ASTM B831-22

(Test Method)Standard Test Method for Shear Testing of Thin Aluminum Alloy Products

Standard Test Method for Shear Testing of Thin Aluminum Alloy Products

SIGNIFICANCE AND USE

5.1 The intent of this test method is to provide a means of measuring the ultimate shear strength of thin aluminum alloy wrought and cast products. It is recognized that the loading conditions developed by this test method, and by most others, are not ideal in that they do not strictly satisfy the definitions of pure shear. However, rarely do pure shear conditions exist in structures.

Note 1: Results from this test method are not interchangeable with results from Test Methods B565 and B769. Shear strengths obtained by this test method have been shown to differ from values determined with other methods.3

SCOPE

1.1 This test method covers single shear testing of thin wrought and cast aluminum alloy products to determine shear ultimate strengths. It is intended for products that are too thin to be tested according to Test Method B769.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B831 − 22

Standard Test Method for

1

Shear Testing of Thin Aluminum Alloy Products

This standard is issued under the fixed designation B831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers single shear testing of thin

E691 Practice for Conducting an Interlaboratory Study to

wrought and cast aluminum alloy products to determine shear

Determine the Precision of a Test Method

ultimate strengths. It is intended for products that are too thin

E2208 Guide for Evaluating Non-Contacting Optical Strain

to be tested according to Test Method B769.

Measurement Systems

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions—The definitions of terms relating to me-

and are not considered standard.

chanical testing in Terminology E6 are applicable to the terms

1.3 This standard does not purport to address all of the

used in this test method.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety, health, and environmental practices and deter-

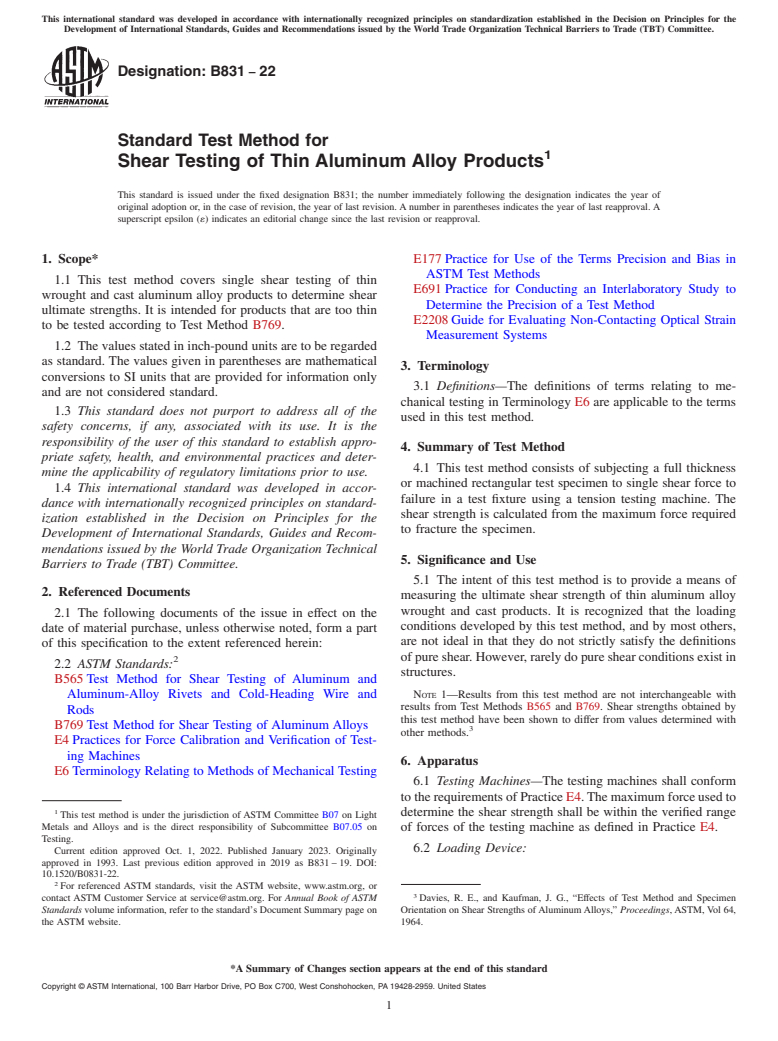

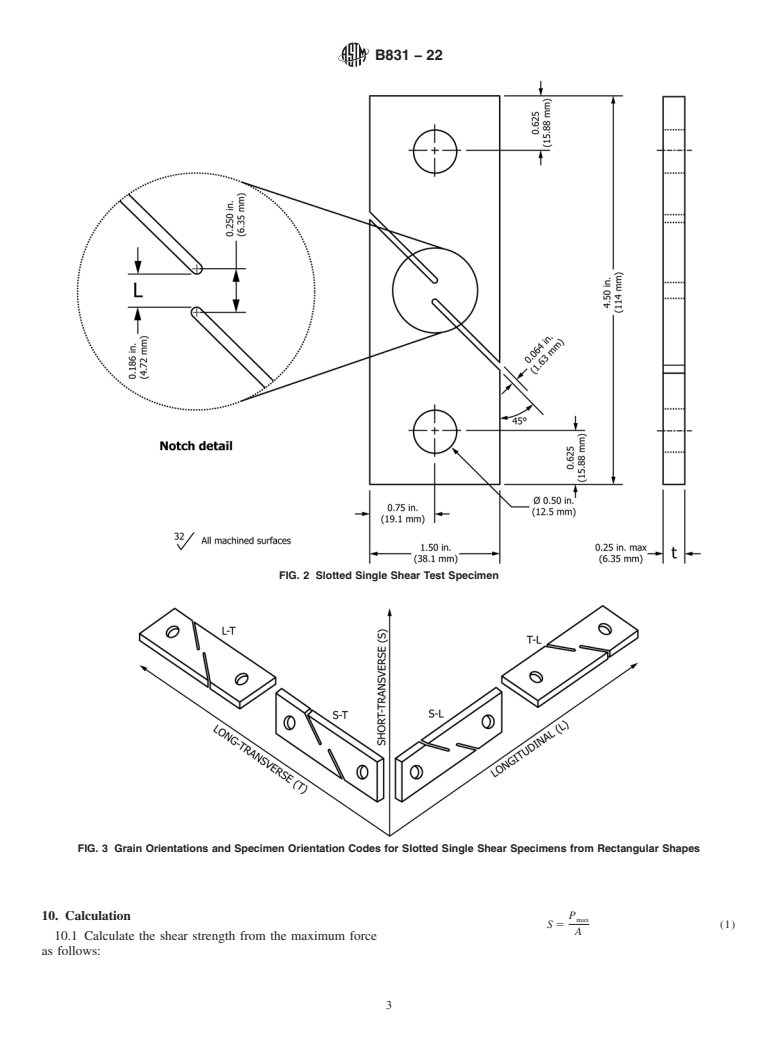

4.1 This test method consists of subjecting a full thickness

mine the applicability of regulatory limitations prior to use.

or machined rectangular test specimen to single shear force to

1.4 This international standard was developed in accor-

failure in a test fixture using a tension testing machine. The

dance with internationally recognized principles on standard-

shear strength is calculated from the maximum force required

ization established in the Decision on Principles for the

to fracture the specimen.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 The intent of this test method is to provide a means of

2. Referenced Documents

measuring the ultimate shear strength of thin aluminum alloy

wrought and cast products. It is recognized that the loading

2.1 The following documents of the issue in effect on the

conditions developed by this test method, and by most others,

date of material purchase, unless otherwise noted, form a part

are not ideal in that they do not strictly satisfy the definitions

of this specification to the extent referenced herein:

ofpureshear.However,rarelydopureshearconditionsexistin

2

2.2 ASTM Standards:

structures.

B565 Test Method for Shear Testing of Aluminum and

NOTE 1—Results from this test method are not interchangeable with

Aluminum-Alloy Rivets and Cold-Heading Wire and

results from Test Methods B565 and B769. Shear strengths obtained by

Rods

this test method have been shown to differ from values determined with

B769 Test Method for Shear Testing of Aluminum Alloys

3

other methods.

E4 Practices for Force Calibration and Verification of Test-

ing Machines

6. Apparatus

E6 Terminology Relating to Methods of Mechanical Testing

6.1 Testing Machines—The testing machines shall conform

totherequirementsofPracticeE4.Themaximumforceusedto

1

determine the shear strength shall be within the verified range

This test method is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on

of forces of the testing machine as defined in Practice E4.

Testing.

6.2 Loading Device:

Current edition approved Oct. 1, 2022. Published January 2023. Originally

approved in 1993. Last previous edition approved in 2019 as B831 – 19. DOI:

10.1520/B0831-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Davies, R. E., and Kaufman, J. G., “Effects of Test Method and Specimen

Standards volume information, refer to the standard’s Document Summary page on Orientation on Shear Strengths ofAluminumAlloys,” Proceedings,ASTM, Vol 64,

the ASTM website. 1964.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B831 − 22

6.2.1 The device for applying force to the spe

...

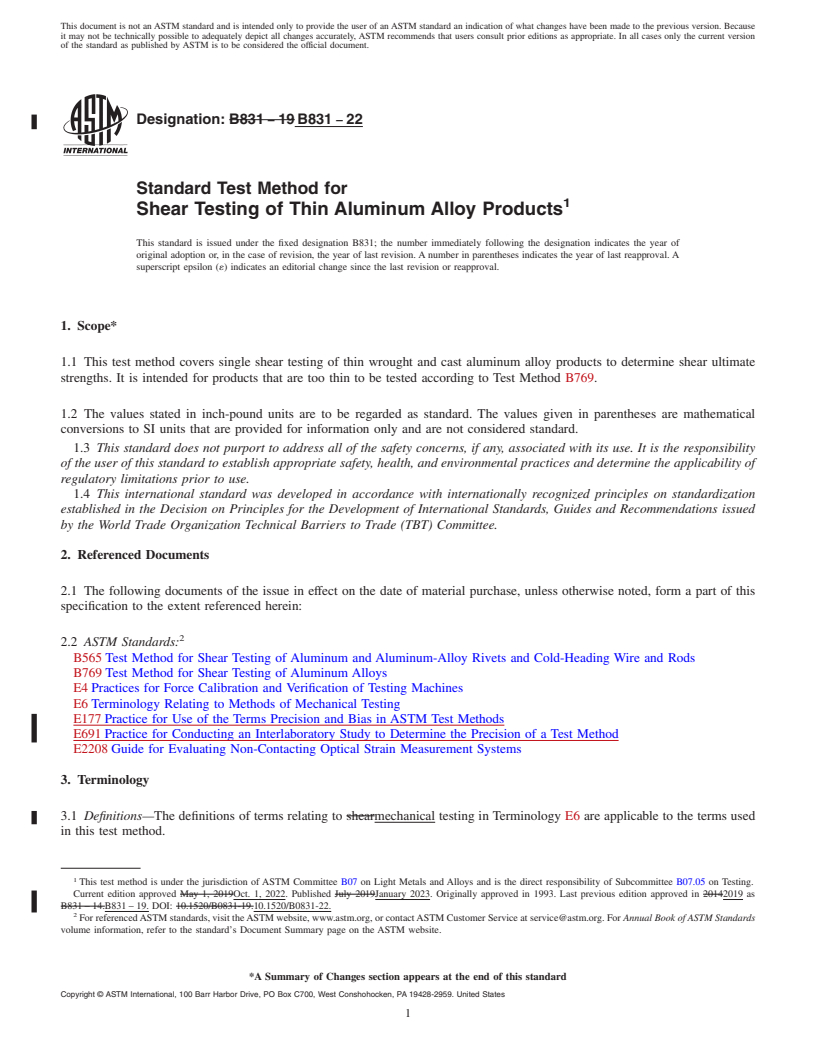

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B831 − 19 B831 − 22

Standard Test Method for

1

Shear Testing of Thin Aluminum Alloy Products

This standard is issued under the fixed designation B831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers single shear testing of thin wrought and cast aluminum alloy products to determine shear ultimate

strengths. It is intended for products that are too thin to be tested according to Test Method B769.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase, unless otherwise noted, form a part of this

specification to the extent referenced herein:

2

2.2 ASTM Standards:

B565 Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Wire and Rods

B769 Test Method for Shear Testing of Aluminum Alloys

E4 Practices for Force Calibration and Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2208 Guide for Evaluating Non-Contacting Optical Strain Measurement Systems

3. Terminology

3.1 Definitions—The definitions of terms relating to shearmechanical testing in Terminology E6 are applicable to the terms used

in this test method.

1

This test method is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on Testing.

Current edition approved May 1, 2019Oct. 1, 2022. Published July 2019January 2023. Originally approved in 1993. Last previous edition approved in 20142019 as

B831 – 14.B831 – 19. DOI: 10.1520/B0831-19.10.1520/B0831-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

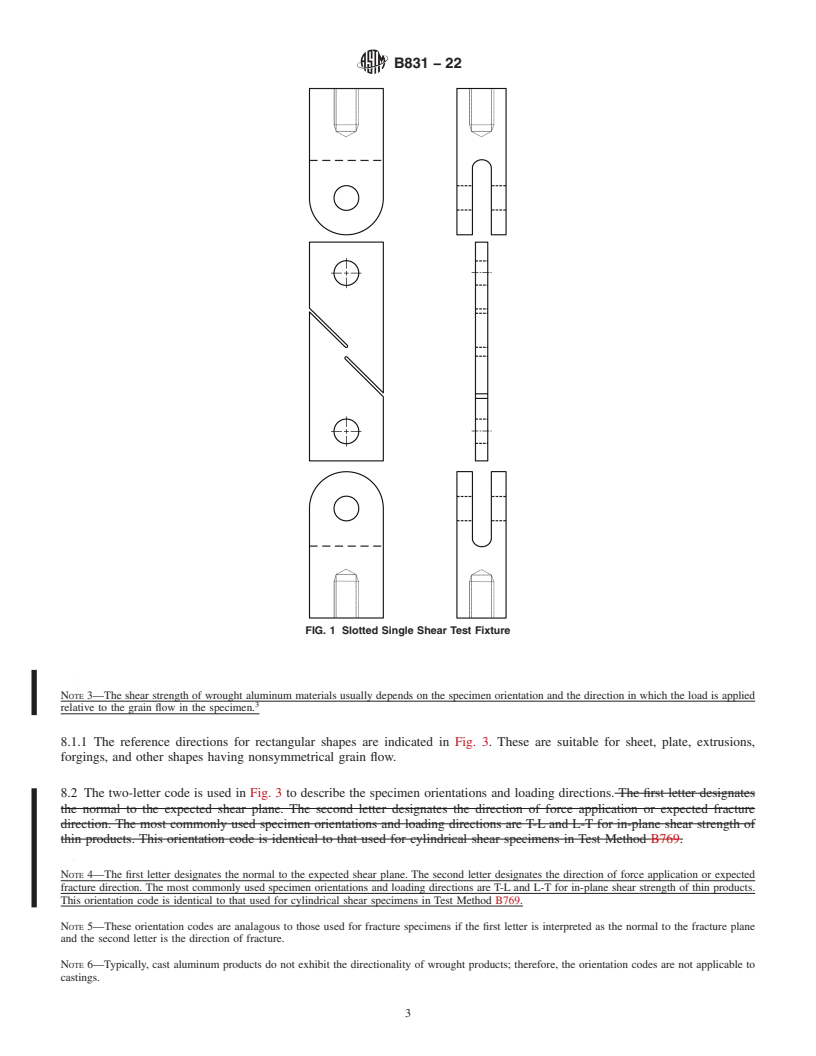

B831 − 22

4. Summary of Test Method

4.1 This test method consists of subjecting a full thickness or machined rectangular test specimen to single shear force to failure

in a test fixture using a tension testing machine. The shear strength is calculated from the maximum force required to fracture the

specimen.

5. Significance and Use

5.1 The intent of this test method is to provide a means of measuring the ultimate shear strength of thin aluminum alloy wrought

and cast products. It is recognized that the loading conditions developed by this test method, and by most others, are not ideal in

that they do not strictly satisfy the definitions of pure shear. However, rarely do pure shear conditions exist in structures.

NOTE 1—Results from this test method are not interchangeable with results from Test Methods B565 and B769. Shear strengths obtained by this test

3

method have been shown to differ from values determined with other methods.

6. Apparatus

6.1 Testing Machines—The testing machines shall conform to the requirements of Practice E4. The maximum force used to

determine the shear strength shall be within the verified force range of forces of the testing machine as defined in Practice E4.

6.2 Loading Device:

6.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.