ASTM C1452-00

(Specification)Standard Specification for Reinforced Autoclaved Aerated Concrete Elements

Standard Specification for Reinforced Autoclaved Aerated Concrete Elements

SCOPE

1.1 This specification covers load-bearing and nonload-bearing reinforced autoclaved aerated concrete (AAC) floor, roof, wall, and stair elements used as components for building construction. Autoclaved aerated concrete is a cementitous product based on calcium silicate hydrates in which low density is attained by the inclusion of an agent resulting in macroscopic voids and is subjected to high-pressure steam curing. Installed units covered by this specification shall be protected against direct exposure to moisture using a coating material accepted by the AAC manufacturer.

1.2 The raw materials used in the production of autoclaved aerated concrete are portland cement, quartz sand, water, lime, gypsum or anhydrite, and an agent resulting in macroscopic voids. The quartz sand used as a raw material may be replaced by a siliceous fine aggregate other than sand and usually is ground to a fine powder before use. Fly ash may be used as a sand replacement. The batched raw materials are mixed together to form a slurry. The slurry is cast into steel molds. Due to the chemical reactions that take place within the slurry, the volume expands. After setting, and before hardening, the mass is machine cut with high accuracy into elements of various sizes. The elements then are steam-cured under pressure in autoclaves where the matrix is transformed into a solid calcium silicate hydrate.Note 1

LOI up to 12 % may be acceptable for production of AAC provided supporting test data is presented by the manufacturer.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only. ^^COMMITTEE: C27 ^SUBCOMMITTEE: 6000 ^BOS: 04.05 ^ORGINFO: none ^ACTION: NEW_STANDARD ^MISCPUB: ^PDESIG: C1452 ^PYEAR: 2000 ^CLASS: Specification

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1452 – 00

Standard Specification for

Reinforced Autoclaved Aerated Concrete Elements

This standard is issued under the fixed designation C 1452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 22/C 22M Specification for Gypsum

C 33 Specification for Concrete Aggregates

1.1 This specification covers load-bearing and nonload-

C 144 Specification for Aggregate for Masonry Mortar

bearing reinforced autoclaved aerated concrete (AAC) floor,

C 150 Specification for Portland Cement

roof, wall, and stair elements used as components for building

C 332 Specification for LightweightAggregates for Insulat-

construction. Autoclaved aerated concrete is a cementitous

ing Concrete

product based on calcium silicate hydrates in which low

C 595 Specifications for Blended Hydraulic Cements

density is attained by the inclusion of an agent resulting in

C 618 Specification for Coal Fly Ash and Raw or Calcined

macroscopic voids and is subjected to high-pressure steam

Natural Pozzolan for Use as a Mineral Admixture in

curing. Installed units covered by this specification shall be

Concrete

protected against direct exposure to moisture using a coating

C 1386 Specification for Precast Autoclaved Aerated Con-

material accepted by the AAC manufacturer.

crete (PAAC) Wall Construction Units

1.2 The raw materials used in the production of autoclaved

aerated concrete are portland cement, quartz sand, water, lime,

3. Classification

gypsum or anhydrite, and an agent resulting in macroscopic

3.1 Autoclaved aerated concrete elements manufactured in

voids. The quartz sand used as a raw material may be replaced

accordance with this specification are classified according to

by a siliceous fine aggregate other than sand and usually is

their strength class as shown in Table 1.

ground to a fine powder before use. Fly ash may be used as a

sand replacement. The batched raw materials are mixed to-

4. Materials and Manufacture

gether to form a slurry. The slurry is cast into steel molds. Due

4.1 Raw Materials—Materials shall conform to the follow-

to the chemical reactions that take place within the slurry, the

ing specifications:

volume expands.After setting, and before hardening, the mass

4.1.1 Quicklime, in accordance with manufacturer’s speci-

is machine cut with high accuracy into elements of various

fication.

sizes. The elements then are steam-cured under pressure in

4.1.2 Aggregate, in accordance with Specification C 33,

autoclaveswherethematrixistransformedintoasolidcalcium

C 144, or C 332.

silicate hydrate.

4.1.3 Portland Cement, in accordance with Specification

NOTE 1—LOI up to 12 % may be acceptable for production of AAC

C 150.

provided supporting test data is presented by the manufacturer.

4.1.4 Blended Cements, in accordance with Specification

1.3 The values stated in inch-pound units are to be regarded C 595.

as the standard. The values given in parentheses are provided

4.1.5 Gypsum, in accordance with Specification C 22/

for information only. C 22M.

4.1.6 Pozzolan, in accordance with Specification C 618.

2. Referenced Documents

4.1.7 Gas-producing agent conforming to the manufactur-

2.1 ASTM Standards:

er’s specification.

A 82 Specification for Steel Wire, Plain, for Concrete Re-

4.2 Steel Reinforcing—Steel reinforcing shall conform to

inforcement

the following specification and the requirements of Table 2.

4.2.1 Steel Wire, in accordance with Specification A 82.

This specification is under the jurisdiction of ASTM Committee C-27 on

Precast Concrete Products and is the direct responsibility of Subcommittee C27.60

on Precast Autoclaved Aerated Concrete. Annual Book of ASTM Standards, Vol 04.01.

Current edition approved Jan. 10, 2000. Published February 2000. Annual Book of ASTM Standards, Vol 04.02.

2 5

Annual Book of ASTM Standards, Vol 01.04. Annual Book of ASTM Standards, Vol 04.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

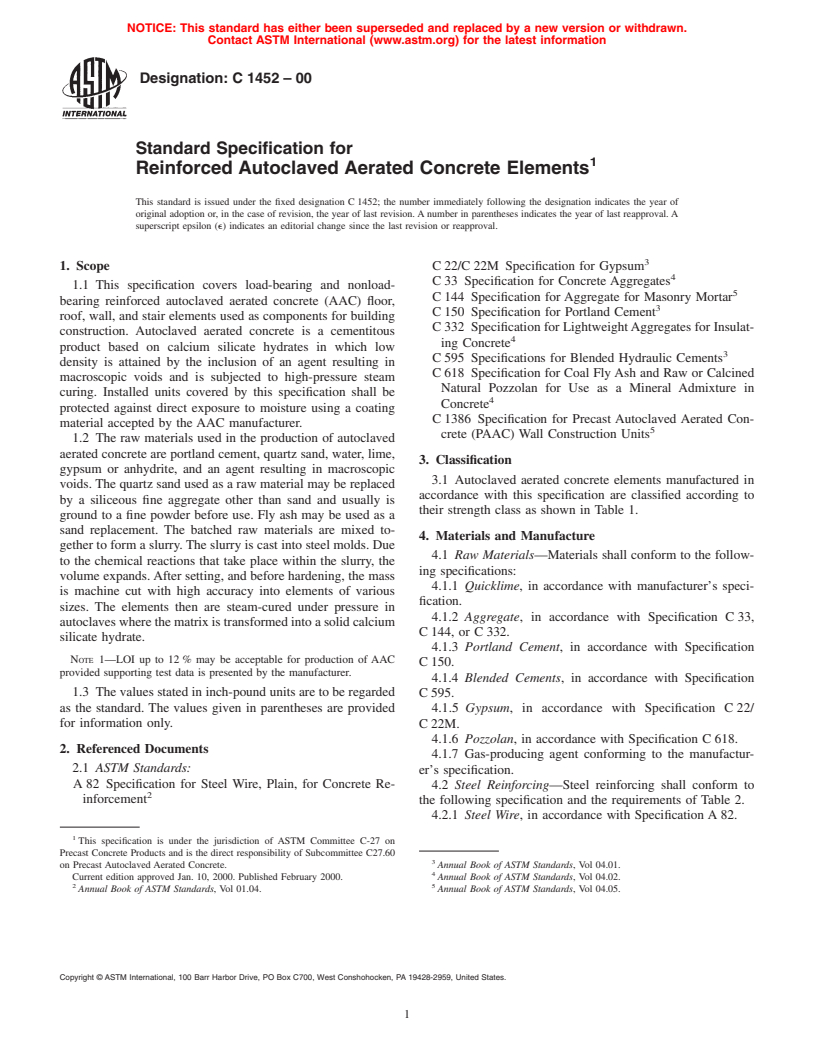

C 1452

TABLE 1 Physical Requirements

Strength Minimum Compressive Strength of AAC, Nominal Dry Bulk Density Limits, Average Drying Maximum Area of

3 3 A

Class psi (MPa) Density, lb/ft (kg/m ) Shrinkage Steel Corrosion

3 3

lb/ft (kg/m ) (%) (%)

Average Min

AAC-2 360 (2.5) 290 (2.0) 25 (400) 22 (350)—28 (450)

31 (500) 28 (450)—34 (550)

AAC-4 725 (5.0) 580 (4.0) 31 (500) 28 (450)—34 (550)

37 (600) 34 (550)—41 (650)

# 0.02 # 5.0

44 (700) 41 (650)—47 (750)

AAC-6 1090 (7.5) 870 (6.0) 37 (600) 35 (550)—41 (650)

44 (700) 41 (650)—47 (750)

50 (800) 47 (750)—53 (850)

A

As determined according to Section 7, indicated by a slight trace of rust on the surface of the steel. No flaking or deep rust should be evident on the steel surface.

TABLE 2 Properties of Steel Reinforcement

5.8 The load-bearing capacity of the reinforced AAC ele-

Property Minimum Characteristic Value ments shall be determined using the test method in Section 9,

or by calculation provided adequate test data are available for

Yield strength, min, ksi (MPa) 70 (485)

Tensile strength, min, ksi, (MPa) 80 (550)

verification of the calculation method.

A

Reduction of area, min, % 30

A

For material testing over 100 ksi (690 MPa) tensile strength, the reduction of

6. Dimensions and Permissible Variations

area shall be not less than 25 %.

6.1 The dimensions of the reinforced elements shall be as

specified by the AAC manufacturer. The allowable deviations

5. Physical Requirements

for the element dimensions shall be as specified in Table 4.

5.1 CompressiveStrength—The compressive strength of the

AAC material shall be determined according to Specification

7. Corrosion Protection of Steel Reinforcement in AAC

C 1386 and shall conform to the requirements of Table 1.

7.1 Apparatus:

5.2 BulkDensity—The dry bulk density shall be determined

7.1.1 StorageContainer, with dimensions sufficient to com-

according to Specification C 1386 and shall conform to the

pletely immerse AAC specimens.

requirements of Table 1.

7.2 Test Specimens:

5.3 Shrinkage—The drying shrinkage of the AAC material

7.2.1 Atest set shall consist of six test specimens having the

shall be determined according to Specification C 1386 and

dimensions16in.(400mm)bywidthofthereinforcedelement

shall conform to the requirements of Table 1.

by thickness of the reinforced element. The exposed surface

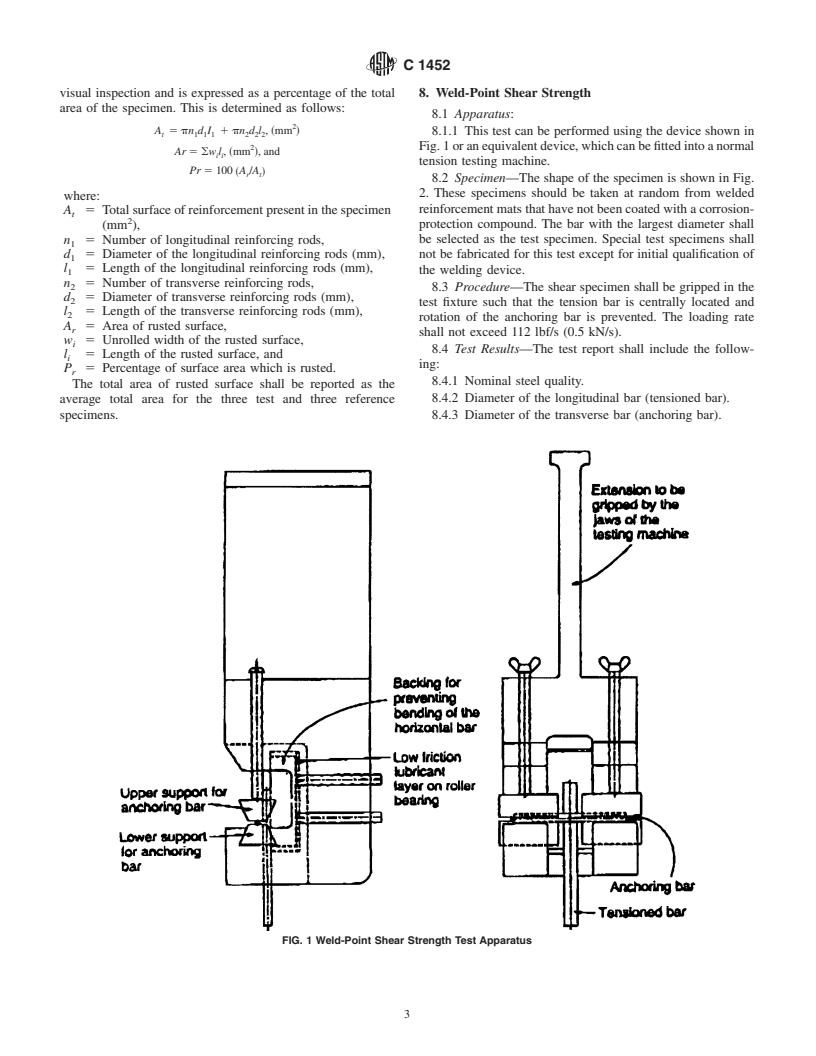

5.4 Weld-Point Shear Strength—The weld-point shear

areasofthesteelreinforcementateachendofthetestspecimen

strengthinthereinforcementshallbedeterminedinaccordance

shall be coated with the corrosion-protection compound and

with Section 8 and shall conform to the requirements of Table

allowed to dry before testing. Three specimens are to be kept

3.

as reference specimens, and three specimens shall be tested.

5.5 Concrete Cover of Steel Reinforcement—The minimum

7.3 Procedure:

concrete cover over the steel reinforcement shall be 0.375 in.

7.3.1 Reference Specimens—The reference specimens are

(10 mm). The reinforcing steel shall receive a rust-resistant

stored in a room having a temperature of 59–68°F (15–20°C)

coating before casting.

and a relative humidity of 50 to 70 %.

5.6 Effectiveness of Corrosion Protection of Steel

7.3.2 Test Specimens—The test specimens are immersed in

Reinforcement—The effectiveness of the corrosion protection

an aqueous sodium chloride solution, 3 % NaCl by mass, for

for the steel reinforcement shall be determined according to

periods of2hat intervals of three days. This is repeated for a

Section 7 and shall conform to the requirements of Table 1.

total of ten test cycles. When the specimens are not immersed

5.7 Steel Reinforcement—The properties of the steel rein-

in the sodium chloride solution, they are stored under the same

forcementshallbedeterminedinaccordancewithSpecification

conditions as the reference specimens.After completion of the

A 82 and shall conform to the requirements of Table 2.

ten testing cycles the specimens are allowed to air dry for 4 h.

7.3.3 Inspection for Rust—After completion of the testing

TABLE 3 Weld-Point Shear Strength

procedure the autoclaved aerated concrete around the steel

Diameter of the Longitudinal Minimum Shear Strength of the Joint,

reinforcing is removed from both the reference and the test

Reinforcement, in. (mm) lbf (kN)

specimens. The area of rust covering the steel is determined by

0.16 (4.0) 495 (2.20)

0.18 (4.5) 598 (2.66)

0.20 (5.0) 771 (3.43)

0.24 (6.0) 1113 (4.95) TABLE 4 Dimensional Tolerances for AAC Reinforced Elements

0.28 (7.0) 1513 (6.73)

Dimension Floor, Roof, and Wall Panels

0.32 (8.0) 1987 (8.84)

0.35 (9.0) 2502 (11.13) Length 6 0.20 in. (6 5 mm)

0.40 (10.0) 3091 (13.75) Width 6 0.12 in. (6 3 mm)

0.43 (11.0) 3741 (16.64) Thickness 6 0.12 in. (6 3 mm)

0.47 (12.0) 5339

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.