ASTM D4953-15

(Test Method)Standard Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

Standard Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

SIGNIFICANCE AND USE

5.1 Vapor pressure is an important physical property of liquid spark-ignition engine fuels. It provides an indication of how a fuel will perform under different operating conditions. For example, vapor pressure is a factor in determining whether a fuel will cause vapor lock at high ambient temperature or at high altitude, or will provide easy starting at low ambient temperature.

5.2 Petroleum product specifications generally include vapor pressure limits to ensure products of suitable volatility performance.

Note 3: Vapor pressure of fuels is regulated by various government agencies.

SCOPE

1.1 This test method covers and is applicable to gasolines and gasoline-oxygenate blends with a vapor pressure range from 35 kPa to 100 kPa (5 psi to 15 psi) (see Note 2). This test method, a modification of Test Method D323 (Reid Method), provides two procedures to determine the vapor pressure (Note 1) of gasoline and gasoline-oxygenate blends.

Note 1: Because the external atmospheric pressure is counteracted by the atmospheric pressure initially present in the air chamber, this vapor pressure is an absolute pressure at 37.8 °C (100 °F) in kilopascals (pounds-force per square inch). This vapor pressure differs from the true vapor pressure of the sample due to some small vaporization of the sample and air in the confined space.

Note 2: Vapor pressure of gasoline or gasoline-oxygenate blends below 35 kPa (5 psi) or greater than 100 kPa (15 psi) can be determined with this test method but the precision and bias (Section 11) do not apply. For materials with a vapor pressure greater than 100 kPa (15 psi), use a 0 kPa to 200 kPa (0 psi to 30 psi) gauge as specified in the annex of Test Method D323.

1.2 Some gasoline-oxygenate blends may show a haze when cooled to 0 °C to 1 °C. If a haze is observed in 9.4, it shall be indicated in the reporting of results. The precision and bias statements for hazy samples have not been determined (see Note 7).

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warnings are given in 7.5, 8.4.1, 8.5.1, 9.1, A1.1, and A1.1.3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4953 − 15

Standard Test Method for

Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends

1

(Dry Method)

This standard is issued under the fixed designation D4953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This test method covers and is applicable to gasolines 2.1 ASTM Standards:

D323 TestMethodforVaporPressureofPetroleumProducts

and gasoline-oxygenate blends with a vapor pressure range

(Reid Method)

from 35 kPa to 100 kPa (5 psi to 15 psi) (see Note 2). This test

D4057 Practice for Manual Sampling of Petroleum and

method, a modification of Test Method D323 (Reid Method),

Petroleum Products

provides two procedures to determine the vapor pressure (Note

D4175 Terminology Relating to Petroleum, Petroleum

1) of gasoline and gasoline-oxygenate blends.

Products, and Lubricants

NOTE 1—Because the external atmospheric pressure is counteracted by

D5190 Test Method for Vapor Pressure of Petroleum Prod-

the atmospheric pressure initially present in the air chamber, this vapor

3

ucts (Automatic Method) (Withdrawn 2012)

pressure is an absolute pressure at 37.8 °C (100 °F) in kilopascals

(pounds-force per square inch). This vapor pressure differs from the true D5191 Test Method for Vapor Pressure of Petroleum Prod-

vaporpressureofthesampleduetosomesmallvaporizationofthesample

ucts (Mini Method)

and air in the confined space.

E1 Specification for ASTM Liquid-in-Glass Thermometers

NOTE 2—Vapor pressure of gasoline or gasoline-oxygenate blends

below 35 kPa (5 psi) or greater than 100 kPa (15 psi) can be determined

3. Terminology

with this test method but the precision and bias (Section 11) do not apply.

3.1 Definitions:

For materials with a vapor pressure greater than 100 kPa (15 psi), use a

0 kPa to 200 kPa (0 psi to 30 psi) gauge as specified in the annex of Test

3.1.1 Bourdon spring gauge, n—pressure measuring device

Method D323.

that employs a bourdon tube connected to an indicator.

1.2 Somegasoline-oxygenateblendsmayshowahazewhen

3.1.2 Bourdon tube, n—flattened metal tube bent to a curve

cooled to 0 °C to 1 °C. If a haze is observed in 9.4, it shall be

that straightens under internal pressure.

indicated in the reporting of results. The precision and bias

3.1.3 dry method, n—in vapor pressure methods, a specific

statements for hazy samples have not been determined (see

empirical test method (D4953) for measuring the vapor pres-

Note 7).

sure of gasoline and other volatile products in which contact of

1.3 The values stated in SI units are to be regarded as

the test specimen with water is not allowed.

standard. The values given in parentheses are for information

3.1.4 dry vapor pressure equivalent (DVPE), n—value cal-

only.

culated by a defined correlation equation, that is expected to be

1.4 This standard does not purport to address all of the comparable to the vapor pressure value obtained by Test

safety concerns, if any, associated with its use. It is the Method D4953, Procedure A.

responsibility of the user of this standard to establish appro-

3.1.5 oxygenate, n—oxygen-containing ashless organic

priate safety and health practices and determine the applica-

compound, such as an alcohol or ether, which may be used as

bility of regulatory limitations prior to use. Specific warnings

a fuel or fuel supplement. D4175

are given in 7.5, 8.4.1, 8.5.1, 9.1, A1.1, and A1.1.3.

3.1.6 vapor pressure, n—pressure exerted by the vapor of a

liquid when in equilibrium with the liquid D4175

1 2

This test method is under the jurisdiction of Committee D02 on Petroleum For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mittee D02.08 on Volatility. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 1, 2015. Published June 2015. Originally the ASTM website.

3

approved in 1989. Last previous edition approved in 2012 as D4953 – 06 (2012). The last approved version of this historical standard is referenced on

DOI: 10.1520/D4953-15. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

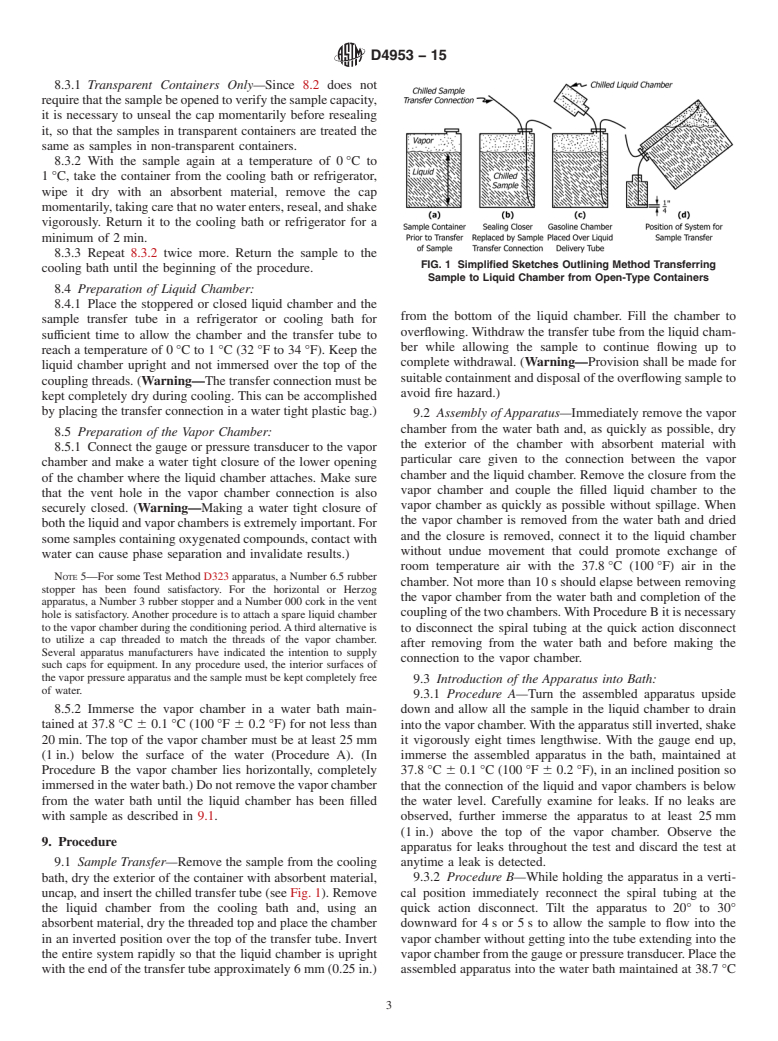

---------------------- Page: 1 ----------------------

D4953 − 15

3.2 Abbreviations: 7.4 Sample Container Size:

3.2.1 DVPE, n—dry vapor pressure equivalent

7.4.1 The size of the sample container from which the vapor

pressure sa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4953 − 06 (Reapproved 2012) D4953 − 15

Standard Test Method for

Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends

1

(Dry Method)

This standard is issued under the fixed designation D4953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers and is applicable to gasolines and gasoline-oxygenate blends with a vapor pressure range from 35

to 100 kPa (5 to 15 psi) 35 kPa to 100 kPa (5 psi to 15 psi) (see Note 2). This test method, a modification of Test Method D323

(Reid Method), provides two procedures to determine the vapor pressure (Note 1) of gasoline and gasoline-oxygenate blends.

NOTE 1—Because the external atmospheric pressure is counteracted by the atmospheric pressure initially present in the air chamber, this vapor pressure

is an absolute pressure at 37.8°C (100°F)37.8 °C (100 °F) in kilopascals (pounds-force per square inch). This vapor pressure differs from the true vapor

pressure of the sample due to some small vaporization of the sample and air in the confined space.

NOTE 2—Vapor pressure of gasoline or gasoline-oxygenate blends below 35 kPa (5 psi) 35 kPa (5 psi) or greater than 100 kPa (15 psi) 100 kPa (15 psi)

can be determined with this test method but the precision and bias (Section 11) do not apply. For materials with a vapor pressure greater than 100 kPa

(15 psi), 100 kPa (15 psi), use a 0 to 200 kPa (0 to 30 psi) 0 kPa to 200 kPa (0 psi to 30 psi) gauge as specified in the annex of Test Method D323.

1.2 Some gasoline-oxygenate blends may show a haze when cooled to 00 °C to 1°C.1 °C. If a haze is observed in 9.4, it shall

be indicated in the reporting of results. The precision and bias statements for hazy samples have not been determined (see Note

7).

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warnings are given in 7.5, 8.4.1, 8.5.1, 9.1, A1.1, and A1.1.3.

2. Referenced Documents

2

2.1 ASTM Standards:

D323 Test Method for Vapor Pressure of Petroleum Products (Reid Method)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

3

D5190 Test Method for Vapor Pressure of Petroleum Products (Automatic Method) (Withdrawn 2012)

D5191 Test Method for Vapor Pressure of Petroleum Products (Mini Method)

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1 Definitions:

3.1.1 Bourdon spring gauge, n—pressure measuring device that employs a bourdon tube connected to an indicator.

3.1.2 Bourdon tube, n—flattened metal tube bent to a curve that straightens under internal pressure.

3.1.3 dry method, n—in vapor pressure methods, a specific empirical test method (D4953) for measuring the vapor pressure of

gasoline and other volatile products in which contact of the test specimen with water is not allowed.

3.1.4 dry vapor pressure equivalent (DVPE), n—value calculated by a defined correlation equation, that is expected to be

comparable to the vapor pressure value obtained by Test Method D4953, Procedure A.

1

This test method is under the jurisdiction of Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.08 on Volatility.

Current edition approved Nov. 1, 2012June 1, 2015. Published November 2012June 2015. Originally approved in 1989. Last previous edition approved in 20062012 as

D4953D4953 – 06 (2012).–06. DOI: 10.1520/D4953-06R12.10.1520/D4953-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.