ASTM D3512-05(2007)e1

(Test Method)Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Random Tumble Pilling Tester

Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Random Tumble Pilling Tester

SCOPE

1.1 This test method covers the resistance to the formation of pills and other related surface changes on textile fabrics using the random tumble pilling tester. The procedure is generally applicable to all types of woven and knitted apparel fabrics.

Note 1 - For other test methods for the pilling resistance of textiles, refer to Test Methods D 3511, D 3514, and D 4970.

1.2 Some fabrics that have been treated with a silicone resin may not be satisfactorily tested by this procedure because the silicone resin may transfer onto the cork liners in the test chamber and cause erroneous results.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are to be regarded as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D3512–05 (Reapproved 2007)

Standard Test Method for

Pilling Resistance and Other Related Surface Changes of

Textile Fabrics: Random Tumble Pilling Tester

This standard is issued under the fixed designation D 3512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made in August 2007

1. Scope lated Surface Changes of Textile Fabrics: Brush Pilling

Tester

1.1 This test method covers the resistance to the formation

D 3514 Test Method for Pilling Resistance and Other Re-

of pills and other related surface changes on textile fabrics

lated Surface Changes of Textile Fabrics: Elastomeric Pad

using the random tumble pilling tester. The procedure is

D 4970 Test Method for Pilling Resistance and Other Re-

generally applicable to all types of woven and knitted apparel

lated Surface Changes of Textile Fabrics: Martindale

fabrics.

Tester

NOTE 1—For other test methods for the pilling resistance of textiles,

E 104 Practice for Maintaining Constant Relative Humidity

refer to Test Methods D 3511, D 3514, and D 4970.

by Means of Aqueous Solutions

1.2 Some fabrics that have been treated with a silicone resin

2.2 ASTM Adjuncts:

may not be satisfactorily tested by this procedure because the

12-435120-00 Set of 5 Photographic Standards for Random

silicone resin may transfer onto the cork liners in the test

Tumble Pilling Test

chamber and cause erroneous results.

3. Terminology

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as the standard. Within the text,

3.1 Definitions:

the inch-pound units are to be regarded as the standard. Within

3.1.1 fuzz, n—untangled fiber ends that protrude from the

the text, the inch-pound units are shown in parentheses. The

surface of a yarn or fabric.

values stated in each system are not exact equivalents; there-

3.1.2 pilling resistance, n—resistance to the formation of

fore, each system shall be used independently of the other.

pills on the surface of a textile fabric.

Combining values from the two systems may result in noncon-

3.1.3 pills, n—bunches or balls of tangled fibers which are

formance with the specification.

held to the surface of a fabric by one or more fibers.

1.4 This standard does not purport to address all of the

3.1.4 For definitions of other textile terms used in this test

safety concerns, if any, associated with its use. It is the

method, refer to Terminology D 123.

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4.1 Pilling and other changes in surface appearance, such as

fuzzing, that occur in normal wear are simulated on a labora-

2. Referenced Documents

tory testing machine. Pills are caused to form on fabric by a

2.1 ASTM Standards:

random rubbing action produced by tumbling specimens in a

D 123 Terminology Relating to Textiles

cylindrical test chamber lined with a mildly abrasive material.

D 1776 Practice for Conditioning and Testing Textiles

Toformpillswithappearanceandstructurethatresemblethose

D 3511 Test Method for Pilling Resistance and Other Re-

produced in actual wear, small amounts of short-length gray

cotton fiber are added to each test chamber with the specimens.

The degree of fabric pilling is evaluated by comparison of the

tested specimens with visual standards that may be actual

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

fabrics, or photographs of fabrics, showing a range of pilling

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

resistance. The observed resistance to pilling is reported using

Specific.

Current edition approved July 1, 2007. Published August 2007. Originally

an arbitrary rating scale.

approved in 1976. Last previous edition approved in 2005 as D 3512 – 05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD3512.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D3512–05 (2007)

5. Significance and Use pilling resistance.The observed resistance to pilling is reported

on an arbitrary scale ranging from 5 (no pilling) to 1 (very

5.1 Acceptance Testing—This method of testing fabrics for

severe pilling).

resistancetopillingisnotrecommendedforacceptancetesting.

5.5 This test method is applicable to a wide variety of

If it is used for acceptance testing, it should be used with

woven and knitted fabrics that vary in pilling propensity as a

caution because the between-laboratory precision is poor. In

result of variations in fiber, yarn and fabric structure, and

some cases the purchaser and the supplier may have to test a

finish.

commercial shipment of one or more specific materials by the

best available test method, even though the test method is not

6. Apparatus and Materials

recommended for acceptance testing.

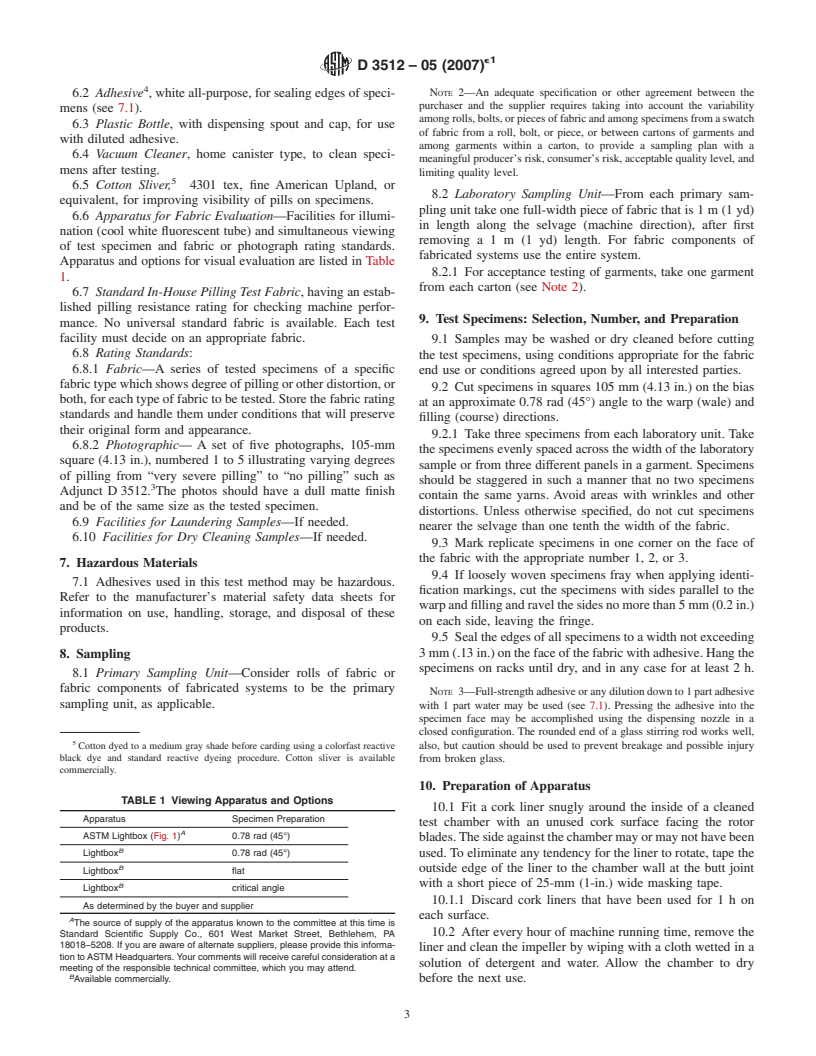

6.1 Random Tumble Pilling Tester (Fig. 1):

5.1.1 If there are differences or practical significance be-

6.1.1 Cork Cylinder Liners, about 146 mm (5.75 in.) wide

tween reported test results for two laboratories (or more),

by 452 mm (17.81 in) long cut from 1.5-mm (.063-in.) thick

comparative tests should be performed to determine if there is

flat sheets of Type P2117A material conforming to Classifica-

a statistical bias between them, using competent statistical

tion System F104, Appendix X2. The original surface of the

assistance.As a minimum, the test samples should be used that

liner, produced by slicing the material, should be used without

are as homogeneous as possible, drawn from the material from

any further treatment such as sanding. Store liners in original

which the disparate test results were obtained, and randomly

packaging in a cool, dry place.

assigned in equal numbers to each laboratory for testing. Other

6.1.2 Air Injection Device to give 14-21 kPa (2-3 psi) air

materials with established test values may be used for this

pressure in each test chamber, either included in new testers or

purpose. The test results from the two laboratories should be

a modification to older testers.

compared using a statistical test for unpaired data, at a

probability level chosen prior to the testing series. If a bias is

found, either its cause must be found and corrected, or future

test results must be adjusted in consideration of the known

Apparatus and accessories are commercially available.

bias.

5.2 The pilling of textile fabrics is a very complex property

because it is affected by many factors which may include type

of fiber or blends, fiber dimensions, yarn and fabric construc-

tion, fabric finishing treatments and refurbishing method.

Testing before refurbishing may be adviseable. The pilling

resistance of a specific fabric in actual wear varies more with

general conditions of use and individual wearers than in

replicate fabric specimens subjected to controlled laboratory

tests. This experience should be borne in mind when adopting

levels of acceptability for any series of standards.

5.3 Pills vary appreciably in size and appearance and

depend on the presence of lint and degree of color contrast.

These factors are not evaluated when pilling is rated solely on

the number of pills. The development of pills may be accom-

panied by other surface phenomena such as loss of cover, color

change, or the development of fuzz. Since the overall accept-

ability of a specific fabric is dependent on both the character-

istics of the pills and the other factors affecting surface

appearance, it is suggested that fabrics tested in the laboratory

be evaluated subjectively with regard to their acceptability and

not rated solely on the number of pills developed. A series of

standards, based on graduated degrees of surface change of the

fabric type being tested, may be set up to provide a basis for

subjective ratings. The visual standards are most advantageous

when the laboratory test specimens correlate closely in appear-

ance with worn fabrics and show a similar ratio of pills to fuzz.

Counting the pills and weighing their number with respect to

their size and contrast, as a combined measure of pilling

resistance, is not recommended because of the excessive time

required for counting, sizing, and calculating.

5.4 The degree of fabric pilling is evaluated by comparing

the tested specimens with visual standards, which may be

actual fabrics or photographs of fabrics, showing a range of FIG. 1 Random Tumble Piling Tester

e1

D3512–05 (2007)

NOTE 2—An adequate specification or other agreement between the

6.2 Adhesive , white all-purpose, for sealing edges of speci-

purchaser and the supplier requires taking into account the variability

mens (see 7.1).

amongrolls,bolts,orpiecesoffabricandamongspecimensfromaswatch

6.3 Plastic Bottle, with dispensing spout and cap, for use

of fabric from a roll, bolt, or piece, or between cartons of garments and

with diluted adhesive.

among garments within a carton, to provide a sampling plan with a

6.4 Vacuum Cleaner, home canister type, to clean speci-

meaningful producer’s risk, consumer’s risk, acceptable quality level, and

mens after testing.

limiting quality level.

6.5 Cotton Sliver, 4301 tex, fine American Upland, or

8.2 Laboratory Sampling Unit—From each primary sam-

equivalent, for improving visibility of pills on specimens.

pling unit take one full-width piece of fabric that is1m(1yd)

6.6 Apparatus for Fabric Evaluation—Facilities for illumi-

in length along the selvage (machine direction), after first

nation (cool white fluorescent tube) and simultaneous viewing

removing a 1 m (1 yd) length. For fabric components of

of test specimen and fabric or photograph rating standards.

fabricated systems use the entire system.

Apparatus and options for visual evaluation are listed in Table

8.2.1 For acceptance testing of garments, take one garment

1.

from each carton (see Note 2).

6.7 Standard In-House Pilling Test Fabric, having an estab-

lished pilling resistance rating for checking machine perfor-

9. Test Specimens: Selection, Number, and Preparation

mance. No universal standard fabric is available. Each test

facility must decide on an appropriate fabric.

9.1 Samples may be washed or dry cleaned before cutting

6.8 Rating Standards:

the test specimens, using conditions appropriate for the fabric

6.8.1 Fabric—A series of tested specimens of a specific

end use or conditions agreed upon by all interested parties.

fabrictypewhichshowsdegreeofpillingorotherdistortion,or

9.2 Cut specimens in squares 105 mm (4.13 in.) on the bias

both, for each type of fabric to be tested. Store the fabric rating

at an approximate 0.78 rad (45°) angle to the warp (wale) and

standards and handle them under conditions that will preserve

filling (course) directions.

their original form and appearance.

9.2.1 Take three specimens from each laboratory unit. Take

6.8.2 Photographic— A set of five photographs, 105-mm

the specimens evenly spaced across the width of the laboratory

square (4.13 in.), numbered 1 to 5 illustrating varying degrees

sample or from three different panels in a garment. Specimens

of pilling from “very severe pilling” to “no pilling” such as

should be staggered in such a manner that no two specimens

Adjunct D 3512. The photos should have a dull matte finish

contain the same yarns. Avoid areas with wrinkles and other

and be of the same size as the tested specimen.

distortions. Unless otherwise specified, do not cut specimens

6.9 Facilities for Laundering Samples—If needed.

nearer the selvage than one tenth the width of the fabric.

6.10 Facilities for Dry Cleaning Samples—If needed.

9.3 Mark replicate specimens in one corner on the face of

the fabric with the appropriate number 1, 2, or 3.

7. Hazardous Materials

9.4 If loosely woven specimens fray when applying identi-

7.1 Adhesives used in this test method may be hazardous.

fication markings, cut the specimens with sides parallel to the

Refer to the manufacturer’s material safety data sheets for

warpandfillingandravelthesidesnomorethan5mm(0.2in.)

information on use, handling, storage, and disposal of these

on each side, leaving the fringe.

products.

9.5 Seal the edges of all specimens to a width not exceeding

3mm(.13in.)onthefaceofthefabricwithadhesive.Hangthe

8. Sampling

specimens on racks until dry, and in any case for at least 2 h.

8.1 Primary Sampling Unit—Consider rolls of fabric or

fabric components of fabricated systems to be the primary

NOTE 3—Full-strengthadhesiveoranydilutiondownto1partadhesive

sampling unit, as applicable.

with 1 part water may be used (see 7.1). Pressing the adhesive into the

specimen face may be accomplished using the dispensing nozzle in a

closed configuration. The rounded end of a glass stirring rod works well,

also, but caution should be used to prevent breakage and possible injury

Cotton dyed to a medium gray shade before carding using a colorfast reactive

black dye and standard reactive dyeing procedure. Cotton sliver is available from broken glass.

commercially.

10. Preparation of Apparatus

TABLE 1 Viewing Apparatus and Options

10.1 Fit a cork liner snugly around the inside of a cleaned

Apparatus Specimen Preparation

test chamber with an unused cork surface facing the rotor

A

ASTM Lightbox (Fig. 1) 0.78 rad (45°)

blades.Thesideagainstthechambermayormaynothavebeen

B

Lightbox 0.78 rad (45°) used. To eliminate any tendency for the liner to rotate, tape the

B

outside edge of the liner to the chamber wall at the butt joint

Lightbox flat

B with a short piece of 25-mm (1-in.) wide masking tape.

Lightbox critical angle

10.1.1 Discard cork liners that have been used for1hon

As determined by the buyer and supplier

each surface.

A

The source of supply of the apparatus known to the committee at this time is

Standard Scientific Supply Co., 601 West Market Street, Bethlehem, PA 10.2 After every hour of machine running time, remove the

18018–5208. If you are aware of alternate suppliers, please provide this informa-

liner and clean the impeller by wiping with a cloth wetted in a

tion to ASTM Headquarters. Your comments will receive careful consideration at a

solution of detergent and water. Allow the chamber to dry

meeting of the responsibl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.