ASTM F513-00

(Specification)Standard Safety Specification for Eye and Face Protective Equipment for Hockey Players

Standard Safety Specification for Eye and Face Protective Equipment for Hockey Players

SCOPE

1.1 This consumer safety specification covers eye and face protective equipment for hockey players.

1.2 This specification is intended to reduce the demonstrated hazards associated with the sport of ice hockey involving the face including eyes.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 7 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 513 – 00

Standard Safety Specification for

Eye and Face Protective Equipment for Hockey Players

This standard is issued under the fixed designation F513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Ice hockey is a contact sport with intrinsic hazards. Protective equipment can not eliminate all

injuries, but will substantially reduce their severity and frequency. Participation in this sport by a

playerimpliesacceptanceofsomeinjuryrisk.Thegoalofprotectiveequipmentistominimizetherisk

of injury.

After careful consideration of the mechanisms and forces involved in hockey injuries, this

specification for eye and facial protective equipment has been prepared. A significant reduction of

oculo-facial injuries by the use of facial protective equipment is an expected result.

Performance requirements are presented that are intended to minimize injury with minimal

impairment of the form and appeal of the sport. The committee considers this specification as

preliminary, subject to revision as indicated by subsequent injury statistics.With these goals in mind,

the impact and penetration requirements were determined. It is realized that ocular and facial injuries

will still be possible; however, it was felt that more stringent requirements may interfere with player

performance.

In addition to the use of facial protective equipment conforming to this specification, the following

recommendations are made: (1) A minimal stick blade width of 70 mm (2.8 in.) (per accepted rule

book limits); (2) Modification to rear blade of the ice skate to prevent penetration through wire mesh

masks; (3) Stricter rules against high sticking; and (4) Stricter rules and enforcement against fighting.

All of the requirements of this specification are subject to modification if future statistics demonstrate

significant injuries under game conditions; (5) If full face wire protectors are used for goaltenders, a

throat protector must be affixed.

1. Scope 2. Referenced Documents

1.1 This consumer safety specification covers eye and face 2.1 Federal Standards:

protective equipment for hockey players. National Institute of Standards and Technology Special

1.2 This specification is intended to reduce the demon- Publication 374

strated hazards associated with the sport of ice hockey involv- Federal Test Methods Standards, No. 46, Method3022

ing the face including eyes. 2.2 American National Standards:

1.3 The values stated in SI units are to be regarded as the ANSI Z80.1, 1979, Requirements for First-Quality Pre-

standard. The values given in parentheses are for information scription Opthalmic Lenses

only. ANSI Z80.3, 1977, Requirements for Nonprescription Sun-

glasses and Fashion Eyewear

1.4 The following precautionary caveat pertains only to the

test method portion, Section 7 of this specification: This ANSI Z87.1, 1979, Practice for Occupational and Educa-

standard does not purport to address all of the safety concerns, tional Eye and Face Protectors

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety and health

3.1 Definitions:

practices and determine the applicability of regulatory limita-

tions prior to use. 3.1.1 astigmatism, n—a condition in a lens that creates two

axiallyseparatedlinefociofeachobjectpoint.Thelinesbeing

This specification is under the jurisdiction ofASTM Committee F08 on Sports

EquipmentandFacilitiesandisthedirectresponsibilityofSubcommitteeF08.15on Available from the Superintendent of Documents, U.S. Government Printing

Hockey. Office, Washington, DC 20402.

Current edition approved June 10, 2000. Published August 2000. Originally Available from American National Standards Institute, 11 W. 42nd St., 13th

published as F513–77. Last previous edition F513–99. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 513

mutually perpendicular. In other words, the lens has two 3.1.14 protective device (or protector), n—a device that

different refractive powers in meridians that are 90° apart. provides protection to the wearer’s eyes against specific

hazards encountered in sports.

3.1.2 binocular, adj—relating to the field of view which is

shared by both eyes simultaneously. 3.1.15 refractive power, n—the focusing effect of a lens

expressed in diopters.

3.1.3 central viewing zone, n—that part of the lens which

3.1.16 resolution (optical), n—the characteristic of a lens

has its center in line with the wearer’s line of sight when

that allows separate distinct points in close proximity to be

looking straight.The zone is a truncated circle 60 mm (2.4 in.)

discerned when looking through the lens.

in diameter centered on the above points. The upper portion is

3.1.17 spherical power, n—the most positive meridional

truncated 20 mm (0.8 in.) above the center line. The center of

astigmatic power of a lens.

thecentralviewingzoneshallbethepointofintersectionofthe

3.1.18 tint, n—a characteristic of a transparent material that

line of sight with the lens as mounted on the Alderson

allows a specific color to appear dominant and reduces the

headform.

material’s luminous transmittance properties.

3.1.4 eye, n—relating to the eye of a test headform or the

3.2 Definitions of Terms Specific to This Standard:

eye of a person wearing a protector or that part of an eye

3.2.1 cleanable, adj—theabilityofaprotectivedevicetobe

protective device through which a wearer’s eye would nor-

made readily free of dirt or grime without being damaged

mally look.

during an appropriate cleaning process in accordance with the

3.1.5 eye of the headform, n—all structures contained

manufacturer’s instructions.

within the orbital rim of the Alderson fiftieth percentile

3.2.2 coverage, n—a characteristic of a protective device

headform.

that obstructs straight line paths that are coincident with the

3.1.6 haze, n—the fraction of the total transmitted light

wearer’s eyes.

from a normally incident beam which is not transmitted in a

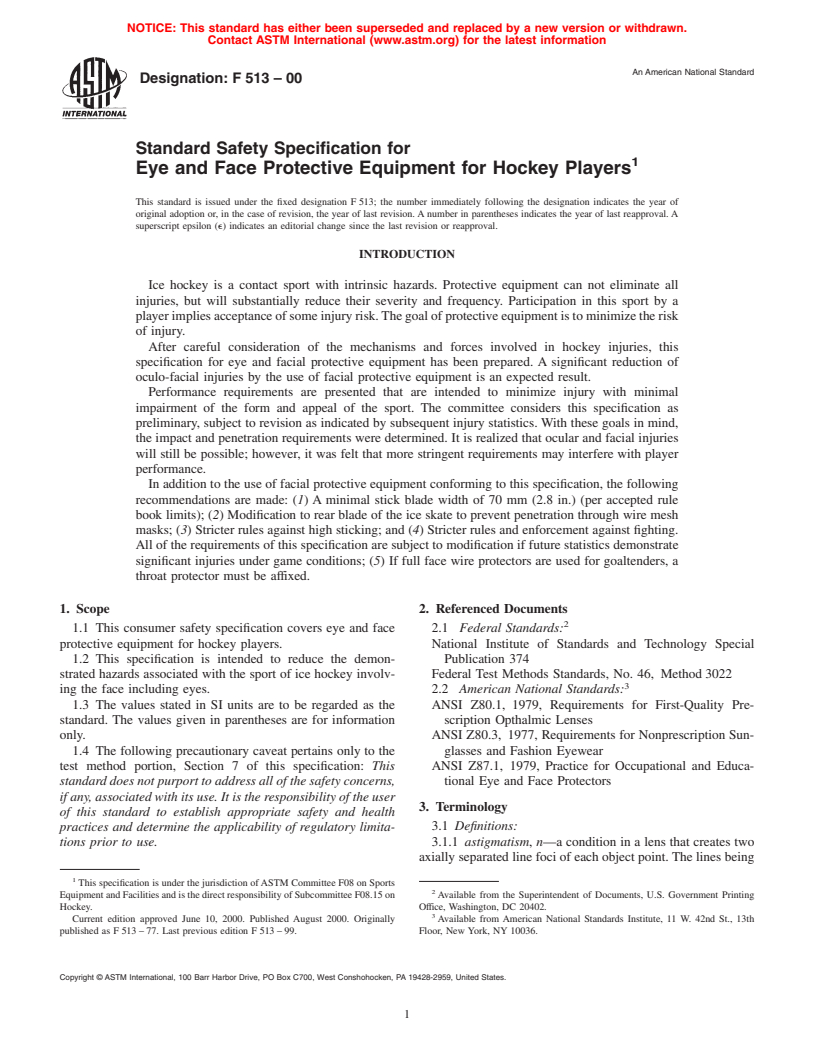

3.2.3 peripheral field, n—the outer limits of vision which,

focused condition but scattered by inclusions or surface de-

as shown in charts of the visual fields, extends to 40° and

fects. Excessive haze will reduce contrast and visibility.

above, to 60° below, and to 90° temporally.

3.1.7 impact resistant, adj—the ability of a device to afford

protection from impact as required by this standard.

4. Types of Protectors

3.1.8 interpupillary distance, P.D., n—the distance between

4.1 Type 1—A full face protector intended for use by any

the center of the pupils of the eyes.

persons other than goaltenders.

3.1.9 lens, n—when so equipped, the transparent part or

4.2 Type 2—A full face protector intended for use by

partsofaprotectivedevicethroughwhichthewearernormally

persons 10 years of age or younger, other than goaltenders.

sees.

3.1.10 luminous transmittance, n—luminous transmittance

5. Performance Requirements

isafunctionofaspectraltransmittanceofthelensweightedby

the corresponding ordinates of the photopic luminous effi-

5.1 Alltestingshallbedonewiththeprotectorsmountedon

ciency distribution of the CIE (1931) standard colormetric

a helmet of a make or model as specified by the protector

observerandbythespectralintensityofstandardilluminant A.

manufacturerandplacedonaheadformidenticalindimensions

(See ANSI Z80.3, 1977, paragraph 2.9.1).

to the Aero Medical Laboratory (AML) headform, as to be

3.1.11 power imbalance, n—a condition that exists when

worn by the consumer (see Table 1).

the refractive power created by the right lens of a protective 5.2 All portions of the protectors, shall be capable of

device is different from that of the left lens.

meeting impact and optical requirements at any temperature

3.1.12 prism, n—the angular deviation of a ray of light as it between 20 and−26°C (68 and−13°F).

passes through a lens resulting from the angle at which the ray 5.3 Optical Requirements, (all protectors):

strikes each surface of the lens and the index of refraction of 5.3.1 Peripheral Field of View—When tested in accordance

the material from which it is made. with7.1.1at20 62°C(68 63.6°F)protectorsshallhavefields

of view equal or exceeding the following:

3.1.13 prism imbalance:

3.1.13.1 vertical imbalance, n—the difference in prismatic (a) Temporal—90°,

(b) Inferior field—60°, and

deviationbetweenparallellightbeamsincidentonthetwoeyes

(c) Superior field—40°

of a protective device in the vertical meridian.

SeeFig.1,Fig.2,andFig.3forillustrationsoftheseangles.

3.1.13.2 horizontal imbalance, n—the difference in pris-

5.4 Optical Requirements (clear shields):

maticdeviationofincidentparallellightbeamsonthetwoeyes

ofaprotectivedeviceinahorizontalmeridian.(SeeSection7.)

3.1.13.3 base-in, adj—relating to the type of prism imbal-

TABLE 1 Facially Featured Headforms

ance that tends to cause parallel rays of light passing through

Material:

a protector, spaced apart by the interpupillary distance to

Urethane 60–65 (shore A)

Durometer:

converge.

Size Hat Size (circ. Prothane Reference

3.1.13.4 base-out, adj—relating to the type of prism imbal- mm) Number

Youth 6 ⁄2 (521) AA-7FF-413-M

ancewhichtendstocauseparallelraysoflightpassingthrough

Juvenile 6 ⁄8 (550) JJ-7FF-413-M

a protector, spaced apart by the interpupillary distance to

Adult 7 (559) AD-7FF-413-M

diverge.

F 513

FIG. 1 Peripheral Field of Vision Testing

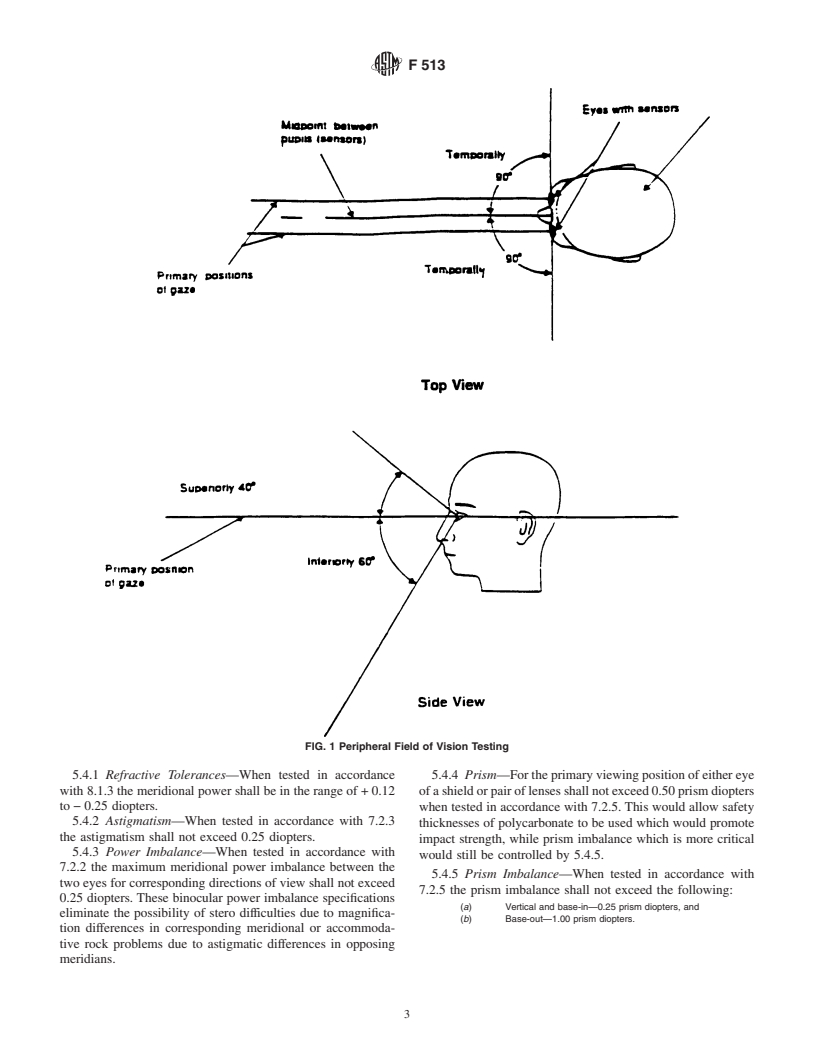

5.4.1 Refractive Tolerances—When tested in accordance 5.4.4 Prism—Fortheprimaryviewingpositionofeithereye

with 8.1.3 the meridional power shall be in the range of+0.12 ofashieldorpairoflensesshallnotexceed0.50prismdiopters

to−0.25 diopters.

when tested in accordance with 7.2.5. This would allow safety

5.4.2 Astigmatism—When tested in accordance with 7.2.3

thicknesses of polycarbonate to be used which would promote

the astigmatism shall not exceed 0.25 diopters.

impact strength, while prism imbalance which is more critical

5.4.3 Power Imbalance—When tested in accordance with

would still be controlled by 5.4.5.

7.2.2 the maximum meridional power imbalance between the

5.4.5 Prism Imbalance—When tested in accordance with

two eyes for corresponding directions of view shall not exceed

7.2.5 the prism imbalance shall not exceed the following:

0.25 diopters. These binocular power imbalance specifications

(a) Vertical and base-in—0.25 prism diopters, and

eliminate the possibility of stero difficulties due to magnifica-

(b) Base-out—1.00 prism diopters.

tion differences in corresponding meridional or accommoda-

tive rock problems due to astigmatic differences in opposing

meridians.

F 513

NOTE 1—Both CRPand CLPare located at the center of the cornea on the respective pupil of the headform and are not located on the surface of the

face protector:

CRP = center of the right pupil,

and

CLP = center of the left pupil.

FIG. 2 Quality Field of Vision

5.4.6 Luminous Transmittance—When tested in accordance toughnesstestfailureconditionsforclearshieldandwiremesh

with7.2.6protectorsshallhavealuminoustransmittanceofnot face protectors as described in 5.5.2 and 5.5.3 shall also apply.

less than 80% for a clear device and not less than 60% for 5.5.1.1 In all cases, a check shall be made to ensure that

tinted devices. Additionally, the difference in values as would there is no chipping, cracking or breakage of the full face

be viewed by the two eyes through a single protector as worn protector or separation of the full face protector from the

shall not exceed 0.9 to 1.1 times the other value (measured at helmet. Such damage shall constitute a failure.

the design line of sight) unless specifically prescribed by an 5.5.2 Toughness Test—Failure Conditions (Clear

ophthalmic professional. Shields)—Aclearshieldshallfailifanyfullthicknesscracksor

fractures occur on any specimen as a result of impact.

5.4.7 Haze—When tested in accordance with 7.2.7 the haze

5.5.3 Toughness Test—Failure Conditions (Wire Mesh

in the protector shall not exceed 38.

Protectors)—A wire mesh protector shall fail if any weld

5.4.8 Optical Quality—Striae, warpage, or surface ripples

completelyseparatesorifanyfractureinthewirebetweenany

within the central viewing zone that are visible under test

two welds occurs on any specimen as a result of impact.

conditions of 7.2.8 and that would impair the function of the

5.6 Penetration Requirements—When tested in accordance

lens shall be cause for rejection. Beyond the central viewing

with 7.4, the test blade shall not penetrate the face protector so

zone, the protective device shall be free of surface ripples,

astotouchthesurfaceoftheheadformwhenenteredwithinthe

lenticulations, haze, and other defects that would impair its

perimeter of the face protector.

intendedfunctions,norshalltherebeabruptopticalchangesin

the area of the protector designed for viewing. These striae

6. Sample Preparation

warpages and ripples shall be evaluated by method 7.2.9.

6.1 Only complete protectors as offered for sale shall be

5.4.9 Surface Imperfections and Internal Defects—Pits,

scratches, grayness, bubbles, cracks, or water marks that are tested.

6.2 Protectors shall be conditioned and tested at the appli-

visibleunderthetestconditionsof7.2.9andthatwouldimpair

the function of the lens shall be cause for rejection. cabletesttemperaturesandatarelativehumiditynotexceeding

55% for a minimum period of 4 h prior to test. If no

5.5 Impact Requirements—All protectors shall be subjected

conditioning temperature is specified, protectors shall be con-

toatotalofsiximpacts by performing one impact oneachone

ditioned at 22.8 6 5°C (73 6 9°F).

ofsixspecimens.Thesiximpactsshallbeinthethreelocations

6.3 Protectors shall be assembled for the test in accordance

specified in 7.3. Conditioning of the samples shall be as

with instructions provided (see 9.1).

specified in 7.3.3.1 for the contact test velocity specified in

6.4 Protector/helmetassembliesshallbemountedonthetest

Table 2, and as specified in 7.3.3.2 for the toughness test

headforminaccordancewiththemanufacturersinstructionsfor

velocity specified in Table 2.

proper fit.

5.5.1 Contact Test—Failure Conditions (All Protectors)—

After the test is complete, the headform shall be examined to

7. Test Methods

determine if the full face protector, or puck contacted the

headform.Contactwiththeheadformexceptinthehatchedand 7.1 Optical Tests (All Protectors):

cross-hatched areas in Fig. 6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.