ASTM D2534-88(1999)

(Test Method)Standard Test Method for Coefficient of Kinetic Friction for Wax Coatings

Standard Test Method for Coefficient of Kinetic Friction for Wax Coatings

SCOPE

1.1 This test method covers the determination of the coefficient of kinetic friction for a petroleum wax coating or wax-based hot melt coating when sliding over itself.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2534 – 88 (Reapproved 1999)

Standard Test Method for

Coefficient of Kinetic Friction for Wax Coatings

This standard is issued under the fixed designation D 2534; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers the determination of the coef- 5.1 The coefficient of friction is related to the slip properties

ficient of kinetic friction for a petroleum wax coating or of many commercial articles which have been coated with

wax-based hot melt coating when sliding over itself. petroleum wax (for example, butter cartons and wax impreg-

1.2 This standard does not purport to address all of the nated or hot melt coated corrugated board).

safety concerns, if any, associated with its use. It is the

6. Apparatus

responsibility of the user of this standard to establish appro-

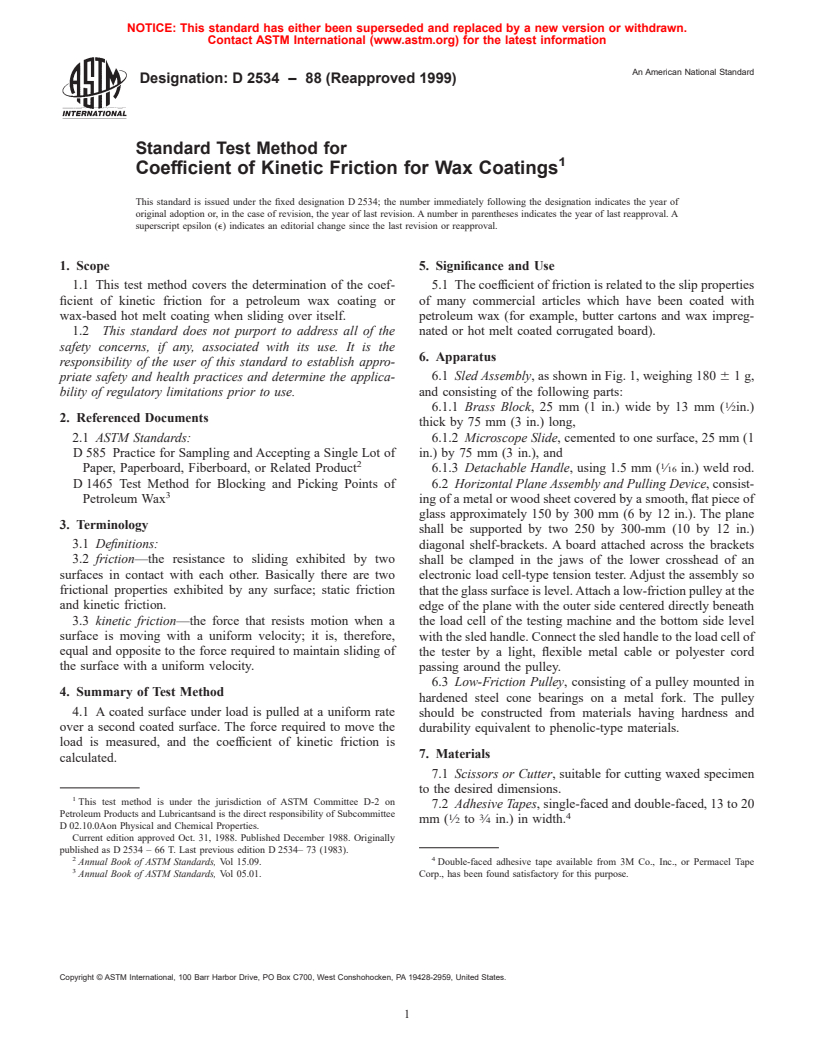

priate safety and health practices and determine the applica- 6.1 Sled Assembly, as shown in Fig. 1, weighing 180 6 1g,

and consisting of the following parts:

bility of regulatory limitations prior to use.

6.1.1 Brass Block, 25 mm (1 in.) wide by 13 mm ( ⁄2in.)

2. Referenced Documents

thick by 75 mm (3 in.) long,

2.1 ASTM Standards: 6.1.2 Microscope Slide, cemented to one surface, 25 mm (1

D 585 Practice for Sampling and Accepting a Single Lot of in.) by 75 mm (3 in.), and

Paper, Paperboard, Fiberboard, or Related Product 6.1.3 Detachable Handle, using 1.5 mm ( ⁄16 in.) weld rod.

D 1465 Test Method for Blocking and Picking Points of 6.2 Horizontal Plane Assembly and Pulling Device, consist-

Petroleum Wax ing of a metal or wood sheet covered by a smooth, flat piece of

glass approximately 150 by 300 mm (6 by 12 in.). The plane

3. Terminology

shall be supported by two 250 by 300-mm (10 by 12 in.)

3.1 Definitions: diagonal shelf-brackets. A board attached across the brackets

3.2 friction—the resistance to sliding exhibited by two

shall be clamped in the jaws of the lower crosshead of an

surfaces in contact with each other. Basically there are two electronic load cell-type tension tester. Adjust the assembly so

frictional properties exhibited by any surface; static friction that the glass surface is level. Attach a low-friction pulley at the

and kinetic friction.

edge of the plane with the outer side centered directly beneath

3.3 kinetic friction—the force that resists motion when a the load cell of the testing machine and the bottom side level

surface is moving with a uniform velocity; it is, therefore,

with the sled handle. Connect the sled handle to the load cell of

equal and opposite to the force required to maintain sliding of the tester by a light, flexible metal cable or polyester cord

the surface with a uniform velocity.

passing around the pulley.

6.3 Low-Friction Pulley, consisting of a pulley mounted in

4. Summary of Test Method

hardened steel cone bearings on a metal fork. The pulley

4.1 A coated surface under load is pulled at a uniform rate

should be constructed from materials having hardness and

over a second coated surface. The force required to move the

durability equivalent to phenolic-type materials.

load is measured, and the coefficient of kinetic friction is

7. Materials

calculated.

7.1 Scissors or Cutter, suitable for cutting waxed specimen

to the desired dimensions.

This test method is under the jurisdiction of ASTM Committee D-2 on

7.2 Adhesive Tapes, single-faced and double-faced, 13 to 20

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

1 3

mm ( ⁄2 to ⁄4 in.) in width.

D 02.10.0Aon Physical and Chemical Properties.

Current edition approved Oct. 31, 1988. Published December 1988. Originally

published as D 2534 – 66 T. Last previous edition D 2534– 73 (1983).

2 4

Annual Book of ASTM Standards, Vol 15.09. Double-faced adhesive tape available from 3M Co., Inc., or Permacel Tape

Annual Book of ASTM Standards, Vol 05.01. Corp., has been found satisfactory for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2534

FIG. 1 Coefficient of Kinetic Friction Sled Assembly

NOTE 2—For wax coated paper, make the attachment so that the

8. Sampling and Test Specimens

specimen is free of wrinkles.

8.1 Test specimens may be flexible, such as wax-coated

paper or rigid such as wax-coated paperboard or corrugated 10.2.1 For wax-coated paper, tape the ends of the 120 by 25

(Note 1). From each test unit obtained in accordance with mm (5 by 1 in.) specimen to the top of the sled,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.