ASTM F2156-06

(Test Method)Standard Test Method for Measuring Optical Distortion in Transparent Parts Using Grid Line Slope

Standard Test Method for Measuring Optical Distortion in Transparent Parts Using Grid Line Slope

SIGNIFICANCE AND USE

Transparent parts, such as aircraft windshields, canopies, cabin windows, and visors, shall be measured for compliance with optical distortion specifications using this test method. This test method is suitable for assessing optical distortion of transparent parts as it relates to the visual perception of distortion. It is not suitable for assessing distortion as it relates to pure angular deviation of light as it passes through the part. Either Test Method F 801 or Practice F 733 is appropriate and shall be used for this latter application. This test method is not recommended for raw material.

SCOPE

1.1 When an observer looks through an aerospace transparency, relative optical distortion results, specifically in thick, highly angled, multilayered plastic parts. Distortion occurs in all transparencies but is especially critical to aerospace applications such as combat and commercial aircraft windscreens, canopies, or cabin windows. This is especially true during operations such as takeoff, landing, and aerial refueling. It is critical to be able to quantify optical distortion for procurement activities.

1.2 This test method covers the apparatus and procedures that are suitable for measuring the grid line slope (GLS) of transparent parts, including those that are small or large, thin or thick, flat or curved, or already installed. This test method is not recommended for raw material.

1.3 The values stated in SI units shall be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2156–06

Standard Test Method for

Measuring Optical Distortion in Transparent Parts Using

1

Grid Line Slope

This standard is issued under the fixed designation F2156; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Transparent Parts Using the Double-Exposure Method

F801 TestMethodforMeasuringOpticalAngularDeviation

1.1 When an observer looks through an aerospace transpar-

of Transparent Parts

ency, relative optical distortion results, specifically in thick,

highly angled, multilayered plastic parts. Distortion occurs in

3. Terminology

all transparencies but is especially critical to aerospace appli-

3.1 Definitions of Terms Specific to This Standard:

cations such as combat and commercial aircraft windscreens,

3.1.1 design eye, n—the reference point in aircraft design

canopies, or cabin windows. This is especially true during

from which all anthropometrical design considerations are

operations such as takeoff, landing, and aerial refueling. It is

taken.

critical to be able to quantify optical distortion for procurement

3.1.2 distortion, n—the rate of change of deviation resulting

activities.

from an irregularity in a transparent part.

1.2 This test method covers the apparatus and procedures

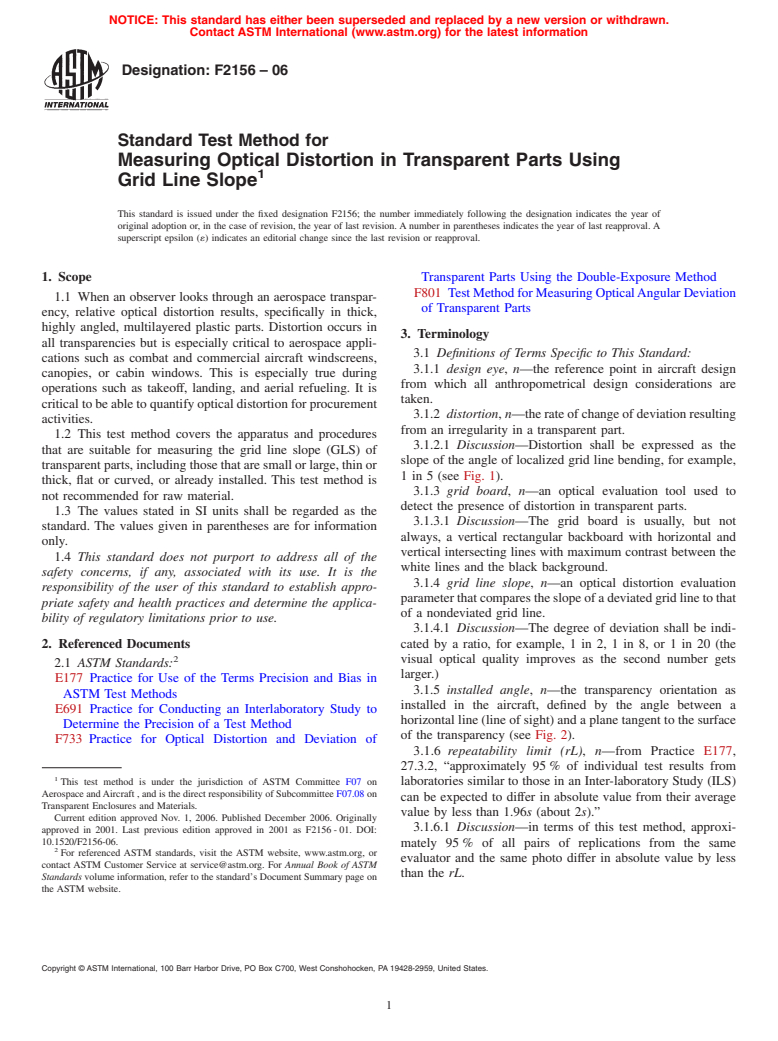

3.1.2.1 Discussion—Distortion shall be expressed as the

that are suitable for measuring the grid line slope (GLS) of

slope of the angle of localized grid line bending, for example,

transparentparts,includingthosethataresmallorlarge,thinor

1 in 5 (see Fig. 1).

thick, flat or curved, or already installed. This test method is

3.1.3 grid board, n—an optical evaluation tool used to

not recommended for raw material.

detect the presence of distortion in transparent parts.

1.3 The values stated in SI units shall be regarded as the

3.1.3.1 Discussion—The grid board is usually, but not

standard. The values given in parentheses are for information

always, a vertical rectangular backboard with horizontal and

only.

vertical intersecting lines with maximum contrast between the

1.4 This standard does not purport to address all of the

white lines and the black background.

safety concerns, if any, associated with its use. It is the

3.1.4 grid line slope, n—an optical distortion evaluation

responsibility of the user of this standard to establish appro-

parameterthatcomparestheslopeofadeviatedgridlinetothat

priate safety and health practices and determine the applica-

of a nondeviated grid line.

bility of regulatory limitations prior to use.

3.1.4.1 Discussion—The degree of deviation shall be indi-

2. Referenced Documents cated by a ratio, for example, 1 in 2, 1 in 8, or 1 in 20 (the

2 visual optical quality improves as the second number gets

2.1 ASTM Standards:

larger.)

E177 Practice for Use of the Terms Precision and Bias in

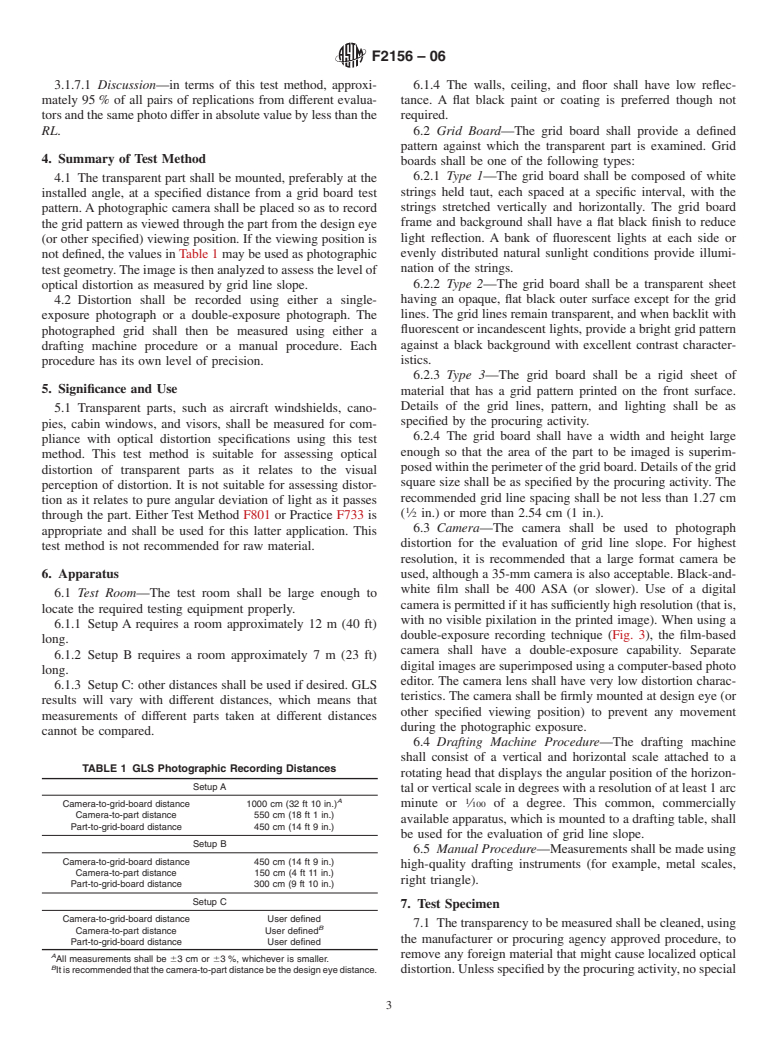

3.1.5 installed angle, n—the transparency orientation as

ASTM Test Methods

installed in the aircraft, defined by the angle between a

E691 Practice for Conducting an Interlaboratory Study to

horizontal line (line of sight) and a plane tangent to the surface

Determine the Precision of a Test Method

of the transparency (see Fig. 2).

F733 Practice for Optical Distortion and Deviation of

3.1.6 repeatability limit (rL), n—from Practice E177,

27.3.2, “approximately 95 % of individual test results from

1

This test method is under the jurisdiction of ASTM Committee F07 on laboratories similar to those in an Inter-laboratory Study (ILS)

Aerospace andAircraft , and is the direct responsibility of Subcommittee F07.08 on

can be expected to differ in absolute value from their average

Transparent Enclosures and Materials.

value by less than 1.96s (about 2s).”

Current edition approved Nov. 1, 2006. Published December 2006. Originally

3.1.6.1 Discussion—in terms of this test method, approxi-

approved in 2001. Last previous edition approved in 2001 as F2156 - 01. DOI:

10.1520/F2156-06.

mately 95 % of all pairs of replications from the same

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

evaluator and the same photo differ in absolute value by less

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

than the rL.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2156–06

FIG. 1 Optical Distortion Represented By Tangent

FIG. 2 Schematic Diagrams of GLS Photographic Recording Distances

3.1.7 reproducibility limit (RL), n—from Practice E177, differ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.