ASTM F1344-04

(Specification)Standard Specification for Rubber Floor Tile

Standard Specification for Rubber Floor Tile

ABSTRACT

This specification covers requirements for the compound and physical characteristics of rubber floor tile. The polymeric binder of the rubber floor tile shall have been vulcanized such that it becomes thermoset. The rubber floor tile made from this compound shall be resistant to neutral pH cleaners. For homogeneous rubber floor tile, the surface coloring or mottling shall be uniform throughout the entire thickness of the rubber floor tile. For layered rubber floor tile, the surface color or mottling need not extend through the entire thickness of the rubber floor tile, but must extend throughout the entire thickness of the wear layer. The material shall be tested for heat resistance, abrasion resistance, dimensional stability, and light resistance.

SCOPE

1.1 This specification covers requirements for the compound and physical characteristics of rubber floor tile.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1344 – 04

Standard Specification for

1

Rubber Floor Tile

This standard is issued under the fixed designation F 1344; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope F 925 Test Method for Resistance to Short-Term Chemical

Exposure of Resilient Flooring

1.1 This specification covers requirements for the com-

F 970 Test Method for Static Load Limit

pound and physical characteristics of rubber floor tile.

F 1482 Guide to Wood Underlayment Products Available

1.2 The values stated in inch-pound units are to be regarded

for Use Under Resilient Flooring

as the standard. The values given in parentheses are for

F 1514 Test Method for Measuring Heat Stability of Resil-

information only.

ient Vinyl Flooring by Color Change

1.3 This standard does not purport to address all of the

F 2055 Test Method for Size and Squareness of Resilient

safety concerns, if any, associated with its use. It is the

Floor Tile by Dial Gage Method

responsibility of the user of this standard to establish appro-

F 2199 Test Method for Determining Dimensional Stability

priate safety and health practices and determine the applica-

of Resilient Floor Tile After Exposure to Heat

bility of regulatory limitations prior to use.

2.3 American National Standards:

2. Referenced Documents

ANSI/ASQC Z1.4 – 1993 Sampling Procedures and Tables

3

for Inspection by Attributes

2.1 The following documents of the issue in effect on the

date of this material purchase form a part of this specification

3. Terminology

to the extent referenced herein:

2

3.1 Definitions—For definitions of other terms used in this

2.2 ASTM Standards:

standard, see Terminology F 141.

D 883 Terminology Relating to Plastics

D 1566 Terminology Relating to Rubber

4. Classification

D 2240 Test Method for Rubber Property—Durometer

4.1 Rubber floor tile covered by this specification shall be

Hardness

classified as:

D 3389 Test Method for Coated Fabrics Abrasion Resis-

Class I—Homogeneous Rubber Floor Tile

tance

A. Solid Color

F 141 Definitions of Terms Relating to Resilient Floor

B. Through Mottled

Coverings Class II—Laminated Rubber Floor Tile

A. Solid Color Wear Layer

F 373 Test Method for Embossed Depth of Resilient Floor

B. Mottled Wear Layer

Coverings

4.2 The tile in 4.1 may have either smooth, embossed, or

F 386 Test Method for Thickness of Resilient Flooring

molded pattern wearing surfaces.

Having Flat Surfaces

4.3 These products shall not contain asbestos.

F 410 Test Method for Wear Layer Thickness of Resilient

Floor Coverings by Optical Measurement

5. Ordering Information

F511 TestMethodforQualityofCutofResilientFloorTile

5.1 Purchaser shall state whether this specification is to be

F 710 Practice for Preparing Concrete Floors and Other

used, select the preferred options permitted herein, and include

Monolithic Floors to Receive Resilient Flooring

the following information in the invitation to bid or purchase

order:

1 5.1.1 Title, number, and date of this specification.

This specification is under the jurisdiction of ASTM Committee F06 on

5.1.2 Class, color, pattern, and wearing surface (see Section

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80

on Specifications.

4).

Current edition approved March 1, 2004. Published April 2004. Originally

5.1.3 Quantity, in square feet, square metres, or cartons.

approved in 1991. Last previous edition approved in 2003 as F 1344–03a.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

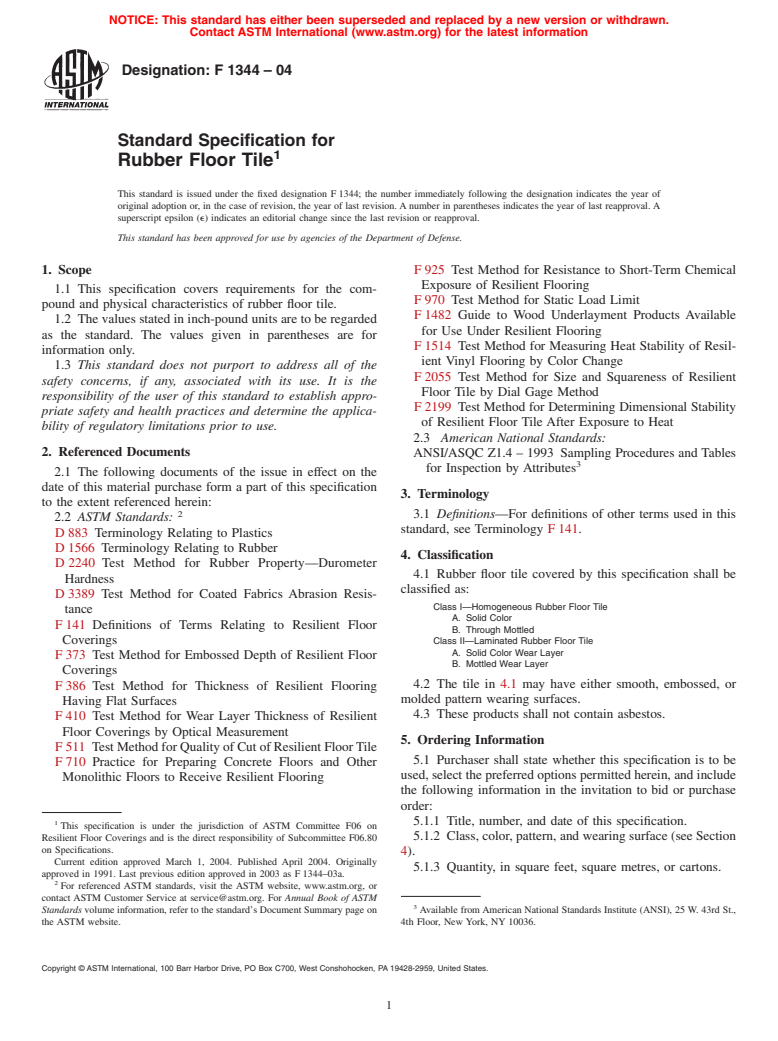

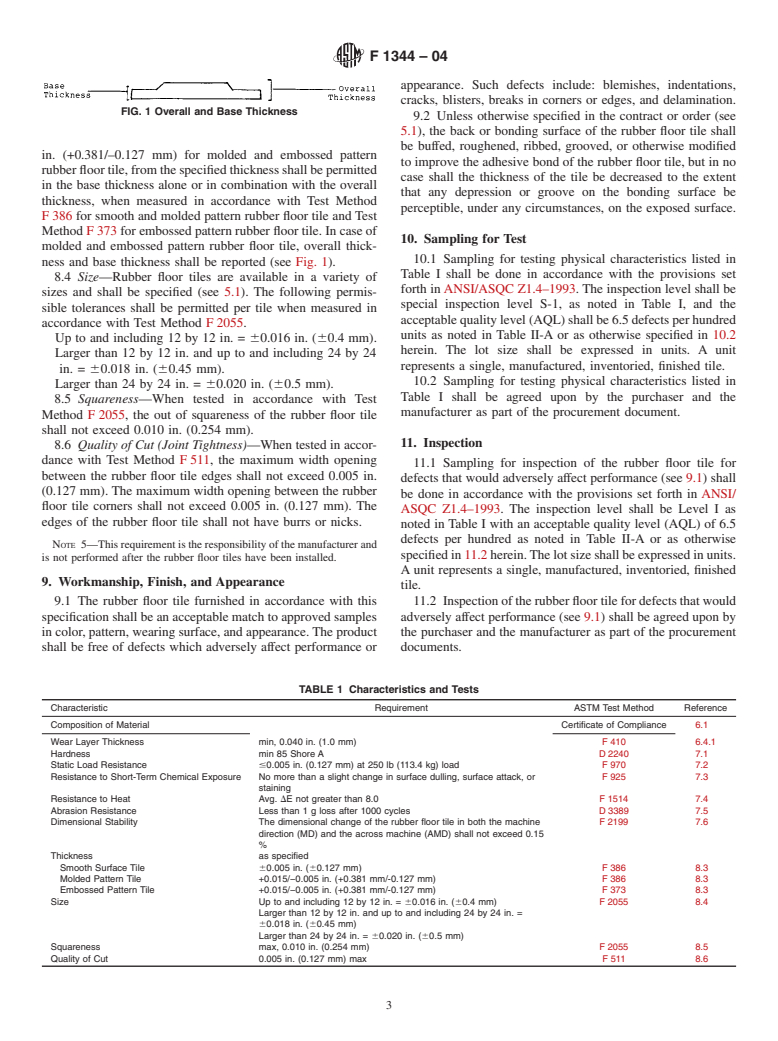

F1344–04

5.1.4 Size required (see 8.4). 7.2 Static Load Limit—WhentestedinaccordancewithTest

Method F 970, with an applied load of 250 lb (113.4 kg), the

5.1.5 Thickness required (see 8.3).

residual indentation shall not be greater than 0.005 in. (0.127

5.1.6 Overall thickness, if molded pattern tile is specified

mm).

(see 8.1).

7.3 Resistance to Short-Term Chemical Exposure—When

5.1.7 Base thickness, if molded pattern tile is specified (see

tested in accordance with Test Method F 925, the rubber floor

8.2).

tile shall have no more than a slight change in surface dulling,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.