ASTM E1938-13(2018)

(Test Method)Standard Test Method for Determination of Titanium in Nickel Alloys by Diantipyrylmethane Spectrophotometry

Standard Test Method for Determination of Titanium in Nickel Alloys by Diantipyrylmethane Spectrophotometry

SIGNIFICANCE AND USE

5.1 This test method is used for the determination of titanium in nickel alloy samples by molecular absorption spectrometry to check compliance with compositional specifications. It is assumed that all who use the procedure will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that the work will be performed in a properly equipped laboratory and that proper waste disposal procedures will be followed. Appropriate quality control practices must be followed such as those described in Guide E882.

SCOPE

1.1 This test method covers the determination of titanium in nickel alloys in the range 0.3 % to 5.0 %. With appropriate reference materials, the test method may be extended down to 0.05 %.

1.2 Molybdenum, if present, may cause a high bias to the extent of 0.001 % titanium for every 1 % molybdenum.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazards associated with the use of this test method, see Practices E50.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1938 − 13 (Reapproved 2018)

Standard Test Method for

Determination of Titanium in Nickel Alloys by

Diantipyrylmethane Spectrophotometry

This standard is issued under the fixed designation E1938; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E135 Terminology Relating to Analytical Chemistry for

Metals, Ores, and Related Materials

1.1 This test method covers the determination of titanium in

E882 Guide for Accountability and Quality Control in the

nickel alloys in the range 0.3 % to 5.0 %. With appropriate

Chemical Analysis Laboratory

reference materials, the test method may be extended down to

E1601 Practice for Conducting an Interlaboratory Study to

0.05 %.

Evaluate the Performance of an Analytical Method

1.2 Molybdenum, if present, may cause a high bias to the 3

2.2 ISO Standards:

extent of 0.001 % titanium for every 1 % molybdenum.

ISO 5725:1986 Precision of Test Methods—Determination

1.3 The values stated in SI units are to be regarded as of Repeatability and Reproducibility for a Standard Test

Method by Inter-Laboratory Tests

standard. No other units of measurement are included in this

standard. ISO 11433:1993(E) Nickel Alloys—Determination of Tita-

nium Content—Diantipyrylmethane Molecular Absorp-

1.4 This standard does not purport to address all of the

tion Spectrometric Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

3.1 Definitions—For definitions of terms used in this test

mine the applicability of regulatory limitations prior to use.

method, refer to Terminology E135.

Forspecifichazardsassociatedwiththeuseofthistestmethod,

see Practices E50.

4. Summary of Test Method

1.5 This international standard was developed in accor-

4.1 This test sample is dissolved in a mixture of HCl and

dance with internationally recognized principles on standard-

HNO . The solution is evaporated to fumes of H SO to

3 2 4

ization established in the Decision on Principles for the

remove the HCl and HNO . Color is developed with

Development of International Standards, Guides and Recom-

diantipyrylmethane, and the absorbance is measured at

mendations issued by the World Trade Organization Technical

390 nm.

Barriers to Trade (TBT) Committee.

5. Significance and Use

2. Referenced Documents

5.1 This test method is used for the determination of

2.1 ASTM Standards:

titanium in nickel alloy samples by molecular absorption

E29 Practice for Using Significant Digits in Test Data to

spectrometry to check compliance with compositional specifi-

Determine Conformance with Specifications

cations. It is assumed that all who use the procedure will be

E50 Practices for Apparatus, Reagents, and Safety Consid-

trained analysts capable of performing common laboratory

erations for Chemical Analysis of Metals, Ores, and

procedures skillfully and safely. It is expected that the work

Related Materials

will be performed in a properly equipped laboratory and that

properwastedisposalprocedureswillbefollowed.Appropriate

quality control practices must be followed such as those

This test method is under the jurisdiction of ASTM Committee E01 on

described in Guide E882.

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

responsibility of Subcommittee E01.08 on Ni and Co and HighTemperatureAlloys.

6. Apparatus

Current edition approved Oct. 1, 2018. Published November 2018. Originally

6.1 Spectrophotometer, capable of measuring absorbance at

approved in 1997. Last previous edition approved in 2013 as E1938 – 13. DOI:

10.1520/E1938-13R18.

a wavelength of 390 nm.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1938 − 13 (2018)

6.2 Cells, to fit spectrophotometer, having an optical path of 9. Procedure

1 cm.

9.1 Preparation of Test Solution:

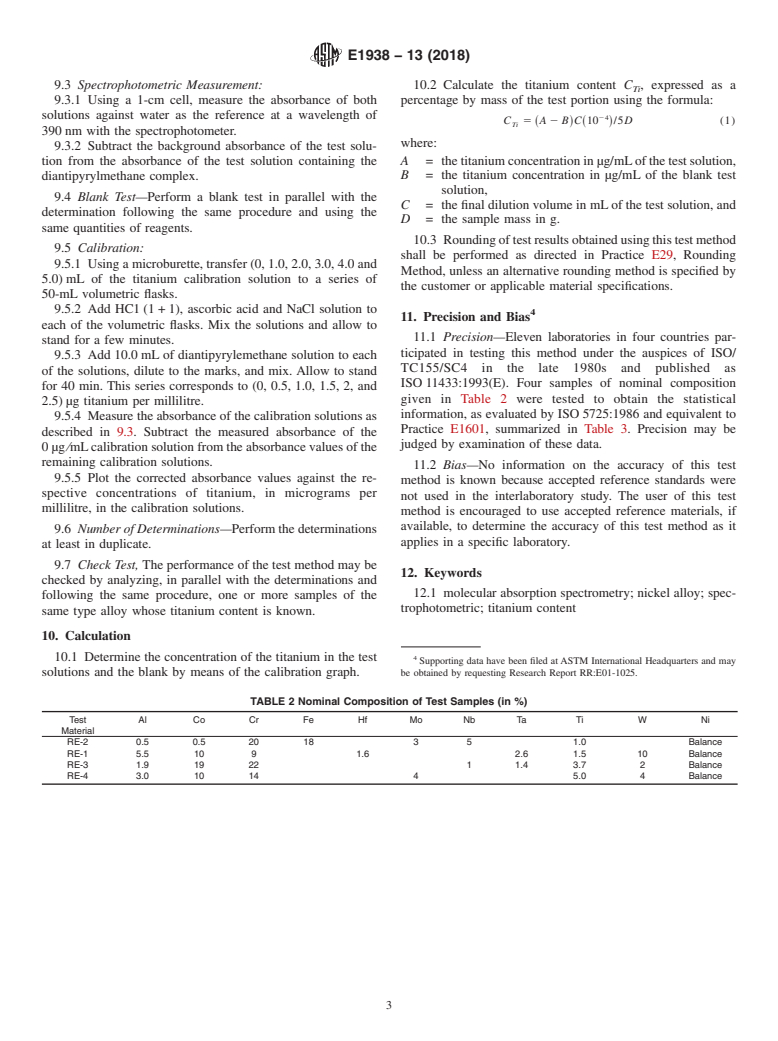

9.1.1 Test Portion—Weigh the test portion of the sample in

NOTE 1—Cells having other dimensions can be used, provided suitable

adjustments can be made in the amount of sample and reagents used. accordance with Table 1.

9.1.2 Dissolution of Test Portion—Transfer the test portion

7. Reagents

toa125-mLErlenmeyerflaskandadd10 mLofHC1and3 mL

of HNO . Apply sufficient heat to initiate and maintain the

7.1 Purity and Concentration of Reagents—The purity and

reaction until dissolution is complete. If the alloy resists

concentration of common chemical reagents and water shall

dissolution, some adjustment in the acid mixture may be

conform to Practices E50. The reagents should be free of or

required.AddHC1in1-mLincrementsandcontinueheatingto

contain only minimal amounts (< 0.1 µg⁄g) of titanium.

dissolve the test portion.

7.2 Potassium Hydrogen Sulfate (KHSO ).

4 9.1.3 Preparation of Final Test Solution:

9.1.3.1 Add 7 mL of H SO (1 + 1) and evaporate the

2 4

7.3 Ascorbic Acid Solution—Dissolve 20 g of ascorbic acid

solution until dense white fumes appear. Cool the contents and

(C H O ) in water, dilute to 200 mL, and mix.

6 8 6

proceed as directed in 9.1.3.2 or 9.1.3.3, depending on whether

7.4 Oxalic Acid Solution—Dissolve 10 g of oxalic acid

tantalum is present in the sample or not.

dihydrate [(COOH) 2H O] in water, dilute to 200 mL, and

2 2

9.1.3.2 In the absence of tantalum, add 20 mLof oxalic acid

mix.

solution and heat to dissolve the salts. Cool the solution and, in

tungsten free alloys, proceed as directed in 9.1.4. If the alloy

7.5 Diantipyrylmethane Solution—Dissolve 4 g of dian-

containstungsten,addsufficientammoniumhydroxidetomake

tipyrylmethane monohydrate (C H N O H O) in water con-

23 24 4 2 2

the solution alkaline. Boil the solution until the tungstic acid is

taining 25 mL HCl (1 + 1). Dilute to 200 mL and mix.

dissolved. Cool the solution and re-acidify by adding 20 mLof

7.6 Sodium Chloride Solution—Dissolve 117 g of sodium

HC1. Cool the solution and proceed as directed in 9.1.4.

chloride (NaCl) in water, dilute to 500 mL, and mix.

9.1.3.3 In the presence of tantalum, add 30 mL of water,

heat to dissolve the salts and cool again. Filter the solution

7.7 Titanium Stock Calibration Solution (200 µg⁄mL Ti)—

through a tightly packed filter pulp pad. Wash the precipitate

Dissolve 0.739 g of potassium titanyl oxalate dihydrate

with warm water. Retain the filtrate. Transfer the pad and

[K TiO(C O ) 2H O] in water. Add 50 mL of H SO (1+1)

2 2 4 2 2 2 4

precipitate to a platinum crucible, ignite at 800 °C, and cool.

and evaporate to dense fumes. Cool, dilute, and transfer the

Add 1 g of potassium pyrosulfate, cover the crucible with a

room temperature solution to a 500-mL volumetric flask.

platinum lid and fuse carefully over a flame. Cool and transfer

Dilute to the mark and mix.

thecrucibletoa150-mLbeakercontaining20 mLoftheoxalic

7.7.1 Alternative Preparation:Transfer 0.1000 g of titanium

acid solution. Heat carefully until the melt is dissolved. Wash

metal (purity: 99.9

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.