ASTM D4953-06(2012)

(Test Method)Standard Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

Standard Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

SIGNIFICANCE AND USE

5.1 Vapor pressure is an important physical property of liquid spark-ignition engine fuels. It provides an indication of how a fuel will perform under different operating conditions. For example, vapor pressure is a factor in determining whether a fuel will cause vapor lock at high ambient temperature or at high altitude, or will provide easy starting at low ambient temperature.

5.2 Petroleum product specifications generally include vapor pressure limits to ensure products of suitable volatility performance. Note 3—Vapor pressure of fuels is regulated by various government agencies.

SCOPE

1.1 This test method covers and is applicable to gasolines and gasoline-oxygenate blends with a vapor pressure range from 35 to 100 kPa (5 to 15 psi) (see Note 2). This test method, a modification of Test Method D323 (Reid Method), provides two procedures to determine the vapor pressure (Note 1) of gasoline and gasoline-oxygenate blends. Note 1—Because the external atmospheric pressure is counteracted by the atmospheric pressure initially present in the air chamber, this vapor pressure is an absolute pressure at 37.8°C (100°F) in kilopascals (pounds-force per square inch). This vapor pressure differs from the true vapor pressure of the sample due to some small vaporization of the sample and air in the confined space.Note 2—Vapor pressure of gasoline or gasoline-oxygenate blends below 35 kPa (5 psi) or greater than 100 kPa (15 psi) can be determined with this test method but the precision and bias (Section 11) do not apply. For materials with a vapor pressure greater than 100 kPa (15 psi), use a 0 to 200 kPa (0 to 30 psi) gauge as specified in the annex of Test Method D323.

1.2 Some gasoline-oxygenate blends may show a haze when cooled to 0 to 1°C. If a haze is observed in 9.4, it shall be indicated in the reporting of results. The precision and bias statements for hazy samples have not been determined (see Note 7).

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warnings are given in 7.5, 8.4.1, 8.5.1, 9.1, A1.1, and A1.1.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4953 − 06(Reapproved 2012)

Standard Test Method for

Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends

(Dry Method)

This standard is issued under the fixed designation D4953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers and is applicable to gasolines 2.1 ASTM Standards:

and gasoline-oxygenate blends with a vapor pressure range D323 TestMethodforVaporPressureofPetroleumProducts

from35to100kPa(5 to 15 psi) (seeNote 2).This test method, (Reid Method)

D4057 Practice for Manual Sampling of Petroleum and

a modification of Test Method D323 (Reid Method), provides

two procedures to determine the vapor pressure (Note 1)of Petroleum Products

D4175 Terminology Relating to Petroleum, Petroleum

gasoline and gasoline-oxygenate blends.

Products, and Lubricants

NOTE 1—Because the external atmospheric pressure is counteracted by

D5190 Test Method for Vapor Pressure of Petroleum Prod-

the atmospheric pressure initially present in the air chamber, this vapor

ucts (Automatic Method)

pressure is an absolute pressure at 37.8°C (100°F) in kilopascals (pounds-

force per square inch). This vapor pressure differs from the true vapor D5191 Test Method for Vapor Pressure of Petroleum Prod-

pressure of the sample due to some small vaporization of the sample and

ucts (Mini Method)

air in the confined space.

E1 Specification for ASTM Liquid-in-Glass Thermometers

NOTE 2—Vapor pressure of gasoline or gasoline-oxygenate blends

below 35 kPa (5 psi) or greater than 100 kPa (15 psi) can be determined

3. Terminology

with this test method but the precision and bias (Section 11) do not apply.

3.1 Definitions:

For materials with a vapor pressure greater than 100 kPa (15 psi), use a 0

to 200 kPa (0 to 30 psi) gauge as specified in the annex of Test Method

3.1.1 Bourdon spring gauge, n—pressure measuring device

D323.

that employs a bourdon tube connected to an indicator.

1.2 Somegasoline-oxygenateblendsmayshowahazewhen

3.1.2 Bourdon tube, n—flattened metal tube bent to a curve

cooled to 0 to 1°C. If a haze is observed in 9.4, it shall be

that straightens under internal pressure.

indicated in the reporting of results. The precision and bias

3.1.3 dry method, n—in vapor pressure methods, a specific

statements for hazy samples have not been determined (see

empirical test method (D4953) for measuring the vapor pres-

Note 7).

sure of gasoline and other volatile products in which contact of

1.3 The values stated in SI units are to be regarded as

the test specimen with water is not allowed.

standard. The values given in parentheses are for information

3.1.4 dry vapor pressure equivalent (DVPE), n—value cal-

only.

culated by a defined correlation equation, that is expected to be

1.4 This standard does not purport to address all of the

comparable to the vapor pressure value obtained by Test

safety concerns, if any, associated with its use. It is the

Method D4953, Procedure A.

responsibility of the user of this standard to establish appro-

3.1.5 gasoline-oxygenate blend, n—spark-ignition engine

priate safety and health practices and determine the applica-

fuel consisting primarily of gasoline with one or more oxygen-

bility of regulatory limitations prior to use. Specific warnings

ates.

are given in 7.5, 8.4.1, 8.5.1, 9.1, A1.1, and A1.1.3.

3.1.6 oxygenate, n—oxygen-containing ashless organic

compound, such as an alcohol or ether, which may be used as

a fuel or fuel supplement. D4175

This test method is under the jurisdiction of Committee D02 on Petroleum

Products and Lubricants and is the direct responsibility of Subcommittee D02.08 on

Volatility. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2012. Published November 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1989. Last previous edition approved in 2006 as D4953–06. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4953-06R12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4953 − 06 (2012)

3.1.7 vapor pressure, n—pressure exerted by the vapor of a fuels containing oxygenates where the Water Displacement

liquid when in equilibrium with the liquid D4175 Procedure section (10.3.1.8) of D4057 must not be used.

3.2 Abbreviations: 7.4 Sample Container Size:

3.2.1 DVPE, n—dry vapor pressure equivalent 7.4.1 The size of the sample container from which the vapor

pressure sample is taken shall be 1 L (1 qt). It shall be 70 to

4. Summary of Test Method

80 % filled with sample.

7.4.2 The present precision statement has been derived

4.1 The liquid chamber of the vapor pressure apparatus is

using samples in 1-L (1-qt) containers. Samples taken in

filled with the chilled sample and connected to the vapor

containersofothersizesasprescribedinPracticeD4057canbe

chamber at 37.8°C (100°F). The apparatus is immersed in a

used if it is recognized that the precision can be affected. In the

bath at 37.8°C (100°F) until a constant pressure is observed.

case of referee testing the 1-L (1-qt) sample container shall be

The pressure reading, suitably corrected, is reported as the

mandatory.

vapor pressure.

7.5 Hazards:

4.2 Procedure A utilizes the same apparatus and essentially

7.5.1 The vapor pressure determination shall be the first test

the same procedure as Test Method D323 with the exception

withdrawnfromthesamplecontainer.Theremainingsamplein

that the interior surfaces of the liquid and vapor chambers are

the container cannot be used for a second vapor pressure

maintained completely free of water. Procedure B utilizes a

determination. If necessary, obtain a new sample.

semi-automatic apparatus with the liquid and vapor chambers

7.5.2 Samples shall be protected from excessive heat prior

identical in volume to those in Procedure A. The apparatus is

to testing.

suspended in a horizontal bath and rotated while attaining

7.5.3 Samples in leaky containers shall not be tested.

equilibrium.EitheraBourdongaugeorpressuretransducercan

Discard and obtain a new sample.

be used with this procedure. The interior surfaces of the liquid

and vapor chambers are maintained free of water.

7.6 Sample Handling Temperature—In all cases, the sample

container and contents shall be cooled to 0 to 1°C (32 to 34°F)

5. Significance and Use

before the container is opened. Sufficient time to reach this

5.1 Vapor pressure is an important physical property of

temperature shall be assured by direct measurement of the

liquid spark-ignition engine fuels. It provides an indication of

temperature of a similar liquid in a like container placed in the

how a fuel will perform under different operating conditions.

cooling bath at the same time as the sample. See A1.3.1.

For example, vapor pressure is a factor in determining whether

8. Preparation of Apparatus

a fuel will cause vapor lock at high ambient temperature or at

high altitude, or will provide easy starting at low ambient

8.1 This section applies to both ProcedureAand Procedure

temperature. B.

5.2 Petroleum product specifications generally include va-

8.2 Verification of Sample Container Filling—With the

por pressure limits to ensure products of suitable volatility sampleatatemperatureof0to1°C,takethecontainerfromthe

performance.

cooling bath or refrigerator and wipe dry with absorbent

material. If the container is not transparent, unseal it, and using

NOTE 3—Vapor pressure of fuels is regulated by various government

a suitable gauge, confirm that the sample volume equals 70 to

agencies.

80 % of the container capacity (see Note 4). If the sample is

6. Apparatus

contained in a transparent glass container, verify that the

container is 70 to 80 % full by suitable means (see Note 4).

6.1 The apparatus for Procedure A is described in Annex

A1.

NOTE 4—For non-transparent containers, one way to confirm that the

sample volume equals 70 to 80 % of the container capacity is to use a

6.2 Theessentialdimensionsandrequirementsfortheliquid

dipstick that has been pre-marked to indicate the 70 and 80 % container

and vapor chamber for Procedure B are identical with those for

capacities. The dipstick should be of such material that it shows wetting

Procedure A and described in Annex A1. External fittings and

after being immersed and withdrawn from the sample. To confirm the

sample volume, insert the dipstick into the sample container so that it

features will vary depending on whether a gauge or transducer

touches the bottom of the container at a perpendicular angle, before

is used and the provision for rotating the apparatus in the bath.

removing the dipstick. For transparent containers, using a marked ruler or

Details of a commercially available unit are shown in Annex

by comparing the sample container to a like container which has the 70

A2.

and 80 % levels clearly marked, has been found suitable.

8.2.1 Discard the sample if its volume is less than 70 % of

7. Handling of Test Samples

the container capacity.

7.1 This section applies to both Procedure A and B.

8.2.2 If the container is more than 80 % full, pour out

7.2 The extreme sensitivity of vapor pressure measurements enough sample to bring the container contents within 70 to

to losses through evaporation is such as to require the utmost 80 % range. Under no circumstance return any of the poured

precaution and the most meticulous care in handling of out sample to the container.

samples. 8.2.3 Reseal the container, if necessary, and return the

sample container to the cooling bath.

7.3 Sampling shall be done in accordance with the Reid

Vapor Pressure section (10.3) of Practice D4057 except for 8.3 Air Saturation of the Sample in Sample Container:

D4953 − 06 (2012)

8.3.1 Transparent Containers Only—Since 8.2 does not

requirethatthesamplebeopenedtoverifythesamplecapacity,

it is necessary to unseal the cap momentarily before resealing

it, so that the samples in transparent containers are treated the

same as samples in non-transparent containers.

8.3.2 With the sample again at a temperature of 0 to 1°C,

take the container from the cooling bath or refrigerator, wipe it

dry with an absorbent material, remove the cap momentarily,

taking care that no water enters, reseal, and shake vigorously.

Return it to the cooling bath or refrigerator for a minimum of

2 min.

8.3.3 Repeat 8.3.2 twice more. Return the sample to the

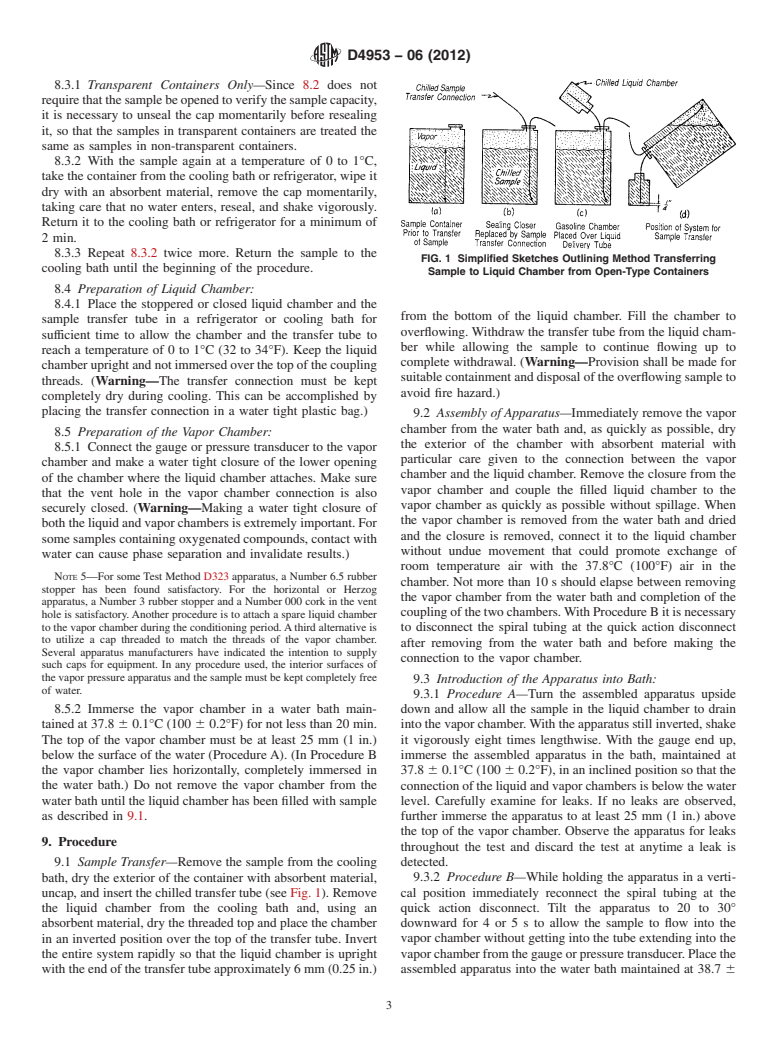

FIG. 1 Simplified Sketches Outlining Method Transferring

cooling bath until the beginning of the procedure.

Sample to Liquid Chamber from Open-Type Containers

8.4 Preparation of Liquid Chamber:

8.4.1 Place the stoppered or closed liquid chamber and the

from the bottom of the liquid chamber. Fill the chamber to

sample transfer tube in a refrigerator or cooling bath for

overflowing. Withdraw the transfer tube from the liquid cham-

sufficient time to allow the chamber and the transfer tube to

ber while allowing the sample to continue flowing up to

reach a temperature of 0 to 1°C (32 to 34°F). Keep the liquid

complete withdrawal. (Warning—Provision shall be made for

chamberuprightandnotimmersedoverthetopofthecoupling

suitable containment and disposal of the overflowing sample to

threads. (Warning—The transfer connection must be kept

avoid fire hazard.)

completely dry during cooling. This can be accomplished by

placing the transfer connection in a water tight plastic bag.)

9.2 Assembly of Apparatus—Immediately remove the vapor

chamber from the water bath and, as quickly as possible, dry

8.5 Preparation of the Vapor Chamber:

the exterior of the chamber with absorbent material with

8.5.1 Connect the gauge or pressure transducer to the vapor

particular care given to the connection between the vapor

chamber and make a water tight closure of the lower opening

chamber and the liquid chamber. Remove the closure from the

of the chamber where the liquid chamber attaches. Make sure

vapor chamber and couple the filled liquid chamber to the

that the vent hole in the vapor chamber connection is also

vapor chamber as quickly as possible without spillage. When

securely closed. (Warning—Making a water tight closure of

the vapor chamber is removed from the water bath and dried

boththeliquidandvaporchambersisextremelyimportant.For

and the closure is removed, connect it to the liquid chamber

some samples containing oxygenated compounds, contact with

without undue movement that could promote exchange of

water can cause phase separation and invalidate results.)

room temperature air with the 37.8°C (100°F) air in the

NOTE 5—For some Test Method D323 apparatus, a Number 6.5 rubber

chamber. Not more than 10 s should elapse between removing

stopper has been found satisfactory. For the horizontal or Herzog

the vapor chamber from the water bath and completion of the

apparatus, a Number 3 rubber stopper and a Number 000 cork in the vent

couplingofthetwochambers.WithProcedureBitisnecessary

hole is satisfactory.Another procedure is to attach a spare liquid chamber

to the vapor chamber during the conditioning period.Athird alternative is

to disconnect the spiral tubing at the quick action disconnect

to utilize a cap threaded to match the threads of the vapor chamber.

after removing from the water bath and before making the

Several apparatus manufacturers have indicated the intention to supply

connection to the vapor chamber.

such caps for equipment. In any procedure used, the interior surfaces of

the vapor pressure apparatus and the sample must be kept completely free

9.3 Introduction of the Apparatus into Bath:

of water.

9.3.1 Procedure A—Turn the assembled apparatus upside

8.5.2 Immerse the vapor chamber in a water bath main- down and allow all the sample in the liquid chamber to drain

tained at 37.8 6 0.1°C (100 6 0.2°F) for not less than 20 min. into the vapor chamber.With the apparatus still inverted, shake

The top of the vapor chamber must be at least 25 mm (1 in.) it vigorously eight times lengthwise. With the gauge end up,

below the surface of the water (ProcedureA). (In Procedure B immerse the assembled apparatus in the bath, maintained at

the vapor chamber lies horizontally, completely immersed in 37.8 6 0.1°C (100 6 0.2°F), in an inclined position so that the

the water bath.) Do not remove the vapor chamber from the connectionoftheliquidandvaporchambersisbelowthewater

water bath until the liquid chamber has been filled with sample level. Carefully examine for leaks.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.