ASTM E77-14(2021)

(Test Method)Standard Test Method for Inspection and Verification of Thermometers

Standard Test Method for Inspection and Verification of Thermometers

SIGNIFICANCE AND USE

4.1 The test method described in this standard will ensure that the thermometers listed in Specifications E1 and E2251 will indicate temperatures within the maximum scale errors listed, be compatible with the apparatus, and serve the purpose for which they were designed.

4.2 Thermometers that do not pass the visual and dimensional inspection tests may give erroneously high or low temperature readings, or may not fit into existing equipment used in ASTM methods. For accurate temperature measurements the scale readings of the thermometer should be verified as described in this test method.

SCOPE

1.1 This test method covers visual and dimensional inspection and test for scale accuracy to be used in the verification of liquid-in-glass thermometers as specified in Specifications E1 and E2251. However, these procedures may be applied to other liquid-in-glass thermometers.2

Note 1: The use of NIST SP250-232 is recommended.

1.2 Warning—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E77 −14 (Reapproved 2021)

Standard Test Method for

Inspection and Verification of Thermometers

ThisstandardisissuedunderthefixeddesignationE77;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers visual and dimensional inspec-

E1Specification for ASTM Liquid-in-Glass Thermometers

tion and test for scale accuracy to be used in the verification of

E344Terminology Relating to Thermometry and Hydrom-

liquid-in-glass thermometers as specified in Specifications E1

etry

andE2251.However,theseproceduresmaybeappliedtoother

E2251Specification for Liquid-in-Glass ASTM Thermom-

liquid-in-glass thermometers.

eters with Low-Hazard Precision Liquids

NOTE 1—The use of NIST SP250-23 is recommended.

1.2 Warning—Mercuryhasbeendesignatedbymanyregu- 3. Terminology

latoryagenciesasahazardoussubstancethatcancauseserious

3.1 Definitions:

medicalissues.Mercury,oritsvapor,hasbeendemonstratedto

3.1.1 The definitions given in Terminology E344 apply.

be hazardous to health and corrosive to materials. Use caution

Some that are considered essential to this standard are given

when handling mercury and mercury-containing products. See

below.

the applicable product Safety Data Sheet (SDS) for additional

3.1.2 calibration, n—of a thermometer or thermometric

information. The potential exists that selling mercury or

system, the set of operations that establish, under specified

mercury-containing products, or both, is prohibited by local or

conditions, the relationship between the values of a thermo-

national law. Users must determine legality of sales in their

metric quantity indicated by a thermometer or thermometric

location.

system and the corresponding values of temperature realized

by standards.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1.2.1 Discussion—(1) The result of a calibration permits

either the assignment of values of temperature to indicated

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- values of thermometric quantity or determination of correc-

tions with respect to indications. (2) A calibration may also

mine the applicability of regulatory limitations prior to use.

determine other metrological properties such as the effect of

1.4 This international standard was developed in accor-

influence quantities. (3) The result of a calibration may be

dance with internationally recognized principles on standard-

communicatedinadocumentsuchasacalibrationcertificateor

ization established in the Decision on Principles for the

acalibrationreport.(4)Thetermcalibrationhasalsobeenused

Development of International Standards, Guides and Recom-

to refer to the result of the operations, to representations of the

mendations issued by the World Trade Organization Technical

result, and to the actual relationship between values of the

Barriers to Trade (TBT) Committee.

thermometric quantity and temperature.

3.1.3 complete-immersionthermometer,n—aliquid-in-glass

thermometer, not specified in ASTM documents, designed to

This test method is under the jurisdiction of ASTM Committee E20 on

Temperature Measurement and is the direct responsibility of Subcommittee E20.05 indicate temperature correctly when the entire thermometer is

on Liquid-in-Glass Thermometers and Hydrometers.

exposed to the temperature being measured.

Current edition approved May 1, 2021. Published June 2021. Originally

ε1

approved in 1949. Last previous edition approved in 2014 as E77–14 . DOI:

10.1520/E0077-14R21.

2 3

“Liquid-in-Glass Thermometer Calibration Service,” NIST Special Publication For referenced ASTM standards, visit the ASTM website, www.astm.org, or

250-23, 1988. Available from U.S. Government Printing Office, Superintendent of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http:// Standards volume information, refer to the standard’s Document Summary page on

www.access.gpo.gov. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E77−14 (2021)

3.1.4 partial-immersion thermometer, n—a liquid-in-glass resistance is determined by comparison with a standard

thermometer designed to indicate temperature correctly when resistor, using a potentiometer, a Kelvin-type double bridge, or

the bulb and a specified part of the stem are exposed to the aWheatstonebridge,(preferablyoftheMuellertype)oranAC

temperature being measured. resistance bridge. Temperatures may then be calculated using

suitable resistance-temperature equations. In order that it shall

3.1.5 total-immersion thermometer, n—a liquid-in-glass

be satisfactory for such use, the thermometer should meet the

thermometer designed to indicate temperature correctly when

requirement that the ratio of resistances at the steam and ice

just that portion of the thermometer containing the liquid is

pointsshallbegreaterthan1.3925.Morecompleteinformation

exposed to the temperature being measured.

on the construction and use of primary standard thermometers

3.2 Definitions of Terms Specific to This Standard: 4

may be obtained from NIST SP250-22.

3.2.1 referencepoint,n—atemperatureatwhichathermom-

5.5 Secondary Standard Thermometers—Secondary stan-

eter is checked for changes in the bulb volume.

dardthermometersaremoresuitableforroutinework,andmay

3.2.2 verification, n—the process of testing a thermometer

beofvarioustypesasdescribedbelow.Theyaresimplertouse

for compliance with specifications.

than a primary standard thermometer with its accessory

3.2.3 verification temperatures, n—the specified tempera-

equipment,thelatterbeingcapableofanorderofprecisionand

tures at which thermometers are tested for compliance with

accuracy far in excess of that attainable with liquid-in-glass

scale error limits.

thermometers. The choice of a secondary standard will be

governed by various factors. The following criteria should, in

3.2.4 Other descriptions of terms relating to thermometers

so far as possible, be satisfied: The standard should be a

are included in Sections 3 and 17 of Specification E1.

calibratedthermometerofequalorpreferablyhighersensitivity

4. Significance and Use

thanthethermometertobeverified,anditshouldbecapableof

giving results of an equal or preferably higher order of

4.1 The test method described in this standard will ensure

accuracy and also of an equal or preferably higher order of

that the thermometers listed in Specifications E1 and E2251

reproducibility or precision. Scale corrections should always

will indicate temperatures within the maximum scale errors

be applied in the use of these standards. Secondary standards

listed, be compatible with the apparatus, and serve the purpose

may be of the following types.

for which they were designed.

5.5.1 Direct-reading Resistance Thermometers—Direct-

4.2 Thermometers that do not pass the visual and dimen-

reading resistance thermometers are available commercially,

sional inspection tests may give erroneously high or low

are very convenient to use, and have the advantage over the

temperature readings, or may not fit into existing equipment

primary type that temperature indications are given directly in

used in ASTM methods. For accurate temperature measure-

theinstrumentreading.Theyshouldbecompletelyrecalibrated

ments the scale readings of the thermometer should be verified

every 6 to 12 months, depending upon the temperatures of

as described in this test method.

usage. Ice points should be taken every three months.

5.5.2 Liquid-in-glass Thermometers—Liquid-in-glass

5. Apparatus

thermometers, when used as secondary standards, may be

5.1 Graduated Metal Scales or Templates—Maximum and

classified into two groups, those intended for testing general

minimum specified linear dimensions are measured with

purposetotalorpartial-immersionthermometers,andthosefor

graduated metal scales and templates on which lines are ruled

testing special use partial-immersion thermometers.

atsuitabledistancesfromreferencepointscorrespondingtothe

5.5.2.1 Total-immersion Thermometers—In the case of gen-

maximumandminimumvaluesoftheseveralspecifieddimen-

eral purpose total-immersion thermometers, the sensitivity of

sions.

the thermometers to be tested will govern the choice of

5.2 Micrometers and Ring Guages—Specified diameters of

standard. For thermometers graduated in 1, 2, or 5° divisions,

ASTM thermometers are checked using micrometers, or more

a set of well-made thermometers will be adequate when

conveniently with ring gauges consisting of metal plates in

calibrated and used with applicable corrections. For fraction-

which holes have been formed corresponding to the maximum

ally graduated thermometers a calibrated set of the following

and minimum values of the several specified dimensions. The

thermometers is recommended. Specifications for theseASTM

thickness of such gauges should approximate the diameters of

Precision Thermometers appear in Specification E1.

the holes to minimize errors resulting from the axis of the

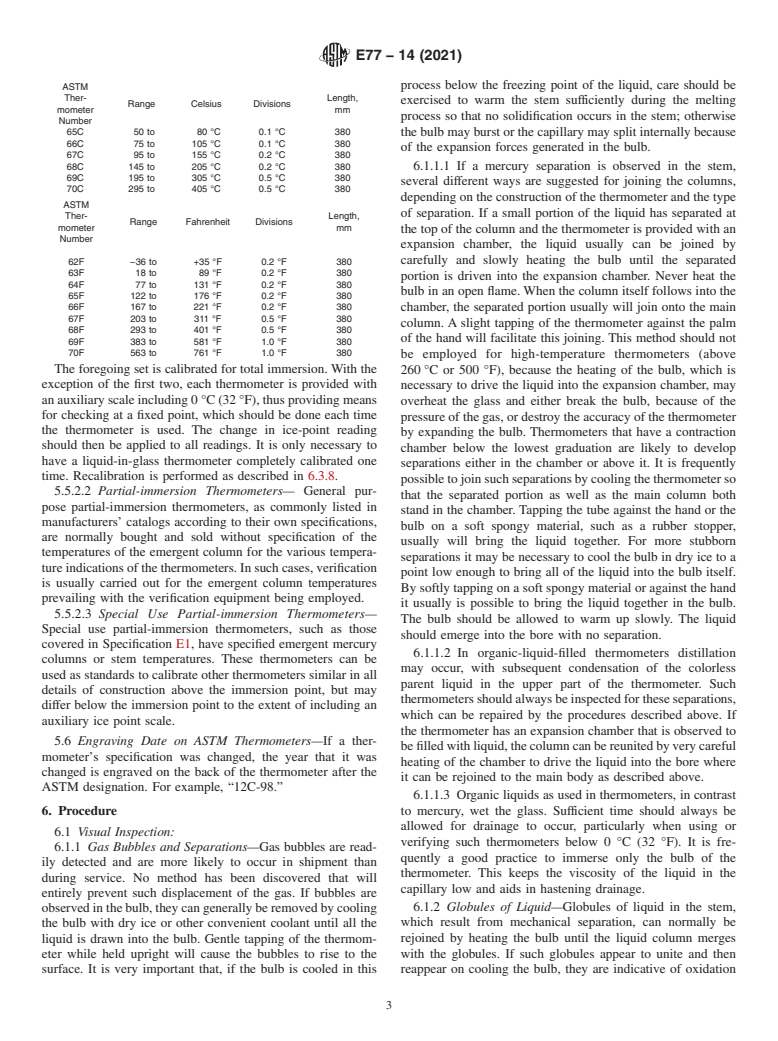

ASTM

thermometer stem being other than normal to the plane of the

Ther- Length,

Range Celsius Divisions

mometer mm

gauge. When specified, diameters may also be checked with

Number

conventional snap gauges having plane parallel working faces.

62C −38 to +2 °C 0.1 °C 380

5.3 Comparators—Comparators are required for verifica-

63C −8 to +32 °C 0.1 °C 380

tionofscaleaccuracyofliquid-in-glassthermometers.Suitable

64C 25 to 55 °C 0.1 °C 380

types are described in Appendix X1.

5.4 Primary Standard Thermometer—The primary standard

“Platinum Resistance Thermometer Calibrations,” NIST Special Publication

thermometer in the range from−183 to 630 °C (−297 to

NIST Special Publication 250-22.Available from U.S. Government Printing Office,

1166°F)istheplatinum-resistancethermometer.Temperatures

Superintendent of Documents, 732 N. Capitol St., NW, Washington, DC 20401-

are not measured directly with this instrument. Its electrical 0001, http://www.access.gpo.gov.

E77−14 (2021)

process below the freezing point of the liquid, care should be

ASTM

Ther- Length,

exercised to warm the stem sufficiently during the melting

Range Celsius Divisions

mometer mm

process so that no solidification occurs in the stem; otherwise

Number

65C 50 to 80 °C 0.1 °C 380

thebulbmayburstorthecapillarymaysplitinternallybecause

66C 75 to 105 °C 0.1 °C 380

of the expansion forces generated in the bulb.

67C 95 to 155 °C 0.2 °C 380

68C 145 to 205 °C 0.2 °C 380 6.1.1.1 If a mercury separation is observed in the stem,

69C 195 to 305 °C 0.5 °C 380

several different ways are suggested for joining the columns,

70C 295 to 405 °C 0.5 °C 380

dependingontheconstructionofthethermometerandthetype

ASTM

of separation. If a small portion of the liquid has separated at

Ther- Length,

Range Fahrenheit Divisions

mometer mm

the top of the column and the thermometer is provided with an

Number

expansion chamber, the liquid usually can be joined by

62F −36 to +35 °F 0.2 °F 380 carefully and slowly heating the bulb until the separated

63F 18 to 89 °F 0.2 °F 380

portion is driven into the expansion chamber. Never heat the

64F 77 to 131 °F 0.2 °F 380

bulb in an open flame.When the column itself follows into the

65F 122 to 176 °F 0.2 °F 380

66F 167 to 221 °F 0.2 °F 380 chamber, the separated portion usually will join onto the main

67F 203 to 311 °F 0.5 °F 380

column. A slight tapping of the thermometer against the palm

68F 293 to 401 °F 0.5 °F 380

of the hand will facilitate this joining. This method should not

69F 383 to 581 °F 1.0 °F 380

70F 563 to 761 °F 1.0 °F 380

be employed for high-temperature thermometers (above

The foregoing set is calibrated for total immersion.With the 260°C or 500 °F), because the heating of the bulb, which is

exception of the first two, each thermometer is provided with

necessary to drive the liquid into the expansion chamber, may

anauxiliaryscaleincluding0°C(32°F),thusprovidingmeans

overheat the glass and either break the bulb, because of the

for checking at a fixed point, which should be done each time

pressureofthegas,ordestroytheaccuracyofthethermometer

the thermometer is used. The change in ice-point reading

by expanding the bulb. Thermometers that have a contraction

should then be applied to all readings. It is only necessary to

chamber below the lowest graduation are likely to develop

have a liquid-in-glass thermometer completely calibrated one

separations either in the chamber or above it. It is frequently

time. Recalibration is performed as described in 6.3.8.

possibletojoinsuchseparationsbycoolingthethermometerso

5.5.2.2 Partial-immersion Thermometers— General pur-

that the separated portion as well as the main column both

pose partial-immersion thermometers, as commonly listed in

stand in the chamber. Tapping the tube against the hand or the

manufacturers’ catalogs according to their own specifications,

bulb on a soft spongy material, such as a rubber stopper,

are normally bought and sold without specification of the

usually will bring the liquid together. For more stubborn

temperatures of the emergent column for the various tempera-

separations it may be necessary to cool the bulb in dry ice to a

tureindicationsofthethermometers.Insuchcases,verification

point low enough to bring all of the liquid into the bulb itself.

is usually carried out for the emergent column temperatures

Bysoftlytappingonasoftspongymaterialoragainstthehand

prevailing with the verification equipment being employed.

it usually is possible to bring the liquid together in the bulb.

5.5.2.3 Special Use Partial-immersion Thermometers—

The bulb should be allowed to warm up slowly. The liquid

Special use partial-immersion thermometers, such as those

should emerge into the bore with no separation.

covered in Specification E1, have specified emergent mercury

6.1.1.2 In organic-liquid-filled thermometers distillation

columns or stem temperatures. These thermometers can be

may occur, with subsequent condensation of the colorless

used as standards to calibrate other thermometers similar in all

parent liquid in the upper part of the thermometer. Such

details of con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.