ASTM F1505-10(2015)

(Specification)Standard Specification for Insulated and Insulating Hand Tools

Standard Specification for Insulated and Insulating Hand Tools

ABSTRACT

This specification covers the testing and corresponding design and performance requirements for insulated and insulating hand tools used for working on, or in close proximity to, energized electrical apparatus or conductors operating at maximum voltage of 1000 V ac or 1500 V dc. The hand tools covered here are screwdrivers, wrenches, pliers, nippers, strippers, cable cutting tools, cable scissors, knives, and tweezers. These tools shall be evaluated via visual and dimensional checks, ambient temperature and extreme low temperature impact tests, dielectric tests, indentation tests, adhesion tests for insulating material coatings, flame resistance tests, and mechanical tests such as bending, torque, and locking tests. Routine tests, acceptance criteria, and quality assurance plan for these tools are considered as well.

SIGNIFICANCE AND USE

6.1 The performance and durability of the tools covered in this specification are not covered beyond those referenced in the applicable ASME, ANSI, or ISO standards.

6.2 The technical requirements of this specification either meet or exceed IEC 60900:2004 at the time of issue.

SCOPE

1.1 This specification covers the testing of insulated and insulating hand tools used for working on, or in close proximity to, energized electrical apparatus or conductors operating at maximum voltage of 1000 V ac or 1500 V dc.

1.2 The specific use of these tools is beyond the scope of this specification.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.4 The following precautionary caveat pertains to the test method portion only, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This specification does not purport to address all of the safety problems associated with the use of tools on, or in close proximity to, energized electrical apparatus.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1505 −10 (Reapproved 2015)

Standard Specification for

Insulated and Insulating Hand Tools

This standard is issued under the fixed designation F1505; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.3 IEC Standard:

IEC 60900:2004 Live Working – Hand tools for use up to

1.1 This specification covers the testing of insulated and

1000 V ac and 1500 V dc

insulating hand tools used for working on, or in close proxim-

ity to, energized electrical apparatus or conductors operating at 2.4 ISO Standards:

maximum voltage of 1000 V ac or 1500 V dc.

ISO 1174-1:1996 Assembly tools for screws and nuts—

Driving Squares—Part 1: Driving squares for hand socket

1.2 The specific use of these tools is beyond the scope of

tools

this specification.

ISO 5744:2004 Pliers and nippers—Methods of test

1.3 The values stated in SI units are to be regarded as the

standard. The inch-pound units given in parentheses are for

3. Terminology

information only.

3.1 Definitions:

1.4 The following precautionary caveat pertains to the test

3.1.1 insulated hand tools, n—those covered with insulating

method portion only, Section 7, of this specification: This

material in order to protect the user from electric shock and to

standard does not purport to address all of the safety concerns,

minimize the risk of short circuits between parts at different

if any, associated with its use. It is the responsibility of the user

potentials.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita- 3.1.2 insulating hand tools, n—those made predominantly

tions prior to use. of insulating material, except for metal inserts at the working

1.5 This specification does not purport to address all of the head or active part or used for reinforcement but with no

safety problems associated with the use of tools on, or in close

exposed metal parts. In either case, to protect the user from

proximity to, energized electrical apparatus. electric shocks, as well as, to prevent short-circuits between

exposed parts at different potentials.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.2.1 acceptance test, n—a contractual test to prove to the

D149 Test Method for Dielectric Breakdown Voltage and

customer that the device meets certain conditions of its

DielectricStrengthofSolidElectricalInsulatingMaterials

specification.

at Commercial Power Frequencies

D618 Practice for Conditioning Plastics for Testing 3.2.2 formation of lots or batches, n—the product is as-

sembled into identifiable lots, sub-lots, batches, or in such

D5025 Specification for Laboratory Burner Used for Small-

Scale Burning Tests on Plastic Materials other manner as may be prescribed. Each lot or batch, as far as

practicable, consists of units of product of a single type, grade,

2.2 ASME/ANSI Standards:

ASME B18.3-2002 Socket Cap, Shoulder, Set Screws, Hex class, size, and composition, manufactured under essentially

and Spline Keys the same conditions and essentially the same time.

3.2.3 routine test, n—a test to which each individual device

This specification is under the jurisdiction of ASTM Committee F18 on

is subjected during or after manufacture to ascertain whether it

Electrical Protective Equipment for Workers and is the direct responsibility of

complies with certain criteria.

Subcommittee F18.35 on Tools & Equipment.

Current edition approved Oct. 1, 2015. Published November 2015. Originally

3.2.4 sampling test, n—a test on a number of devices taken

approved in 1994. Last previous edition approved in 2010 as F1505-10. DOI:

at random from a batch.

10.1520/F1505-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

Available from American Society of Mechanical Engineers (ASME), ASME 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

International Headquarters, Three Park Ave., New York, NY 10016-5990, http:// Available from International Organization for Standardization (ISO), 1 rue de

www.asme.org. Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1505−10 (2015)

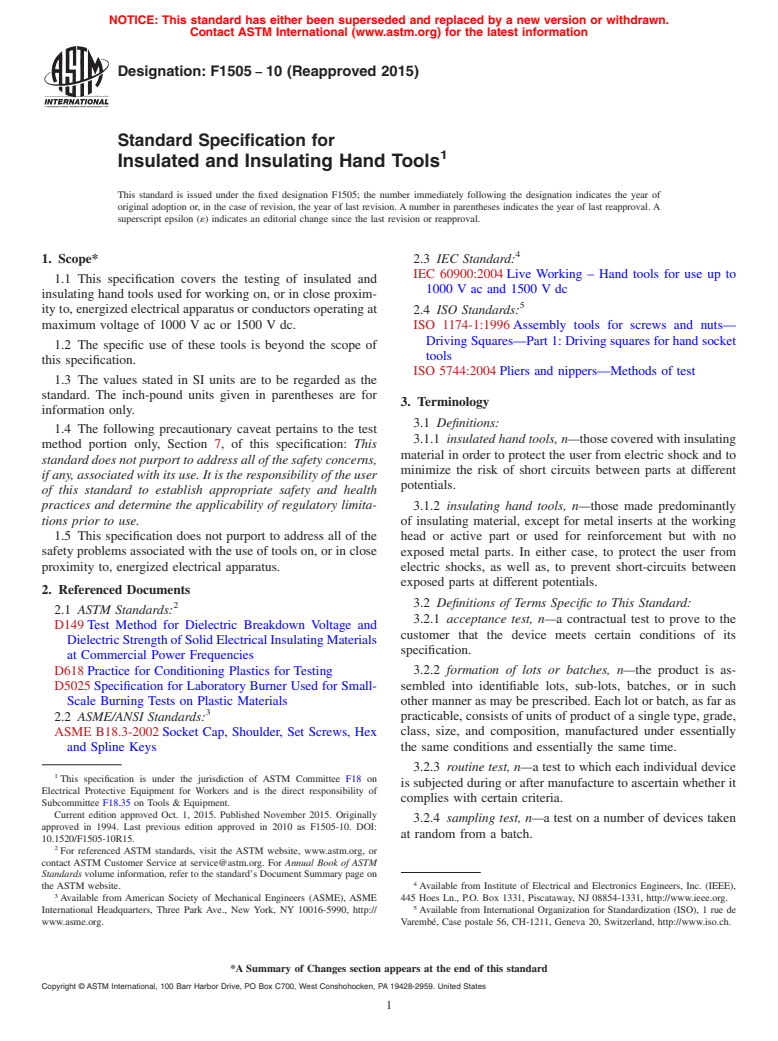

3.2.5 type test, n—a test of one or more devices made to a 4.10.3 Tools Capable of Being Assembled with Square

certain design to show that the design meets certain specifica- Drives—Tools capable of being assembled with square drives

tions. shall have square drives and square sockets in accordance with

ISO 1174-1 (for separating forces, see 7.9.1). To ensure

compatibility of insulation between different manufacturers,

4. Performance Requirements

these tools shall be designated with overlapping elements

4.1 Insulated and insulating tools shall be designed and

described in Fig. 1.Their dimensions and tolerances shall be in

manufacturedinsuchawaythattheydonotconstituteadanger

accordance with Table 1.

for the user or the installation if they are used properly.

4.10.4 Interchangeability of Components Made by Different

4.2 The mechanical specifications for insulated and insulat-

Manufacturers—Tools capable of being assembled and de-

ing hand tools having the same function shall comply with the

signed to be interchangeable between different manufacturers

correspondingANSI or ISO standards. The mechanical perfor-

shallbespecificallymarkedinaccordancewith5.6.5.Thereare

mance of the working parts shall be maintained even after the

considerable difficulties in developing a unified standard for

application of any insulating layer(s). The insulation material

the mechanical joining systems for components and tools for

shall be such that it will adequately withstand the electrical,

different manufacturers. For safety reasons, only mechanically

mechanical, and thermal stresses to which it may be exposed

locked retaining systems shall be used for these kind of tools.

during normal use. Insulating hand tools specially designed for

Manufacturers shall include the following information in the

live working in an environment of live parts at different

instructions for use: To ensure that the complete assembly of

potentials (boxes with electrical equipment, live working on

insulated tool components from different manufacturers will

underground cables, etc.), that generally are used to hold or

withstand separating forces that are expected during the

move live conductors or to cut wires of small section, must

intended use, prior to the use of any assembly the use shall

have adequate mechanical properties to avoid the risk of

ensure, by pulling by hand in a separating direction, that the

breaking and the possible corresponding electrical conse-

retaining devices of all used elements are working efficiently

quences.These tools shall be checked for compliance with 7.8. and no component gets separated.

4.3 All insulating material shall be flame resistant in accor-

5. Additional Requirements

dance with 7.7.

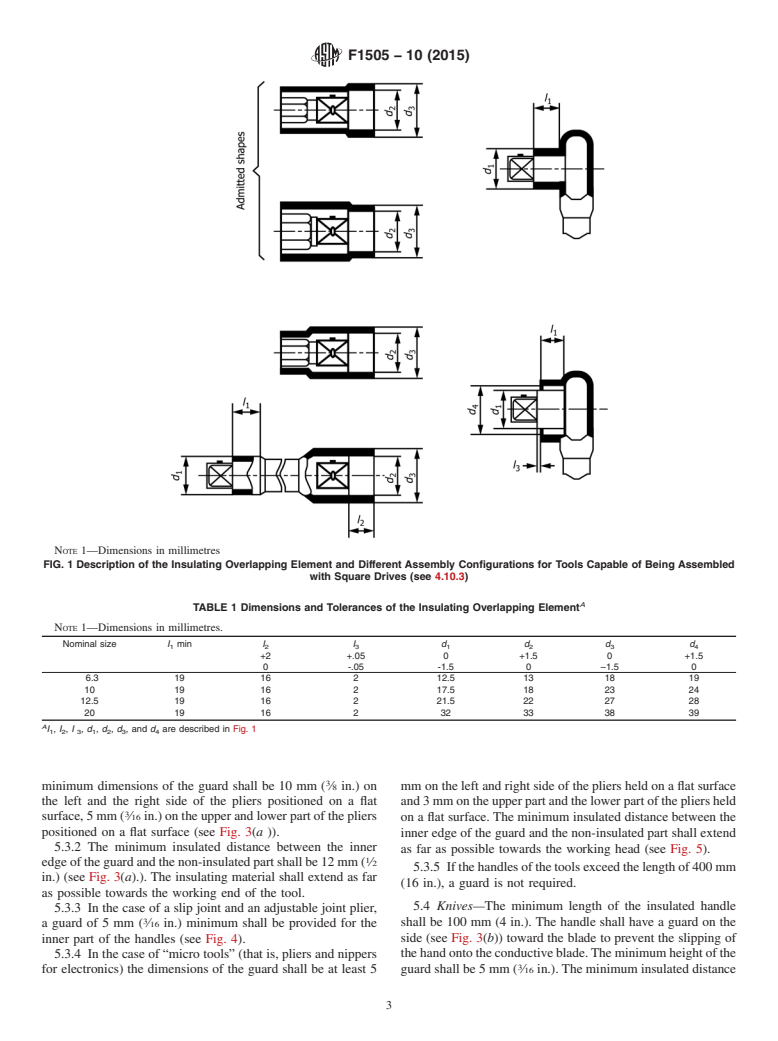

5.1 Screwdrivers and Wrenches—The following uninsulated

4.4 The insulating coating may consist of one or more

areas on the working head are permissible (see Fig. 2):

layers. If two or more layers are utilized, contrasting colors

5.1.1 Screwdrivers for slotted head screws, 15-mm ( ⁄16-in.)

shall be employed.

maximum length,

4.5 Thedesignandconstructionofthehandlesshallprovide

5.1.2 Other Types of Screwdrivers , 18-mm ( ⁄4-in.) maxi-

a secure handhold and prevent unintentional slipping.

mum length, and

5.1.3 Box Wrenches, Socket Wrenches, and T-Wrenches—

4.6 The tool shall have an operating temperature range from

The working surfaces that contact the fastener.

– 20 to + 70°C.

5.1.4 Engineer’s Wrenches—The working surface.

4.7 The insulating material shall adhere securely to the

NOTE 1—At the request of the customer, the uninsulated area may be

conductive parts of the tool and any outer layer of the material

extended to the working head.

over the temperature range from – 20 to + 70°C.

5.1.5 Bit Screwdrivers—Bit screwdrivers are regarded as

4.8 Tools intended for use at extremely low temperatures

tools capable of being assembled. They shall meet the relevant

(–40°C) shall be designated “Category C” and shall be de-

requirements. The outer diameter of the insulation may exceed

signed for this purpose.

the dimensions of 5.2.

5.1.6 Screwdrivers with Screw Retaining Devices—If a

4.9 Double-ended tools such as box wrenches, keys for

screwdriver has a screw retaining device, the screwdriver itself

hexagonal socket screws, double ended socket wrenches,

shall meet the requirements of this standard. The outer diam-

double-head open-end wrenches, etc., are not allowed for

eter of the retaining device may exceed the dimensions of 5.2.

insulated tools but are allowed for insulating tools.

The retaining device shall be made from insulating material.

4.10 Tools Capable of Being Assembled:

5.2 The blade insulation of screwdrivers shall be bonded to

4.10.1 Retaining Devices for Tools Capable of Being

the handle. The outer diameter of the insulation, over a length

Assembled—Tools capable of being assembled shall have

of 30 mm ( ⁄16 in.), in Area C of Fig. 2, shall not exceed the

suitableretainingdevicestopreventunintentionalseparationof

width of the blade at the tip by more than 2 mm ( ⁄16 in.). This

theassembly.Theretainingforcesshallbetestedinaccordance

area may be parallel or tapered towards the tip.

with 7.9.

5.3 Pliers, Strippers, Cable Cutting Tools, Cable Scissors:

4.10.2 Insulation Design for Tools Capable of Being

Assembled—In the case of connecting parts of tools capable of 5.3.1 The handle insulation shall have a guard so that the

being assembled, the insulation shall be applied in such a hand is prevented from slipping towards the uncovered metal

manner that if any part becomes detached during use, no parts of the head (see Fig. 3(a) as an example). The height of

conductive part, which may still be live, can be inadvertently the guard shall be sufficient to resist slippage of the fingers

touched or cause a disruptive charge. towards the conductive part during work. For pliers, the

F1505−10 (2015)

NOTE 1—Dimensions in millimetres

FIG. 1Description of the Insulating Overlapping Element and Different Assembly Configurations for Tools Capable of Being Assembled

with Square Drives (see 4.10.3)

A

TABLE 1 Dimensions and Tolerances of the Insulating Overlapping Element

NOTE 1—Dimensions in millimetres.

Nominal size I min I I d d d d

1 2 3 1 2 3 4

+2 +.05 0 +1.5 0 +1.5

0 -.05 -1.5 0 –1.5 0

6.3 19 16 2 12.5 13 18 19

10 19 16 2 17.5 18 23 24

12.5 19 16 2 21.5 22 27 28

20 19 16 2 32 33 38 39

A

I , I , I , d , d , d , and d are described in Fig. 1

1 2 3 1 2 3 4

minimum dimensions of the guard shall be 10 mm ( ⁄8 in.) on mm on the left and right side of the pliers held on a flat surface

the left and the right side of the pliers positioned on a flat and3mmontheupperpartandthelowerpartofthepliersheld

surface,5mm( ⁄16in.)ontheupperandlowerpartofthepliers

on a flat surface. The minimum insulated distance between the

positioned on a flat surface (see Fig. 3(a )).

inner edge of the guard and the non-insulated part shall extend

5.3.2 The minimum insulated distance between the inner

as far as possible towards the working head (see Fig. 5).

edgeoftheguardandthenon-insulatedpartshallbe12mm( ⁄2

5.3.5 Ifthehandlesofthetoolsexceedthelengthof400mm

in.) (see Fig. 3(a).). The insulating material shall extend as far

(16 in.), a guard is not required.

as possible towards the working end of the tool.

5.4 Knives—The minimum length of the insulated handle

5.3.3 In the case of a slip joint and an adjustable joint plier,

shall be 100 mm (4 in.). The handle shall have a guard on the

a guard of 5 mm ( ⁄16 in.) minimum shall be provided for the

inner part of the handles (see Fig. 4). side (see Fig. 3(b)) toward the blade to prevent the slipping of

thehandontotheconductiveblade.Theminimumheightofthe

5.3.4 In the case of “micro tools” (that is, pliers and nippers

for electronics) the dimensions of the guard shall be at least 5 guard shall be 5 mm ( ⁄16 in.). The minimum insulated distance

F1505−10 (2015)

NOTE 1—Dimensions in millimetres.

NOTE 2—a = conductive part,

b = working part,

c = insulation, and

d = contact part.

FIG. 2Illustrations of Insulation of Typical Tools—Examples (see 5.1 and 5.2)

between the inner edge of the guard and the non-insulated part 5.6 Marking—Eachtoolortoolcomponent,orboth,shallbe

shall be 12 mm ( ⁄2 in.) (see Fig. 3(b), letter b). The length of marked permanently and legibly with the following informa-

the uninsulated part of the knife blade shall not be longer than tion:

65 mm (2 ⁄2-in.) (see Fig. 3(b), letter c).

5.6.1 On the insulating material layer or on the metal

conductive part include the following information:

5.5 Tweezers (see Fig. 6):

5.5.1 The total length (l) shall be 130-mm (5-in.) minimum 5.6.1.1 Manufacturer’s name or trademark,

and 200-mm (8-in.) maximum. The length of the handle (g)

5.6.1.2 Type or product reference.

shall be 80-mm (3-in.) minimum.

5.6.2 On the insulating material layer include the following

5.5.2 Both handles of the tweezers shall have a guard

(see Fig. 7):

towards the working head. The guard shall not be movable. Its

5.6.2.1 The double triangle symbol,

height h and width b shall be sufficient (5 mm ( ⁄16 in.)

5.6.2.2 1000 V (the electrical working limit for alternating

minimum, to prevent any slipping of the fingers during the

current), and

work towards the uninsulated working head u. On both

5.6.2.3 Year of manufacture (at least the last two digits of

handles, the insulated part between the guard and the working

the year).

1 3

head e shall be 12-mm ( ⁄2-in.) minimum and 35-mm (1- ⁄8-in.)

5.6.2.4 Fortoolsdesignedforuseatextremelylowtempera-

maximum.

tures (–40°C), include letter “C”.

5.5.3 In the case of tweezers with a metallic working head,

the metallic part shall have a minimum hardness of 35 HCR 5.6.2.5 The number of the relevant ASTM standard in the

(Rockwell Hardness – C Scale) at least from the working head vici

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1505 − 10 F1505 − 10 (Reapproved 2015)

Standard Specification for

Insulated and Insulating Hand Tools

This standard is issued under the fixed designation F1505; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the testing of insulated and insulating hand tools used for working on, or in close proximity to,

energized electrical apparatus or conductors operating at maximum voltage of 1000 V ac or 1500 V dc.

1.2 The specific use of these tools is beyond the scope of this specification.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for

information only.

1.4 The following precautionary caveat pertains to the test method portion only, Section 7, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This specification does not purport to address all of the safety problems associated with the use of tools on, or in close

proximity to, energized electrical apparatus.

2. Referenced Documents

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D618 Practice for Conditioning Plastics for Testing

D5025 Specification for Laboratory Burner Used for Small-Scale Burning Tests on Plastic Materials

2.2 ASME/ANSI Standards:

ASME B18.3-2002 Socket Cap, Shoulder, Set Screws, Hex and Spline Keys

2.3 IEC Standard:

IEC 60900:2004 Live Working – Hand tools for use up to 1000 V ac and 1500 V dc

2.4 ISO Standards:

ISO 1174-1:1996 Assembly tools for screws and nuts—Driving Squares—Part 1: Driving squares for hand socket tools

ISO 5744:2004 Pliers and nippers—Methods of test

3. Terminology

3.1 Definitions:

3.1.1 insulated hand tools, n—those covered with insulating material in order to protect the user from electric shock and to

minimize the risk of short circuits between parts at different potentials.

3.1.2 insulating hand tools, n—those made predominantly of insulating material, except for metal inserts at the working head

or active part or used for reinforcement but with no exposed metal parts. In either case, to protect the user from electric shocks,

as well as, to prevent short-circuits between exposed parts at different potentials.

This specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.35 on Tools & Equipment.

Current edition approved Dec. 1, 2010Oct. 1, 2015. Published January 2011November 2015. Originally approved in 1994. Last previous edition approved in 20072010

as F1505-07.-10. DOI: 10.1520/F1505-10.10.1520/F1505-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Available from International Organization for Standardization (ISO), 1 rue de Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1505 − 10 (2015)

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptance test, n—a contractual test to prove to the customer that the device meets certain conditions of its specification.

3.2.2 formation of lots or batches, n—the product is assembled into identifiable lots, sub-lots, batches, or in such other manner

as may be prescribed. Each lot or batch, as far as practicable, consists of units of product of a single type, grade, class, size, and

composition, manufactured under essentially the same conditions and essentially the same time.

3.2.3 routine test, n—a test to which each individual device is subjected during or after manufacture to ascertain whether it

complies with certain criteria.

3.2.4 sampling test, n—a test on a number of devices taken at random from a batch.

3.2.5 type test, n—a test of one or more devices made to a certain design to show that the design meets certain specifications.

4. Performance Requirements

4.1 Insulated and insulating tools shall be designed and manufactured in such a way that they do not constitute a danger for the

user or the installation if they are used properly.

4.2 The mechanical specifications for insulated and insulating hand tools having the same function shall comply with the

corresponding ANSI or ISO standards. The mechanical performance of the working parts shall be maintained even after the

application of any insulating layer(s). The insulation material shall be such that it will adequately withstand the electrical,

mechanical, and thermal stresses to which it may be exposed during normal use. Insulating hand tools specially designed for live

working in an environment of live parts at different potentials (boxes with electrical equipment, live working on underground

cables, etc.), that generally are used to hold or move live conductors or to cut wires of small section, must have adequate

mechanical properties to avoid the risk of breaking and the possible corresponding electrical consequences. These tools shall be

checked for compliance with 7.8.

4.3 All insulating material shall be flame resistant in accordance with 7.7.

4.4 The insulating coating may consist of one or more layers. If two or more layers are utilized, contrasting colors shall be

employed.

4.5 The design and construction of the handles shall provide a secure handhold and prevent unintentional slipping.

4.6 The tool shall have an operating temperature range from – 20 to + 70°C.

4.7 The insulating material shall adhere securely to the conductive parts of the tool and any outer layer of the material over the

temperature range from – 20 to + 70°C.

4.8 Tools intended for use at extremely low temperatures (–40°C) shall be designated “Category C” and shall be designed for

this purpose.

4.9 Double-ended tools such as box wrenches, keys for hexagonal socket screws, double ended socket wrenches, double-head

open-end wrenches, etc., are not allowed for insulated tools but are allowed for insulating tools.

4.10 Tools Capable of Being Assembled:

4.10.1 Retaining Devices for Tools Capable of Being Assembled—Tools capable of being assembled shall have suitable retaining

devices to prevent unintentional separation of the assembly. The retaining forces shall be tested in accordance with 7.9.

4.10.2 Insulation Design for Tools Capable of Being Assembled—In the case of connecting parts of tools capable of being

assembled, the insulation shall be applied in such a manner that if any part becomes detached during use, no conductive part, which

may still be live, can be inadvertently touched or cause a disruptive charge.

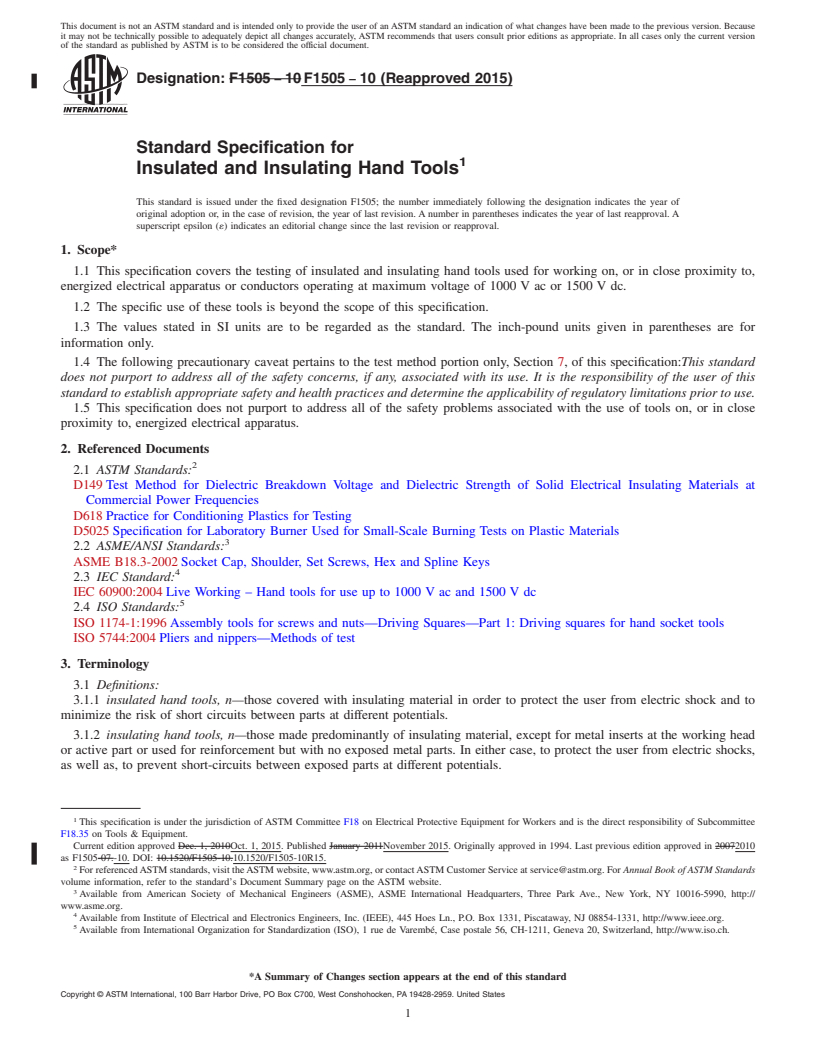

4.10.3 Tools Capable of Being Assembled with Square Drives—Tools capable of being assembled with square drives shall have

square drives and square sockets in accordance with ISO 1174-1 (for separating forces, see 7.9.1). To ensure compatibility of

insulation between different manufacturers, these tools shall be designated with overlapping elements described in Fig. 1. Their

dimensions and tolerances shall be in accordance with Table 1.

4.10.4 Interchangeability of Components Made by Different Manufacturers—Tools capable of being assembled and designed to

be interchangeable between different manufacturers shall be specifically marked in accordance with 5.6.5. There are considerable

difficulties in developing a unified standard for the mechanical joining systems for components and tools for different

manufacturers. For safety reasons, only mechanically locked retaining systems shall be used for these kind of tools. Manufacturers

shall include the following information in the instructions for use: To ensure that the complete assembly of insulated tool

components from different manufacturers will withstand separating forces that are expected during the intended use, prior to the

use of any assembly the use shall ensure, by pulling by hand in a separating direction, that the retaining devices of all used elements

are working efficiently and no component gets separated.

5. Additional Requirements

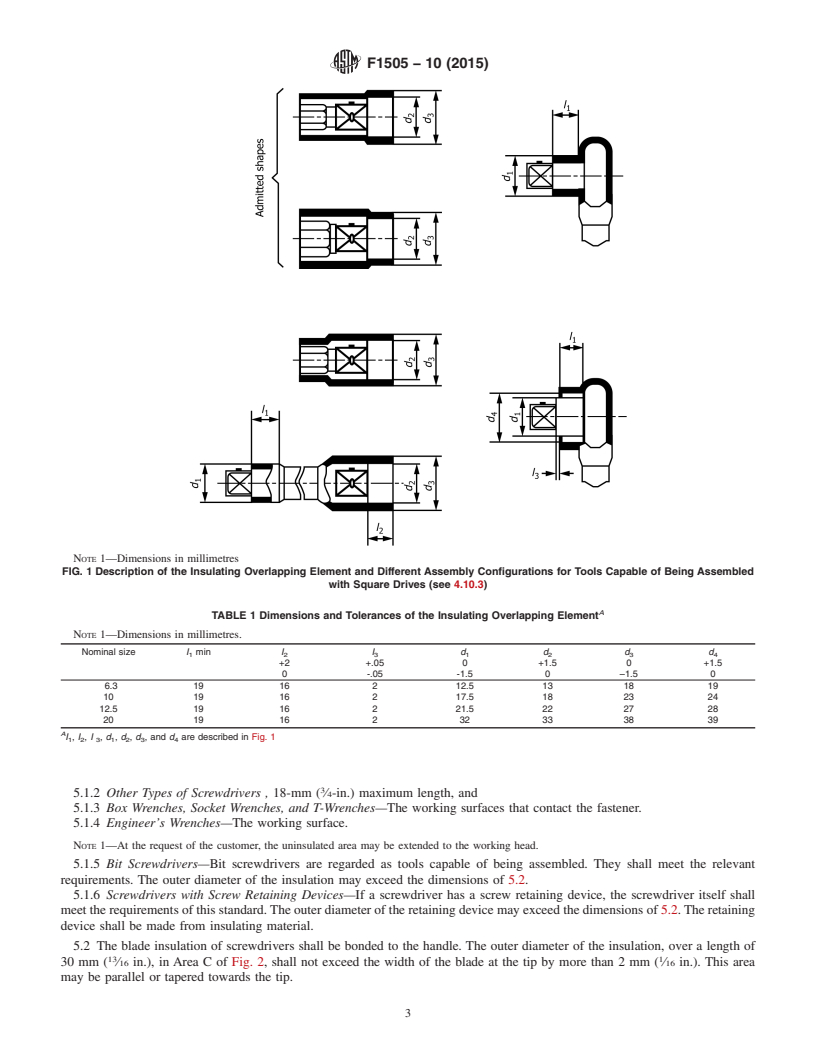

5.1 Screwdrivers and Wrenches—The following uninsulated areas on the working head are permissible (see Fig. 2):

5.1.1 Screwdrivers for slotted head screws, 15-mm ( ⁄16-in.) maximum length,

F1505 − 10 (2015)

NOTE 1—Dimensions in millimetres

FIG. 1 Description of the Insulating Overlapping Element and Different Assembly Configurations for Tools Capable of Being Assembled

with Square Drives (see 4.10.3)

A

TABLE 1 Dimensions and Tolerances of the Insulating Overlapping Element

NOTE 1—Dimensions in millimetres.

Nominal size I min I I d d d d

1 2 3 1 2 3 4

+2 +.05 0 +1.5 0 +1.5

0 -.05 -1.5 0 –1.5 0

6.3 19 16 2 12.5 13 18 19

10 19 16 2 17.5 18 23 24

12.5 19 16 2 21.5 22 27 28

20 19 16 2 32 33 38 39

A

I , I , I , d , d , d , and d are described in Fig. 1

1 2 3 1 2 3 4

5.1.2 Other Types of Screwdrivers , 18-mm ( ⁄4-in.) maximum length, and

5.1.3 Box Wrenches, Socket Wrenches, and T-Wrenches—The working surfaces that contact the fastener.

5.1.4 Engineer’s Wrenches—The working surface.

NOTE 1—At the request of the customer, the uninsulated area may be extended to the working head.

5.1.5 Bit Screwdrivers—Bit screwdrivers are regarded as tools capable of being assembled. They shall meet the relevant

requirements. The outer diameter of the insulation may exceed the dimensions of 5.2.

5.1.6 Screwdrivers with Screw Retaining Devices—If a screwdriver has a screw retaining device, the screwdriver itself shall

meet the requirements of this standard. The outer diameter of the retaining device may exceed the dimensions of 5.2. The retaining

device shall be made from insulating material.

5.2 The blade insulation of screwdrivers shall be bonded to the handle. The outer diameter of the insulation, over a length of

13 1

30 mm ( ⁄16 in.), in Area C of Fig. 2, shall not exceed the width of the blade at the tip by more than 2 mm ( ⁄16 in.). This area

may be parallel or tapered towards the tip.

F1505 − 10 (2015)

NOTE 1—Dimensions in millimetres.

NOTE 2—a = conductive part,

b = working part,

c = insulation, and

d = contact part.

FIG. 2 Illustrations of Insulation of Typical Tools—Examples (see 5.1 and 5.2)

5.3 Pliers, Strippers, Cable Cutting Tools, Cable Scissors:

5.3.1 The handle insulation shall have a guard so that the hand is prevented from slipping towards the uncovered metal parts

of the head (see Fig. 3(a) as an example). The height of the guard shall be sufficient to resist slippage of the fingers towards the

conductive part during work. For pliers, the minimum dimensions of the guard shall be 10 mm ( ⁄8 in.) on the left and the right

side of the pliers positioned on a flat surface, 5 mm ( ⁄16 in.) on the upper and lower part of the pliers positioned on a flat surface

(see Fig. 3(a )).

5.3.2 The minimum insulated distance between the inner edge of the guard and the non-insulated part shall be 12 mm ( ⁄2 in.)

(see Fig. 3(a).). The insulating material shall extend as far as possible towards the working end of the tool.

5.3.3 In the case of a slip joint and an adjustable joint plier, a guard of 5 mm ( ⁄16 in.) minimum shall be provided for the inner

part of the handles (see Fig. 4).

5.3.4 In the case of “micro tools” (that is, pliers and nippers for electronics) the dimensions of the guard shall be at least 5 mm

on the left and right side of the pliers held on a flat surface and 3 mm on the upper part and the lower part of the pliers held on

a flat surface. The minimum insulated distance between the inner edge of the guard and the non-insulated part shall extend as far

as possible towards the working head (see Fig. 5).

5.3.5 If the handles of the tools exceed the length of 400 mm (16 in.), a guard is not required.

5.4 Knives—The minimum length of the insulated handle shall be 100 mm (4 in.). The handle shall have a guard on the side

(see Fig. 3(b)) toward the blade to prevent the slipping of the hand onto the conductive blade. The minimum height of the guard

shall be 5 mm ( ⁄16 in.). The minimum insulated distance between the inner edge of the guard and the non-insulated part shall be

1 1

12 mm ( ⁄2 in.) (see Fig. 3(b), letter b). The length of the uninsulated part of the knife blade shall not be longer than 65 mm (2 ⁄2-in.)

(see Fig. 3(b), letter c).

5.5 Tweezers (see Fig. 6):

5.5.1 The total length (l) shall be 130-mm (5-in.) minimum and 200-mm (8-in.) maximum. The length of the handle (g) shall

be 80-mm (3-in.) minimum.

F1505 − 10 (2015)

(a) Insulation of Pliers

(b) Insulation of Knives

NOTE 1—Dimensions in millimetres.

NOTE 2—a = insulated handle or leg,

b = guard,

c = working head (not insulated), and

d = distance between the inner edge of the guard and the non-insulated part.

FIG. 3 (a and b) Illustrations of Insulation of Pliers and Knives (see 5.3.1, 5.3.2 and 5.4)

5.5.2 Both handles of the tweezers shall have a guard towards the working head. The guard shall not be movable. Its height h

and width b shall be sufficient (5 mm ( ⁄16 in.) minimum, to prevent any slipping of the fingers during the work towards the

uninsulated working head u. On both handles, the insulated part between the guard and the working head e shall be 12-mm ( ⁄2-in.)

minimum and 35-mm (1- ⁄8-in.) maximum.

5.5.3 In the case of tweezers wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.