ASTM D3543-93(2016)

(Test Method)Standard Test Method for Metal Glide Adhesion

Standard Test Method for Metal Glide Adhesion

SIGNIFICANCE AND USE

3.1 This test method is used to determine the effect of plasticizers in tile on the floor polish itself. If the floor polish is softened by the plasticizers in the tile it will become an adhesive and adhere to the metal glide that is placed on the polish under standard weights at standard temperatures. Various degrees of attack on the polish are evaluated by the damage to the tile underneath the polish.

SCOPE

1.1 This test method2 covers a laboratory procedure for determining damage resulting from metal glide adhesion on floor surfaces.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautions are given in 8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3543 − 93 (Reapproved 2016)

Standard Test Method for

Metal Glide Adhesion

This standard is issued under the fixed designation D3543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Apparatus

4.1 Metal Glide Adhesion Tester.

1.1 This test method covers a laboratory procedure for

4,5

determining damage resulting from metal glide adhesion on

4.2 Metal Glides.

floor surfaces.

4.3 Oven, or other facility, capable of maintaining 37.8 6

2.8°C(100 65°F)andlargeenoughtoaccommodatethemetal

1.2 The values stated in SI units are to be regarded as the

glide adhesion tester.

standard.

4.4 Black Offıcial Vinyl Composition Tile, 304.8 by 304.8

1.3 This standard does not purport to address all of the

6,5

mm (12 by 12 in.).

safety concerns, if any, associated with its use. It is the

4.5 Steel Wool (00 grade or finer).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Description of Metal Glide Adhesion Apparatus

bility of regulatory limitations prior to use. Specific precau-

5.1 The test apparatus (Figs. 1-3) consists of three basic

tions are given in 8.2.

parts: a housing frame, a support cover, and nine brass weights

and metal glides.

2. Referenced Documents

5.1.1 The housing frame consists of base plate A, frame

2.1 ASTM Standards:

sections C and D, all made of plastic, and support plate B,

D1436 Test Methods for Application of Emulsion Floor

made of plate glass (see Fig. 1).

Polishes to Substrates for Testing Purposes

5.1.2 The support cover is constructed of plastic and fits

D3153 Test Method for Recoatability of Water-Emulsion

snugly onto the housing frame. The nine tubes allow for

Floor Polishes supportingandpositioningofuptoninebrassweights(seeFig.

2).

8,5

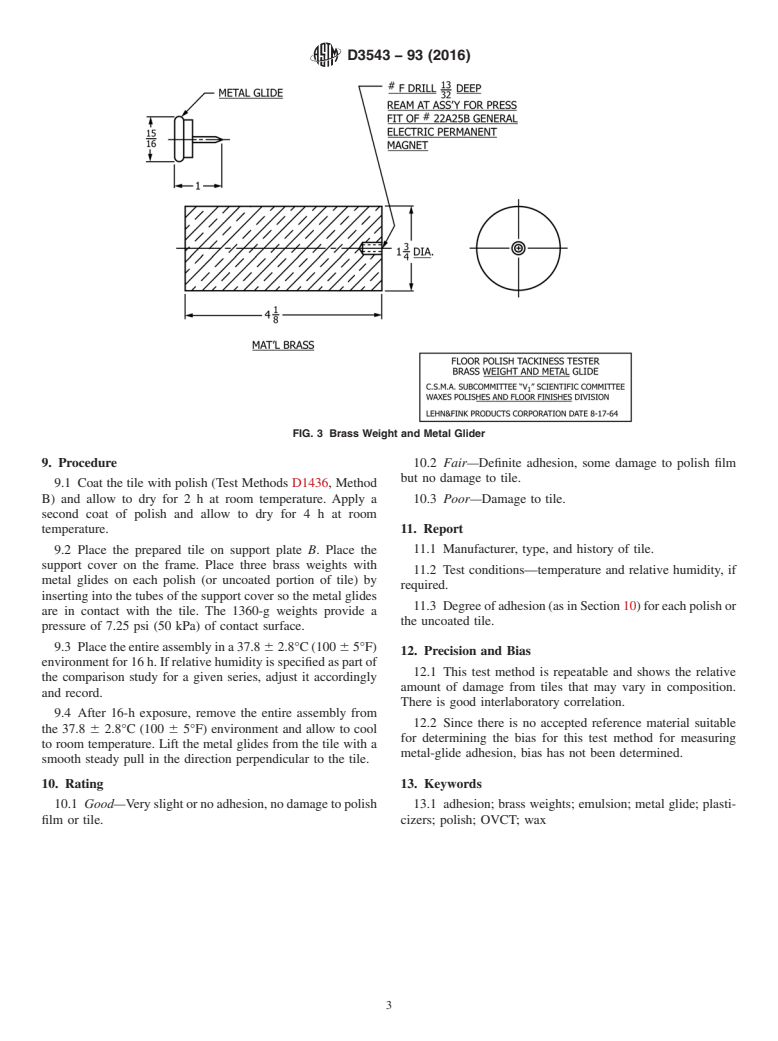

3. Significance and Use 5.1.3 Brass weights are provided with a recessed magnet

at one end to accommodate the metal glides and provide ease

3.1 This test method is used to determine the effect of

of handling (see Fig. 3). Each brass weight should weigh 1360

plasticizers in tile on the floor polish itself. If the floor polish

65g.

is softened by the plasticizers in the tile it will become an

adhesive and adhere to the metal glide that is placed on the 6. Reagents

polish under standard weights at standard temperatures. Vari-

6.1 Wax Stripping Solution.

ousdegreesofattackonthepolishareevaluatedbythedamage

6.2 Acetone.

to the tile underneath the polish.

Metal glides, 0.035–in. cold roll temper 5, nickel plate, |n & -in. base diameter,

available from Faultless Caster Corp., Evansville, IN, or their equivalent, have been

ThistestmethodisunderthejurisdictionofASTMCommitteeD21onPolishes found satisfactory.

and is the direct responsibility of Subcommittee D21.04 on Performance Tests. Thisisthesolesourceofsupplyoftheapparatusknowntothecommitteeatthis

Current edition approved Oct. 1, 2016. Published October 2016. Originally time. If you are aware of alternative suppliers, please provide this information to

approved in 1976. Last previous edition approved in 2008 as D3543 – 93 (2008). ASTM International Headquarters. Your comments will receive careful consider-

DOI: 10.1520/D3543-93R16. ation at a meeting of the responsible technical committee, which you may attend.

2 6

The test method is empirical in that it allows a comparison of the relative AvailablefromChemicalSpecialtiesManufacturersAssoc.,1913EyeSt.,N.W.

performance of up to three polishes on the same substrate for each test. It also Washington, DC 20006.

permits comparison of two polishes with an uncoated portion of the substrate for The preferred material for constructing housing frame and support cover is

each test. plastic such as poly(methyl methacrylate). However, other materials of construction

For referenced ASTM standards, visit the ASTM website, www.astm.org, or may be used provided that variables are not introduced due to warping or bending.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Magnets such as General Electric Sintered Alnico 2 Magnet Sleeve. Catalog

Standa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3543 − 93 (Reapproved 2008) D3543 − 93 (Reapproved 2016)

Standard Test Method for

Metal Glide Adhesion

This standard is issued under the fixed designation D3543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a laboratory procedure for determining damage resulting from metal glide adhesion on floor

surfaces.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautions are given in 8.2.

2. Referenced Documents

2.1 ASTM Standards:

D1436 Test Methods for Application of Emulsion Floor Polishes to Substrates for Testing Purposes

D3153 Test Method for Recoatability of Water-Emulsion Floor Polishes

3. Significance and Use

3.1 This test method is used to determine the effect of plasticizers in tile on the floor polish itself. If the floor polish is softened

by the plasticizers in the tile it will become an adhesive and adhere to the metal glide that is placed on the polish under standard

weights at standard temperatures. Various degrees of attack on the polish are evaluated by the damage to the tile underneath the

polish.

4. Apparatus

4.1 Metal Glide Adhesion Tester.

4,5

4.2 Metal Glides.

4.3 Oven, or other facility, capable of maintaining 37.8 6 2.8°C (100 6 5°F) and large enough to accommodate the metal glide

adhesion tester.

6,5

4.4 Black Offıcial Vinyl Composition Tile, 304.8 by 304.8 mm (12 by 12 in.).

4.5 Steel Wool (00 grade or finer).

5. Description of Metal Glide Adhesion Apparatus

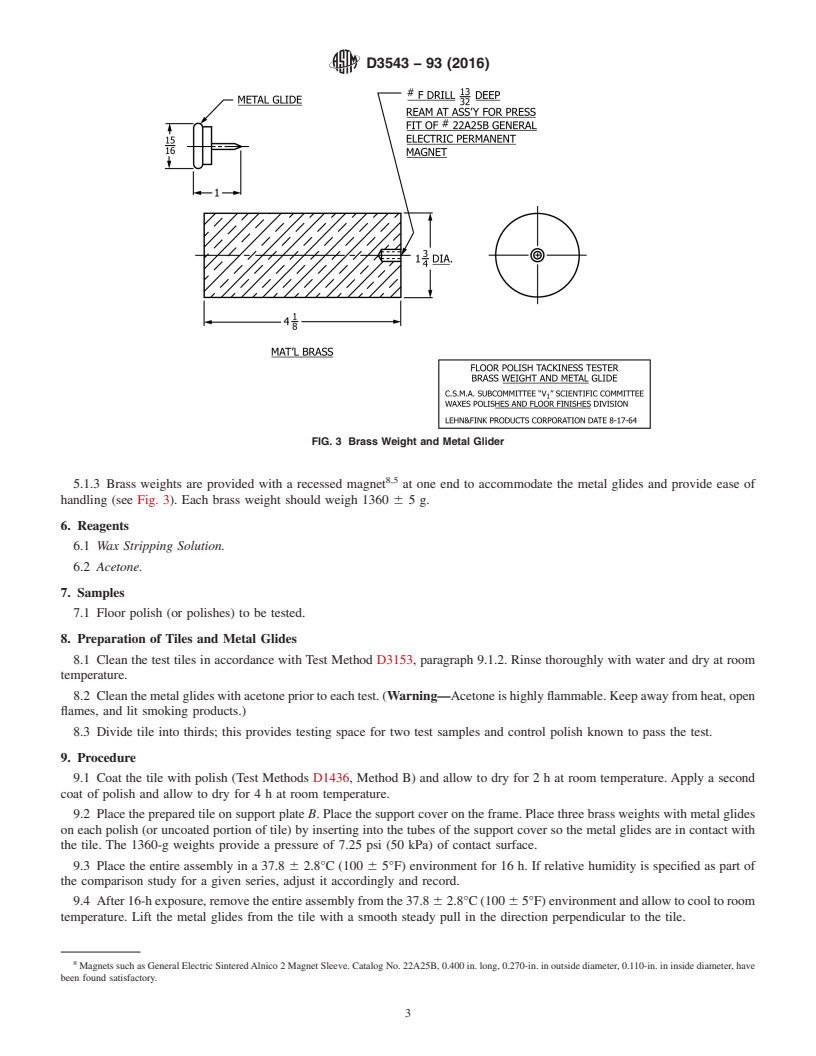

5.1 The test apparatus (Figs. 1-3) consists of three basic parts: a housing frame, a support cover, and nine brass weights and

metal glides.

This test method is under the jurisdiction of ASTM Committee D21 on Polishes and is the direct responsibility of Subcommittee D21.04 on Performance Tests.

Current edition approved March 1, 2008Oct. 1, 2016. Published April 2008October 2016. Originally approved in 1976. Last previous edition approved in 20022008 as

D3543 – 93 (2008).(2002). DOI: 10.1520/D3543-93R08.10.1520/D3543-93R16.

The test method is empirical in that it allows a comparison of the relative performance of up to three polishes on the same substrate for each test. It also permits

comparison of two polishes with an uncoated portion of the substrate for each test.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Metal glides, 0.035–in. cold roll temper 5, nickel plate, |n & -in. base diameter, available from Faultless Caster Corp., Evansville, IN, or their equivalent, have been found

satisfactory.

This is the sole source of supply of the apparatus known to the committee at this time. If you are aware of alternative suppliers, please provide this information to ASTM

International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

Available from Chemical Specialties Manufacturers Assoc., 1913 Eye St., N.W. Washington, DC 20006.

The preferred material for constructing housing frame and support cover is plastic such as poly(methyl methacrylate). However, other materials of construction may be

used provided that variables are not introduced due to warping or bending.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3543 − 93 (2016)

FIG. 1 Housing Frame

FIG. 2 Support Cover

5.1.1 The housing frame consists of base plate A, frame sections C and D, all made of plastic, and support plate B, made of plate

glass (see Fig.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.