ASTM A759-10

(Specification)Standard Specification for Carbon Steel Crane Rails

Standard Specification for Carbon Steel Crane Rails

ABSTRACT

This specification covers for carbon steel crane rails of special designs only, and nominal weights for crane runway use. Manufacturing practice shall follow strict procedures for melting, discard, control cooling, end hardening, high strength rails, chamfering, and ends prepared for electric arc welding. The material shall undergo heat or cast analysis and product analysis shall be within the specified limits on chemical composition of carbon, manganese, phosphorus, sulfur, and silicon. Materials that fail to conform to the requirements of this specification shall be rejected and be reported to the manufacturer or supplier promptly in writing.

SCOPE

1.1 This specification covers carbon steel crane rails of special designs only, and nominal weights of 104 lb/yd (51.6 kg/m) through 175 lb/yd (86.8 kg/m) for crane runway use.

1.2 When standard tee rail sections are desired, they shall be ordered in accordance with Specification A1.

1.3 Supplementary Requirements S1 through S3 of an optional nature are provided. They shall apply only when specified by the purchaser in the order.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A759 −10

StandardSpecification for

1

Carbon Steel Crane Rails

This standard is issued under the fixed designation A759; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3.1.6 Supplementary requirements that shall apply (see S1

through S3), and

1.1 This specification covers carbon steel crane rails of

3.1.7 Certification and Test Report Requirements (see Sec-

special designs only, and nominal weights of 104 lb/yd (51.6

tion 10).

kg/m) through 175 lb/yd (86.8 kg/m) for crane runway use.

1.2 Whenstandardteerailsectionsaredesired,theyshallbe

4. Manufacture

ordered in accordance with Specification A1.

4.1 MeltingPractice—The steel shall be made by any of the

1.3 Supplementary Requirements S1 through S3 of an

following processes: basic-oxygen or electric-furnace.

optional nature are provided. They shall apply only when

4.1.1 The steel may be cast by a continuous process, or in

specified by the purchaser in the order.

ingots.

1.4 The values stated in inch-pound units are to be regarded

4.2 Discard—A sufficient discard shall be made to secure

as standard. The values given in parentheses are mathematical

freedom from injurious segregation and piping.

conversions to SI units that are provided for information only

4.3 Control Cooling:

and are not considered standard.

4.3.1 Rails shall be control cooled in accordance with the

following procedure, except when produced from vacuum-

2. Referenced Documents

degassed steel or control cooled blooms, in which case the rails

2

2.1 ASTM Standards:

may be air cooled and 4.3.2-4.3.6 are not applicable.

A1 Specification for Carbon Steel Tee Rails

4.3.2 All rails shall be cooled on hot beds or runways until

A700 Practices for Packaging, Marking, and Loading Meth-

full transformation is accomplished, and then charge immedi-

ods for Steel Products for Shipment

ately into the containers. In no case should the rail be charged

below 725°F (386°C).

3. Ordering Information

4.3.3 The temperature of the rails before charging shall be

3.1 Orders for crane rails under this specification shall

determined with reliable equipment at the head of the rail at

include the following information as appropriate:

least 12 in. (305 mm) from the end.

3.1.1 Quantity (tons or pieces),

4.3.4 The cover shall be placed on the container immedi-

3.1.2 ASTM designation and year of issue,

ately after completion of the charge and shall remain in place

3.1.3 Complete identification of section with dimensional

for at least 10 h. After the removal or raising of the lid of the

drawing if required (see Section 2),

container, no rails shall be removed until the temperature of the

3.1.4 Length of rails or length of runway as required, (see

top layer of rails has fallen to 300°F (149°C) or lower.

6.3),

4.3.5 The temperature between an outside rail and the

3.1.5 Arrangement of drilled bolt holes with dimensional

adjacent rail in the bottom tier of the container at a point not

drawing if required,

lessthan12in.(305mm),normorethan36in.(914mm),from

the rail end shall be recorded. This temperature shall be the

control for judging rate of cooling.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4.3.6 The container shall be so protected and insulated that

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

the control temperature shall not drop below 300°F (149°C) in

A01.01 on Steel Rails and Accessories.

7 h from the time that the bottom tier is placed in the container.

Current edition approved Nov. 1, 2010. Published December 2010. Originally

If this cooling requirement is not met, the rails shall be

approved in 1978. Last previous edition approved in 2005 as A759 – 00 (2005).

DOI: 10.1520/A0759-10.

considered control cooled provided the temperature at a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

location not less than 12 in. (305 mm) from the end of a rail at

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approximatelythecenterofthemiddletierdoesnotdropbelow

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 300°F (149°C) in less than 15 h.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A759−10

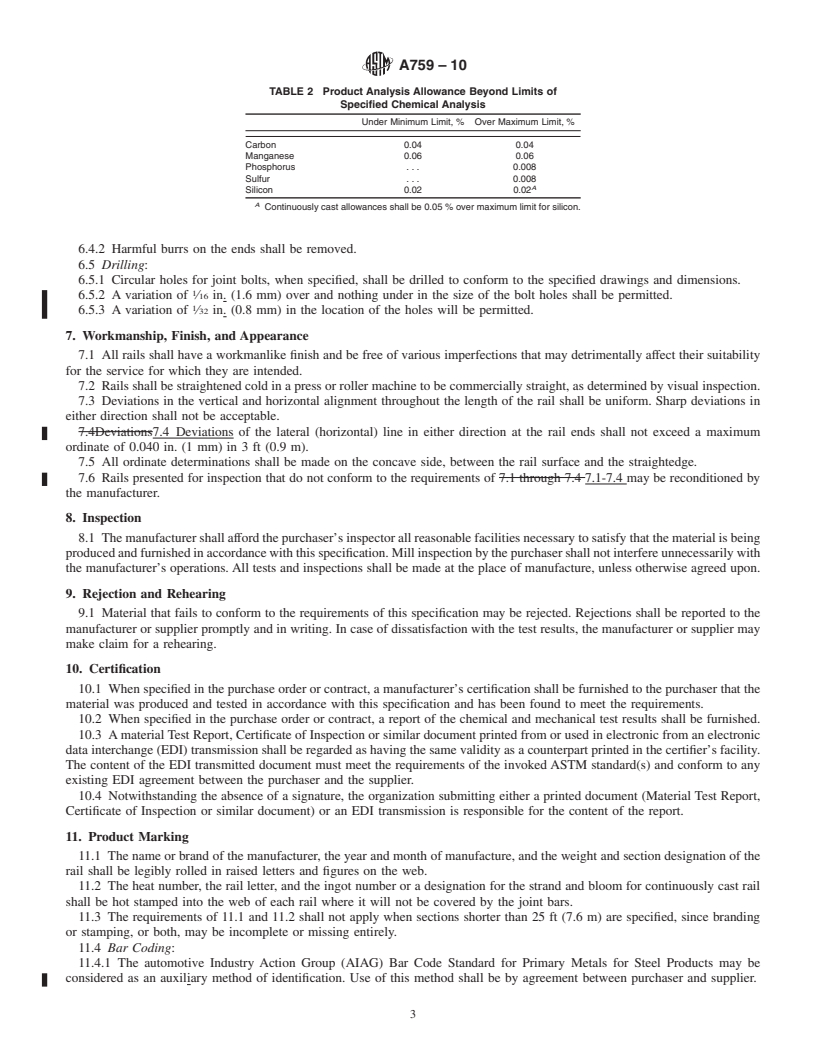

TABLE 1 Chemical Requirements,%

6.2 Weight—A variation of 1 % from the calcu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A759–00 (Reapproved 2005) Designation: A759 – 10

Standard Specification for

1

Carbon Steel Crane Rails

This standard is issued under the fixed designation A759; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers carbon steel crane rails of special designs only, and nominal weights of 104 lb/yd (51.6 kg/m)

through 175 lb/yd (86.8 kg/m) for crane runway use.

1.2 When standard tee rail sections are desired, they shall be ordered in accordance with Specification A1.

1.3Supplementary Requirements S1 through S4 of an optional nature are provided. They shall apply only when specified by the

purchaser in the order.

1.4The values stated in inch-pound units are to be regarded as the standard.

1.3 Supplementary Requirements S1 through S3 of an optional nature are provided. They shall apply only when specified by

the purchaser in the order.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A1 Specification for Carbon Steel Tee Rails

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

2.2 Design details for the special crane rails are indicated in the crane rail catalogs of individual manufacturers, and referred to

in the following documents:

American Institute of Steel Construction, Inc. (AISC), Manual of Steel Construction, Seventh Edition, pp. 1–136and 1–137

Association of Iron and Steel Engineers (AISE), Standard No. 6,May 1, 1969, pp. MD-22 through MD-25

Crane Manufacturers Association, Inc. (CMAA), Specification No. 70, 1971, pp. 20 and 34

3. Ordering Information

3.1 Orders for crane rails under this specification shall include the following information as appropriate:

3.1.1 Quantity (tons or pieces),

3.1.2 ASTM designation and year of issue,

3.1.3 Complete identification of section with dimensional drawing if required (see 2.1 and Section 2.22),

3.1.4 Length of rails or length of runway as required, (see 6.3),

3.1.5 Arrangement of drilled bolt holes with dimensional drawing if required,

3.1.6 Supplementary requirements that shall apply (see S1 through S4),S3), and

3.1.7 Certification and Test Report Requirements (see Section 10).

4. Manufacture

4.1 Melting Practice:Melting Practice—The steel shall be made by any of the following processes: basic-oxygen or

electric-furnace.

4.1.1 The steel may be cast by a continuous process, or in ingots.

4.2 Discard—A sufficient discard shall be made to secure freedom from injurious segregation and piping.

4.3 Control Cooling:

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.01

on Steel Rails and Accessories.

Current edition approved MarchNov. 1, 2005.2010. Published March 2005.December 2010. Originally approved in 1978. Last previous edition approved in 20002005 as

A759 – 00 (2005). DOI: 10.1520/A0759-00R05.10.1520/A0759-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A759 – 10

4.3.1 Rails shall be control cooled in accordance with the following procedure, except when produced from vacuum-degassed

steel or control cooled blooms, in which case the rails may be air cooled and 4.3.2 through 4.3.6 4.3.2-4.3.6 are not applicable.

4.3.2 All rails shall be cooled on hot beds or runways until full transformation is accomplished, and then charge immediately

into the containers. In no case should the rail be charged below 725°F (386°C).

4.3.3 The temperature of the rails before charging shall be determined with reliable equipment at the head of the rail at least

12 in. (305 mm) from the end.

4.3.4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.