ASTM D7998-19

(Test Method)Standard Test Method for Measuring the Effect of Temperature on the Cohesive Strength Development of Adhesives using Lap Shear Bonds under Tensile Loading

Standard Test Method for Measuring the Effect of Temperature on the Cohesive Strength Development of Adhesives using Lap Shear Bonds under Tensile Loading

SIGNIFICANCE AND USE

4.1 The test method enables strength values for wood and other materials bonded with an adhesive under a range of controlled bonding temperature, time, and pressure conditions to be evaluated. Bond formation and subsequent testing is affected in a coordinated fashion, and this enables transient strength values of sets of similar bond types to be explored with diverse parameters as independent variables. Principal among these variables is the temperature at which bonds are formed and the time that selected temperatures are maintained prior to testing. The use of controlled methods of adhesive application, the rapid attainment of stable bond formation conditions, and the rapid transition to the bond testing mode enables snapshots of bond strength to be attained as bonds progress from limited strength (or initial tack) to maximum strength. Derived data may be used to evaluate and compare the strength development characteristics of diverse types and formulations of adhesive. The method may thus be used to aid in tailoring and matching adhesives to the manufacture of diverse bonded products that involve heating.

4.2 The method may also be used to evaluate the co-dependent effect of temperature and time on the degradation of sample bonds. Pressing temperatures up to 265°C (509°F) may be necessary for such investigations of thermal degradation. Specimens are pressed for a range of times and temperatures and very shortly thereafter tested either at elevated temperature or immediately following rapid forced air cooling. Alternatively, thermal damage of pre-formed bond samples may be evaluated by subjecting them to controlled temperature and time sequences prior to testing.

4.3 The method may also be used to evaluate the effect of wood type and variability, or of non-wood materials, on bond strength development.

4.4 By hermetically sealing the overlap region of sample bonds during their formation, the method may also be used to evaluate the effect of moisture and oth...

SCOPE

1.1 This test method concerns bonding and testing of wood adhesives and related adhesives using small scale tensile lap-shear samples in a manner that emphasizes transient cohesive strength as a function of bonding time and temperature.

1.2 Use of thin adherends enables bondlines to be rapidly heated to elevated temperatures and maintained at those temperatures for a range of times at a controlled pressure before testing.

1.3 Optional rapid forced air cooling of bonds after pressing and immediately before testing enables the effect of testing temperature on transient strength to be evaluated.

1.4 Bond overlap distance is specified to ensure that failure occurs in the bondline rather than in unbonded portions of adherend strips, and also to minimize the effect of shear stress non-uniformity along the overlap during tensile testing.

1.5 Standard wood or alternative non-standard materials must be of specified high quality and uniformity of structure and dimension to minimize variability of bonding and maximize stress transfer into the bonds during testing.

1.6 The effect of wood variability and type, or of the properties of alternative non-wood materials, on bond strength development may be explored using the method.

1.7 Optional hermetic sealing of bond overlaps during their heated pressing enables the effect of moisture on bonding to be evaluated.

1.8 Thermal damage, either of pre-formed bonds or by prolonging bond forming times, may be evaluated as a function of time and elevated temperature using this test method.

1.9 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicabil...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7998 − 19

Standard Test Method for

Measuring the Effect of Temperature on the Cohesive

Strength Development of Adhesives using Lap Shear Bonds

1

under Tensile Loading

This standard is issued under the fixed designation D7998; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

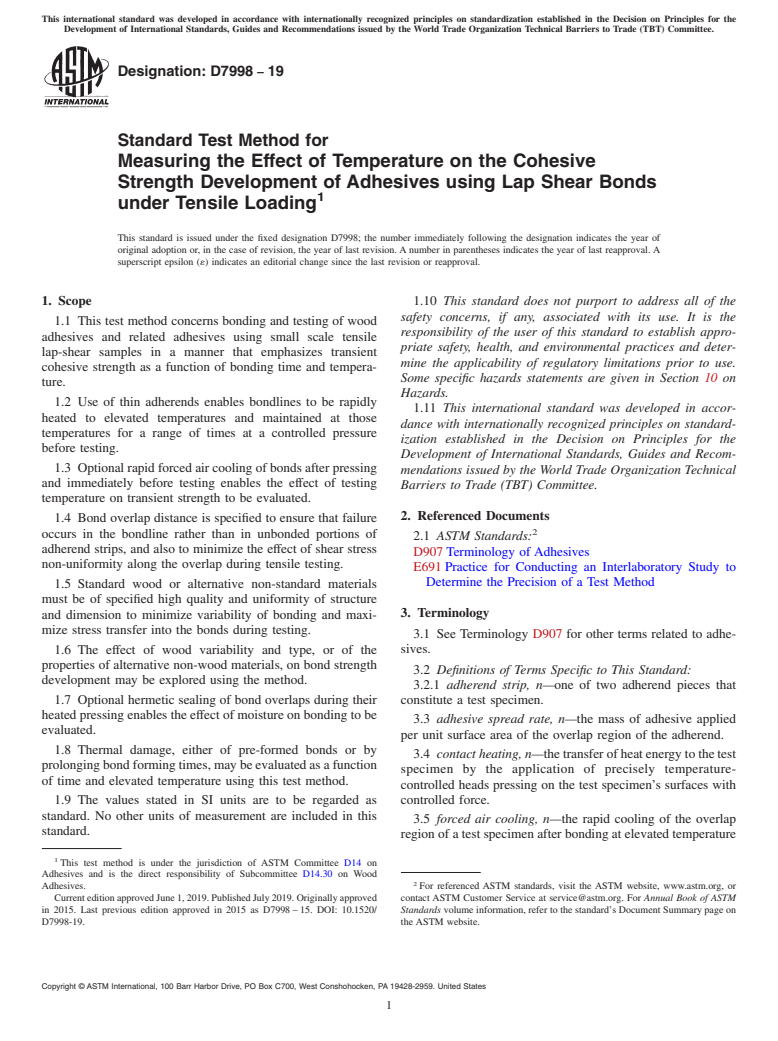

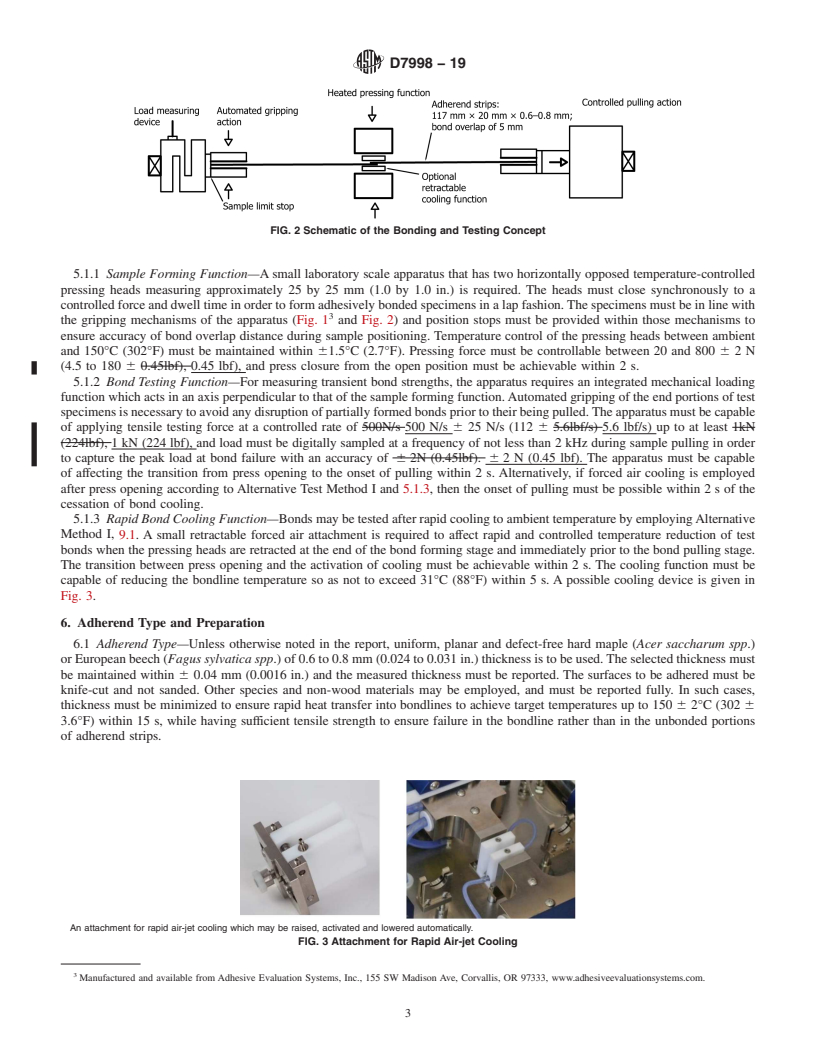

1. Scope 1.10 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method concerns bonding and testing of wood

responsibility of the user of this standard to establish appro-

adhesives and related adhesives using small scale tensile

priate safety, health, and environmental practices and deter-

lap-shear samples in a manner that emphasizes transient

mine the applicability of regulatory limitations prior to use.

cohesive strength as a function of bonding time and tempera-

Some specific hazards statements are given in Section 10 on

ture.

Hazards.

1.2 Use of thin adherends enables bondlines to be rapidly

1.11 This international standard was developed in accor-

heated to elevated temperatures and maintained at those

dance with internationally recognized principles on standard-

temperatures for a range of times at a controlled pressure

ization established in the Decision on Principles for the

before testing.

Development of International Standards, Guides and Recom-

1.3 Optional rapid forced air cooling of bonds after pressing

mendations issued by the World Trade Organization Technical

and immediately before testing enables the effect of testing

Barriers to Trade (TBT) Committee.

temperature on transient strength to be evaluated.

2. Referenced Documents

1.4 Bond overlap distance is specified to ensure that failure

2

occurs in the bondline rather than in unbonded portions of

2.1 ASTM Standards:

adherend strips, and also to minimize the effect of shear stress

D907 Terminology of Adhesives

non-uniformity along the overlap during tensile testing.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.5 Standard wood or alternative non-standard materials

must be of specified high quality and uniformity of structure

3. Terminology

and dimension to minimize variability of bonding and maxi-

mize stress transfer into the bonds during testing.

3.1 See Terminology D907 for other terms related to adhe-

1.6 The effect of wood variability and type, or of the sives.

properties of alternative non-wood materials, on bond strength

3.2 Definitions of Terms Specific to This Standard:

development may be explored using the method.

3.2.1 adherend strip, n—one of two adherend pieces that

1.7 Optional hermetic sealing of bond overlaps during their constitute a test specimen.

heated pressing enables the effect of moisture on bonding to be

3.3 adhesive spread rate, n—the mass of adhesive applied

evaluated.

per unit surface area of the overlap region of the adherend.

1.8 Thermal damage, either of pre-formed bonds or by

3.4 contact heating, n—thetransferofheatenergytothetest

prolongingbondformingtimes,maybeevaluatedasafunction

specimen by the application of precisely temperature-

of time and elevated temperature using this test method.

controlled heads pressing on the test specimen’s surfaces with

1.9 The values stated in SI units are to be regarded as controlled force.

standard. No other units of measurement are included in this

3.5 forced air cooling, n—the rapid cooling of the overlap

standard.

region of a test specimen after bonding at elevated temperature

1

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

2

Adhesives. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2019.PublishedJuly2019.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2015. Last previous edition approved in 2015 as D7998 – 15. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7998-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7998 − 19

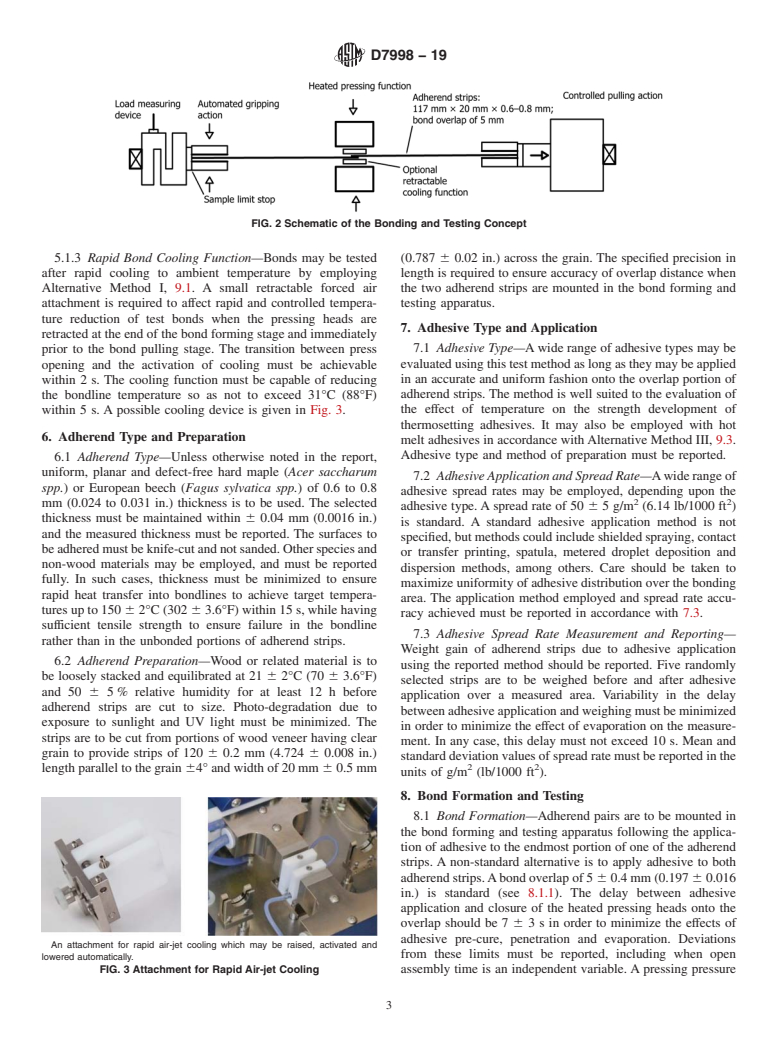

by the controlled application of air jets onto both external faces

of the overlap portion of the specimen.

3.6 test specimen, n—the lap shear sample made up of an

adhesive between two pieces of adhe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7998 − 15 D7998 − 19

Standard Test Method for

Measuring the Effect of Temperature on the Cohesive

Strength Development of Adhesives using Lap Shear Bonds

1

under Tensile Loading

This standard is issued under the fixed designation D7998; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method concerns bonding and testing of wood adhesives and related adhesives using small scale tensile lap-shear

samples in a manner that emphasizes transient cohesive strength as a function of bonding time and temperature.

1.2 Use of thin adherends enables bondlines to be rapidly heated to elevated temperatures and maintained at those temperatures

for a range of times at a controlled pressure before testing.

1.3 Optional rapid forced air cooling of bonds after pressing and immediately before testing enables the effect of testing

temperature on transient strength to be evaluated.

1.4 Bond overlap distance is specified to ensure that failure occurs in the bondline rather than in unbonded portions of adherend

strips, and also to minimize the effect of shear stress non-uniformity along the overlap during tensile testing.

1.5 Standard wood or alternative non-standard materials must be of specified high quality and uniformity of structure and

dimension to minimize variability of bonding and maximize stress transfer into the bonds during testing.

1.6 The effect of wood variability and type, or of the properties of alternative non-wood materials, on bond strength

development may be explored using the method.

1.7 Optional hermetic sealing of bond overlaps during their heated pressing enables the effect of moisture on bonding to be

evaluated.

1.8 Thermal damage, either of pre-formed bonds or by prolonging bond forming times, may be evaluated as a function of time

and elevated temperature using this test method.

1.9 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 1010 on Hazards.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D907 Terminology of Adhesives

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 See Terminology D907 for other terms related to adhesives.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood Adhesives.

Current edition approved Sept. 15, 2015June 1, 2019. Published November 2015July 2019. Originally approved in 2015. Last previous edition approved in 2015 as

D7998 – 15. DOI: 10.1520/D7998-15.10.1520/D7998-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7998 − 19

3.2.1 adherend strip, n—one of two adherend pieces that constitute a test specimen.

3.3 adhesive spread rate, n—the mass of adhesive applied per unit surface area of the overlap region of the adherend.

3.4 contact heating, n—the transfer of heat energy to the test specimen by the application of precisely temperature-controlled

heads pressing on the test specimen’s surfaces with controlled force.

3.5 forced air cooling, n—the rapid cooling of the overlap region of a test specimen after bonding at elevated temperatur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.