ASTM F735-94

(Test Method)Standard Test Method for Abrasion Resistance of Transparent Plastics and Coatings Using the Oscillating Sand Method

Standard Test Method for Abrasion Resistance of Transparent Plastics and Coatings Using the Oscillating Sand Method

SCOPE

1.1 This test method determines the resistance of transparent plastics and transparent coatings utilized in windows or viewing ports, to surface abrasion using oscillating sand.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 735 – 94

Standard Test Method for

Abrasion Resistance of Transparent Plastics and Coatings

Using the Oscillating Sand Method

This standard is issued under the fixed designation F 735; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.3 The thickness or height of the sand, which rests on top

of the test specimen, remains relatively constant over the test

1.1 This test method determines the resistance of transpar-

specimen itself during the motion of the cradle. Therefore, the

ent plastics and transparent coatings utilized in windows or

average pressure of the sand also remains constant, giving

viewing ports, to surface abrasion using oscillating sand.

highly reproducible results over the entire surface of the test

1.2 This standard does not purport to address all of the

specimen.

safety concerns, if any, associated with its use. It is the

3.4 The degree of abrasion is measured by the amount of

responsibility of the user of this standard to establish appro-

change in luminous transmission and haze after exposure to the

priate safety and health practices and determine the applica-

test.

bility of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents

4.1 Many types of plastics are used in the making of

2.1 ASTM Standards:

transparencies and enclosures or covers. It is the intent of this

C 136 Test Method for Sieve Analysis of Fine and Coarse

test to provide a means of determining the relative abrasion

Aggregates

resistance of plastics or coatings, or both, to such operational

D 618 Practice for Conditioning Plastics and Electrical

uses as the cleaning of dirt, removal of bug residue, or any

Insulating Materials for Testing

other rubbing action that can cause abrasion.

D 1003 Test Method for Haze and Luminous Transmittance

of Transparent Plastics

5. Apparatus

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

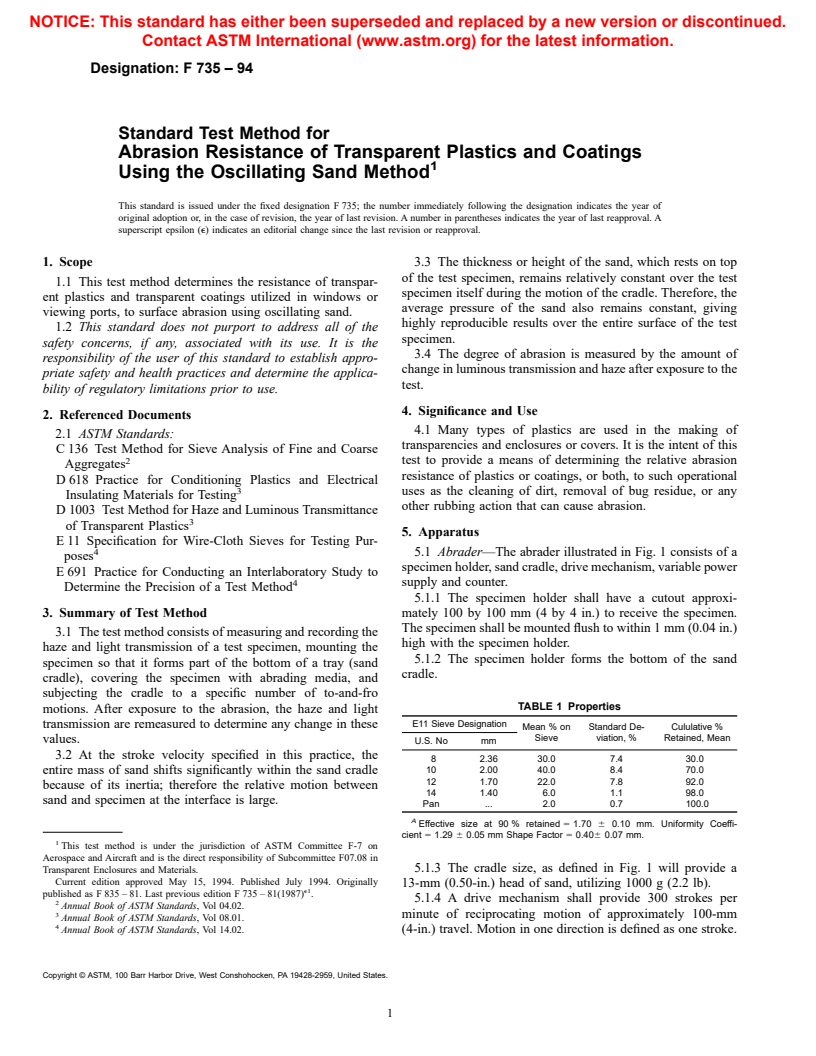

4 5.1 Abrader—The abrader illustrated in Fig. 1 consists of a

poses

specimen holder, sand cradle, drive mechanism, variable power

E 691 Practice for Conducting an Interlaboratory Study to

4 supply and counter.

Determine the Precision of a Test Method

5.1.1 The specimen holder shall have a cutout approxi-

3. Summary of Test Method mately 100 by 100 mm (4 by 4 in.) to receive the specimen.

The specimen shall be mounted flush to within 1 mm (0.04 in.)

3.1 The test method consists of measuring and recording the

high with the specimen holder.

haze and light transmission of a test specimen, mounting the

5.1.2 The specimen holder forms the bottom of the sand

specimen so that it forms part of the bottom of a tray (sand

cradle.

cradle), covering the specimen with abrading media, and

subjecting the cradle to a specific number of to-and-fro

TABLE 1 Properties

motions. After exposure to the abrasion, the haze and light

transmission are remeasured to determine any change in these E11 Sieve Designation

Mean % on Standard De- Cululative %

Sieve viation, % Retained, Mean

values.

U.S. No mm

3.2 At the stroke velocity specified in this practice, the

8 2.36 30.0 7.4 30.0

10 2.00 40.0 8.4 70.0

entire mass of sand shifts significantly within the sand cradle

12 1.70 22.0 7.8 92.0

because of its inertia; therefore the relative motion between

14 1.40 6.0 1.1 98.0

sand and specimen at the interface is large.

Pan . 2.0 0.7 100.0

A

Effective size at 90 % retained 5 1.70 6 0.10 mm. Uniformity Coeffi-

cient 5 1.29 6 0.05 mm Shape Factor 5 0.406 0.07 mm.

This test method is under the jurisdiction of ASTM Committee F-7 on

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 in

5.1.3 The cradle size, as defined in Fig. 1 will provide a

Transparent Enclosures and Materials.

Current edition approved May 15, 1994. Published July 1994. Originally

13-mm (0.50-in.) head of sand, utilizing 1000 g (2.2 lb).

e1

published as F 835 – 81. Last previous edition F 735 – 81(1987) .

5.1.4 A drive mechanism shall provide 300 strokes per

Annual Book of ASTM Standards, Vol 04.02.

minute of reciprocating motion of approximately 100-mm

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 14.02. (4-in.) travel. Motion in one direction is defined as one stroke.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 735

FIG. 1 Oscillating Sand Abrader

5.1.5 A variable power supply shall be utilized to control the 6.1.2.2 Plot the cumulative percent retained, on logarithmic

abrader motor to operate at 300 strokes per minute. probability paper.

5.1.6 A counter shall record the number of strokes during a 6.1.2.3 Read from the plot the sizes in millimetres at 40, 50,

test. and 90 % retained.

5.2 Photometer—An integrating sphere photoelectric pho- 6.1.2.4 Calculate the uniformity coef

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.