ASTM F835-04e1

(Specification)Standard Specification for Alloy Steel Socket Button and Flat Countersunk Head Cap Screws

Standard Specification for Alloy Steel Socket Button and Flat Countersunk Head Cap Screws

ABSTRACT

This specification covers the requirements for quenched and tempered alloy steel hexagon socket button (SBHCS) and flat countersunk (SFHCS) head cap screws having material properties for high-strength requirements. Materials shall be tested and shall conform to specified values of materials requirements; chemical composition; mechanical properties such as thread size, stress area, tensile strength, yield strength, elongation, and hardness (Rockwell C and Vickers DPH); and other requirements such as decarburization, and embrittlement. Workmanship, finish, and appearance are also detailed.

SCOPE

1.1 This specification covers the requirements for quenched and tempered alloy steel hexagon socket button (SBHCS) 0.060 through 0.625 thread sizes and flat countersunk (SFHCS) 0.060 through 1.5 thread sizes head cap screws having material properties for high-strength requirements.

1.2 Fasteners meeting this specification are intended for shear-type applications and have tensile requirements ranging from 122 to 150 ksi.

1.3 The hazard statement applies only to the test method section, Section 11, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F835 – 04

Standard Specification for

Alloy Steel Socket Button and Flat Countersunk Head Cap

1

Screws

ThisstandardisissuedunderthefixeddesignationF835;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Sections 2.2 and 3.1.9 were editorially revised in October 2006.

1. Scope* F606M Test Methods for Determining the Mechanical

PropertiesofExternallyandInternallyThreadedFasteners,

1.1 This specification covers the requirements for quenched

Washers, and Rivets (Metric)

and tempered alloy steel hexagon socket button (SBHCS)

F788/F788M Specification for Surface Discontinuities of

0.060through0.625threadsizesandflatcountersunk(SFHCS)

Bolts, Screws, and Studs, Inch and Metric Series

0.060through1.5threadsizesheadcapscrewshavingmaterial

3

2.2 ASME Standards:

properties for high-strength requirements.

B18.3 Socket Cap, Shoulder and Set Screws—Inch Series

1.2 Fasteners meeting this specification are intended for

B18.24 Part Identifying Number (PIN) Code System Stan-

shear-type applications and have tensile requirements ranging

dard for B18 Fastener Products

from 122 to 150 ksi.

1.3 The hazard statement applies only to the test method

3. Ordering Information

section, Section 11, of this specification. This standard does

3.1 Ordersformaterialunderthisspecificationshallinclude

not purport to address all of the safety concerns, if any,

the following:

associated with its use. It is the responsibility of the user of this

3.1.1 Quantity (number of screws).

standard to establish appropriate safety and health practices

3.1.2 Dimensions, including nominal thread designation,

and determine the applicability of regulatory limitations prior

thread pitch, and nominal screw length (inches). A standard

to use.

part number may be used for this definition.

2. Referenced Documents 3.1.3 Name of the screw: SBHCS or SFHCS.

2

3.1.4 Coating, if required. If a protective finish other than

2.1 ASTM Standards:

black oxide is required, it must be specified on the order or

A751 TestMethods,Practices,andTerminologyforChemi-

product standard.

cal Analysis of Steel Products

3.1.5 Lot testing, if required (see 10.3).

D3951 Practice for Commercial Packaging

3.1.6 Certification, if required (see 14.1).

E3 Guide for Preparation of Metallographic Specimens

3.1.7 ASTM designation and year of issue.

E18 Test Methods for Rockwell Hardness of Metallic Ma-

3.1.8 Any special requirements.

terials

3.1.9 For establishment of a part identifying system, see

E112 Test Methods for Determining Average Grain Size

ASME B18.24.

E384 Test Method for Microindentation Hardness of Mate-

3.2 Example—1000 pieces 0.250 − 20 3 0.375 SBHCS lot

rials

tensile test. ASTM F835–XX.

4. Materials and Manufacture

1

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

4.1 The screws shall be fabricated from alloy steel made to

Nuts, Rivets, and Washers.

fine grain practice. In the event of controversy over grain size,

Current edition approved Aug. 1, 2004. Published August 2004. Originally

referee tests on finished screws conducted in accordance with

approved in 1986. Last previous edition approved in 2003 as F835–03. DOI:

10.1520/F0835-04E01. Test Methods E112 shall prevail.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on

Available from American Society of Mechanical Engineers (ASME), ASME

the ASTM website. International Headquarters, Three Park Ave., New York, NY 10016-5990.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F835 – 04

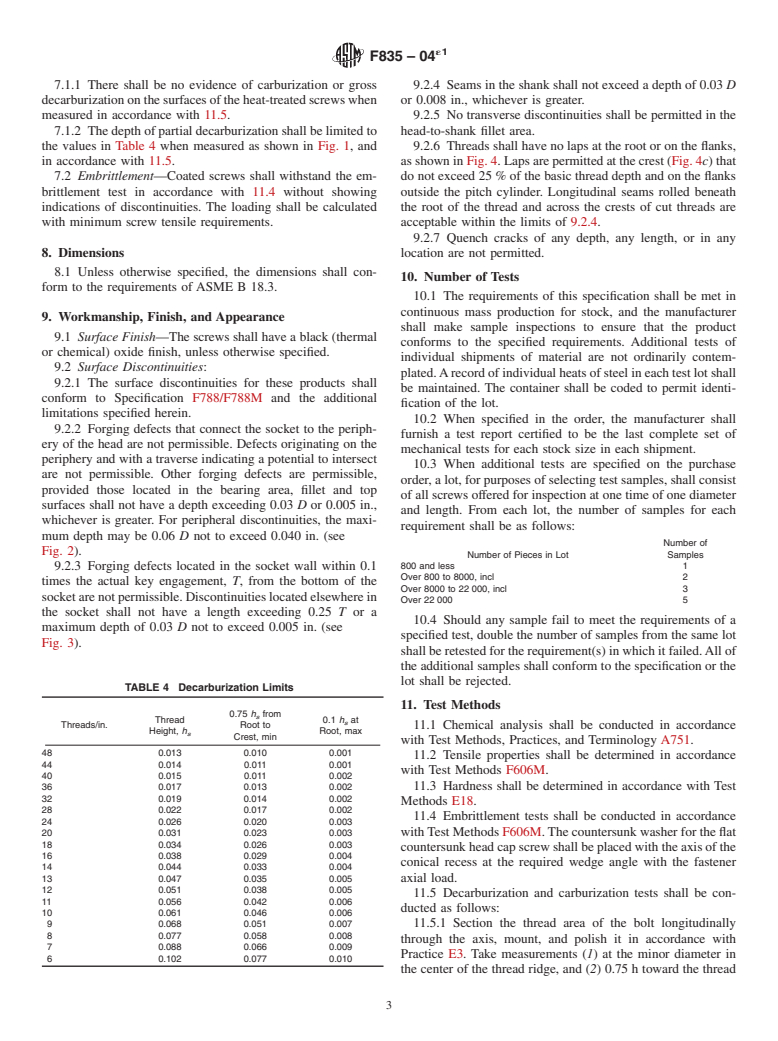

TABLE 2 Chemical Requirements

4.2 Screws shall be hot or cold upset or extruded, or both.

4.3 Unless otherwise specified, threads shall be rolled for

Composition, %

diametersthrough0.625in.andforscrewlengthsthrough4in.

Element

Heat Product

For diameters and lengths other than this, threads may be

Analysis Analysis

rolled, cut or ground.

Carbon 0.30 to 0.48 0.28 to 0.50

4.4 Screws shall be heat treated by quenching in oil from

Phosphorus, max 0.035 0.040

above the transformation temperature and then tempering by

Sulfur, max 0.040 0.045

Alloying elements see 5.2 see 5.2

reheating to at least 650°F to be within the hardness r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.