ASTM D1896/D1896M-10(2017)

(Practice)Standard Practice for Transfer Molding Test Specimens of Thermosetting Compounds

Standard Practice for Transfer Molding Test Specimens of Thermosetting Compounds

SIGNIFICANCE AND USE

4.1 Transfer molding is particularly suited to thermosetting materials of intermediate plasticity. Fixed molding parameters cannot be specified for each type of material. Molding compounds of the same type come in many different plasticities measured in accordance with Test Methods D3123 and D3795. Consequently, for a given material type, the molding parameters required to produce satisfactory test specimens will often vary dependent on the plasticity of the specific material grade.

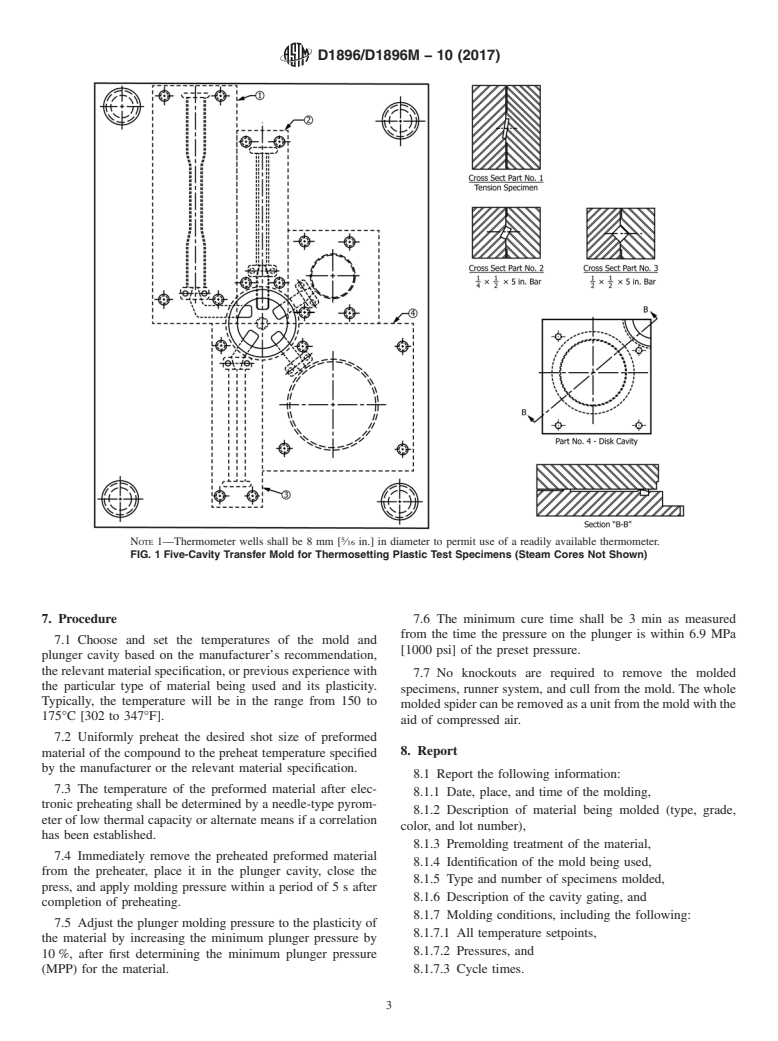

4.2 The mold shown in this practice provides for a set of five specimens. However, if only certain specimens are desired, the other cavities can be blocked by inserting gate blanks.

4.3 Typically, breathing of the mold is not required to release trapped volatile matter as the gas is free to flow from the vent end of the mold. This is a particular advantage for heat-resistant compounds and reduces the tendency for molded specimens to blister at high exposure temperatures.

4.4 Flow and knit lines in a molded piece are often sites of mechanical or electrical weakness and can be found in some degree of severity throughout the molded piece. The semisolid molding compound passing through the gate is subject to non-Newtonian flow and, consequently, wrinkles and folds as it travels down the mold cavity. Fibers and other reinforcements in the molding compound align with the flow pattern and, consequently, can orient perpendicular to the axis of the bar at the center and parallel at the surface of the bar. Mold temperature, thermal conductivity and plasticity of the molding compound, degree of preheat, and plunger pressure are parameters that influence the time to fill the mold cavities and the formation of knit lines.

Note 3: If the temperature of the mold is held constant and the plunger pressure varied for a designated thermosetting molding compound, two extreme characteristic conditions can be obtained. If the pressure is low, then the vent end of the cavity will not fully fill, and...

SCOPE

1.1 This practice covers a general procedure for the transfer molding of mechanical and electrical test specimens of thermosetting molding materials.

Note 1: The utility of this practice has been demonstrated for the molding of thermosetting molding compounds exhibiting intermediate viscosity non-Newtonian flow.

1.2 The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system are not always exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems can result in nonconformance with this practice.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2: There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1896/D1896M − 10 (Reapproved 2017)

Standard Practice for

Transfer Molding Test Specimens of Thermosetting

Compounds

This standard is issued under the fixed designation D1896/D1896M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mosetting Molding Compounds

D3795 Test Method for Thermal Flow, Cure, and Behavior

1.1 This practice covers a general procedure for the transfer

Properties of PourableThermosetting Materials byTorque

molding of mechanical and electrical test specimens of ther-

Rheometer

mosetting molding materials.

NOTE 1—The utility of this practice has been demonstrated for the

3. Terminology

molding of thermosetting molding compounds exhibiting intermediate

3.1 Definitions:

viscosity non-Newtonian flow.

3.1.1 General—Definitions of terms applying to this prac-

1.2 The values stated in either SI or inch-pound units are to

tice appear in Terminology D883.

be regarded separately as standard. The values stated in each

system are not always exact equivalents; therefore, each 3.1.2 transfer molding, n—a method of forming articles by

system shall be used independently of the other. Combining fusing a plastic material in a chamber and then forcing

values from the two systems can result in nonconformance essentially the whole mass into a hot mold where it solidifies.

with this practice.

3.2 Definitions of Terms Specific to This Standard:

1.3 This standard does not purport to address all of the

3.2.1 breathing, v—theoperationofopeningamoldorpress

safety concerns, if any, associated with its use. It is the

for a very short period of time at an early stage in the process

responsibility of the user of this standard to establish appro-

of cure.

priate safety and health practices and determine the applica-

3.2.1.1 Discussion—Breathing allows the escape of gas or

bility of regulatory limitations prior to use.

vapor from the molding material and reduces the tendency of

thick moldings to blister.

NOTE 2—There is no known ISO equivalent to this standard.

3.2.2 cavity (of a mold), n—the space within a mold to be

1.4 This international standard was developed in accor-

filled to form the molded product.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.2.3 clamp pressure, n—the pressure applied to the mold to

Development of International Standards, Guides and Recom-

keep it closed, in opposition to the fluid pressure of the

mendations issued by the World Trade Organization Technical

compressed molding material.

Barriers to Trade (TBT) Committee.

3.2.4 fill time, n—thetimerequiredtofilleachcavityusedin

the mold. Fill times can be critical to well molded parts (see

2. Referenced Documents

Note 3 under 4.4).

2.1 ASTM Standards:

3.2.5 minimum plunger pressure, n—the minimum pressure,

D883 Terminology Relating to Plastics

on the ram, required to just fill each cavity used in the mold at

D957 Practice for Determining Surface Temperature of

a specified temperature and reasonable fill time.

Molds for Plastics

3.2.6 vent, n—a hole, slot, or groove provided in a mold or

D3123 Test Method for Spiral Flow of Low-Pressure Ther-

machine to allow air and gas to escape during molding,

extrusion, or forming.

This practice is under the jurisdiction ofASTM Committee D20 on Plastics and

is the direct responsibility of Subcommittee D20.09 on Specimen Preparation.

4. Significance and Use

CurrenteditionapprovedMay1,2017.PublishedJuly2017.Originallyapproved

4.1 Transfer molding is particularly suited to thermosetting

in 1961. Last previous edition approved in 2010 as D1896 - 10. DOI: 10.1520/

D1896_D1896M-10R17.

materials of intermediate plasticity. Fixed molding parameters

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cannot be specified for each type of material. Molding com-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pounds of the same type come in many different plasticities

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. measured in accordance with Test Methods D3123 and D3795.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1896/D1896M − 10 (2017)

Consequently, for a given material type, the molding param- psi] and have a minimum plunger loading capacity of 230 cm

eters required to produce satisfactory test specimens will often [14in. ](seeNote4).Theclamppressureshallbeatleast20 %

vary dependent on the plasticity of the specific material grade. higher than the plunger pressure.

4.2 The mold shown in this practice provides for a set of

NOTE 4—Plunger molding pressure under actual molding conditions is

a variable that is difficult to control. Pressure standardization should be

fivespecimens.However,ifonlycertainspecimensaredesired,

carried out on an empty cavity with the plunger against the mold-stop

the other cavities can be blocked by inserting gate blanks.

plate. The speed of the moveable platen is not important as the mold is

4.3 Typically, breathing of the mold is not required to closed before the plunger operates. A ram speed of 3.6 m/min [140

in./min] and a plunger speed of 2.2 m/min [85 in./min] have been found

release trapped volatile matter as the gas is free to flow from

satisfactory when the mold is not loaded. The plunger speed is subject to

the vent end of the mold. This is a particular advantage for

the flow properties of the molding material when the plunger cavity is

heat-resistant compounds and reduces the tendency for molded

loaded with molding compound.

specimens to blister at high exposure temperatures.

5.2 Mold—A five-cavity mold similar to that shown in Fig.

4.4 Flow and knit lines in a molded piece are often sites of

1 has been found satisfactory, although molds with fewer

mechanical or electrical weakness and can be found in some

cavities or different configurations of the tension specimen can

degree of severity throughout the molded piece. The semisolid

be used. Specimens can be eliminated by blocking the runners

molding compound passing through the gate is subject to

to particular cavities and reducing injection pressure and shot

non-Newtonian flow and, consequently, wrinkles and folds as

size accordingly.The gates for each of the cavities in this mold

it travels down the mold cavity. Fibers and other reinforce-

are 6.4 mm wide by 1.52 mm deep [ ⁄4 by 0.060 in.]. Suitable

ments in the molding compound align with the flow pattern

venting must be provided from each cavity. A cavity surface

and, consequently, can orient perpendicular to the axis of the

finish of SPI-A3 is recommended , as is chrome plating of the

bar at the center and parallel at the surface of the bar. Mold

mold surface.

temperature,thermalconductivityandplasticityofthemolding

NOTE5—Althoughthemoldshownisgenerallyuseful,itispreferredto

compound, degree of preheat, and plunger press

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.