ASTM E641-01(2006)

(Test Method)Standard Methods for Testing Hydraulic Spray Nozzles Used in Agriculture

Standard Methods for Testing Hydraulic Spray Nozzles Used in Agriculture

SIGNIFICANCE AND USE

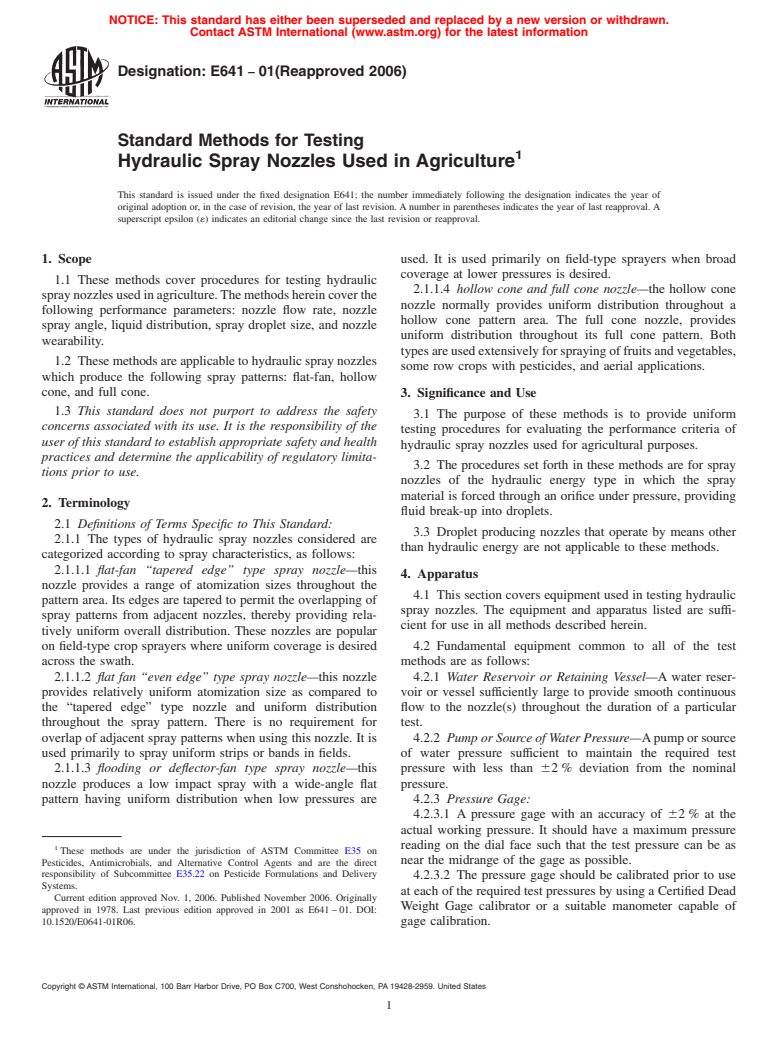

The purpose of these methods is to provide uniform testing procedures for evaluating the performance criteria of hydraulic spray nozzles used for agricultural purposes.

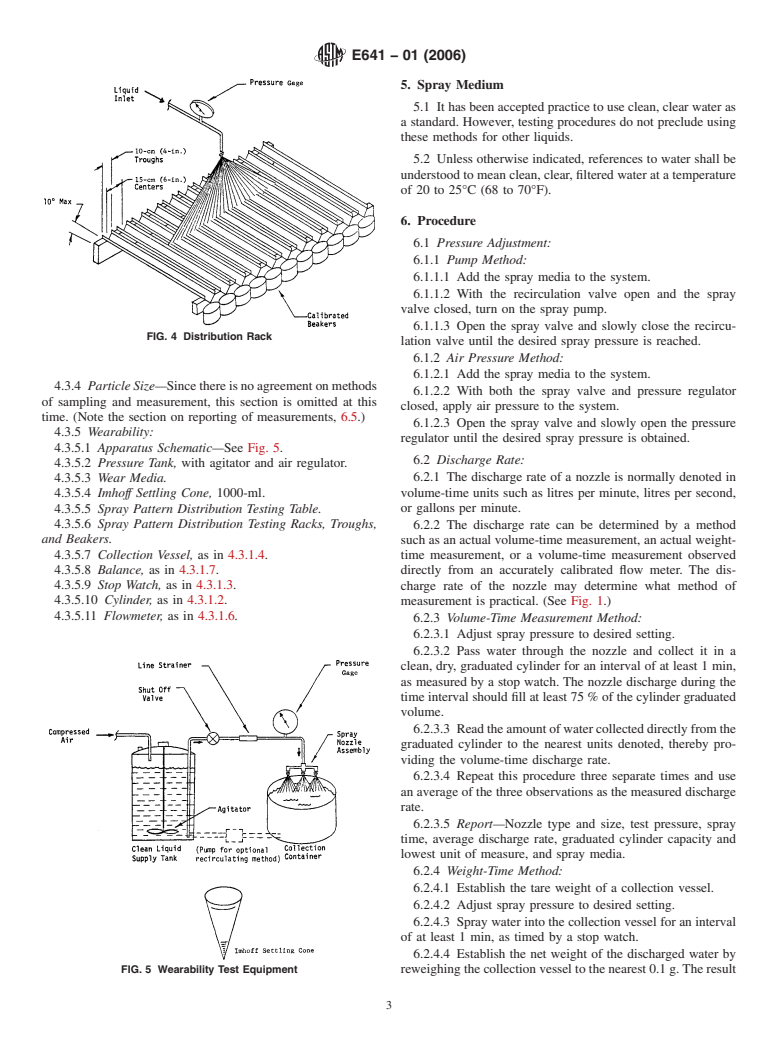

The procedures set forth in these methods are for spray nozzles of the hydraulic energy type in which the spray material is forced through an orifice under pressure, providing fluid break-up into droplets.

Droplet producing nozzles that operate by means other than hydraulic energy are not applicable to these methods.

SCOPE

1.1 These methods cover procedures for testing hydraulic spray nozzles used in agriculture. The methods herein cover the following performance parameters: nozzle flow rate, nozzle spray angle, liquid distribution, spray droplet size, and nozzle wearability.

1.2 These methods are applicable to hydraulic spray nozzles which produce the following spray patterns: flat-fan, hollow cone, and full cone.

This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E641 − 01(Reapproved 2006)

Standard Methods for Testing

1

Hydraulic Spray Nozzles Used in Agriculture

This standard is issued under the fixed designation E641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope used. It is used primarily on field-type sprayers when broad

coverage at lower pressures is desired.

1.1 These methods cover procedures for testing hydraulic

2.1.1.4 hollow cone and full cone nozzle—the hollow cone

spraynozzlesusedinagriculture.Themethodshereincoverthe

nozzle normally provides uniform distribution throughout a

following performance parameters: nozzle flow rate, nozzle

hollow cone pattern area. The full cone nozzle, provides

spray angle, liquid distribution, spray droplet size, and nozzle

uniform distribution throughout its full cone pattern. Both

wearability.

typesareusedextensivelyforsprayingoffruitsandvegetables,

1.2 These methods are applicable to hydraulic spray nozzles

some row crops with pesticides, and aerial applications.

which produce the following spray patterns: flat-fan, hollow

cone, and full cone.

3. Significance and Use

1.3 This standard does not purport to address the safety

3.1 The purpose of these methods is to provide uniform

concerns associated with its use. It is the responsibility of the

testing procedures for evaluating the performance criteria of

user of this standard to establish appropriate safety and health

hydraulic spray nozzles used for agricultural purposes.

practices and determine the applicability of regulatory limita-

3.2 The procedures set forth in these methods are for spray

tions prior to use.

nozzles of the hydraulic energy type in which the spray

material is forced through an orifice under pressure, providing

2. Terminology

fluid break-up into droplets.

2.1 Definitions of Terms Specific to This Standard:

3.3 Droplet producing nozzles that operate by means other

2.1.1 The types of hydraulic spray nozzles considered are

than hydraulic energy are not applicable to these methods.

categorized according to spray characteristics, as follows:

2.1.1.1 flat-fan “tapered edge” type spray nozzle—this

4. Apparatus

nozzle provides a range of atomization sizes throughout the

4.1 This section covers equipment used in testing hydraulic

pattern area. Its edges are tapered to permit the overlapping of

spray nozzles. The equipment and apparatus listed are suffi-

spray patterns from adjacent nozzles, thereby providing rela-

cient for use in all methods described herein.

tively uniform overall distribution. These nozzles are popular

on field-type crop sprayers where uniform coverage is desired 4.2 Fundamental equipment common to all of the test

across the swath. methods are as follows:

2.1.1.2 flat fan “even edge” type spray nozzle—this nozzle 4.2.1 Water Reservoir or Retaining Vessel—A water reser-

provides relatively uniform atomization size as compared to voir or vessel sufficiently large to provide smooth continuous

the “tapered edge” type nozzle and uniform distribution flow to the nozzle(s) throughout the duration of a particular

throughout the spray pattern. There is no requirement for test.

overlap of adjacent spray patterns when using this nozzle. It is 4.2.2 Pump or Source of Water Pressure—Apump or source

used primarily to spray uniform strips or bands in fields. of water pressure sufficient to maintain the required test

2.1.1.3 flooding or deflector-fan type spray nozzle—this pressure with less than 62 % deviation from the nominal

nozzle produces a low impact spray with a wide-angle flat pressure.

pattern having uniform distribution when low pressures are 4.2.3 Pressure Gage:

4.2.3.1 A pressure gage with an accuracy of 62 % at the

actual working pressure. It should have a maximum pressure

reading on the dial face such that the test pressure can be as

1

These methods are under the jurisdiction of ASTM Committee E35 on

near the midrange of the gage as possible.

Pesticides, Antimicrobials, and Alternative Control Agents and are the direct

responsibility of Subcommittee E35.22 on Pesticide Formulations and Delivery

4.2.3.2 The pressure gage should be calibrated prior to use

Systems.

at each of the required test pressures by using a Certified Dead

Current edition approved Nov. 1, 2006. Published November 2006. Originally

Weight Gage calibrator or a suitable manometer capable of

approved in 1978. Last previous edition approved in 2001 as E641 – 01. DOI:

10.1520/E0641-01R06. gage calibration.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.