ASTM F649-80(1999)

(Practice)Standard Practice for Secondary Calibration of Airborne Particle Counter Using Comparison Procedures

Standard Practice for Secondary Calibration of Airborne Particle Counter Using Comparison Procedures

SCOPE

1.1 This practice covers procedures for adjusting the size ranges of an airborne discrete particle counter (DPC) to match size/concentration data from a reference DPC that has been calibrated for counting and sizing accuracy in accordance with Practice F 328 and is kept in good working order. The practice is applied in situations where time, capabilities, or both, required for carrying out procedures in Practice F 328 are not available. It is particularly useful where more than one DPC may be required to observe an environment where the particulate material being counted and sized is different in composition from the precision spherical particulate materials used for calibration in Practice F 328 and/or all of the DPCs in use are not similar in optical or electronic design.

1.2 Procedures covered here include those to measure sampled and observed air volume or flow rate, zero count level, particle sizing and counting accuracy, particle sizing resolution, particle counting efficiency, and particle concentration limit.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 649 – 80 (Reapproved 1999)

Standard Practice for

Secondary Calibration of Airborne Particle Counter Using

Comparison Procedures

This standard is issued under the fixed designation F 649; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope obtained by two APCs sampling the same air parcel, even when

the APCs have been recently placed in good operating condi-

1.1 This practice covers procedures for adjusting the size

tion and are operating within their design specifications.

ranges of an automatic airborne particle counter (APC) to

4.2 Identical or closely similar data are not developed by the

match size-concentration data from a reference APC that has

APCs as a result of several causes. The most important is the

been calibrated for counting and sizing accuracy in accordance

difference in the ambient aerosol and the calibration aerosol in

with Practice F 328 and is kept in good working order. The

terms of both composition and particle size distribution.

practice is applied in situations where time or capabilities, or

Another cause is variation in design and performance between

both, required for carrying out procedures in Practice F 328 are

the two APCs. Another cause is normal sample variance and

not available. It is particularly useful where more than one

the effect of sample size. Thus, even with good sample

APC may be required to observe an environment with particu-

handling procedure these causes may result in differences of up

late material that differs in composition from the precision

to an order of magnitude in concentrations reported by two or

spherical particulate materials used for calibration in Practice

more APCs.

F 328.

NOTE 1—A more detailed discussion of these factors is given in

2. Referenced Documents

Appendix X1.

2.1 ASTM Standards:

5. Interferences

F 328 Practice for Determining Counting and Sizing Accu-

racy of an Airborne Particle Counter Using Near- 5.1 Since the APC is typically a high-sensitivity device it

Monodisperse Spherical Particulate Materials may be affected by radio frequency or electromagnetic inter-

2.2 Military Standard: ference. Precautions should be taken to ensure that the test area

MIL-F-51068C Military Specification, Filter, Particulate, environment does not exceed the RFE-EMI capabilities of the

High Efficiency, Fire Resistant APC. Electronic or operational verification can be made, such

as indication of acceptable background level.

3. Summary of Practice

6. Apparatus

3.1 The APC under test is used to sample from an environ-

ment containing polydisperse aerosol whose nature is similar to 6.1 Reference APC—This APC should have been calibrated

that anticipated where the APC will be used. At the same time within the last 6-month period in accordance with Practice

the reference APC that has been calibrated in accordance with F 328 and maintained in good operating order. It is recom-

Practice F 328, and maintained in good working order, is used mended that the reference APC be retained in a standardization

to sample from the same environment. The size range settings or calibration laboratory and used only as a standard instru-

of the APC under test are adjusted so that its concentration data ment.

are essentially in agreement with the concentration data pro- 6.2 Gas Flowmeter—A flowmeter with low pressure drop

duced by the reference APC. characteristics is required to measure flow into the APC. Use a

variable-area flowmeter with APC flow near the top of a

4. Significance

variable area flowmeter scale. The flowmeter should be cali-

4.1 In some aerosol measurements, two or more APCs must

brated and operated for low pressure drop across the flowmeter.

be used. APC operators have noted that differing results can be 6.3 Tubing—Smooth-walled tubing with inside diameter

sized in accordance with the APC inlet section is to be used.

The tubing should be no longer than 1 m and should be metal

This practice is under the jurisdiction of ASTM Committee E-21 on Space

(such as stainless steel or copper), glass, or should be of plastic

Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination. material that will not release plasticizer in use or build up

Current edition approved March 3, 1980. Published May 1980.

electrostatic charge.

Annual Book of ASTM Standards, Vol 15.03.

6.4 Filtered Air Supply—Compressed air that has been

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

passed through a high-efficiency filter (see MIL-F-51068C)

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 649

should be available. The filtered air must be available in APC. Determine the air flow into each of the APCs with a

quantity equal to or greater than the combined flow rate of both flowmeter and with the sample inlet line in the configuration

the APC under test and the reference APC if the ambient air that it will take within the test chamber. Record this datum.

concentration exceeds the limits indicated in 7.2. 9.2 Connect the APC(s) under test and a reference APC to

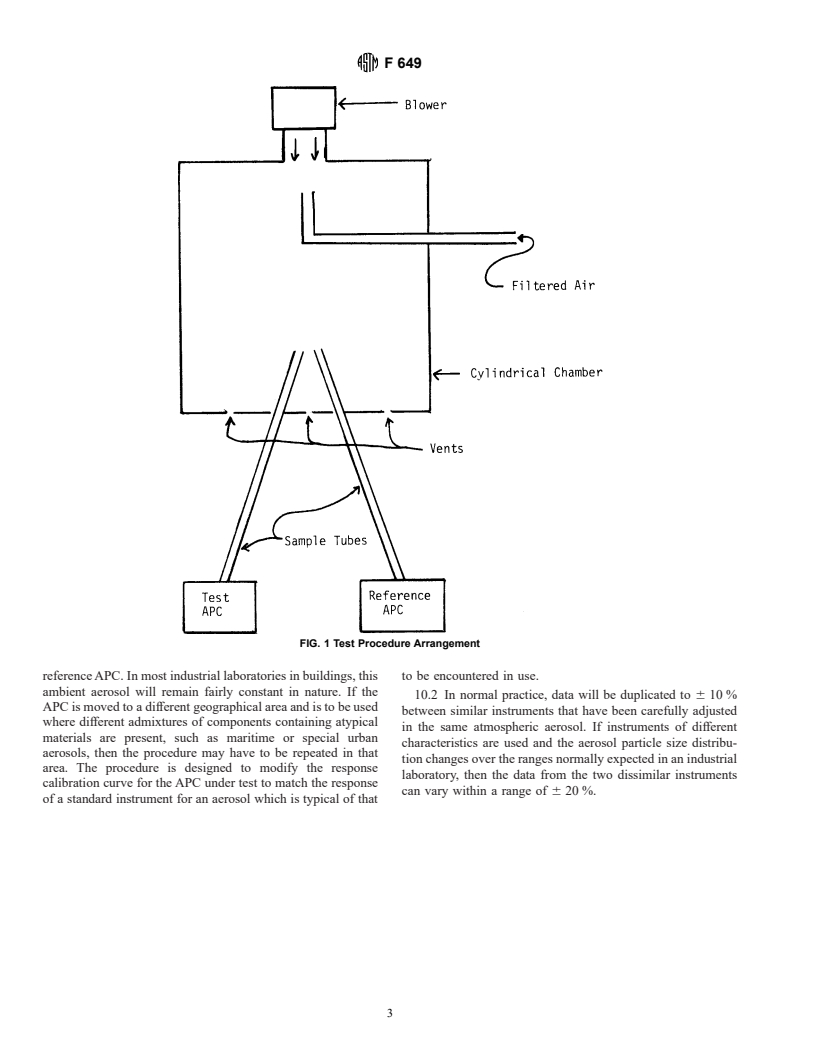

6.5 Blower, with free air capacity of approximately 2m / the test chamber as shown in Fig. 1.

min and cut off static pressure of at least 49.8 Pa is recom- 9.3 Perform the manufacturer’s recommended preoperation

mended. A damper for flow control is required. warmup and field standardization procedures on the APC(s)

6.6 Aerosol Mixing and Sample Supply Chamber—A cham- under test.

ber whose volume is 1 to 2 times the volume handled by the 9.4 Verify that the APC under test operates at a satisfactory

APC(s) in 1 min is recommended. The volume is not critical background level. For example, actuate the APC(s) that are

and any convenient container could be used. As an example, connected to the test chamber and start filtered air supply into

for a 28.3 L/min APC a commercial cylindrical fiberboard the test chamber. Do not operate the blower at this time.

powder shipping container of 380-mm inside diameter and 460 Establish that an excess of filtered air over and above the APC

mm long will provide a 50-L cylindrical chamber. Once the withdrawal rate is flowing into the test chamber by noting that

powder has been removed and the interior cleaned, the fiber- positive gas flow is present out of the blower or vents, or both.

board walls can be easily drilled or manipulated, or both, for 9.5 Verify that all APC(s) record zero count after the filtered

aerosol inlets and outlets. air supply has been operating for a sufficient period of time to

clean out the interior of the air chamber (in most cases a time

7. Preparation

period sufficient to flush the chamber four times will be

7.1 Preparation of Aerosol Chamber—Attach the blower to adequate).

one end of the chamber, for example, if the 50-L cylinder is 9.6 Start the centrifugal blower and reduce the filtered air

used, attach the blower to one end of the cylinder so that supply inlet rate until the reference APC shows a particle

ambient air will be blown into the chamber. Next, place the concentration of approximately 10 % of the manufacturer’s

filtered air supply line so that it exhausts at the center of the recommended maximum concentration for the APC(s) under

chamber and mixes with the air from the centrifugal blower. test.

Next, at the other end of the chamber insert the inlet lines to the 9.7 Adjust the reference APC gain, size ranges, or channel

APC(s) under test and to the reference APC, as shown in the threshold settings to the desired levels and repeat these settings

sketch below. The inlet section of the lines to the APC(s) for the APC(s) under test, in accordance with the manufactur-

should be close to the central portion of the chamber and the er’s recommended settings.

configuration of the lines to the APC(s) should be nearly 9.8 Determine the concentration of particles in each of the

identical with the line inlets as close together as possible. reference APC size range(s) for the ambient aerosol-filtered air

mixture presented to the test chamber and the several APCs.

NOTE 2—Any system that meets the requirements of 8.2, 9.5, and 9.10

Determine concentration from the particle count and flow (see

can be used.

9.1) for each APC.

8. Calibration and Standardization

9.9 Adjust the sensitivity for each of the individual channels

or size settings for the APC(s) under test until the number

8.1 The APC under test should be in good operating order.

concentration is equivalent to that recorded by the reference

Refere

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.