ASTM D906-98(2004)

(Test Method)Standard Test Method for Strength Properties of Adhesives in Plywood Type Construction in Shear by Tension Loading

Standard Test Method for Strength Properties of Adhesives in Plywood Type Construction in Shear by Tension Loading

SIGNIFICANCE AND USE

The way adhesives are used in plywood makes shear strength an important performance criteria.

Shear strength measured by this test is suitable for use in adhesive development, manufacturing quality control, and in materials performance specifications.

SCOPE

1.1 This test method covers the determination of the comparative shear strengths of adhesives in plywood-type construction, when tested on a standard specimen and under specified conditions of preparation, conditioning, and testing. This test method is intended to be applied only to adhesives used in bonding wood to wood.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D906–98(Reapproved2004)

Standard Test Method for

Strength Properties of Adhesives in Plywood Type

Construction in Shear by Tension Loading

This standard is issued under the fixed designation D906; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

The accuracy of the results of strength tests of adhesive bonds will depend on the conditions under

which the bonding process is carried out. Unless otherwise agreed upon between the manufacturer and

the purchaser, the bonding conditions shall be prescribed by the manufacturer of the adhesive. In order

to ensure that complete information is available to the individual conducting the tests, the

manufacturer of the adhesive shall furnish numerical values and other specific information for each of

the following variables:

(1) The moisture content of the wood at the time of bonding.

(2) Complete mixing directions for the adhesive.

(3) Conditions for application of the adhesive including the rate of spread or thickness of film,

number of coats to be applied, whether more than one coat is required.

(4) Assembly conditions before application of pressure, including the room temperature, length of

time, and whether open or closed assembly is to be used.

(5) Curing conditions, including the amount of pressure to be applied, the length of time under

pressure and the temperature of the assembly when under pressure. It should be stated whether this

temperature is that of the bond line, or of the atmosphere at which the assembly is to be maintained.

(6) Conditioning procedure before testing, unless a standard procedure is specified, including the

length of time, temperature, and relative humidity.

Arange may be prescribed for any variable by the manufacturer of the adhesive if it can be assumed

by the test operator that any arbitrarily chosen value within such a range or any combination of such

values for several variables will be acceptable to both the manufacturer and the purchaser of the

adhesive.

1. Scope specified conditions of preparation, conditioning, and testing.

This test method is intended to be applied only to adhesives

1.1 This test method covers the determination of the com-

used in bonding wood to wood.

parative shear strengths of adhesives in plywood-type con-

1.2 The values stated in SI units are to be regarded as the

struction, when tested on a standard specimen and under

standard. The values given in parentheses are provided for

information purposes only.

1.3 This standard does not purport to address all of the

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

safety concerns, if any, associated with its use. It is the

Adhesives.

responsibility of the user of this standard to establish appro-

Current edition approved April 1, 2004. Published April 2004. Originally

priate safety and health practices and determine the applica-

approved in 1947. Last previous edition approved in 1998 as D906 – 98. DOI:

10.1520/D0906-98R04. bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D906–98 (2004)

2. Referenced Documents

2.1 ASTM Standards:

D143 Test Methods for Small Clear Specimens of Timber

D907 Terminology of Adhesives

3. Terminology

3.1 Definitions—Many terms in this test method are defined

in Terminology D907.

3.1.1 plywood, n—a panel generally flat built up of layers of

veneer called plies, united under pressure by an adhesive to

create a panel with the bond between the plies as strong as, or

stronger than, the wood, and that has the following character-

istics: (1) is constructed of an odd number of layers with grain

of adjacent layers perpendicular, (2) with a layer consisting of

either a single ply or two or more plies laminated with parallel

grain direction, and (3) with outer layers and all odd numbered

layers generally having the grain direction oriented parallel to FIG. 1 Grips and Jaws

the long dimension of the panel.

3.1.1.1 Discussion—Generally, the grain of one or more

plies is approximately at right angles to the other plies, and

almost always an odd number of plies are used.

3.1.2 shear, n—in an adhesively bonded joint, stress, strain

or failure resulting from applied forces that tend to cause

adjacent planes of a body to slide parallel in opposite direc-

tions.

Metric Equivalents

4. Significance and Use

1 1

in. ⁄8 1 3 ⁄4

4.1 The way adhesives are used in plywood makes shear

mm 3.2 25.4 82.6

strength an important performance criteria.

FIG. 2 Form and Dimensions of Test Specimen

4.2 Shearstrengthmeasuredbythistestissuitableforusein

adhesive development, manufacturing quality control, and in

materials performance specifications.

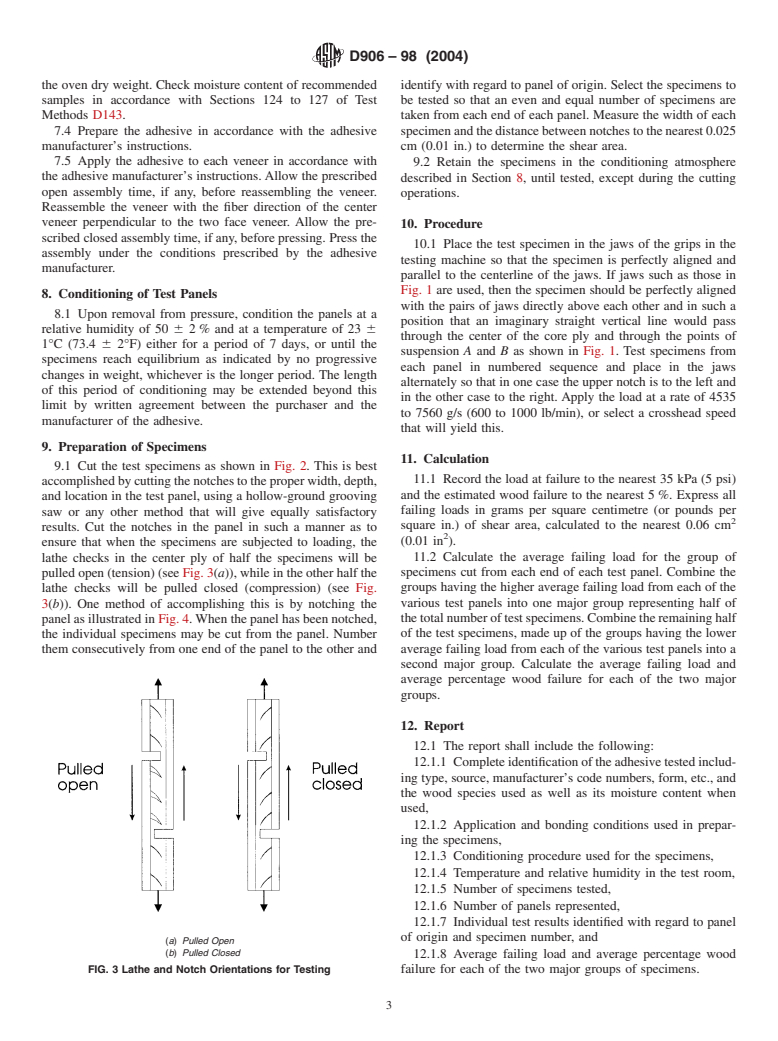

6.2 At least 40 specimens, representing at least five different

panels, shall be prepared, selected and tested as prescribed in

5. Apparatus

Sections 9 and 10.

5.1 The testing machine shall be adjusted to a loading rate

of between 4535 and 7560 g/s (600 and 1000 lb/min). Where

7. Preparation and Test Panels

the testing machine is adjusted by rate of crosshead movement

7.1 The standard substrate for this test method is 1.6–mm

rather than load application rate, an appropriate head move-

(1/16–in.) thick rotary-cut or sliced veneer of sweet birch

ment rate shall be selected so as to yield an average load

(Betula lenta) or yellow birch (Betula alleghaniensis). Any

application rate in the 4535 to 7560 g/s (600 to 1000 lb/min)

other thickness or species of veneer may be substituted upon

range. It shall be provided with suitable grips and jaws so that

written agreement between the party requesting this test and

the specimen can be gripped tightly and held in alignment as

the manufacturer of the adhesive. Select veneer that is free of

the load is applied. The grips and jaws shown in Fig. 1 have

defects such as knots or distorted grain around knots, cracks,

been found satisfactory.The testing machine shall be located in

short grain (fibers out of plane), rough surfaces, or unusual

an atmosphere such that the moisture content of the specimens

discoloration that would indicate decay. Do not sand the

developed under the conditions prescribed in Section 8 is not

veneer.

noticeably altered during testing.

7.2 Cut the selected veneer into a size suitable for pressing

and for cutting specimens with minimal waste. Allow at least

6. Test Specimens

⁄2-in. (13 mm) for trim around the edges.

6.1 The test specimens shall conform to the form and

NOTE 1—When cutting the veneer to size, ensure that the fiber direction

dimensions shown in Fig. 2. The specimens shall be cut from

is parallel and perpendicular to the edges.Ap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.