ASTM D6011-96

(Test Method)Standard Test Method for Determining the Performance of a Sonic Anemometer/Thermometer

Standard Test Method for Determining the Performance of a Sonic Anemometer/Thermometer

SCOPE

1.1 This test method covers the determination of the dynamic performance of a sonic anemometer/thermometer which employs the inverse time measurement technique for velocity or speed of sound, or both. Performance criteria include (a) acceptance angle, (b) acoustic pathlength, (c) system delay, (d) system delay mismatch, (e) thermal stability range, (f) shadow correction, (g) velocity calibration range, and (h) velocity resolution.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6011 – 96

Standard Test Method for

Determining the Performance of a Sonic

Anemometer/Thermometer

This standard is issued under the fixed designation D 6011; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope at which an abrupt decrease in an object’s drag coefficient

occurs (2).

1.1 This test method covers the determination of the dy-

3.2.2.1 Discussion—The transducer shadow corrections are

namic performance of a sonic anemometer/thermometer which

no longer valid above the critical Reynolds number due to a

employs the inverse time measurement technique for velocity

discontinuity in the axial attenuation coefficient.

or speed of sound, or both. Performance criteria include: (a)

3.2.3 Reynolds number (R )—the ratio of inertial to viscous

e

acceptance angle, (b) acoustic pathlength, (c) system delay, (d)

forces on an object immersed in a flowing fluid based on the

system delay mismatch, (e) thermal stability range, (f) shadow

object’s characteristic dimension, the fluid velocity, and vis-

correction, (g) velocity calibration range, and (h) velocity

cosity.

resolution.

3.2.4 shadow correction (v /v )—the ratio of the true

dm d

1.2 This standard does not purport to address all of the

along-axis velocity v , as measured in a wind tunnel or by

dm

safety concerns, if any, associated with its use. It is the

another accepted method, to the instrument along-axis wind

responsibility of the user of this standard to establish appro-

measurement v .

d

priate safety and health practices and determine the applica-

3.2.4.1 Discussion—This correction compensates for flow

bility of regulatory limitations prior to use.

shadowing effects of transducers and their supporting struc-

2. Referenced Documents tures. The correction can take the form of an equation (3) or a

lookup table (4).

2.1 ASTM Standards:

3.2.5 speed of sound (c, (m/s))—the propagation rate of an

C 384 Test Method for Impedance and Absorption of

adiabatic compression wave

Acoustical Materials by the Impedance Tube Method

0.5

D 1356 Terminology Relating to Sampling and Analysis of

c 5 ~g]P/]r! (1)

s

Atmospheres

where:

D 5527 Practice for Measuring Surface Wind and Tempera-

r = density,

ture by Acoustic Means

g = specific heat ratio, and

E 380 Practice for Use of the International System of Units

4 s = isentropic (adiabatic) process (6).

(SI) (the Modernized Metric System)

3.2.5.1 Discussion—The velocity of the compression wave

3. Terminology

defined along each axis of a Cartesian coordinate system is the

3.1 Definitions—For definitions of terms related to this test

sum of propagation speed c plus the motion of the gas along

method, refer to Terminology D 1356.

that axis. In a perfect gas (5):

3.2 Definitions of Terms Specific to This Standard:

0.5

c 5 ~gR* T/M! (2)

3.2.1 axial attenuation coeffıcient—a ratio of the free stream

wind velocity (as defined in a wind tunnel) to velocity along an The approximation for propagation in air is:

acoustic propagation path (v /v ) (1). 0.5 0.5

t d

c 5 403 T 1 1 0.32 e/P 5 403 T (3)

@ ~ !# ~ !

air s

3.2.2 critical Reynolds number (R )—the Reynolds number

c

3.2.6 system clock—the clock used for timing acoustic

wavefront travel between a transducer pair.

3.2.7 system delay (dt, μs)—the time delay through the

This test method is under the jurisdiction of ASTM Committee D-22 on

Sampling and Analysis of Atmospheresand is the direct responsibility of Subcom-

transducer and electronic circuitry (7).

mittee D22.11on Meteorology.

3.2.7.1 Discussion—Each path through every sonic array

Current edition approved Oct. 10, 1996. Published December 1996.

axis can have unique delay characteristics. Delay (on the order

Annual Book of ASTM Standards, Vol 04.06.

Annual Book of ASTM Standards, Vol 11.03. of 10 to 20 μs) can vary as a function of temperature and

Annual Book of ASTM Standards, Vol 14.02.

direction of signal travel through the transducers and electronic

The boldface numbers in parentheses refer to the list of references at the end of

this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6011

circuitry. The average system delay for each axis in an acoustic range of velocity between creeping flow and the flow at which

array is the average of the delays measured in each direction a critical Reynolds number is reached.

along the axis 3.2.12.1 Discussion—The shadow correction is valid over a

range of velocities where no discontinuities are observed in the

dt 5 ~dt 1dt !/2 (4)

1 2

axial attenuation coefficient.

3.2.8 system delay mismatch (dt , μs)—the absolute differ-

t

3.2.13 velocity resolution (dv, (m/s))—the largest change in

ence in microseconds between total transit times t in each

t

an along-axis wind component that would cause no change in

direction (t , t ) through the system electronics and transduc-

t1 t2

the pulse arrival time count.

ers.

3.2.13.1 Discussion—Velocity resolution defines the small-

3.2.8.1 Discussion—Due principally to slight differences in

est resolvable wind velocity increment as determined from

transducer performance, the total transit time obtained with the

system clock rate. For some systems, dv defined as the standard

signal originating at one transducer can differ from the total

deviation of system dither can also be reported.

transit time obtained with the signal originating at its paired

3.3 Symbols:

transducer. The manufacturer should specify the system delay

mismatch tolerance.

c = speed of sound, m/s,

dt 5 ? t 2 t ? (5)

t t1 t2

C = specific heat at constant pressure, J/(kg·K),

p

3.2.9 thermal stability range (°C)—a range of temperatures

C = specific heat at constant volume, J/(kg·K),

v

over which the corrected velocity output in a zero wind

e = vapor pressure, Pa,

chamber remains at or below instrument resolution.

d = acoustic pathlength, m,

3.2.9.1 Discussion—Thermal stability range defines a range

f = compressibility factor, dimensionless,

of temperatures over which there is no step change in system

M = molecular weight of a gas, g/mol,

delay. P = pressure, Pa,

3.2.10 time resolution (Dt, μs)—resolution of the internal R* = universal gas constant, 8.31436 J/(mol·K),

RH = relative humidity, %,

clock used to measure time.

t = transit time, μs,

3.2.11 transit time (t, μs)—the time required for an acoustic

t = total transit time, μs,

t

wavefront to travel from the transducer of origin to the

T = absolute temperature, K,

receiving transducer.

T = sonic absolute temperature, K,

s

3.2.11.1 Discussion—Transit time (also known as time of

U = upper limit for creeping flow, m/s,

c

flight) is determined by acoustic pathlength d, the speed of

U = critical Reynolds number velocity, m/s,

s

sound c, the velocity component along the acoustic propaga-

v = velocity component along acoustic propagation

d

tion path v , and cross-path velocity components) v (8)

d n

path, m/s,

2 2 0.5 2 2 2

t 5 d c 2 v ! 6 V / c 2 v 1 v ! (6) v = tunnel velocity component parallel to the array axis

@~ # @ ~ #

n d d n dm

(v , cos u), m/s,

t

The transit time difference between acoustic wavefront propagation

v = velocity component normal to an acoustic propaga-

n

in one direction (t , computed for + v ) and the other (t , computed

1 d 2

tion path, m/s,

for − v ) for each transducer pair determines the magnitude of a

d

v = free stream wind velocity component (unaffected by

velocity component. The inverse transit time solution for the along-axis t

velocity is (9) the presence of an obstacle such as the acoustic

array), m/s,

d 1 1

v 5 2 (7)

F G dt = system delay, μs,

d

2 t t

1 2

dt = system delay mismatch, μs,

The total transit times t and t , include the sum of actual transit t

t1 t2

Dt = clock pulse resolution, s,

times plus system delay through the electronics and transducers in each

a = acceptance angle, degree,

direction along an acoustic path, d and d . System delay must be

t1 t2

removed to calculate v , that is, g = specific heat ratio (C /C ), dimensionless,

d p v

dv = velocity resolution, m/s,

t 5 t 2d (8)

1 t1 t1

u = array angle of attack, degree, and

r = gas density, kg/m .

t 5 t 2d (9)

2 t2 t2

3.4 Abbreviations:Units—Units of measurement are in ac-

3.2.11.2 Discussion—Procedures in this test method include

cordance with Practice E 380.

a test to determine whether separate determinations of d t and

4. Summary of Test Method

dt are needed, or whether an average dt can be used. The

relationship of transit time to speed of sound is

4.1 Acoustic pathlength, system delay, and system delay

2 mismatch are determined using the dual gas or zero wind

d 1 1

2 2

c 5 1 1 v (10)

F S DG

n

chamber method. The acoustic pathlength and system clock

2 t t

1 2

rate are used to calculate the velocity resolution. Thermal

and the inverse transit time solution for sonic temperature in air is as

sensitivity range is defined using a zero wind chamber. The

follows (6):

axial attenuation coefficient, velocity calibration range, and

2 2 2

d 1 1 v

n

transducer shadow effects are defined in a wind tunnel. Wind

T 5 1 1 (11)

S DF G

s

1612 t t 403

1 2

tunnel results are used to compute shadow corrections and to

3.2.12 velocity calibration range (U to U , (m/s))—the define acceptance angles.

c s

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6011

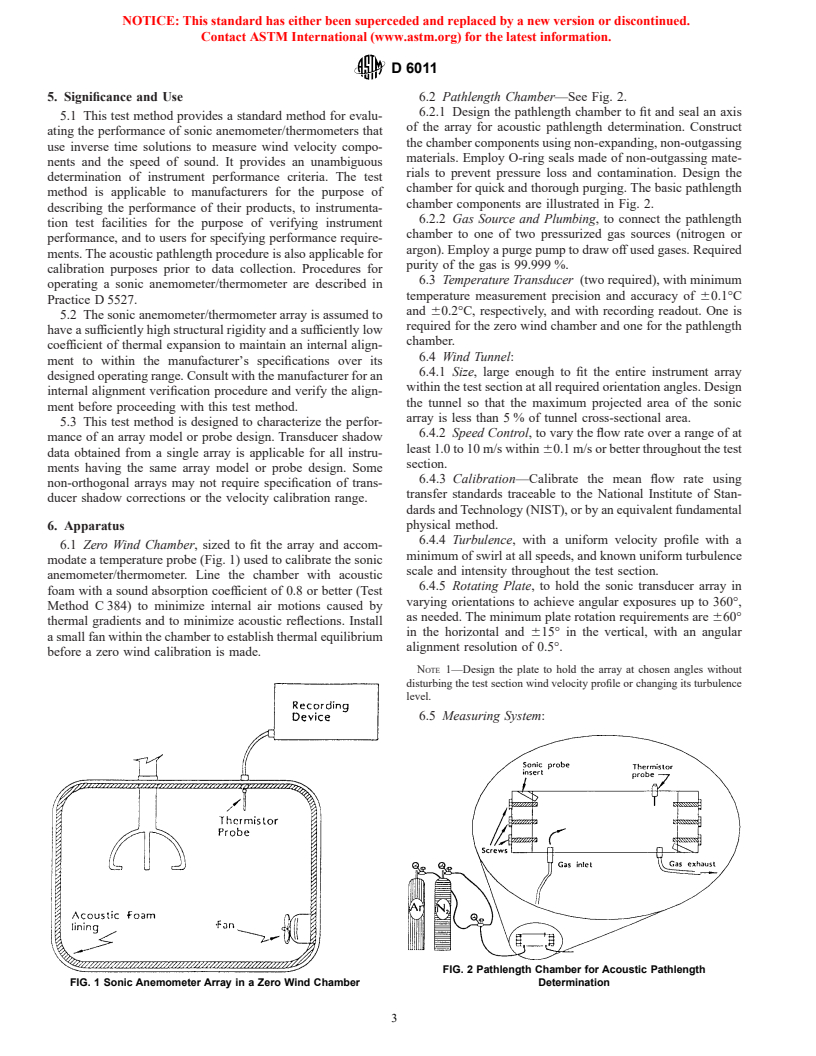

5. Significance and Use 6.2 Pathlength Chamber—See Fig. 2.

6.2.1 Design the pathlength chamber to fit and seal an axis

5.1 This test method provides a standard method for evalu-

of the array for acoustic pathlength determination. Construct

ating the performance of sonic anemometer/thermometers that

the chamber components using non-expanding, non-outgassing

use inverse time solutions to measure wind velocity compo-

materials. Employ O-ring seals made of non-outgassing mate-

nents and the speed of sound. It provides an unambiguous

rials to prevent pressure loss and contamination. Design the

determination of instrument performance criteria. The test

chamber for quick and thorough purging. The basic pathlength

method is applicable to manufacturers for the purpose of

chamber components are illustrated in Fig. 2.

describing the performance of their products, to instrumenta-

6.2.2 Gas Source and Plumbing, to connect the pathlength

tion test facilities for the purpose of verifying instrument

chamber to one of two pressurized gas sources (nitrogen or

performance, and to users for specifying performance require-

argon). Employ a purge pump to draw off used gases. Required

ments. The acoustic pathlength procedure is also applicable for

purity of the gas is 99.999 %.

calibration purposes prior to data collection. Procedures for

6.3 Temperature Transducer (two required), with minimum

operating a sonic anemometer/thermometer are described in

temperature measurement precision and accuracy of 60.1°C

Practice D 5527.

and 60.2°C, respectively, and with recording readout. One is

5.2 The sonic anemometer/thermometer array is assumed to

required for the zero wind chamber and one for the pathlength

have a sufficiently high structural rigidity and a sufficiently low

chamber.

coefficient of thermal expansion to maintain an internal align-

6.4 Wind Tunnel:

ment to within the manufacturer’s specifications over its

6.4.1 Size, large enough to fit the entire instrument array

designed operating range. Consult with the manufacturer for an

within the test section at all required orientation angles. Design

internal alignment verification procedure and verify the align-

the tunnel so that the maximum projected area of the sonic

ment before proceeding with this test method.

array is less than 5 % of tunnel cross-sectional area.

5.3 This test method is designed to characterize the perfor-

6.4.2 Speed Control, to vary the flow rate over a range of at

mance of an array model or probe design. Transducer shadow

least 1.0 to 10 m/s within 60.1 m/s or better throughout the test

data obtained from a single array is applicable for all instru-

section.

ments having the same array model or probe design. Some

6.4.3 Calibration—Calibrate the mean flow rate using

non-orthogonal arrays may not require specification of trans-

transfer standards traceable to the National Institute of Stan-

ducer shadow corrections or the velocity calibration range.

dards and Technology (NIST), or by an equivalent fundamental

physical method.

6. Apparatus

6.4.4 Turbulence, with a uniform velocity profile with a

6.1 Zero Wind Chamber, sized to fit the array and accom-

minimum of swirl at all speeds, and known uniform turbulence

modate a temperature probe (Fig. 1) used to calibrate the sonic

scale and intensity throughout the test section.

anemometer/thermometer. Line the chamber with acoustic

6.4.5 Rotating Plate, to hold the sonic transducer array in

foam with a sound absorption coefficient of 0.8 or better (Test

varying orientations to achieve angular exposures up to 360°,

Method C 384) to minimize internal air motions caused by

as needed. The minimum plate rotation requirements are 660°

thermal gradients and to minimize acoustic reflections. Install

in the horizontal and 615° in the vertical, with an angular

a small fan within the chamber to establish thermal equilibrium

alignment resolution of 0.5°.

before a zero wind calibration is made.

NOTE 1—Design the plate to hold the array at chosen angles without

disturbing the test section wind velocity profile or changing its turbulence

level.

6.5 Measuring System:

FIG. 2 Pathlength Chamber for Acoustic Pathlength

FIG. 1 Sonic Anemometer Array in a Zero Wind Chamber Determination

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6011

6.5.1 Counter, to log the anemometer velocity component apparatus permits. Reverse the process, going back through 0°

readings, with a count resolution equaling or exceeding the to − 60°, and return to 0°. Average the results to a single value

clock rate of the sonic anemometer/thermometer. for each angular position. Use a measurement period of 30 s at

6.5.2 Recorder, with at least a 10 Hz rate and a resolution each angle, and begin measure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.