ASTM D2591-07(2013)

(Test Method)Standard Test Method for Linear Density of Elastomeric Yarns (Short Length Specimens)

Standard Test Method for Linear Density of Elastomeric Yarns (Short Length Specimens)

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments because current estimates of between-laboratory precision are acceptable and the method is used extensively in the trade for acceptance testing.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use samples for such comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing, and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

5.2 Linear density of elastomeric yarns is used in some calculations for tensile and elastic properties.

5.3 The test method is based on elastomeric yarns in lthe “as-produced” condition, but may be used for treated elastomeric yarns provided the treatment is specified. The method does not cover the removal of finish for the determination of linear density of “finish-free” elastomeric yarns.

SCOPE

1.1 This test method covers the determination of the linear density of short lengths of “as produced” elastomeric yarns made from rubber, spandex or other elastomers.Note 1—For the determination of linear density of elastomeric yarns using skeins, refer to Test Method D6717.

1.2 This test method is not applicable to covered, wrapped, or core-spun yarns, or yarns spun from elastomeric staple, or elastomeric yarns removed from fabrics.

1.3 This test method is applicable to elastomeric yarns having a range of 40 to 3200 dtex (36 to 2900 denier).

1.4 The values stated in either SI units or U.S. Customary units are to be regarded separately as standard. Within the test the US Customary units are in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2591 − 07 (Reapproved 2013)

Standard Test Method for

Linear Density of Elastomeric Yarns (Short Length

Specimens)

This standard is issued under the fixed designation D2591; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the linear 3.1 For all terminology relating to D13.58, Yarns and

density of short lengths of “as produced” elastomeric yarns Fibers, refer to Terminology D4849.

made from rubber, spandex or other elastomers. 3.1.1 The following terms are relevant to this standard:

denier, elastomeric yarn, linear density, tex.

NOTE 1—For the determination of linear density of elastomeric yarns

using skeins, refer to Test Method D6717.

3.2 For all other terminology related to textiles, refer to

Terminology D123.

1.2 This test method is not applicable to covered, wrapped,

or core-spun yarns, or yarns spun from elastomeric staple, or

4. Summary of Test Method

elastomeric yarns removed from fabrics.

4.1 A pre-relaxed specimen is fastened in vertically

1.3 This test method is applicable to elastomeric yarns

mountedapparatusunderaspecifiedtension.Aspecifiedlength

having a range of 40 to 3200 dtex (36 to 2900 denier).

is cut from the specimen and weighed, and the linear density

1.4 The values stated in either SI units or U.S. Customary

calculated.

units are to be regarded separately as standard. Within the test

5. Significance and Use

theUSCustomaryunitsareinparentheses.Thevaluesstatedin

each system are not exact equivalents; therefore, each system

5.1 This test method is considered satisfactory for accep-

shall be used independently of the other.

tance testing of commercial shipments because current esti-

mates of between-laboratory precision are acceptable and the

1.5 This standard does not purport to address all of the

method is used extensively in the trade for acceptance testing.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 5.1.1 If there are differences of practical significance be-

tween reported test results for two laboratories (or more),

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. comparative tests should be performed to determine if there is

a statistical bias between them, using competent statistical

2. Referenced Documents

assistance. As a minimum, use samples for such comparative

teststhatareashomogeneousaspossible,drawnfromthesame

2.1 ASTM Standards:

lot of material as the samples that resulted in disparate results

D123 Terminology Relating to Textiles

during initial testing, and randomly assigned in equal numbers

D2258 Practice for Sampling Yarn for Testing

to each laboratory. The test results from the laboratories

D6717 Test Method for Linear Density of ElastomericYarns

involved should be compared using a statistical test for

(Skein Specimens)

unpaired data, at a probability level chosen prior to the testing

D4849 Terminology Related to Yarns and Fibers

series. If bias is found, either its cause must be found and

corrected, or future test results for that material must be

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

adjusted in consideration of the known bias.

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

Current edition approved July 1, 2013. Published September 2013. Originally

5.2 Linear density of elastomeric yarns is used in some

approved in 1967. Last previous edition approved in 2007 as D2591 – 07. DOI:

calculations for tensile and elastic properties.

10.1520/D2591-07R13.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 The test method is based on elastomeric yarns in lthe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

“as-produced” condition, but may be used for treated elasto-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. meric yarns provided the treatment is specified. The method

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2591 − 07 (2013)

does not cover the removal of finish for the determination of 6.2.3.1 The slots are positioned such that the distance

linear density of “finish-free” elastomeric yarns. between the slot midlines provides a gage length of 1000 mm

when using the tex system or 900 mm when using the denier

6. Apparatus

system. If necessary, the two gage lengths can be obtained by

having the upper slot assembly adjustable, or by having two

6.1 Specimen Boards, with short pile or plush surfaces of

separate test apparatuses.

black or contrasting color, for storing specimens during relax-

ation period.

6.3 TensioningWeights, with varioius masses from 10 mg to

3gasrequired,topretensionthespecimensto1.0 60.1cN/tex

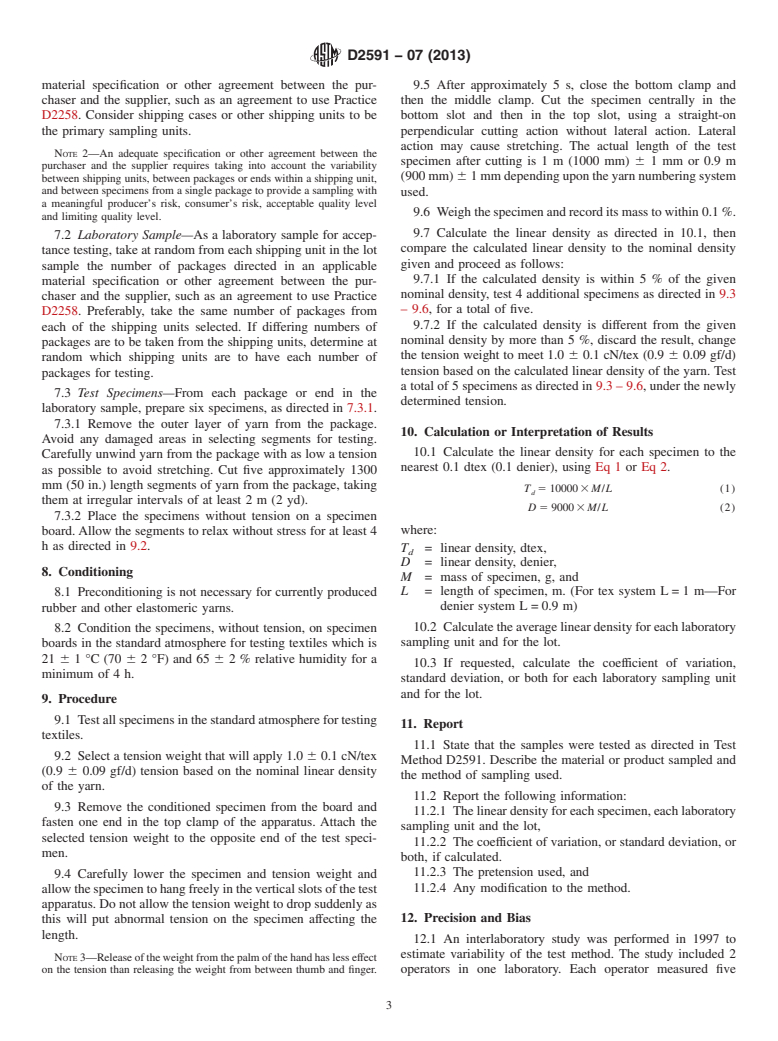

6.2 Linear Density Apparatus, mounted vertically on a wall

(0.9 6 0.09 gf/d) tension based on the nominal linear density

or in a sturdy, stable vertical support and containing the

of the yarn.

essential parts listed below. See Fig. 1 and Annex A1 for

general construction details of suitable apparatus.

6.4 Razor Blades, safety single-edge, or wood-carving type

6.2.1 Steel Plate, about 100 mm (4 in.) wide and 1.3 m (1.4

knife.

yd) long.

6.5 Balance, with an accuracy of 6 0.1% of the expected

6.2.2 Clamps, three toggle-action type with rubber tips.

mass of the specimens.

6.2.3 Brass Plates, two, with slots at right angles to be used

for controlling the alignment and length of the specimen.

7. Sampling, Test Specimens, and Test Units

7.1 LotSample—Asalotsampleforacceptancetesting,take

a random number of shipping units directed in an applicable

Components are commercially available.

NOTE 1—Drawing not to scale. For conversion to U.S. customary units,

divide mm by 25.4 to obtain inches

FIG. 1 Linear Density Apparatus

D2591 − 07 (2013)

material specification or other agreement between the pur- 9.5 After approximately 5 s, close the bottom clamp and

chaser and the supplier, such as an agreement to use Practice then the middle clamp. Cut the specimen centrally in the

D2258. Consider shipping cases or other shipping units to be bottom slot and then in the top slot, using a straight-on

the primary sampling units. perpendicular cutting action without lateral action. Lateral

action may cause stretching. The actual length of the test

NOTE 2—An adequate specification or other agreement between the

specimen after cutting is 1 m (1000 mm) 61mmor0.9m

purchaser and the supplier requires taking into account the variability

(900mm) 61mmdependingupontheyarnnumberingsystem

between shipping units, between packages or ends within a shipping unit,

and between specimens from a single package to provide a sampling with

used.

a meaningful producer’s risk, consumer’s risk, acceptable quality level

9.6 Weighthespecimenandrecorditsmasstowithin0.1%.

and limiting quality level.

9.7 Calculate the linear density as directed in 10.1, then

7.2 Laboratory Sample—As a laboratory sample for accep-

compare the calculated linear density to the nominal density

tance testing, take at random from each shipping unit in the lot

given and proceed as follows:

sample the number of packages directed in an applicable

9.7.1 If the calculated density is within5%ofthe given

material specification or other agreement between the pur-

nominal density, test 4 additional specimens as directed in 9.3

chaser and the supplier, such as an agreement to use Practice

– 9.6, for a total of five.

D2258. Preferably, take the same number of packages from

9.7.2 If the calculated density is different from the given

each of the shipping units selected. If differing numbers of

nominal density by more than 5 %, discard the result, change

packages are to be taken from the shipping units, determine at

the tension weight to meet 1.0 6 0.1 cN/tex (0.9 6 0.09 gf/d)

random which shipping units are to have each number of

tension based on the calculated linear density of the yarn. Test

packages for testing.

a total of 5 specimens as directed in 9.3 – 9.6, under the newly

7.3 Test Specimens—From each package or end in the

determined tension.

laboratory s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.