ASTM D5266-13(2020)

(Practice)Standard Practice for Estimating the Percentage of Wood Failure in Adhesive Bonded Joints

Standard Practice for Estimating the Percentage of Wood Failure in Adhesive Bonded Joints

SIGNIFICANCE AND USE

4.1 An estimate of wood failure is one of the principal means for determining the quality of an adhesively bonded wood joint.

4.2 When evaluated after a water soaking, water soaking and drying, or boiling and drying, the percentage of estimated wood failure is an important criterion for qualifying adhesives for use in plywood, laminated structural timber, adhesively bonded wood products and for daily quality control of the processes for manufacturing various adhesively bonded wood products including but not limited to plywood and laminated timbers. Standards that use the percentage of wood failure are included in Section 2.

4.3 In plywood manufactured from North American softwood species, the percentage of wood failure of Test Method D906 specimens, tested wet after either a vacuum-pressure soak-dry or boil-dry treatment, correlates with the percentage of panels that delaminate in outdoor exposure without protection.7

4.4 Similar correlations for other products have not been published.

SCOPE

1.1 This practice provides procedures for estimating the percentage of wood failure that occurs in plywood-shear, block-shear, finger joint test specimens, or any other bondline involving wood.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5266 − 13 (Reapproved 2020)

Standard Practice for

Estimating the Percentage of Wood Failure in Adhesive

Bonded Joints

This standard is issued under the fixed designation D5266; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5751SpecificationforAdhesivesUsedforLaminateJoints

in Nonstructural Lumber Products

1.1 This practice provides procedures for estimating the

2.2 American National Standards:

percentage of wood failure that occurs in plywood-shear,

ANSI/HPVA HP-1-2009American National Standard for

block-shear, finger joint test specimens, or any other bondline

Hardwood and Decorative Plywood

involving wood.

ANSI A190.1-2012American National Standard for Wood

1.2 The values stated in SI units are to be regarded as the 3

Products—Structural Glued, Laminated Timber

standard. The values in parentheses are provided for informa-

2.3 Other Documents:

tion only.

American Plywood Association Proposed Standard Method

1.3 This standard does not purport to address all of the for Estimating Percentage Wood Failure on Plywood

safety concerns, if any, associated with its use. It is the

Shear Specimens

responsibility of the user of this standard to establish appro- PS 1U.S. Product Standard for Construction and Industrial

priate safety, health, and environmental practices and deter-

Plywood

mine the applicability of regulatory limitations prior to use. CSA O112.9Evaluation of Adhesives for Structural Wood

1.4 This international standard was developed in accor-

Products (Exterior Exposure)

dance with internationally recognized principles on standard- General Technical Report FPL-GTR-190

ization established in the Decision on Principles for the

Inspection Bureau Memorandum No. 1Interpretation of

Development of International Standards, Guides and Recom- Wood Failure

mendations issued by the World Trade Organization Technical

2.4 ASTM Adjunct:

Barriers to Trade (TBT) Committee. PhotographsforVisuallyEstimatingthePercentageofWood

Failure in Standard Adhesively Bonded Specimens

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions:

D905Test Method for Strength Properties of Adhesive

3.1.1 deep wood failure, n—failurethatisinvariablyseveral

Bonds in Shear by Compression Loading

to many cells away from the adhesive layer, in which the

D906Test Method for Strength Properties of Adhesives in

fracture path is strongly influenced by the grain angle and

Plywood Type Construction in Shear by Tension Loading

growth–ring structure.

D2559Specification for Adhesives for Bonded Structural

Wood Products for Use Under Exterior Exposure Condi-

3.1.2 shallow wood failure, n—failure that is invariably

tions

within the first one or two layers of cells beyond the adhesive

D4688Test Method for Evaluating StructuralAdhesives for

layer in which the fracture path is not influenced by the

Finger Jointing Lumber

wood–grain angle or growth-ring structure (see 7.7 and 8.1).

D5572SpecificationforAdhesivesUsedforFingerJointsin

3.1.3 wood failure, n—the rupturing of wood fibers in

Nonstructural Lumber Products

strength tests on bonded specimens, usually expressed as the

percentageofthetotalareainvolvedwhichshowssuchfailure.

This practice is under the jurisdiction ofASTM Committee D14 on Adhesives

and is the direct responsibility of Subcommittee D14.30 on Wood Adhesives. Available from Hardwood Plywood & Veneer Association, 1825 Michael

Current edition approved April 1, 2020. Published April 2020. Originally Faraday Drive, P.O. Box 2789, Reston, VA 20190, www.hpva.org.

approved in 1992. Last previous edition approved in 2013 as D5266–13. DOI: Available fromAPA–The EngineeredWoodAssociation, 7011 South 19th St.,

10.1520/D5266-13R20. Tacoma, WA 98466, www.apawood.org.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Wood Handbook: Wood as an Engineering Material, Madison, WI: U. S.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM DepartmentofAgriculture,ForestService,ForestProductsLaboratory,508p.2010.

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Request Adjunct No.

the ASTM website. ADJD5266. Original adjunct produced in 1991.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5266 − 13 (2020)

4. Significance and Use

4.1 An estimate of wood failure is one of the principal

means for determining the quality of an adhesively bonded

wood joint.

4.2 When evaluated after a water soaking, water soaking

and drying, or boiling and drying, the percentage of estimated

wood failure is an important criterion for qualifying adhesives

for use in plywood, laminated structural timber, adhesively

bonded wood products and for daily quality control of the

processes for manufacturing various adhesively bonded wood

products including but not limited to plywood and laminated

timbers. Standards that use the percentage of wood failure are

included in Section 2.

4.3 In plywood manufactured from North American soft-

wood species, the percentage of wood failure of Test Method

D906 specimens, tested wet after either a vacuum-pressure

soak-dry or boil-dry treatment, correlates with the percentage

of panels that delaminate in outdoor exposure without protec-

tion.

4.4 Similar correlations for other products have not been

published.

5. Apparatus

5.1 Variouslightsourceshavebeenfoundusefulinestimat-

ing wood failure. In determining compliance to standard

specifications, the source must be agreed upon by the user of

this practice and the individual or agency requiring these tests.

5.1.1 Dual-Element Fluorescent Desk Lamp equipped with

one 15 W daylight and one 15 W cool white tube.

NOTE 1—In this case, a standard D905 shear block is shown.

NOTE 1—This source is used by the APA – The Engineered Wood

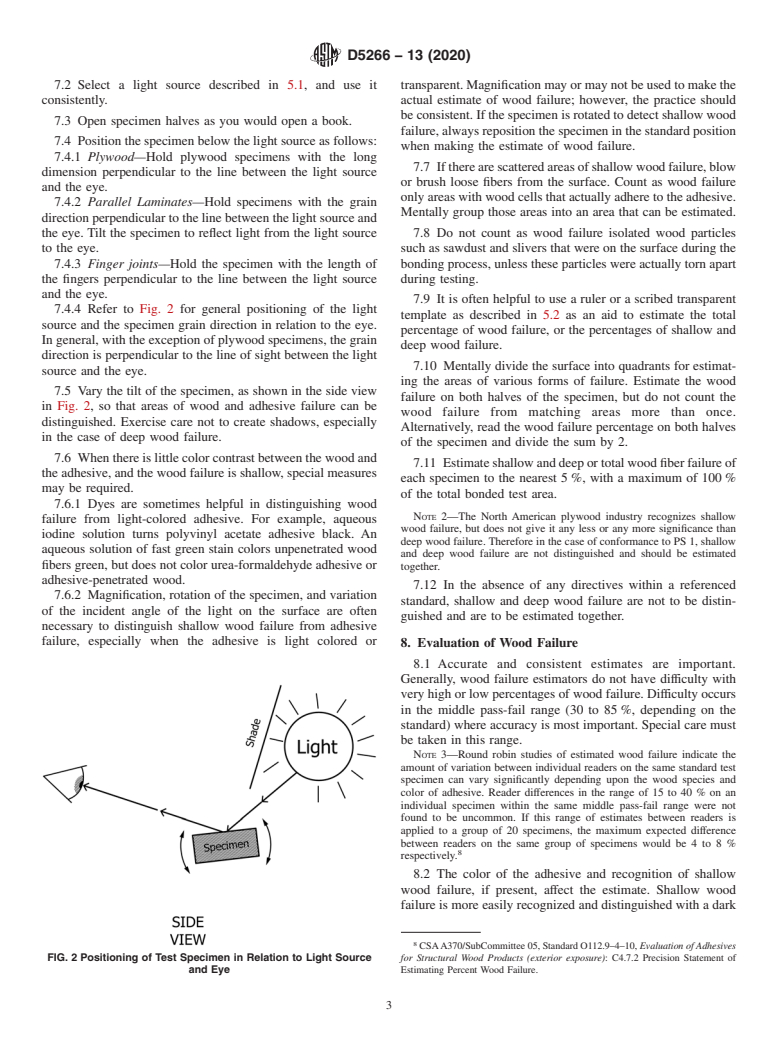

FIG. 1 Example of Plastic Template Scribed with Lines and

Association for compliance to the commercial standard PS 1.

Shapes Representing Known Percentages of Given Area

5.1.2 Circular Fluorescent Desk Lamp with 5× viewing

magnifier in the center of the lamp.

depicted with wood failure estimates provided by trained

5.1.3 Diffuse Natural Light from a window facing away

technical personnel familiar with the process of reading wood

from the sun.

failure. (See Figs. X1.1-X1.4.)

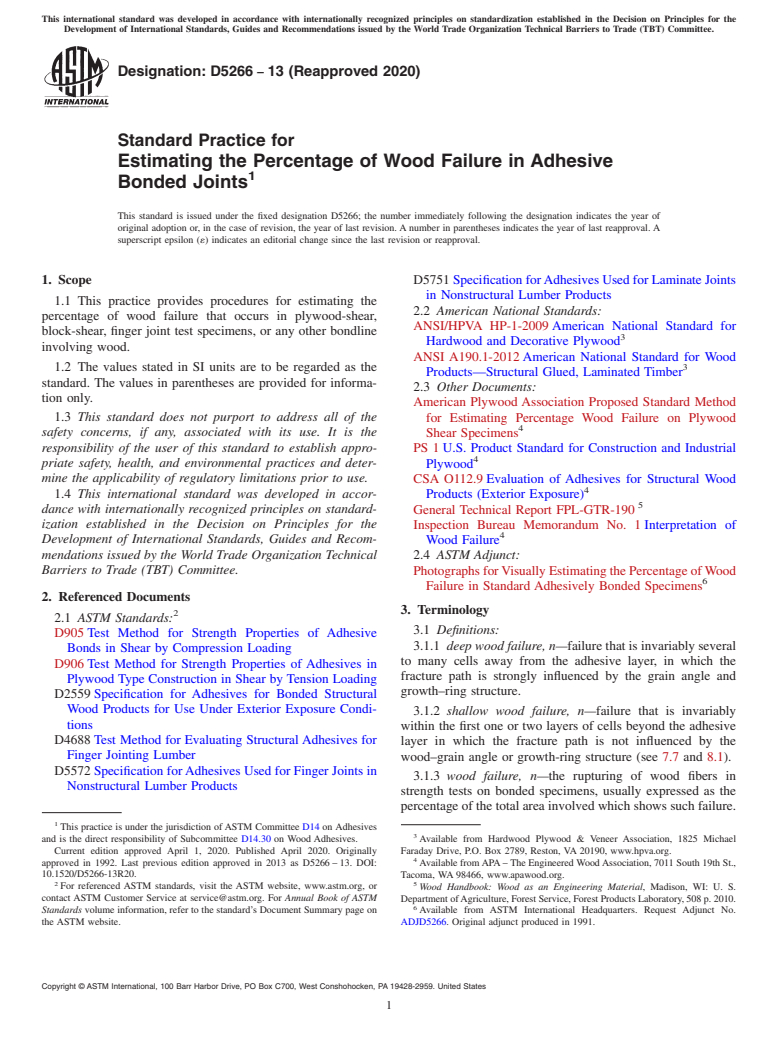

5.2 Ruler,with2.54mm(0.1-in.)divisionsisrecommended

6. Preparation of Test Specimens

as an aid to estimating the area of torn wood fibers. A

transparent template, the size of the specimen bond area and

6.1 Prepare and test the specimens as outlined in the

scribed with various shapes and areas with known percentages

appropriate test method.

of the total area, is also useful for subdividing the area. An

6.2 Do not estimate wood failure percentage of specimens

example of such a template is shown in Fig. 1.

withlocalizeddefectssuchasknots,knotholes,burl,andvoids

5.3 Low-Power Magnifying Glass,of3to5×,withafieldof

in the bond area, even if they are permitted within the grade of

view able to encompass most of the failed surface, may be

lumber or veneer being tested. Specimens with defects in the

useful for inspecting areas where shallow wood failure is

grip area may or may not be tested at the discretion of the user

suspected.

or in accordance with the policy of the testing organization.

5.4 ASTM Adjunct,whichincludesphotographsforVisually

6.3 Specimens with manufacturing defects, such as wiped

Estimating the Percentage of Wood Failure in Adhesively

bondline, chips, core gaps, and laps, may also be discarded by

Bonded Specimens. The adjunct which is found in theAppen-

agreement between the interested parties.

dix of the digital edition of this practice, and provided as a

6.4 If the specimens were tested wet, dry the failed surfaces

separate document for the print edition, is a useful tool to aid

in an air-circulating oven at 71°C (160°F), or under equivalent

in the training of reading and estimating percent wood failure.

conditions, before estimating the percentage of wood failure.

Both plywood specimens and block shear specimens are

7. Procedure

7.1 Work in a location where direct outside light does not

Perkins, N. S., Predicting Exterior Plywood Performance, Proceedings Forest

Products Research Society, 1950, pp. 1–12. fall on the specimen.

D5266 − 13 (2020)

7.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.