ASTM D4797-88(2004)

(Test Method)Standard Test Methods for Chemical and Gravimetric Analysis of White and Yellow Thermoplastic Traffic Marking Containing Lead Chromate and Titanium Dioxide

Standard Test Methods for Chemical and Gravimetric Analysis of White and Yellow Thermoplastic Traffic Marking Containing Lead Chromate and Titanium Dioxide

SIGNIFICANCE AND USE

The function of these test methods is to define the percent of binder, glass, titanium dioxide, and lead chromate present in the composition of the thermoplastic traffic marking as defined by the applicable specification for the manufacture of a specific thermoplastic traffic marking.

SCOPE

1.1 These test methods cover procedures for the chemical and gravimetric analysis of white and yellow thermoplastic traffic marking containing lead chromate and titanium dioxide pigment.

1.2 The analytical procedures appear in the following order:SectionsPercent Binder10Percent Glass Beads (Note 1)11Percent Titanium Dioxide12Percent Lead Chromate and Analysis of Chrome Yellow and Chrome Orange Pigments (Note 2)13

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—Test for 1.50 glass spheres only.

Note 2—This modified analysis of chrome yellow and chrome orange pigments must be used because the heat resistant chrome yellows in the thermoplastic cannot be analyzed by Test Methods D 126.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4797–88(Reapproved2004)

Standard Test Methods for

Chemical and Gravimetric Analysis of White and Yellow

Thermoplastic Traffic Marking Containing Lead Chromate

and Titanium Dioxide

This standard is issued under the fixed designation D 4797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1394 Test Methods for Chemical Analysis of White

Titanium Pigments

1.1 These test methods cover procedures for the chemical

F 412 Terminology Relating to Plastic Piping Systems

and gravimetric analysis of white and yellow thermoplastic

traffic marking containing lead chromate and titanium dioxide

3. Terminology

pigment.

3.1 Definitions—Definitions are in accordance with Termi-

1.2 The analytical procedures appear in the following order:

nology D 883 and F 412, unless otherwise indicated.

Sections

3.2 Definitions of Terms Specific to This Standard:

Percent Binder 10

Percent Glass Beads (Note 1) 11

3.2.1 ash, n—the inorganic components of thermoplastic

Percent Titanium Dioxide 12

traffic marking including the pigment, glass spheres, and filler.

Percent Lead Chromate and Analysis of Chrome Yellow and 13

3.2.2 binder, n—the organic components of thermoplastic

Chrome Orange Pigments (Note 2)

traffic marking that bind the pigments, glass spheres, and filler

1.3 The values stated in SI units are to be regarded as the

together as a unit.

standard. The values given in parentheses are for information

3.2.3 filler, n—the inorganic components of thermoplastic

only.

traffic marking not including the pigments or glass spheres.

1.4 This standard does not purport to address all of the

3.2.4 pigment, n—titanium dioxide and lead chromate colo-

safety concerns, if any, associated with its use. It is the

rants.

responsibility of the user of this standard to establish appro-

3.2.5 thermoplastic, n—See thermoplastic traffıc marking.

priate safety and health practices and determine the applica-

3.2.6 thermoplastic traffıc marking, n—a highly filled

bility of regulatory limitations prior to use.

100 % total solids highway marking system that when heated

NOTE 1—Test for 1.50 glass spheres only.

toamoltenstatecanbeextrudedorsprayedontoaroadsurface

NOTE 2—This modified analysis of chrome yellow and chrome orange

and when cooled forms a solid durable delineator.

pigments must be used because the heat resistant chrome yellows in the

thermoplastic cannot be analyzed by Test Methods D 126.

4. Summary of Test Method

4.1 The thermoplastic material is prepared for the described

2. Referenced Documents

test methods by melting a sample to its application temperature

2.1 ASTM Standards:

under continuous agitation. The specimen is then poured into

D 126 Test Methods for Analysis of Yellow, Orange, and

round patties on a clean tin plate or baking pan. The patties are

Green Pigments Containing Lead Chromate and Chro-

then broken into pieces for ignition in a muffle furnace. The

mium Oxide Green

percent binder is calculated from the ashed specimen and the

D 883 Terminology Relating to Plastics

various tests for glass spheres, titanium dioxide, and lead

D 1193 Specification for Reagent Water

chromate pigment are performed on the ashed residue. The

tests for pigment type or glass spheres may be run on the same

ashed specimen. Specimen selection and preparation are the

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct same for each sample tested.

responsibility of Subcommittee D01.44 on Traffic Coatings.

Current edition approved June 1, 2004. Published June 2004. Originally

5. Significance and Use

approved in 1988. Last previous edition approved in 1998 as D 4797 – 88 (1998).

5.1 The function of these test methods is to define the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM percent of binder, glass, titanium dioxide, and lead chromate

Standards volume information, refer to the standard’s Document Summary page on

present in the composition of the thermoplastic traffic marking

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

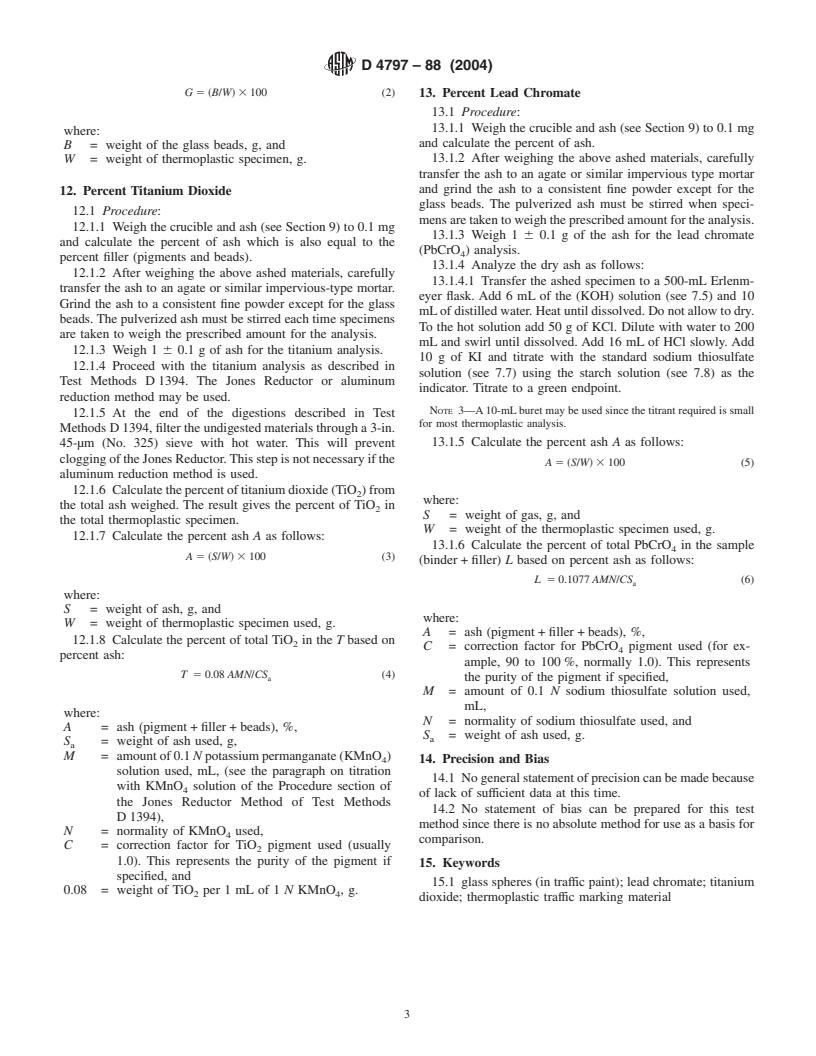

D4797–88 (2004)

as defined by the applicable specification for the manufacture 9.2 Flow the sample out on a smooth clean surface and

of a specific thermoplastic traffic marking. allowittocooltoroomtemperature.Patties3mm( ⁄8in.)thick

willfacilitatebreakingupspecimensforthedescribedanalysis.

6. Apparatus

9.3 Break the specimen into small pieces and weigh 10 g to

6.1 Balance, analytical, accurate to 0.1 mg.

the nearest 0.1 mg into a 30-mL weighed crucible.

6.2 Buret, 10 mL, 0.1-mL divisions.

9.4 Cover the crucible and place into a muffle furnace

6.3 Buret, 50 mL, 0.1-mL divisions.

preheated to 540°C and ash for1hor until no carbonaceous

6.4 Crucibles, 30 mL, porcelain.

materials remain.

6.5 Desiccator.

9.5 Remove the crucible with the ashed remains of the

6.6 Erlenmeyer flask, 500 mL.

specimen and place into a desiccator and cool to room

6.7 Furnace (Muffle), capable of maintaining 1100°C.

temperature.

6.8 Hot Plate, capable of maintaining 537°C.

6.9 Jones Reductor.

10. Percent Binder

6.10 Mortar and Pestle, glazed ceramic or other impervious

type.

10.1 Procedure:

6.11 Oven, capable of maintaining 260°C.

10.1.1 Weigh the crucible and ash (see Section 9) to the

6.12 Sieve, 3 in., 45-µm (No. 325) (metal).

nearest 0.1 mg and calculate the percent of organic binder D as

7. Reagents follows:

7.1 Purity of Reagents—Reagent grade chemicals shall be D 5 [1 2 ~S/W!# 3 100 (1)

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

where:

tee onAnalytical Reagents of theAmerican Chemical Society,

S = ashed weight of thermoplastic specimen, g, and

where such specifications are available. Other grades may be

W = weight of thermoplastic specimen, g.

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

11. Percent Glass Beads

accuracy of the determination.

11.1 Interferences—Acid-insoluble fillers will affect the

7.2 Purity of Water—Unless otherwise indicated, references

to water shall be understood to mean reagent water as defined glass-sphere analysis and must be removed by some physical

by Type IV of Specification D 1193. separation method or accounted for quantitatively, or both.

7.3 Alcohol—Ethyl alcohol 95 %.

11.2 Procedure:

7.4 Potassium Chloride (KCl).

11.2.1 Weigh the crucible and ash (see Section 9) to 0.1 mg

7.5 Potassium Hydroxide Solution—Dissolve 50 g of potas-

and calculate the percent ash.

sium hydroxide (KOH) in 100 mL of freshly distilled water.

11.2.2 After the ashed material has been weighed, transfer

7.6 Potassium Iodide (KI).

the ash to a mortar and pestle and grind with minimal pressure

7.7 Potassium Permanganate Solution (KMnO ) (0.1N).

toreducetheashtoafinegrainedconsistencywithoutcrushing

7.8 Sodium Thiosulfate, Standard Solution—(NA S O

2 2 3

the beads

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.