ASTM D953-02

(Test Method)Standard Test Method for Bearing Strength of Plastics

Standard Test Method for Bearing Strength of Plastics

SIGNIFICANCE AND USE

This bearing strength test for plastics is intended to apply in the specification of various thermoplastic or thermosetting products in sheet form where rivets, bolts, or similar fastenings are to be used in joining members or sections. It also is intended to apply wherever sheet materials of the classes indicated are required to sustain edgewise loads that are applied by means of pins or rods of circular cross section which pierce the sheet perpendicular to the surface.

The purpose of the test is to determine the bearing strength of the material and to show the bearing stress versus the deformation of the hole. The allowable deformation of the hole in the material should be such as to produce no looseness of joints.

While it is a known fact that higher strength materials will generally give higher bearing strengths, there is no satisfactory method by which bearing strength may be estimated from tensile or compressive properties of the material.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions or testing parameters or combination thereof covered in the relevant ASTM materials specification shall take precedence over those in this test method. If there are no relevant ASTM material specifications then the default conditions apply.

SCOPE

1.1 This test method covers the determination of the bearing strength of rigid plastics in either sheet or molded form. Procedure A is applicable for tension loading and Procedure B for compression loading.

1.2 Test data obtained by this test method is relevant and appropriate for use in engineering design.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D953–02

Standard Test Method for

1

Bearing Strength of Plastics

This standard is issued under the fixed designation D953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

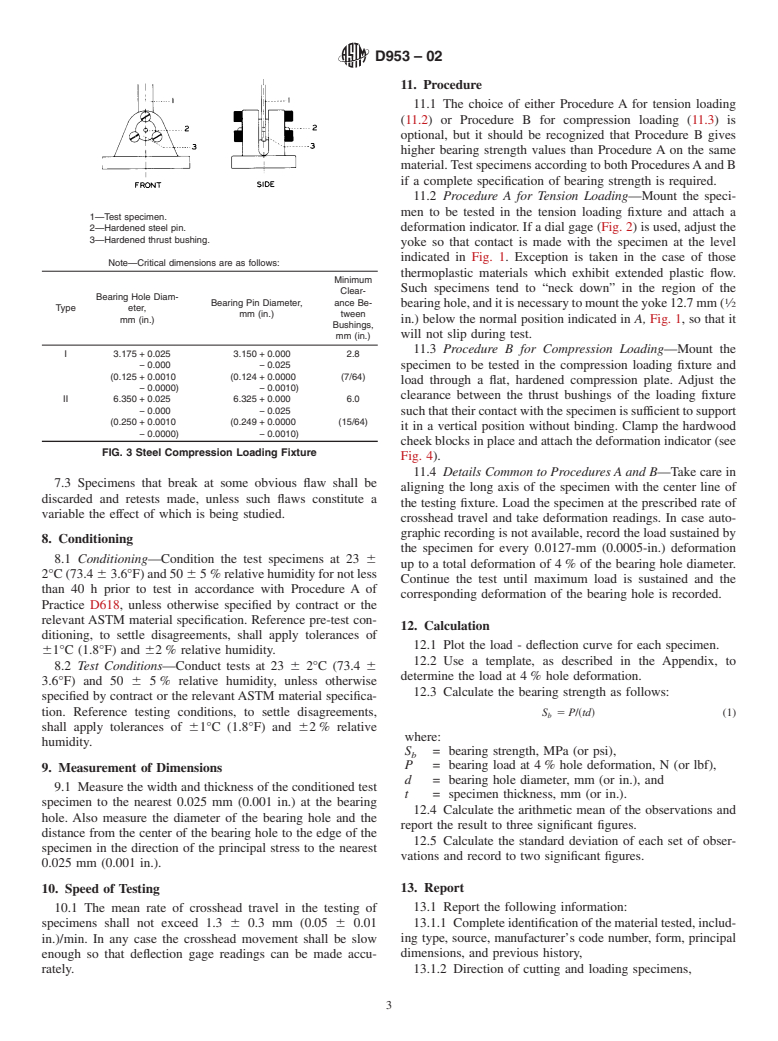

7

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 bearing area—the diameter of the hole multiplied by

1.1 Thistestmethodcoversthedeterminationofthebearing

the thickness of the specimen.

strength of rigid plastics in either sheet or molded form.

3.2.2 bearing strength—the bearing stress at which the

ProcedureAis applicable for tension loading and Procedure B

bearing hole is deformed 4% of its diameter.

for compression loading.

3.2.3 bearing stress—the applied load in newtons (or

1.2 Test data obtained by this test method is relevant and

2 2

pounds-force) divided by the bearing area in mm (or in ).

appropriate for use in engineering design.

3.2.4 edge distance ratio—the distance from the center of

1.3 The values stated in SI units are to be regarded as the

the bearing hole to the edge of the specimen in the direction of

standard. The values given in parentheses are for information

the principal stress, divided by the diameter of the hole.

only.

3.2.5 maximum bearing stress—the maximum load in new-

1.4 This standard does not purport to address all of the

tons (or pounds-force) sustained by the specimen, divided by

safety concerns, if any, associated with its use. It is the

the bearing area.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

4.1 This bearing strength test for plastics is intended to

NOTE 1—There is no known ISO equivalent to this standard.

apply in the specification of various thermoplastic or thermo-

setting products in sheet form where rivets, bolts, or similar

2. Referenced Documents

fasteningsaretobeusedinjoiningmembersorsections.Italso

2

2.1 ASTM Standards:

is intended to apply wherever sheet materials of the classes

2

D618 Practice for Conditioning Plastics for Testing

indicated are required to sustain edgewise loads that are

3

D883 Terminology Relating to Plastics

appliedbymeansofpinsorrodsofcircularcrosssectionwhich

D4000 Classification System for Specifying Plastic Materi-

pierce the sheet perpendicular to the surface.

3

als

4.2 The purpose of the test is to determine the bearing

D4066 Classification System for Nylon Injection and Ex-

strength of the material and to show the bearing stress versus

4

trusion Materials (PA)

the deformation of the hole. The allowable deformation of the

56

D4805 Terminology for Plastics Standards

hole in the material should be such as to produce no looseness

6

E4 Practices for Force Verification of Testing Machines

of joints.

E6 TerminologyRelatingtoMethodsofMechanicalTesting

4.3 While it is a known fact that higher strength materials

will generally give higher bearing strengths, there is no

3. Terminology

satisfactory method by which bearing strength may be esti-

3.1 Definitions—For definitions of technical terms pertain-

mated from tensile or compressive properties of the material.

ing to plastics used in this test method, see Terminology D883

4.4 Before proceeding with this test method, reference

or Terminology D4805.

shouldbemadetothespecificationofthematerialbeingtested.

Any test specimen preparation, conditioning, dimensions or

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

testing parameters or combination thereof covered in the

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

relevant ASTM materials specification shall take precedence

Current edition approved April 10, 2002. Published June 2002. Originally

over those in this test method. If there are no relevant ASTM

published as D953–48T. Last previous edition D953–95. DOI: 10.1520/D0953-

02.

material specifications then the default conditions apply.

2

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vol 08.02.

4

Annual Book of ASTM Standards, Vol 08.03.

5

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

6 7

Annual Book of ASTM Standards, Vol 03.01. Attention is also directed to Terminology E6.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D953–02

5. Apparatus

5.1 Testing Machine—A properly calibrated universal test-

ing machine t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.