

1.1 This test method covers the grab and modified grab test

D 1059 Test Method for Yarn Number Based on Short-

procedures for determining the breaking strength and elonga-

Length Specimens

tionofmosttextilefabrics.Provisionsaremadeforwettesting.

D 1776 Practice for Conditioning and Testing Textiles

1.1.1 The grab test procedure is applicable to woven,

D 5035 Test Method for Breaking Force and Elongation of

nonwoven, and felted fabrics, while the modified grab test

Textile Fabrics (Strip Method)

procedure is used primarily for woven fabrics.

D 4850 Terminology Relating to Fabric

1.2 This test method is not recommended for glass fabrics,

or for knitted fabrics and other textile fabrics which have high

3. Terminology

stretch (more than 11 %).

3.1 For all terminology relating to D13.60, Fabric Test

NOTE 1—For the determination of the breaking force and elongation of

Methods, Specific, refer to Terminology D 4850.

textile fabrics using the raveled strip test procedure and the cut strip test

3.1.1 The following terms are relevant to this standard:

procedure, refer to Test Method D 5035.

breaking force, braking load, constant-rate-of-extension (CRE)

1.3 This test method provides the values in both inch-pound

tensile testing machine, constant-rate-of-traverse (CRT) tensile

units and SI units. Inch-pound units is the technically correct

testing machine, elongation, extension, grab test modified grab

nameforthecustomaryunitsusedintheUnitedStates.SIunits

test, tensile test.

is the technically correct name for the system of metric units

3.2 For all other terminology related to textiles, refer to

known as the International System of Units. The values stated

Terminology D 123.

in either acceptable metric units or in other units shall be

4. Summary of Test Method

regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system

4.1 A100-mm (4.0-in.) wide specimen is mounted centrally

must be used independently of the other, without combining in

in clamps of a tensile testing machine and a force applied until

any way.

the specimen breaks. Values for the breaking force and the

1.4 This standard does not purport to address all of the

elongation of the test specimen are obtained from machine

safety concerns, if any, associated with its use. It is the

scales, dials, autographic recording charts, or a computer

responsibility of the user of this standard to establish appro-

interfaced with the testing machine.

priate safety and health practices and determine the applica-

4.2 This test method describes procedures for carrying out

bility of regulatory limitations prior to use.

fabric grab tensile tests using two types of specimens and three

alternative types of testing machines. For reporting, use the

2. Referenced Documents

following identification system of specific specimen and ma-

2

2.1 ASTM Standards:

chine combinations.

D76 SpecificationforTensileTestingMachinesforTextiles

4.2.1 Type of specimen:

4.2.1.1 G—Grab

4.2.1.2 MG—Modified grab

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

4.2.2 Type of tensile testing machine:

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

Specific.

4.2.2.1 E—Constant-rate-of-extension (CRE)

Current edition approved June 1, 2008. Published July 2008. Replaces Grab

4.2.2.2 L—Constant-rate-of-load (CRL)

Testing sections of Test Method D 1682 – 90. Originally approved in 1990. Last

4.2.2.3 T—Constant-rate-of -traverse (CRT)

previous edition approved in 2001 as D 5034–95(2001).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5034–08

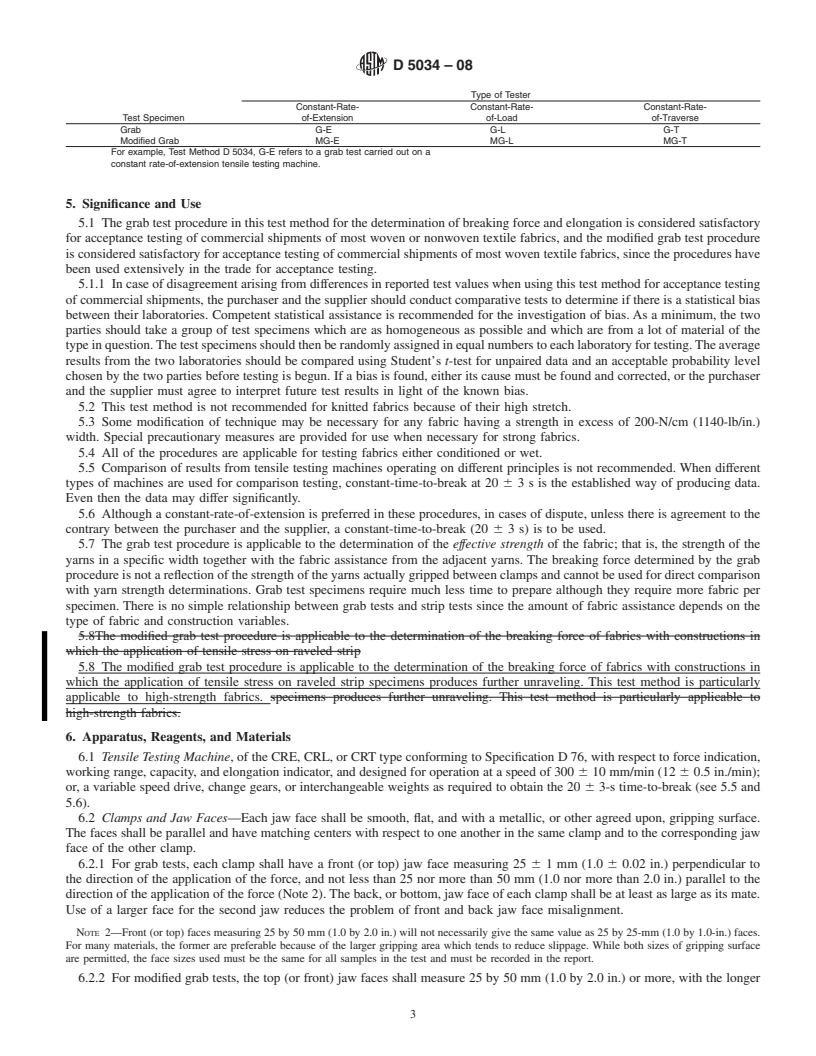

4.2.3 Possible combinations can be identified as follows: Grabtestspecimensrequiremuchlesstimetopreparealthough

they require more fabric per specimen. There is no simple

Type of Tester

Constant-Rate- Constant-Rate- Constant-Rate-

relationship between grab

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5034–95 (Reapproved 2001) Designation: D 5034 – 08

Standard Test Method for

Breaking Strength and Elongation of Textile Fabrics (Grab

1

Test)

This standard is issued under the fixed designation D 5034; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the grab and modified grab test procedures for determining the breaking strength and elongation

of most textile fabrics. Provisions are made for wet testing.

1.1.1 The grab test procedure is applicable to woven, nonwoven, and felted fabrics, while the modified grab test procedure is

used primarily for woven fabrics.

1.2 Thistestmethodisnotrecommendedforglassfabrics,orforknittedfabricsandothertextilefabricswhichhavehighstretch

(more than 11 %).

NOTE 1—For the determination of the breaking force and elongation of textile fabrics using the raveled strip test procedure and the cut strip test

procedure, refer to Test Method D 5035.

1.3 This test method provides the values in both inch-pound units and SI units. Inch-pound units is the technically correct name

for the customary units used in the United States. SI units is the technically correct name for the system of metric units known

astheInternationalSystemofUnits.Thevaluesstatedineitheracceptablemetricunitsorinotherunitsshallberegardedseparately

as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently

of the other, without combining in any way.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 76 Specification for Tensile Testing Machines for Textiles

D 123 Terminology Relating to Textiles

D 629 Test Methods for Quantitative Analysis of Textiles

D 1059 Test Method for Yarn Number Based on Short-Length Specimens

2

D 1776Practice for Conditioning Textiles for Testing Practice for Conditioning and Testing Textiles

D 5035Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Force) Test Method for Breaking Force and

Elongation of Textile Fabrics (Strip Method)

D 4850 Terminology Relating to Fabric

3. Terminology

3.1Definitions:

3.1.1breaking force, n—themaximumforceappliedtoamaterialcarriedtorupture.(Compare breaking point, breaking strength.

Syn. force-at-break.)

3.1.1.1Discussion—Materials that are brittle usually rupture at the maximum force. Materials that are ductile usually experience

a maximum force before rupturing.

3.1.2breaking load, n—deprecated term. Use breaking force.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextilesandisthedirectresponsibilityofSubcommitteeD13.60onFabricTestMethods,Specific.

Current edition approved Sept. 10, 2001. Published May 2002. Originally approved in 1990. Last previous edition approved in 1995 as D5034–95. Replaces Grab Testing

sections of Test Method D1682–90.

Current edition approved June 1, 2008. Published July 2008. Replaces Grab Testing sections of Test Method D 1682 – 90. Originally approved in 1990. Last previous

edition approved in 2001 as D 5034–95(2001).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 07.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5034–08

3.1.3constant-rate-of-extension (CRE) tensile testing machine—a testing machine in which the rate of increase of specimen

length is uniform with time.

3.1.4constant-rate-of-load (CRL) tensile testing machine—a testing machine in which the rate of increase of the load being

applied to the specimen is uniform with time after the first 3 s.

3.1.5constant-rate-of-traverse (CRT) tensile testing machine—a testing machine in which the pulling clamp moves at a uniform

rate and the load is applied through the ot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.