ASTM D5822-03(2007)

(Test Method)Standard Test Method for Determining Seam Strength in Inflatable Restraint Cushions

Standard Test Method for Determining Seam Strength in Inflatable Restraint Cushions

SIGNIFICANCE AND USE

Seam strength testing is used for design validation and for lot acceptance.

This test method constitutes the conditions, procedures, and equipment by which inflatable restraints are tested for seam strength and seam efficiency. It is intended to be used as a guideline in establishing a written part specification or print. The specification or agreement of purchaser and supplier may deviate from the procedures described herein when (based on experience) considerations of equipment, cushion design, or other factors dictate otherwise.

In cases of dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should perform comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens from the same lot of fabric to be evaluated, which utilize a like seam assembly (or standard seam assembly) to achieve seam interaction. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. If a bias is found, either its cause must be determined and corrected, or the purchaser and supplier must agree to interpret future test results in light of the known bias.

Test Method D 5822 is a reliable test method but procedures which may require special attention are identified in the precision and bias section of this test method.

SCOPE

1.1 This test method covers the measurement of seam efficiency and the maximum seam strength in inflatable restraint cushions composed of woven fabrics when a force is applied perpendicular to the seam, using a grab test. For evaluating sewing thread, refer to Test Method D 204.

1.2 This test method is restricted to seams that are obtained from an inflatable restraint cushion. Seams may include but are not limited to sewn, OPW, glued, fused (chemically or thermally).

1.3 This test method is used when the measurement of a resistance to a specified force, a breaking force, a minimum elongation, or a combination thereof are required to determine the seam strength, or seam integrity of a particular fabric for inflatable restraint use.

1.4 Procedures and apparatus other than those stated in this standard may be used by agreement between purchaser and supplier with the specific deviations from the standard acknowledged in the report.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5822 – 03 (Reapproved 2007)

Standard Test Method for

Determining Seam Strength in Inflatable Restraint

Cushions

This standard is issued under the fixed designation D 5822; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3990 Terminology Relating to Fabric Defects

1.1 This test method covers the measurement of seam

3. Terminology

efficiency and the maximum seam strength in inflatable re-

3.1 Definitions:

straint cushions composed of woven fabrics when a force is

3.1.1 seam effıciency, n—in inflatable restraints, the ratio of

applied perpendicular to the seam, using a grab test. For

seam strength to fabric strength.

evaluating sewing thread, refer to Test Method D 204.

3.1.2 seam failure, n—in inflatable restraints, the point at

1.2 This test method is restricted to seams that are obtained

which an external force ruptures a seam assembly or the fabric,

from an inflatable restraint cushion. Seams may include but are

or causes excessive yarn slippage adjacent to the seam assem-

not limited to sewn, OPW, glued, fused (chemically or ther-

bly.

mally).

3.1.3 seam strength, n—in inflatable restraints, the maxi-

1.3 This test method is used when the measurement of a

mum force required to create a seam failure.

resistance to a specified force, a breaking force, a minimum

3.2 For definitions of textile terms relating to inflatable

elongation, or a combination thereof are required to determine

restraints used in this standard, refer to Terminology D 3990.

the seam strength, or seam integrity of a particular fabric for

3.3 For definitions of other textile terms used in this

inflatable restraint use.

standard, refer to Terminology D 123.

1.4 Procedures and apparatus other than those stated in this

standard may be used by agreement between purchaser and

4. Summary of Test Method

supplier with the specific deviations from the standard ac-

4.1 Specimens with and without seam assemblies taken

knowledged in the report.

from inflatable restraint cushions are destructively tested in a

1.5 The values stated in either SI units or inch-pound units

tensile testing machine under laboratory conditions to deter-

are to be regarded separately as standard. The values stated in

mine seam strength and seam efficiency.

each system are not exact equivalents; therefore, each system

must be used independently of the other.

5. Significance and Use

1.6 This standard does not purport to address all of the

5.1 Seam strength testing is used for design validation and

safety concerns, if any, associated with its use. It is the

for lot acceptance.

responsibility of the user of this standard to establish appro-

5.2 This test method constitutes the conditions, procedures,

priate safety and health practices and determine the applica-

and equipment by which inflatable restraints are tested for

bility of regulatory limitations prior to use.

seam strength and seam efficiency. It is intended to be used as

a guideline in establishing a written part specification or print.

2. Referenced Documents

2 The specification or agreement of purchaser and supplier may

2.1 ASTM Standards:

deviate from the procedures described herein when (based on

D 123 Terminology Relating to Textiles

experience) considerations of equipment, cushion design, or

D 204 Test Methods for Sewing Threads

other factors dictate otherwise.

D 1776 Practice for Conditioning and Testing Textiles

5.3 In cases of dispute arising from differences in reported

test results when using this test method for acceptance testing

of commercial shipments, the purchaser and the supplier

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

should perform comparative tests to determine if there is a

and is the direct responsibility of Subcommittee D13.20 on Inflatable Restraints.

statistical bias between their laboratories. Competent statistical

Current edition approved July 1, 2007. Published August 2007. Originally

approved in 1995. Last previous edition approved in 2003 as D 5822 – 03.

assistance is recommended for the investigation of bias. As a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

minimum, the two parties should take a group of test speci-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mens from the same lot of fabric to be evaluated, which utilize

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. a like seam assembly (or standard seam assembly) to achieve

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5822 – 03 (2007)

seam interaction. The test specimens should then be randomly ion specification or as agreed upon by purchaser and supplier.

assigned in equal numbers to each laboratory for testing. If a If seam efficiency testing is to be done, select a portion of

bias is found, either its cause must be determined and cor- unseamed fabric adjacent to the sampled area, from which the

rected, or the purchaser and supplier must agree to interpret seamed specimen was taken. Wherever possible, such speci-

future test results in light of the known bias. mens should contain the same yarns as the seam assemblies

5.4 Test Method D 5822 is a reliable test method but that are to be placed in the clamps oriented parallel to the

procedureswhichmayrequirespecialattentionareidentifiedin traverse direction of test.

the precision and bias section of this test method.

NOTE 2—Specimens are usually specified to be taken from a cushion at

a location on the cushion seam(s) where the greatest stresses are

6. Apparatus

anticipated. In seams involving woven fabric, this is usually where the

6.1 Tensile Testing Machine, of the CRE, CRL or CRT type

warp or filling yarns are parallel to the seam. Cushion design may indicate

conforming to Specification D 76, with respect to force indi-

other stress points of concern.

cation, working range, capacity, and elongation indicator, and

NOTE 3—Use caution in selecting specimens from areas of the cushion

designed for operation at a speed of 300 6 10 mm/min (12 6 where the seams exhibit sharp radius turns. During seam strength testing,

these areas will exhibit uneven point loading at the edges of the test

0.5 in./min); or, a variable speed drive, change gears, or

specimen.

interchangeable weights as required to obtain a 20 6 3-s

NOTE 4—Unless otherwise specified for driver-side cushions, select

time-to-break (see 12.4). The constant-rate-of-extension type

specimens taken from the perimeter seam at the 0 rad (0°), 0.79 rad (45°),

of tensile testing machine is preferred in this test method.

and 1.57 rad (90°) positions, relative to the warp direction of the fabric in

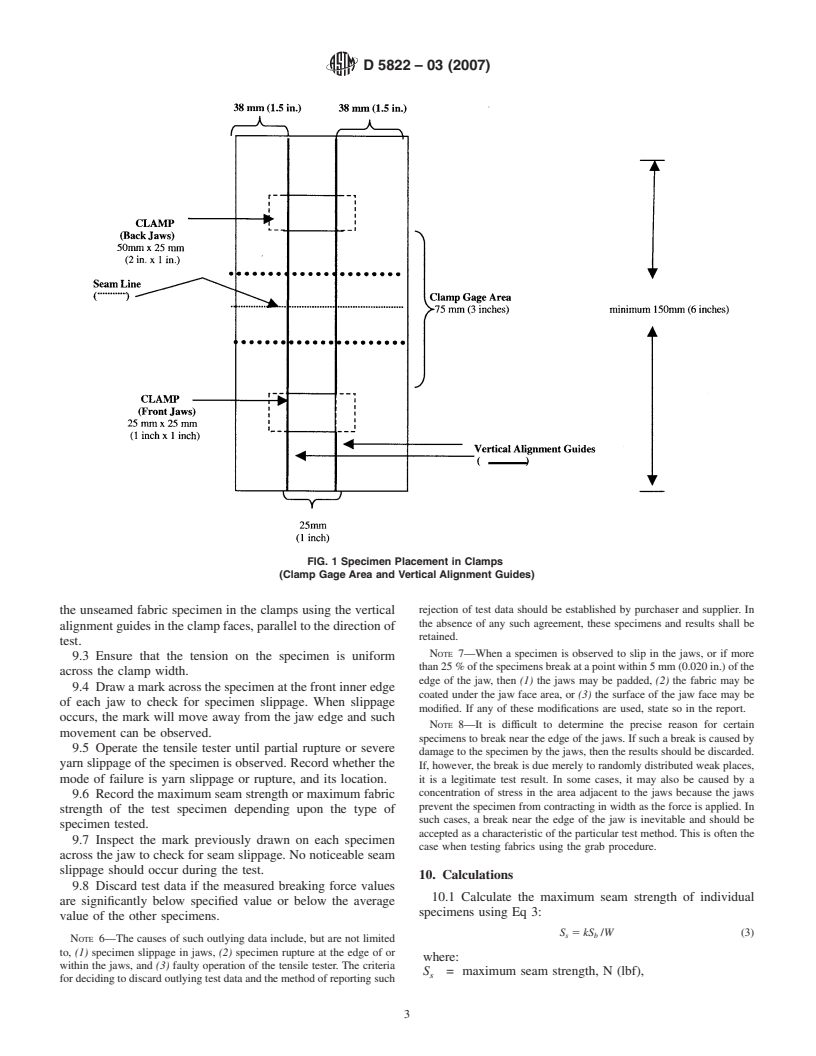

6.2 Clamp and Jaw Faces, adjustable clamps compatible

the front panel.

with tensile testing machine, the jaws of which have smooth,

7.4.1 Cut each specimen 100 61mm(4 6 0.05 in.) wide

flat, metallic gripping surfaces parallel to each other.

by at least 150 mm (6 in.) long (Note 5) with the long

6.2.1 Each clamp shall have a front (or top) jaw face

dimension parallel to the direction of testing and force appli-

measuring 25 6 1 mm (1.0 6 0.02 in.) perpendicular to the

cation. For seamed specimens, the seam shall be centrally

direction of the application of the force, and not less than 25

located perpendicular to the application of force.

nor more than 50 mm (1.0 nor more than 2.0 in.) parallel to the

direction of the application of the force. The back, or bottom,

NOTE 5—The length of the specimen depends on the type of clamps

jawfaceofeachclampshallbeatleastaslargeasitsmate.Use

being used. The specimen should be long enough to extend through the

of a larger face for the second jaw reduces the problem of front

clamps and project at least 10 mm (0.5 in.) at each end. The specimen

and back jaw misalignment. length may be calculated using Eq 1 or Eq 2:

Specimen length, mm 5 C 1 2W (1)

NOTE 1—Front (or top) faces measuring 25 by 50-mm (1.0 by 2.0-in.)

will not necessarily give the same value as 25 by 25-mm (1.0 by 1.0-in.)

Specimen length, in. 5 K 1 2W (2)

faces. For many materials, the former are preferable because of the larger

gripping area which tends to reduce slippage.While both sizes of gripping

where:

surface are permitted, the face sizes used must be the same for all samples

C = 95 mm (constant based on a gage length of 75 plus 20

in the test and must be recorded in the report.

mm for projections beyond the clamp),

6.2.2 At least one clamp should be supported by a free K = 4 in. (constant based on a gage length of 3 plus 1 in.

swivel or universal joint to allow the clamp to rotate in the for projections beyond the clamps), and

W = jaw face width in direction of force, mm (in.).

plane of the fabric.

6.3 For inflatable restraints, all test equipment used in

7.4.2 To aid in aligning the specimens in the clamps of the

accordance with this test method shall be certified for calibra- tensile testing machine, draw vertical lines parallel to the long

tion annually by an independent agency or equipment manu-

direction (and along a yarn of woven fabric) located 37 6 1

facturer whose results are traceable to the National Institute of mm (1.5 6 0.02 in.) in from the edge of both sides of the

Science and Technology (NIST) or other national standards

specimen. The parallel lines serve as a guide to ensure that the

laboratory.The test parameters of the equipment shall be tested

same yarns in the direction of test are gripped in both clamps.

within the operating ranges covered in the cushion specifica-

tion or equivalent document.

8. Conditioning

8.1 Conditioning of specimens for seam strength testing

7. Sampling

shall be at the standard atmosphere for testing textiles for at

7.1 Seam strength testing is a destructive test and therefore

least 4 h prior to test, in accordance with Practice D 1776.

necessitates sampling procedures if used in conjunction with

lot acceptance.

9. Procedure

7.2 For acceptance testing, the lot size is the quantity of

9.1 Select and condition specimens in accordance with

cushions produced in one day.

Sections 7 and 8 of this test method.

7.3 Lot Sample—For acceptance testing, take at random the

number of cushions directed in an applicable cushion specifi- 9.2 For seam assembly testing, place the specimen contain-

cation or other agree

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.