ASTM D4445-91(1996)e1

(Test Method)Standard Test Method for Fungicides for Controlling Sapstain and Mold on Unseasoned Lumber (Laboratory Method)

Standard Test Method for Fungicides for Controlling Sapstain and Mold on Unseasoned Lumber (Laboratory Method)

SCOPE

1.1 This (laboratory) method is used for determining the minimum concentration of fungicide, or formulation of fungicides, that is effective in preventing biodeterioration by sapstain fungi and molds in selected species of wood under optimum laboratory conditions. Note 1-From the results of this test, commercial treating solution concentrations cannot be estimated without further field tests.

1.2 The requirements for test materials and procedures are discussed in the following order: Section Summary of Method 3 Apparatus 5 Reagents 6 Wood 7 Test Fungi 8 Culture Media 9 Preparation of Inoculum 10 Preparation of Test Chambers 11 Treatment of Samples 12 Inoculation and Incubation 13 Evaluation of the Test 14 Report 15

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 4445 – 91 (Reapproved 1996)

Standard Test Method for

Fungicides for Controlling Sapstain and Mold on

Unseasoned Lumber (Laboratory Method)

This standard is issued under the fixed designation D 4445; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in November 1996.

1. Scope levels. The specimens are exposed to sapstain fungi and molds.

The toxicity of fungicides may be tested against individual

1.1 This (laboratory) method is used for determining the

fungi, in which case sterilization of the samples is necessary, or

minimum concentration of fungicide, or formulation of fungi-

against several fungi by using a mixed spore suspension for the

cides, that is effective in preventing biodeterioration by sap-

inoculation of the specimens; in the latter case, sterilization is

stain fungi and molds in selected species of wood under

unnecessary.

optimum laboratory conditions.

3.2 The intensity of surface fungal growth is estimated after

NOTE 1—From the results of this test, commercial treating solution

incubation and the results used to determine the chemical

concentrations cannot be estimated without further field tests.

treatment concentration giving zero growth (CGo).

1.2 The requirements for test materials and procedures are

4. Significance and Use

discussed in the following order:

Section 4.1 This method is useful as a screening procedure for

Summary of Method 3

selecting fungicides or formulations for more rigorous field

Apparatus 5

evaluation.

Reagents 6

Wood 7

Test Fungi 8 5. Apparatus

Culture Media 9

5.1 Incubation Room (or Incubation Cabinet), maintained at

Preparation of Inoculum 10

Preparation of Test Chambers 11 a temperature of 25 6 1°C, and relative humidity between 70

Treatment of Samples 12

and 80 %.

Inoculation and Incubation 13

5.2 Steam Sterilizer.

Evaluation of the Test 14

Report 15 5.3 Containers:

5.3.1 Petri Dishes, with minimum size of 100 (diameter) by

1.3 This standard does not purport to address all of the

20 mm (height) with lid or,

safety concerns, if any, associated with its use. It is the

5.3.2 Aluminum Pans, with minimum size of 24 by 10 by 2

responsibility of the user of this standard to establish appro-

cm (height) with aluminum foil cover.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

6. Reagents

6.1 Purity of Water—Reference to water shall be understood

2. Referenced Documents

to mean sterile reagent water conforming to Type IV of

2.1 ASTM Standards:

Specification D 1193.

D 1193 Specification for Reagent Water

7. Wood

3. Summary of Method

7.1 General Properties—The wood species to be tested

3.1 Unseasoned sapwood specimens are treated either by

should be locally available commercial species selected on the

spraying with, or by immersing in, solutions or dispersions of

basis of their susceptibility to staining fungi (pine or spruce

a fungicide formulation prepared at five or more concentration

species are preferred). Sapwood of the selected wood species,

unseasoned (moisture content higher than 40 %), free of knots,

This method is under the jursidiction of ASTM Committee D-7 on Wood and

visible decay, sapstain and mold, shall be used (Note 2). If the

is the direct responsibility of Subcommittee D07.06 on Treatments for Wood

fungicide is to be used to protect hardwood, the inclusion of

Products.

sapwood from a hardwood species is recommended.

Current edition approved May 15, 1991. Published October 1991. Originally

published as D 4445 – 84. Last previous edition D 4445 – 84.

2 NOTE 2—If wood for the test is collected in a sawmill where logs are

Annual Book of ASTM Standards, Vol 11.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4445

stored in water, it is necessary to collect lumber from at least three

the spore suspension; if the general effectiveness of a fungicide

different logs since depletion of nutrients during water storage may

is being tested using a mixed spore supension, aseptic condi-

strongly affect the growth of molds and staining fungi. Ensure that the

tions are unnecessary. Most laboratory experiments require a

lumber collected in a sawmill has not been treated with a sapstain and

relatively small volume (about 100 mL) of inoculum that may

mold preventive, and if there is any doubt, at least 10 mm of surface wood

be prepared using only the stock test tube cultures; prepare

must be removed and discarded.

larger volumes of inoculum from cultures grown on petri

7.2 Size of Specimens—Specimens should be 7 by 20 mm in

dishes.

cross section and 7 cm long.

NOTE 3—Before using any stock test tube culture, reinoculate new

7.3 Preparation of Specimens—Within two days of collect-

tubes for future use.

ing, the samples shall be cut from the wood using a sharp saw

blade. To prevent drying, the specimens shall be stored in 10.2 For the preparation of a spore suspension, add 5 mL of

polyethylene bags. For storage longer than one day, tightly

sterile water to each culture tube or 10 mL to petri dishes, and

packed specimens may be kept frozen (−20°C or lower) in rub the surface of the malt agar culture with a blunt glass rod

polyethylene bags for up to one year. In this case, one bag

to loosen the spores. After collecting the spores and combining

should contain as many specimens as are used for one them with other similarly collected spores, if desired, adjust the

experiment.

water volume to that required. Although it is a good practice to

prepare fresh spore suspensions just before use, they may be

8. Test Fungi

kept, even without refrigeration, for 2 to 3 weeks.

8.1 Hardwoods:

10.3 For nonsporulating cultures, obtain a mycelial suspen-

8.1.1 Sapstain Fungi:

sion for use by aseptically scraping the surface mycelium off

8.1.1.1 Diplodia natalensis P. Evans (ATCC 34643).

and blending it with sterile water.

8.1.1.2 Ceratocystis virescens (Davidson) C. Moreau

10.4 To evaluate a fungicide use at least six test fungi (three

(ATCC 11066) a form of C. coerulescens found on American

sapstain and three mold) individually, as well as one mixed

hardwoods.

spore suspension of selected fungi.

8.1.1.3 Aureobasidium pullulans (d. By) Arnaud. (ATCC

16624). 11. Preparation of Test Chambers

8.1.2 Mold Fungi:

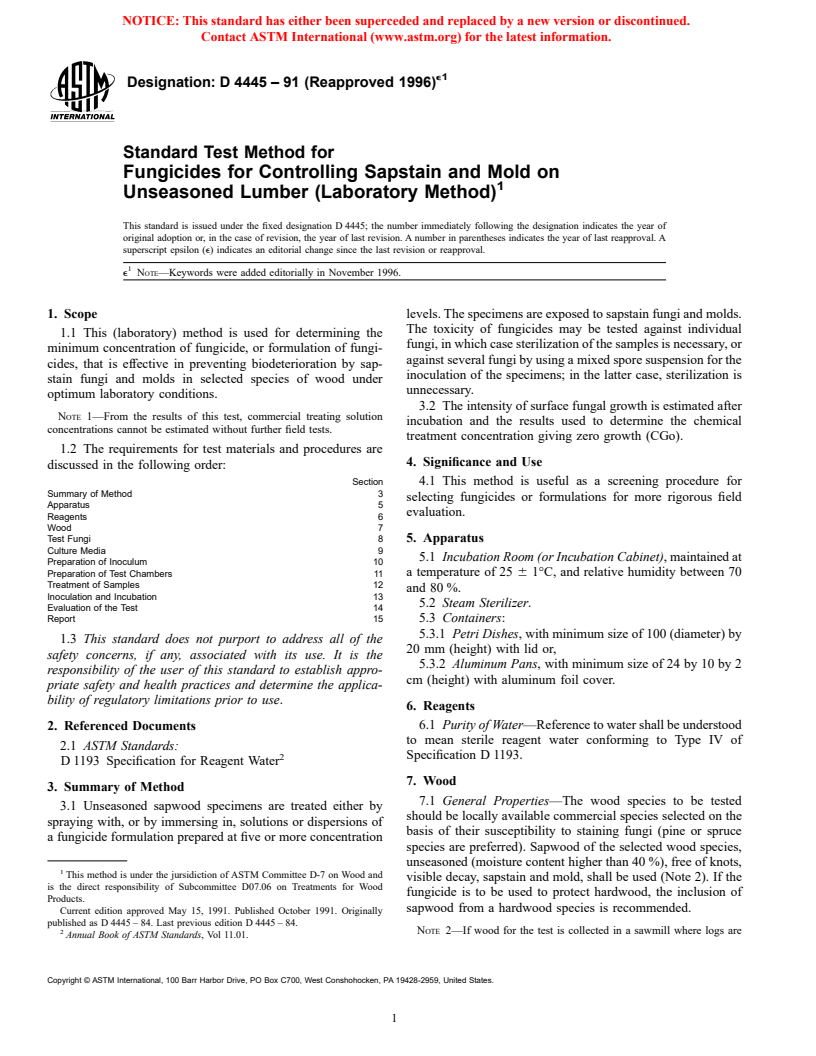

11.1 To maintain high humidity in the petri dishes during

8.1.2.1 Trichoderm pseudokoningii Rifai (ATCC 26801).

the test period, place eight to ten layers of absorbent paper on

8.1.2.2 Cephaloascus fragrans Hanawa (ATCC 12091).

the bottom of each dish. Wet the papers with water until free

8.1.2.3 Gliocladium roseum (Link) Bainier (ATCC 10521).

water appears, and press out any air bubbles trapped under and

8.2 Softwoods:

between the paper disks (thoroughly if the dishes are to be

8.2.1 Sapstain Fungi:

sterilized). Place a U-shaped glass rod (3 mm in diameter) on

8.2.1.1 Diplodia natalensis P. Evans (ATCC 34643).

top of the papers and sterilize the petri dishes if required (Fig.

8.2.1.2 Ceratocystis pilifera (Fr.) C. Moreau (ATCC

1).

15457).

11.2 Aluminum Containers—To maintain high humidity in

8.2.1.3 Aureobasidium pullulans (d By) Arnaud (ATCC

the containers, treat as with the petri dishes. Instead of a

16624).

U-shaped glass rod however, place two (2) straight rods (3 mm

8.2.2 Mold Fungi:

in diameter by 20 cm long) on top of the papers. Sterilize if

8.2.2.1 Trichoderma pseudokoningii (Rifai (ATCC 26801).

required.

8.2.2.2 Cephaloascus fragrans Hanawa (ATCC 12091).

8.2.2.3 Gliocladium roseum (Link) Bainier (ATCC 10521).

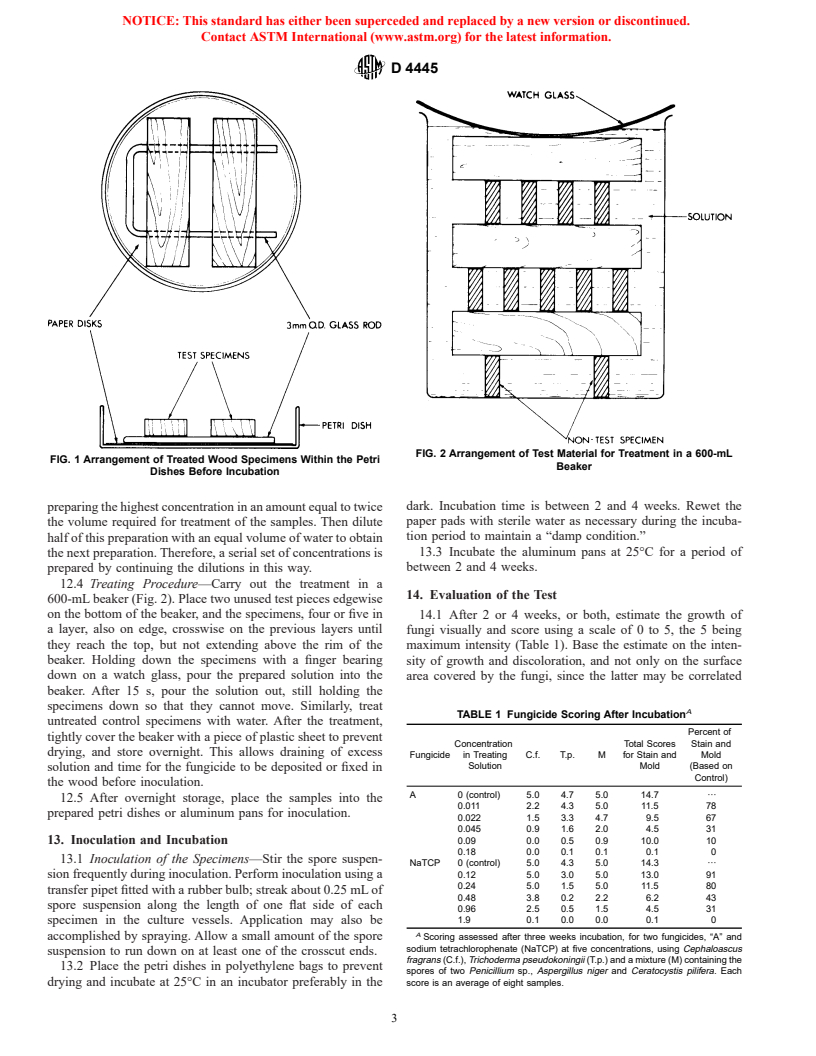

12. Treatment of Specimens

8.3 General Consideration—In addition to the above fungi,

12.1 Specimens—If the wood samples were stored frozen,

others that are known to cause discoloration on wood species

allow them to thaw in the polyethylene bags. Because of the

used in test may be included, for example, Cytospora sp.

variation in the susceptibility of wood to fungi, distribute an

(Pine); Phialophora sp.; Graphium sp.; Ceratocystis sp.; Al-

equal number of specimens from each log, into each treatment

ternaria sp.; Penicillium sp.; Aspergillis sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.