ASTM B550/B550M-07(2012)

(Specification)Standard Specification for Zirconium and Zirconium Alloy Bar and Wire

Standard Specification for Zirconium and Zirconium Alloy Bar and Wire

ABSTRACT

This specification covers three grades of zirconium and zirconium alloy bar and wire as grade R60702, unalloyed zirconium; grade R60704, zirconium-tin; and grade R60705, zirconium-niobium. The chemical composition; and mechanical properties requirements, such as tensile strength, yield strength, and elongation; are detailed.

SCOPE

1.1 This specification covers three grades of zirconium and zirconium alloy bar and wire.

1.2 Unless a single unit is used, for example corrosion mass gain in mg/dm2, the values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. SI values cannot be mixed with inch-pound values.

1.3 The following precautionary caveat pertains only to the test methods portions of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B550/B550M −07(Reapproved 2012)

Standard Specification for

Zirconium and Zirconium Alloy Bar and Wire

This standard is issued under the fixed designation B550/B550M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope same heat treatment parameters. Unless otherwise agreed

between manufacturer and purchaser, a lot shall be limited to

1.1 This specification covers three grades of zirconium and

the product of an 8 h period for final continuous anneal, or to

zirconium alloy bar and wire.

a single furnace load for final batch anneal.

1.2 Unless a single unit is used, for example corrosion mass

2 3.2.2 Forms:

gain in mg/dm , the values stated in either inch-pound or SI

3.2.2.1 bar, n—a hot rolled, forged, or cold worked semi-

units are to be regarded separately as standard. The values

finished solid section product whose cross sectional area is

stated in each system are not exact equivalents; therefore each

2 2

equaltoorlessthan16in. [10323mm ];rectangularbarmust

system must be used independently of the other. SI values

be less than or equal to 10 in. [254 mm] in width and greater

cannot be mixed with inch-pound values.

than 0.1875 in. [4.8 mm] in thickness.

1.3 The following precautionary caveat pertains only to the

3.2.2.2 wire, n—rounds, flats, or special shapes less than or

test methods portions of this specification.This standard does

equal to 0.1875 in. [4.8 mm] in thickness or major dimension.

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

4. Classification

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

4.1 The bar or wire is to be furnished in three grades as

to use.

follows:

4.1.1 Grade R60702—Unalloyed zirconium.

2. Referenced Documents

4.1.2 Grade R60704—Zirconium-tin.

2.1 ASTM Standards:

4.1.3 Grade R60705—Zirconium-niobium.

E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to

5. Ordering Information

Determine Conformance with Specifications

5.1 Orders for material under this specification should

include the following information:

3. Terminology

5.1.1 Quantity (weight or number of pieces),

3.1 Definitions of Terms Specific to This Standard:

5.1.2 Name of material (zirconium bar or wire) (Table 1),

3.1.1 annealed, n—denotes material that exhibits a recrys-

5.1.3 Grade number (see 4.1),

tallized grain structure.

5.1.4 Standard designation and year of issue, for example

3.2 Lot Definitions:

ASTM Specification B550/B550M- 07, and

3.2.1 bar and wire, n—a lot shall consist of a material of the

5.1.5 Additions to the specification as required.

same size, shape, condition, and finish produced from the same

NOTE 1—Atypical ordering description is as follows: 1000 lb [500 kg]

ingot or powder blend by the same reduction schedule and the

zirconium cold drawn bar, 0.35 in. [10 mm] in diameter by 10 ft [3 m] in

length, ASTM B550 - 01, Grade R60702.

This specification is under the jurisdiction of ASTM Committee B10 on

6. Materials and Manufacture

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.02 on Zirconium and Hafnium.

6.1 Bar and wire covered by this specification shall be

Current edition approved May 1, 2012. Published May 2012. Originally

formed with conventional fabrication methods and equipment

approved in 1971. Last previous edition approved in 2007 as B550/B550M – 07.

found in primary ferrous and nonferrous metal plants.

DOI: 10.1520/B0550_B0550M-07R12.

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

6.2 The products covered include the sections and sizes

cation SB-550 in Section II of that Code.

shown in Table 1.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Bar and wire will be supplied in the conditions pre-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. scribed in Table 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B550/B550M−07(2012)

TABLE 1 Product Sections and Size

Product Section Size

Bars: Hot-finished round, squares, octagons, and hexagons ⁄4 in. [6.4 mm] and over in diameter or size

1 1

Hot-finished flats ⁄4 in. [6.4 mm] to 10 in. [250 mm], incl, in width, and ⁄8

in. [3.2 mm] and over in thickness

A

Cold-finished rounds, squares, octagons, hexagons, and Over ⁄2 in. [13 mm] in diameter or size

shapes

B

3 1

Cold-finished flats ⁄8 in. [9.5 mm] and over in width, and ⁄8 in. [3.2 mm]

C

and over in thickness

Wire: Cold-finished rounds, squares, octagons, hexagons, and ⁄2 in. [13 mm] and under in diameter or size

shapes

1 3

Cold-finished flats ⁄16 in. [1.6 mm] to under ⁄8 in. [9.5 mm] in width, and

0.010 in. [.25 mm] to under ⁄16 in. [4.8 mm] in

thickness

A 1

Sizes ⁄2 in. [13 mm] and under are wire when in coils, and cut wire when finished in straight lengths.

B

3 3

Widths less than ⁄8 in. [9.5 mm] and thicknesses less than ⁄16 in. [4.8 mm] are generally described as flat wire.

C 1 3

Thickness ⁄8 in. [3.2 mm] to under ⁄16 in. [4.8 mm] can be cold-rolled strip as well as bar.

TABLE 2 Condition

9.1.5 Table 10, Permissible Variations in Sectional Dimen-

Form Condition sions for Wire.

Bars hot finished

9.1.6 Table 11, Permissible Variations in Thickness and

hot finished and annealed

Width for Cold-Finished Flat Wire.

cold finished

cold finished and annealed

9.1.7 Table 12, Permissible Variations in Length for Hot-

Wire cold finished

Finished or Cold-Finished Bars.

cold finished and annealed

9.1.8 Table 13, Permissible Variations in Length for Round

and Shape, Straightened and Cut Wire, and Exact Length

Resheared Wire.

7. Chemical Composition

9.1.9 Table 14, Permissible Variations in Straightness for

7.1 The material shall conform to the requirements as to

Hot- or Cold-Finished Bars.

chemical composition prescribed in Table 3.

10. Workmanship, Finish, and Appearance

7.2 The manufacturer’s ingot analysis shall be considered

thechemicalanalysisforbarandwire,exceptforhydrogenand

10.1 Bars in the hot-finished condition which will conform

nitrogen, which shall be determined on the finished product.

to the tolerances prescribed in Tables 6 and 7, shall be

furnished with one of the following finishes as designated on

7.3 When requested by the purchaser and stated in the

the purchase order:

purchase order, a product analysis for any elements listed in

Table 3 shall be made on the finished product. 10.1.1 Not descaled,

7.3.1 The manufacturer’s analysis shall be considered as

10.1.2 Mechanically descaled,

verified if the check analysis confirms the manufacturer’s

10.1.3 Mechanically descaled and pickled, and

reported values within the tolerances prescribed in Table 4.

10.1.4 Turned (round bars only).

8. Mechanical Properties

10.2 Bars and wire in cold-finished condition that will

conform to the tolerances prescribed in Tables 8-12, shall be

8.1 Theannealedmaterialshallconformtotherequirements

furnished with one of the following finishes as designated on

for mechanical properties, at room temperature, as prescribed

the purchase order.

in Table 5. Wire supplied for welding applications shall be

10.2.1 Cold drawn or cold rolled, or swaged,

furnished with a temper suitable for uniform feeding in

10.2.2 Turned (round bars only),

semiautomatic or automatic welding equipment.

10.2.3 Centerless ground (round bars only), and

9. Permissible Variations in Dimensions

10.2.4 Polished (round bars only).

9.1 Unless otherwise specified, all bar or wire shall conform

10.3 Bars or wire shall be free of cracks, seams, slivers,

tothepermissiblevariationsindimensionsprescribedinTables

blisters, burrs, and other injurious imperfections in accordance

6-14, as follows:

with standards of acceptability agreed upon between the

9.1.1 Table 6, Dimensional Tolerances for Hot-Finished

manufacturer and the purchaser.

Rounds, Squares, Octagons, and Hexagons.

9.1.2 Table 7, Dimensional Tolerances in Hot-Rolled Flat

11. Significance of Numerical Limits

Bars.

9.1.3 Table 8, Permissible Variations in Sectional Dimen- 11.1 For the purpose of determining compliance with the

sions for Cold-Finished Bars in Rounds, Hexagons, Octagons, specified limits for requirements of the properties listed in the

and Squares. following table, an observed value or a calculated value shall

9.1.4 Table 9, Permissible Variations in Width and Thick- be rounded as indicated in accordance with the rounding

ness for Cold-Finished Bars in Flats. methods of Practice E29.

B550/B550M−07(2012)

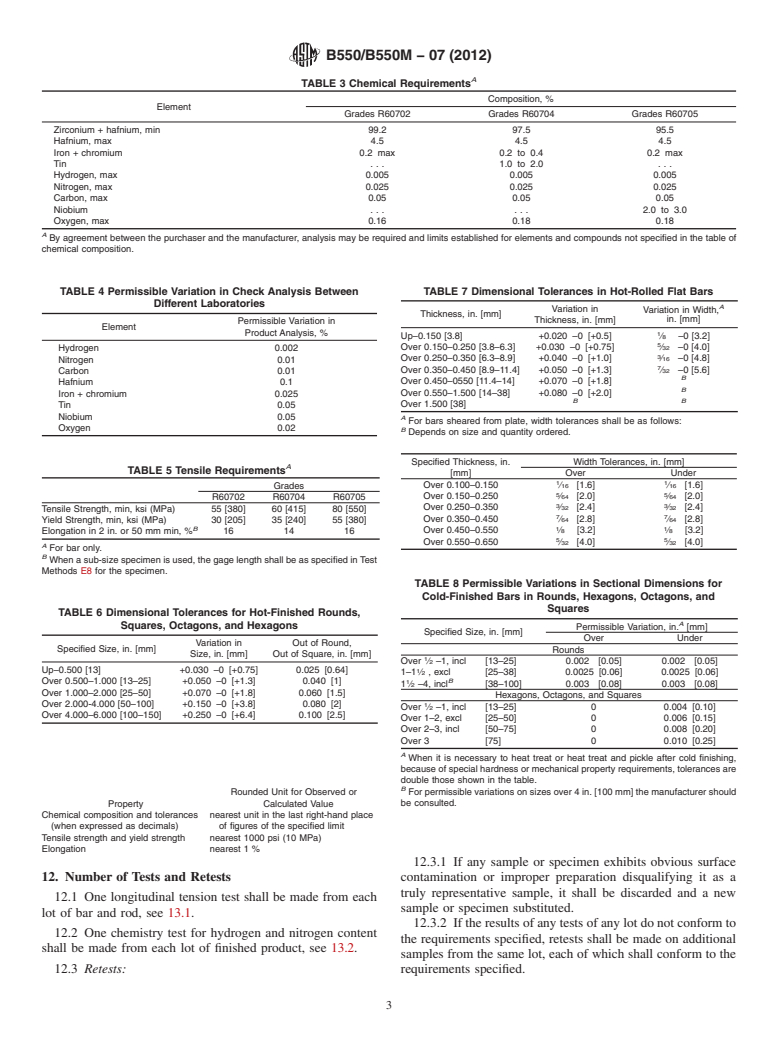

A

TABLE 3 Chemical Requirements

Composition, %

Element

Grades R60702 Grades R60704 Grades R60705

Zirconium + hafnium, min 99.2 97.5 95.5

Hafnium, max 4.5 4.5 4.5

Iron + chromium 0.2 max 0.2 to 0.4 0.2 max

Tin . 1.0 to 2.0 .

Hydrogen, max 0.005 0.005 0.005

Nitrogen, max 0.025 0.025 0.025

Carbon, max 0.05 0.05 0.05

Niobium . . . . . . 2.0 to 3.0

Oxygen, max 0.16 0.18 0.18

A

By agreement between the purchaser and the manufacturer, analysis may be required and limits established for elements and compounds not specified in the table of

chemical composition.

TABLE 4 Permissible Variation in Check Analysis Between TABLE 7 Dimensional Tolerances in Hot-Rolled Flat Bars

Different Laboratories

A

Variation in

Variation in Width,

Thickness, in. [mm]

in. [mm]

Thickness, in. [mm]

Permissible Variation in

Element

Product Analysis, % 1

Up–0.150 [3.8] +0.020 –0 [+0.5] ⁄8 –0 [3.2]

Over 0.150–0.250 [3.8–6.3] +0.030 –0 [+0.75] ⁄32 –0 [4.0]

Hydrogen 0.002

Over 0.250–0.350 [6.3–8.9] +0.040 –0 [+1.0] ⁄16 –0 [4.8]

Nitrogen 0.01

Over 0.350–0.450 [8.9–11.4] +0.050 –0 [+1.3] ⁄32 –0 [5.6]

Carbon 0.01

B

Over 0.450–0550 [11.4–14] +0.070 –0 [+1.8]

Hafnium 0.1

B

Over 0.550–1.500 [14–38] +0.080 –0 [+2.0]

Iron + chromium 0.025

BB

Over 1.500 [38]

Tin 0.05

Niobium 0.05 A

For bars sheared from plate, width tolerances shall be as follows:

Oxygen 0.02

B

Depends on size and quantity ordered.

Specified Thickness, in. Width Tolerances, in. [mm]

A

TABLE 5 Tensile Requirements

[mm] Over Under

1 1

Over 0.100–0.150 ⁄16 [1.6] ⁄16 [1.6]

Grades

5 5

Over 0.150–0.250 ⁄64 [2.0] ⁄64 [2.0]

R60702 R60704 R60705

3 3

Over 0.250–0.350 ⁄32 [2.4] ⁄32 [2.4]

Tensile Strength, min, ksi (MPa) 55 [380] 60 [415] 80 [550]

7 7

Over 0.350–0.450 ⁄64 [2.8] ⁄64 [2.8]

Yield Strength, min, ksi (MPa) 30 [205] 35 [240] 55 [380]

B 1 1

Over 0.450–0.550 ⁄8 [3.2] ⁄8 [3.2]

Elongation in 2 in. or 50 mm min, % 16 14 16

5 5

Over 0.550–0.650 ⁄32 [4.0] ⁄32 [4.0]

A

For bar only.

B

When a sub-size specimen is used, the gage length shall be as specified inTest

Methods E8 for the specimen.

TABLE 8 Permissible Variations in Sectional Dimensions for

Cold-Finished Bars in Rounds, Hexagons, Octagons, and

Squares

TABLE 6 Dimensional Tolerances for Hot-Finished Rounds,

A

Squares, Octagons, and Hexagons Permissible Variation, in. [mm]

Specified Size, in. [mm]

Over Under

Variation in Out of Round,

Specified Size, in. [mm] Rounds

Size, in. [mm] Out of Square, in. [mm]

Over ⁄2 –1, incl [13–25] 0.002 [0.05] 0.002 [0.05]

Up–0.500 [13] +0.030 –0 [+0.75] 0.025 [0.64] 1

1–1 ⁄2 , excl [25–38] 0.0025 [0.06] 0.0025 [0.06]

B

Over 0.500–1.000 [13–25] +0.050 –0 [+1.3] 0.040 [1] 1

1 ⁄2 –4, incl [38–100] 0.003 [0.08] 0.003 [0.08]

Over 1.000–2.000 [25–50] +0.070 –0 [+1.8] 0.060 [1.5]

Hexagons, Octagons, and Squares

Over 2.000-4.000 [50–100] +0.150 –0 [+3.8] 0.080 [2] 1

Over ⁄2 –1, incl [13–25] 0 0.004 [0.10]

Over 4.000–6.000 [100–150] +0.250 –0 [+6.4] 0.100 [2.5]

Over 1–2, excl [25–50] 0 0.006 [0.15]

Over 2–3, incl [50–75] 0 0.008 [0.20]

Over 3 [75] 0 0.010 [0.25]

A

When it is necessary to heat treat or heat treat and pickle after cold finishing,

becauseofspecialhardnessormechanicalpropertyrequirements,tolerancesare

double those shown in the table.

B

For permissible variations on sizes over 4 in. [100 mm] the manufacturer should

Rounded Unit for Observed or

Property Calculated Value be consulted.

Chemical composition and tolerances nearest unit in the last right-hand place

(when expressed as decimals) of figures of the specified limit

Tensile strength and yield strength nearest 1000 psi (10 MPa)

Elongation nearest 1 %

12.3.1 If any sample or specimen exhibits obvious surface

12. Number of Tests and Retests contamination or improper preparation disqualifying it as a

truly representative sample, it shall be discarded and a new

12.1 One longitudinal tension test shall be made from each

sample or specimen substituted.

lot of bar and rod, see 13.1.

12.3.2 If the results of any tests of any lot do not conform to

12.2 One chemistry test for hydrogen and nitrogen content

the requirements specified, retests shall be made on additional

shall be made from each lot of finished product, see 13.2.

samples from the same lot, each of which shall conform to the

12.3 Retests: requirements specified.

B550/B550M−07(2012)

TABLE 9 Permissible Variations in Width and Thickness for Cold-

14. Inspection

Finished Bars in Flats

14.1 The manufacturer shall inspect the material covered by

Permissible Variations in Width for

this specification prior to shipment. If so specified in the

Thicknesses Given, Over and Under,

Width, in. [mm]

A

in. [mm]

purchaseorder,thepurchaserorhisrepresentativemaywitness

1 1

⁄4 [6.4] and under Over ⁄4 [6.4]

the testing and inspection of the material at the place of

Width

3 manufacture. In such cases the purchaser shall state in his

⁄8 –1, incl 0.004 [0.10] 0.002 [0.05]

Over 1–2, incl 0.006 [0.15] 0.003 [0.08]

purchase order which tests he desires to witness. The manu-

Over 2–3, incl 0.008 [0.20] 0.004 [0.10]

facturer shall give ample notice to the purchaser as to the time

B

Over 3–4 ⁄2, incl 0.010 [0.25] 0.005 [0.13]

and place of the designated tests. If the purchaser’s represen-

Thickness

Permissible Variations in Thickness

tative does not present himself at the time agreed upon for the

Thickness, in. [mm]

A

Over and Under, in. [mm]

testing, the manufacturer shall consider the requirement for

⁄8 –1, incl [3.2-25] 0.002 [0.05]

purchaser’s inspection at the place of manufacture to be

Over 1–2, incl [25–50] 0.003 [0.08]

Over 2–3, incl [50–75] 0.004 [0.10]

waived.

B

Over 3–4 ⁄2, incl [75–115] 0.005 [0.13]

14.2 The manufacturer shall afford the inspector represent-

A

When it is necessary to heat treat and pickle afte

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B550/B550M–07 Designation: B550/B550M – 07 (Reapproved 2012)

Standard Specification for

Zirconium and Zirconium Alloy Bar and Wire

This standard is issued under the fixed designation B550/B550M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers three grades of zirconium and zirconium alloy bar and wire.

1.2 Unless a single unit is used, for example corrosion mass gain in mg/dm , the values stated in either inch-pound or SI units

are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must

be used independently of the other. SI values cannot be mixed with inch-pound values.

1.3 The following precautionary caveat pertains only to the test methods portions of this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 annealed, n—denotes material that exhibits a recrystallized grain structure.

3.2 Lot Definitions:

3.2.1 bar and wire, n—a lot shall consist of a material of the same size, shape, condition, and finish produced from the same

ingot or powder blend by the same reduction schedule and the same heat treatment parameters. Unless otherwise agreed between

manufacturer and purchaser, a lot shall be limited to the product of an 8 h period for final continuous anneal, or to a single furnace

load for final batch anneal.

3.2.2 Forms:

3.2.2.1 bar, n—a hot rolled, forged, or cold worked semifinished solid section product whose cross sectional area is equal to

2 [10 323 mm

or less than 16 in. (10 323 mm );]; rectangular bar must be less than or equal to 10 in. (254 mm)[254 mm] in width and

greater than 0.1875 in. (4.8 mm)[4.8 mm] in thickness.

3.2.2.2 wire, n—rounds, flats, or special shapes less than or equal to 0.1875 in. (4.8 mm)[4.8 mm] in thickness or major

dimension.

4. Classification

4.1 The bar or wire is to be furnished in three grades as follows:

4.1.1 Grade R60702—Unalloyed zirconium.

4.1.2 Grade R60704—Zirconium-tin.

4.1.3 Grade R60705—Zirconium-niobium.

5. Ordering Information

5.1 Orders for material under this specification should include the following information:

5.1.1 Quantity (weight or number of pieces),

5.1.2 Name of material (zirconium bar or wire) (Table 1),

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.02 on Zirconium and Hafnium.

Current edition approved May 1, 2007.2012. Published May 2007.2012. Originally approved in 1971. Last previous edition approved in 20022007 as B550/B550M – 027.

DOI: 10.1520/B0550_B0550M-07R12.

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-550 in Section II of that Code.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B550/B550M – 07 (2012)

TABLE 1 Product Sections and Size

Product Section Size

Bars: Hot-finished round, squares, octagons, and hexagons ⁄4 in. (6.4 mm) and over in diameter or size

Bars: Hot-finished round, squares, octagons, and hexagons ⁄4 in. [6.4 mm] and over in diameter or size

1 1

Hot-finished flats ⁄4 in. (6.4 mm) to 10 in. (250 mm), incl, in width, and ⁄8

in. (3.2 mm) and over in thickness

1 1

Hot-finished flats ⁄4 in. [6.4 mm] to 10 in. [250 mm], incl, in width, and ⁄8

in. [3.2 mm] and over in thickness

A

Cold-finished rounds, squares, octagons, hexagons, and Over ⁄2 in. (13 mm) in diameter or size

shapes

A

Cold-finished rounds, squares, octagons, hexagons, and Over ⁄2 in. [13 mm] in diameter or size

shapes

B

3 1

Cold-finished flats ⁄8 in. (9.5 mm) and over in width, and ⁄8 in. (3.2 mm)

C

and over in thickness

B

3 1

Cold-finished flats ⁄8 in. [9.5 mm] and over in width, and ⁄8 in. [3.2 mm]

C

and over in thickness

Wire: Cold-finished rounds, squares, octagons, hexagons, and ⁄2 in. (13 mm) and under in diameter or size

shapes

Wire: Cold-finished rounds, squares, octagons, hexagons, and ⁄2 in. [13 mm] and under in diameter or size

shapes

1 3

Cold-finished flats ⁄16 in. (1.6 mm) to under ⁄8 in. (9.5 mm) in width, and

0.010 in. (.25 mm) to under ⁄16 in. (4.8 mm) in

thickness

1 3

Cold-finished flats ⁄16 in. [1.6 mm] to under ⁄8 in. [9.5 mm] in width, and

0.010 in. [.25 mm] to under ⁄16 in. [4.8 mm] in

thickness

A

Sizes ⁄2 in. ( [13 mm)] and under are wire when in coils, and cut wire when finished in straight lengths.

B

3 3

Widths less than ⁄8 in. ( [9.5 mm)] and thicknesses less than ⁄16 in. ( [4.8 mm)] are generally described as flat wire.

C

1 3

Thickness ⁄8 in. ( [3.2 mm)] to under ⁄16 in. ( [4.8 mm)] can be cold-rolled strip as well as bar.

5.1.3 Grade number (see 4.1),

5.1.4 Standard designation and year of issue, for example ASTM Specification B550/B550M-07, and

5.1.5 Additions to the specification as required.

NOTE 1—A typical ordering description is as follows: 1000 lb (500 kg)[500 kg] zirconium cold drawn bar, 0.35 in. (10 mm)[10 mm] in diameter by

10 ft (3 m)[3 m] in length, ASTM B550 - 01, Grade R60702.

6. Materials and Manufacture

6.1 Bar and wire covered by this specification shall be formed with conventional fabrication methods and equipment found in

primary ferrous and nonferrous metal plants.

6.2 The products covered include the sections and sizes shown in Table 1.

6.3 Bar and wire will be supplied in the conditions prescribed in Table 2.

7. Chemical Composition

7.1 The material shall conform to the requirements as to chemical composition prescribed in Table 3.

7.2 The manufacturer’s ingot analysis shall be considered the chemical analysis for bar and wire, except for hydrogen and

nitrogen, which shall be determined on the finished product.

7.3 When requested by the purchaser and stated in the purchase order, a product analysis for any elements listed inTable 3 shall

be made on the finished product.

7.3.1 The manufacturer’s analysis shall be considered as verified if the check analysis confirms the manufacturer’s reported

values within the tolerances prescribed in Table 4.

8. Mechanical Properties

8.1 The annealed material shall conform to the requirements for mechanical properties, at room temperature, as prescribed in

Table 5. Wire supplied for welding applications shall be furnished with a temper suitable for uniform feeding in semiautomatic

or automatic welding equipment.

TABLE 2 Condition

Form Condition

Bars hot finished

hot finished and annealed

cold finished

cold finished and annealed

Wire cold finished

cold finished and annealed

B550/B550M – 07 (2012)

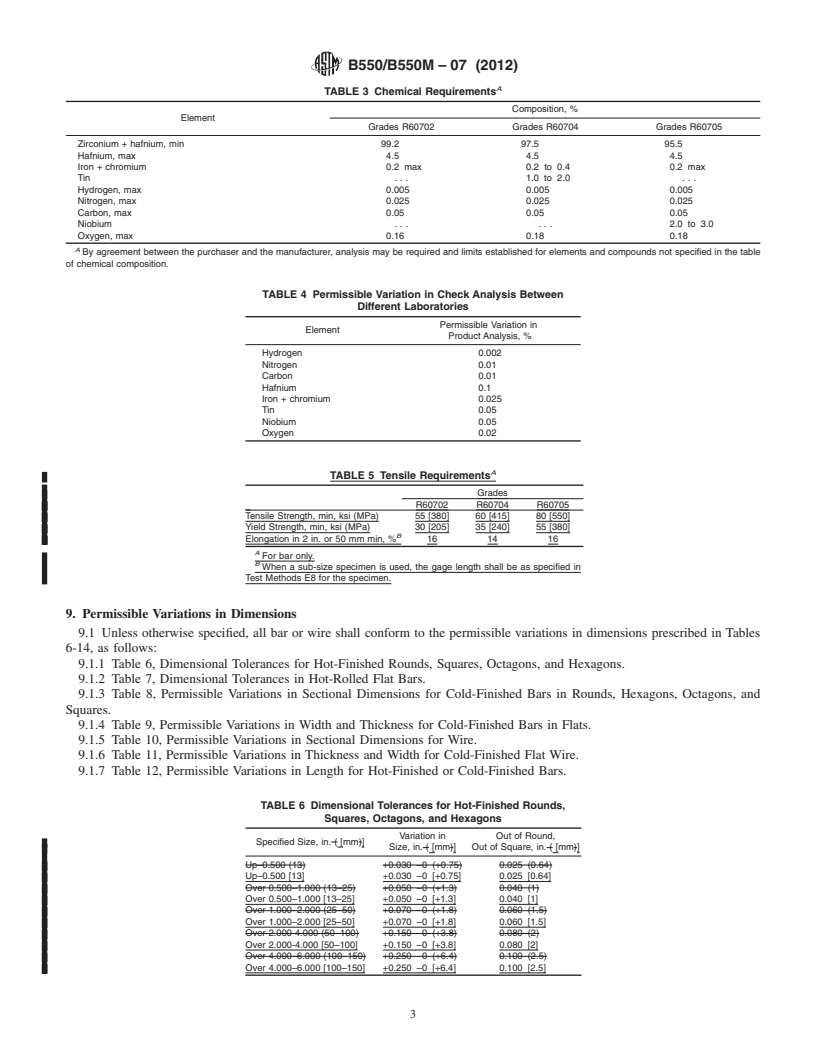

A

TABLE 3 Chemical Requirements

Composition, %

Element

Grades R60702 Grades R60704 Grades R60705

Zirconium + hafnium, min 99.2 97.5 95.5

Hafnium, max 4.5 4.5 4.5

Iron + chromium 0.2 max 0.2 to 0.4 0.2 max

Tin . 1.0 to 2.0 .

Hydrogen, max 0.005 0.005 0.005

Nitrogen, max 0.025 0.025 0.025

Carbon, max 0.05 0.05 0.05

Niobium . . . . . . 2.0 to 3.0

Oxygen, max 0.16 0.18 0.18

A

By agreement between the purchaser and the manufacturer, analysis may be required and limits established for elements and compounds not specified in the table

of chemical composition.

TABLE 4 Permissible Variation in Check Analysis Between

Different Laboratories

Permissible Variation in

Element

Product Analysis, %

Hydrogen 0.002

Nitrogen 0.01

Carbon 0.01

Hafnium 0.1

Iron + chromium 0.025

Tin 0.05

Niobium 0.05

Oxygen 0.02

A

TABLE 5 Tensile Requirements

Grades

R60702 R60704 R60705

Tensile Strength, min, ksi (MPa) 55 [380] 60 [415] 80 [550]

Yield Strength, min, ksi (MPa) 30 [205] 35 [240] 55 [380]

B

Elongation in 2 in. or 50 mm min, % 16 14 16

A

For bar only.

B

When a sub-size specimen is used, the gage length shall be as specified in

Test Methods E8 for the specimen.

9. Permissible Variations in Dimensions

9.1 Unless otherwise specified, all bar or wire shall conform to the permissible variations in dimensions prescribed in Tables

6-14, as follows:

9.1.1 Table 6, Dimensional Tolerances for Hot-Finished Rounds, Squares, Octagons, and Hexagons.

9.1.2 Table 7, Dimensional Tolerances in Hot-Rolled Flat Bars.

9.1.3 Table 8, Permissible Variations in Sectional Dimensions for Cold-Finished Bars in Rounds, Hexagons, Octagons, and

Squares.

9.1.4 Table 9, Permissible Variations in Width and Thickness for Cold-Finished Bars in Flats.

9.1.5 Table 10, Permissible Variations in Sectional Dimensions for Wire.

9.1.6 Table 11, Permissible Variations in Thickness and Width for Cold-Finished Flat Wire.

9.1.7 Table 12, Permissible Variations in Length for Hot-Finished or Cold-Finished Bars.

TABLE 6 Dimensional Tolerances for Hot-Finished Rounds,

Squares, Octagons, and Hexagons

Variation in Out of Round,

Specified Size, in. ( [mm)]

Size, in. ( [mm)] Out of Square, in. ( [mm)]

Up–0.500 (13) +0.030 –0 (+0.75) 0.025 (0.64)

Up–0.500 [13] +0.030 –0 [+0.75] 0.025 [0.64]

Over 0.500–1.000 (13–25) +0.050 –0 (+1.3) 0.040 (1)

Over 0.500–1.000 [13–25] +0.050 –0 [+1.3] 0.040 [1]

Over 1.000–2.000 (25–50) +0.070 –0 (+1.8) 0.060 (1.5)

Over 1.000–2.000 [25–50] +0.070 –0 [+1.8] 0.060 [1.5]

Over 2.000-4.000 (50–100) +0.150 –0 (+3.8) 0.080 (2)

Over 2.000-4.000 [50–100] +0.150 –0 [+3.8] 0.080 [2]

Over 4.000–6.000 (100–150) +0.250 –0 (+6.4) 0.100 (2.5)

Over 4.000–6.000 [100–150] +0.250 –0 [+6.4] 0.100 [2.5]

B550/B550M – 07 (2012)

TABLE 7 Dimensional Tolerances in Hot-Rolled Flat Bars

A

Variation in Variation in Width,

Thickness, in. [mm]

Thickness, in. [mm] in. [mm]

Up–0.150 [3.8] +0.020 –0 [+0.5] ⁄8 –0 [3.2]

Over 0.150–0.250 [3.8–6.3] +0.030 –0 [+0.75] ⁄32 –0 [4.0]

Over 0.250–0.350 [6.3–8.9] +0.040 –0 [+1.0] ⁄16 –0 [4.8]

Over 0.350–0.450 [8.9–11.4] +0.050 –0 [+1.3] ⁄32 –0 [5.6]

B

Over 0.450–0550 [11.4–14] +0.070 –0 [+1.8]

B

Over 0.550–1.500 [14–38] +0.080 –0 [+2.0]

B B

Over 1.500 [38]

A

For bars sheared from plate, width tolerances shall be as follows:

B

Depends on size and quantity ordered.

Width Tolerances, in. [mm]

Specified Thickness, in.

[mm]

Over Under

1 1

Over 0.100–0.150 ⁄16 [1.6] ⁄16 [1.6]

5 5

Over 0.150–0.250 ⁄64 [2.0] ⁄64 [2.0]

3 3

Over 0.250–0.350 ⁄32 [2.4] ⁄32 [2.4]

7 7

Over 0.350–0.450 ⁄64 [2.8] ⁄64 [2.8]

1 1

Over 0.450–0.550 ⁄8 [3.2] ⁄8 [3.2]

5 5

Over 0.550–0.650 ⁄32 [4.0] ⁄32 [4.0]

TABLE 8 Permissible Variations in Sectional Dimensions for

Cold-Finished Bars in Rounds, Hexagons, Octagons, and

Squares

A

Permissible Variation, in. ([mm)]

Specified Size, in. ( [mm)]

Over Under

Rounds

Over ⁄2 –1, incl (13–25) 0.002 (0.05) 0.002 (0.05)

Over ⁄2 –1, incl [13–25] 0.002 [0.05] 0.002 [0.05]

1–1 ⁄2 , excl (25–38) 0.0025 (0.06) 0.0025 (0.06)

1–1 ⁄2 , excl [25–38] 0.0025 [0.06] 0.0025 [0.06]

B

1 ⁄2 –4, incl (38–100) 0.003 (0.08) 0.003 (0.08)

B

1 ⁄2 –4, incl [38–100] 0.003 [0.08] 0.003 [0.08]

Hexagons, Octagons, and Squares

Over ⁄2 –1, incl (13–25) 0 0.004 (0.10)

Over ⁄2 –1, incl [13–25] 0 0.004 [0.10]

Over 1–2, excl (25–50) 0 0.006 (0.15)

Over 1–2, excl [25–50] 0 0.006 [0.15]

Over 2–3, incl (50–75) 0 0.008 (0.20)

Over 2–3, incl [50–75] 0 0.008 [0.20]

Over 3 (75) 0 0.010 (0.25)

Over 3 [75] 0 0.010 [0.25]

A

When it is necessary to heat treat or heat treat and pickle after cold finishing,

because of special hardness or mechanical property requirements, tolerances are

double those shown in the table.

B

For permissible variations on sizes over 4 in. ( [100 mm)] the manufacturer

should be consulted.

9.1.8 Table 13, PermissibleVariations in Length for Round and Shape, Straightened and CutWire, and Exact Length Resheared

Wire.

9.1.9 Table 14, Permissible Variations in Straightness for Hot- or Cold-Finished Bars.

10. Workmanship, Finish and Appearance

10.1 Barsinthehot-finishedconditionwhichwillconformtothetolerancesprescribedinTables6and7,shallbefurnishedwith

one of the following finishes as designated on the purchase order:

10.1.1 Not descaled,

10.1.2 Mechanically descaled,

10.1.3 Mechanically descaled and pickled, and

10.1.4 Turned (round bars only).

10.2 Bars and wire in cold-finished condition that will conform to the tolerances prescribed in Tables 8-12, shall be furnished

with one of the following finishes as designated on the purchase order.

10.2.1 Cold drawn or cold rolled, or swaged,

10.2.2 Turned (round bars only),

10.2.3 Centerless ground (round bars only), and

10.2.4 Polished (round bars only).

10.3 Bars or wire shall be free of cracks, seams, slivers, blisters, burrs, and other injurious imperfections in accordance with

standards of acceptability agreed upon between the manufacturer and the purchaser.

B550/B550M – 07 (2012)

TABLE 9 Permissible Variations in Width and Thickness for

Cold-Finished Bars in Flats

Permissible Variations in Width for

Thicknesses Given, Over and Under,

Width, in. ( [mm)]

A

in. ([mm)]

1 1

⁄4 ([6.4)] and under Over ⁄4 ([6.4)]

Width

⁄8 –1, incl 0.004 (0.10) 0.002 (0.05)

⁄8 –1, incl 0.004 [0.10] 0.002 [0.05]

Over 1–2, incl 0.006 (0.15) 0.003 (0.08)

Over 1–2, incl 0.006 [0.15] 0.003 [0.08]

Over 2–3, incl 0.008 (0.20) 0.004 (0.10)

Over 2–3, incl 0.008 [0.20] 0.004 [0.10]

1 B

Over 3–4 ⁄2 , incl 0.010 (0.25) 0.005 (0.13)

B

Over 3–4 ⁄2 , incl 0.010 [0.25] 0.005 [0.13]

Thickness

Permissible Variations in Thickness

Thickness, in. (mm)

A

Over and Under, in. (mm)

Permissible Variations in Thickness

Thickness, in. [mm]

A

Over and Under, in. [mm]

⁄8 –1, incl (3.2-25) 0.002 (0.05)

⁄8 –1, incl [3.2-25] 0.002 [0.05]

Over 1–2, incl (25–50) 0.003 (0.08)

Over 1–2, incl [25–50] 0.003 [0.08]

Over 2–3, incl (50–75) 0.004 (0.10)

Over 2–3, in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.