ASTM D5400-03(2008)

(Test Method)Standard Test Methods for Hydroxypropylcellulose

Standard Test Methods for Hydroxypropylcellulose

SIGNIFICANCE AND USE

The results of this test are used for calculating the total solids in the sample; and, by common usage, all materials volatile at this test temperature are designated as moisture.

Moisture analysis (along with residue on ignition) is a measure of the amount of active polymer in the material and must be considered when determining the amount of hydroxypropylcellulose to use in various formulations.

SCOPE

1.1 These test methods cover the testing of hydroxypropylcellulose.

1.2 The test procedures appear in the following order:

Sections Moisture 4-9 Viscosity10-16 pH 17-21 Residue on Ignition 22-28 Hydroxypropoxy Content 29-36

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 26.6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5400 −03(Reapproved2008)

Standard Test Methods for

Hydroxypropylcellulose

This standard is issued under the fixed designation D5400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

1.1 These test methods cover the testing of hydroxypropy-

sufficiently high purity to permit its use without lessening the

lcellulose.

accuracy of the determination.

1.2 The test procedures appear in the following order:

3.2 Purity of Water—Unless otherwise indicated, references

Sections

to water shall be understood to mean distilled water.

Moisture 4-9

Viscosity 10-16

MOISTURE

pH 17-21

Residue on Ignition 22-28

Hydroxypropoxy Content 29-36

4. Scope

1.3 The values stated in SI units are to be regarded as the

4.1 Thistestmethodcoversthedeterminationofthevolatile

standard. The values given in parentheses are for information

content of hydroxypropylcellulose.

only.

5. Significance and Use

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 5.1 The results of this test are used for calculating the total

responsibility of the user of this standard to establish appro-

solids in the sample; and, by common usage, all materials

priate safety and health practices and determine the applica- volatile at this test temperature are designated as moisture.

bility of regulatory limitations prior to use. For specific hazard

5.2 Moisture analysis (along with residue on ignition) is a

statements, see 26.6.

measure of the amount of active polymer in the material and

must be considered when determining the amount of hydroxy-

2. Referenced Documents

propylcellulose to use in various formulations.

2.1 ASTM Standards:

6. Apparatus

D3876Test Method for Methoxyl and Hydroxypropyl Sub-

stitution in Cellulose Ether Products by Gas Chromatog- 6.1 Oven, gravity convection, capable of maintaining a

raphy

temperature of 105 6 3°C.

E70Test Method for pH of Aqueous Solutions With the

6.2 Weighing Dish, glass or aluminum, with cover, 50 mm

Glass Electrode

in diameter, 25 mm in height, or equivalent.

6.3 Analytical Balance.

3. Reagents

3.1 Purity of Reagents—Reagent grade chemicals shall be

7. Procedure

used in all tests. Unless otherwise indicated, it is intended that

7.1 Weigh about5gof sample to the nearest 0.001 g in a

all reagents shall conform to the specifications of the Commit-

tared and covered weighing dish.

tee onAnalytical Reagents of theAmerican Chemical Society,

7.2 Place it in an oven at 105 6 1°C for 3 h with the cover

removed.

7.3 Removethedishfromtheoven,immediatelyreplacethe

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct cover, cool in a desiccator, and weigh.

responsibility of Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved June 1, 2008. Published June 2008. Originally

approved in 1993. Last previous edition approved in 2003 as D5400–03. DOI: Reagent Chemicals, American Chemical Society Specifications, American

10.1520/D5400-03R08. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5400−03(2008)

A

TABLE 1 Brookfield Viscometer Spindle and Speed

11.2 This test method determines the relative ability of the

Combinations

polymertothickenaqueoussolutionsandisthereforerelatedto

Viscosity Range, Spindle Speed,

Scale Factor the concentration required in various formulations to achieve

cP Number r/min

the desired finished product viscosity.

10–80 1 60 100 1

20–160 1 30 100 2

50–400 2 60 100 5

12. Apparatus

100–800 2 30 100 10

12.1 Viscometer, Brookfield Type.

400–1600 3 60 100 20

800–3200 3 30 100 40

12.2 Container,glassbottle,350-cm (12-oz)approximately

2000–8000 4 60 100 100

4000–16 000 4 30 100 200 64 mm (2 ⁄2 in.) in outside diameter and 152 mm (6 in.) high.

A 4

Brookfield Viscometer, Model LVF .

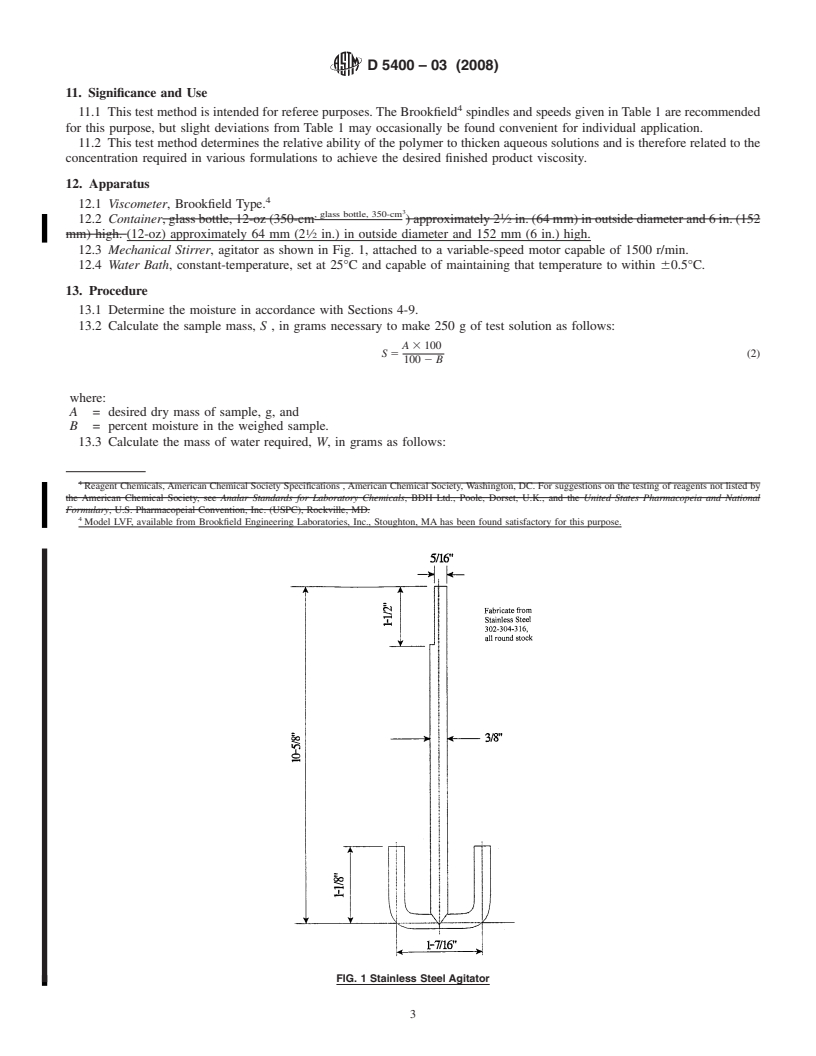

12.3 Mechanical Stirrer, agitator as shown in Fig. 1, at-

tached to a variable-speed motor capable of 1500 r/min.

12.4 Water Bath, constant-temperature, set at 25°C and

8. Calculation capable of maintaining that temperature to within 60.5°C.

8.1 Calculate the percent moisture, M, as follows:

13. Procedure

M 5 ~A/B! 3100 (1)

13.1 Determine the moisture in accordance with Sections

where: 4-9.

A = mass loss on heating, g, and

13.2 Calculate the sample mass, S, in grams necessary to

B = sample used, g.

make 250 g of test solution as follows:

8.2 Report the moisture content to the nearest 0.1%.

A 3100

S 5 (2)

100 2 B

9. Precision and Bias

9.1 Precision—Statistical analysis of intralaboratory test

where:

resultsonsamplescontainingfrom1to6%moistureindicates

A = desired dry mass of sample, g, and

a precision of 60.2% absolute at the 95% confidence level.

B = percent moisture in the weighed sample.

9.2 Bias—No justifiable statement on bias can be made as

no suitable reference material is available as a standard.

VISCOSITY

10. Scope

10.1 This test method is an arbitrary method of determining

theviscosityofaqueoussolutionsofhydroxypropylcellulosein

the viscosity range of 10 to 16 000 cP/s at 25°C.

10.2 The concentration to be used for the test shall be

agreed upon between the purchaser and the seller. It shall be

such that the viscosity of the solution will fall within the range

of this test.

10.3 The results for the viscosity of hydroxypropylcellulose

bythistestmethodwillnotnecessarilycheckwithresultsfrom

other types of instruments used for viscosity measurement.

10.4 The determinations are run on a calculated dry basis;

that is, the amount of hydroxypropylcellulose required for the

desired concentration on a dry basis is calculated from the

known moisture content.

11. Significance and Use

11.1 This test method is intended for referee purposes. The

Brookfield spindles and speeds given in Table 1 are recom-

mended for this purpose, but slight deviations from Table 1

may occasionally be found convenient for individual applica-

tion.

Model LVF, available from Brookfield Engineering Laboratories, Inc., Stough-

ton, MA has been found satisfactory for this purpose. FIG. 1 Stainless Steel Agitator

D5400−03(2008)

13.3 Calculate the mass of water required, W, in grams as 18. Significance and Use

follows:

18.1 This test method determines the relative acidity or

W 5 250 2 S (3) alkalinityofaqueoussolutionsofhydroxypropylcellulose.This

must be taken into consideration when determining materials

where:

of construction for equipment and packaging for handling and

S = sample mass, g.

storing these solutions. Also, pH may affect suitability for

13.4 Weighthewaterintotheglassbottleandplaceitonthe certain end-use applications.

stirrer,mixingataspeedsufficienttocauseavortexbutnotfast

19. Apparatus

enough to splash.

19.1 pH Meter, with glass electrodes.

13.5 Sprinkle the hydroxypropylcellulose sample into the

water slowly, to prevent lumping. Increase stirring speed to

20. Procedure

approximately 900 6 100 r/min and stir until the sample is

completely dissolved (1 to 2 h).

20.1 Determine the pH of the viscosity solution from 13.5,

usingasuitablepHmeterthathasbeenstandardizedaccording

13.6 Removetheglassbottlefromthestirrer,capthebottle,

to Test Method E70.

and place it in the constant temperature bath for 30 min or as

long as necessary to bring the solution to 25 6 0.5°C.

21. Precision and Bias

13.7 Removetheglassbottlefromthewaterbathandinvert

21.1 Precision—Statistical analysis of intralaboratory test

it slowly 4 to 5 times, taking care to minimize the introduction

results on samples with pH values of 4.5 to 8.5 indicates a

of air bubbles.

precision of 65% at the 95% confidence level.

13.8 Measure the viscosity with the Brookfield viscometer,

21.2 Bias—No justifiable statement on bias can be made as

following the manufacturer’s operating instructions. Select the

no suitable reference material is available as a standard.

proper spindle and speed from Table 1. Allow the spindle to

rotate for 3 min before taking the reading. Use the spindle

RESIDUE ON IGNITION

guard.

22. Scope

NOTE 1—If the room temperature is considerably greater or less than

25°C; the entire operation of stirring, standing, and measurement should

22.1 This test method covers the determination of the

be conducted with the glass bottle suspended in the constant temperature

amount of residue left from igniting a sample of hydroxypro-

bath.

pylcellulose after being moistened first with sulfuric acid and

then with hydrofluoric acid.

14. Calculation

14.1 Calculate the viscosity, V, in centipoises as follows:

23. Significance and Use

V 5 r 3 f (4)

23.1 Excessiveresidueonignitioncanaffectsolutionclarity

where: and film properties. The residue on ignition (along with

moisture) is a measure of the amount of active polymer in the

r = scale reading and

materialandmustbeconsideredwhendeterminingtheamount

f = factor from Table 1.

of hydroxypropylcellulose to use in various formulations.

15. Report

23.2 Commercially available hydroxypropylcellulose most

often has up to 0.60% silica added as an anti-ca

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5400–93(Reapproved1997) Designation: D 5400 – 03 (Reapproved 2008)

Standard Test Methods for

Hydroxypropylcellulose

This standard is issued under the fixed designation D 5400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the testing of hydroxypropylcellulose.

1.2 The test procedures appear in the following order:

Sections

Moisture 4to 9

Moisture 4-9

Viscosity10 to 16 10-16

Viscosity 10-16

pH17 to 21 17-21

pH 17-21

Residue on Ignition22 to 28 22-28

Residue on Ignition 22-28

Hydroxypropoxy Content29 to 29-36

Hydroxypropoxy Content 29-36

1.3

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Note 226.6.

2. Referenced Documents

2.1 ASTM Standards:

D 3876 Test Method for Methoxyl and Hydroxypropyl Substitution in Cellulose Ether Products by Gas Chromatography

E 70 Test Method for pH of Aqueous Solutions With the Glass Electrode

3. Reagents

3.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

3.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean distilled water.

MOISTURE

4. Scope

4.1 This test method covers the determination of the volatile content of hydroxypropylcellulose.

These test methods are under the jurisdiction of ASTM Committee D-1 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved May 15, 1993. Published July 1993.

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved June 1, 2008. Published June 2008. Originally approved in 1993. Last previous edition approved in 2003 as D 5400 – 03 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 06.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 15.05.Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For

suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and

the United States Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5400 – 03 (2008)

5. Significance and Use

5.1 The results of this test are used for calculating the total solids in the sample; and, by common usage, all materials volatile

at this test temperature are designated as moisture.

5.2 Moisture analysis (along with residue on ignition) is a measure of the amount of active polymer in the material and must

be considered when determining the amount of hydroxypropylcellulose to use in various formulations.

6. Apparatus

6.1 Oven, gravity convection, capable of maintaining a temperature of 105 6 3°C.

6.2 Weighing Dish, glass or aluminum, with cover, 50 mm in diameter, 25 mm in height, or equivalent.

6.3 Analytical Balance.

7. Procedure

7.1 Weigh about5gof sample to the nearest 0.001 g in a tared and covered weighing dish.

7.2 Place it in an oven at 105 6 1°C for 3 h with the cover removed.

7.3 Remove the dish from the oven, immediately replace the cover, cool in a desiccator, and weigh.

8. Calculation

8.1 Calculate the percent moisture, M, as follows:

M 5 ~A/B! 3 100 (1)

where:

A = mass loss on heating, g, and

B = sample used, g.

8.2 Report the moisture content to the nearest 0.1 %.

9. Precision and Bias

9.1 Precision—Statistical analysis of intralaboratory test results on samples containing from 1 to 6 % moisture indicates a

precision of 60.2 % absolute at the 95 % confidence level.

9.2 Bias—No justifiable statement on bias can be made as no suitable reference material is available as a standard.

VISCOSITY

10. Scope

10.1 This test method is an arbitrary method of determining the viscosity of aqueous solutions of hydroxypropylcellulose in the

viscosity range of 10 to 16 000 cP/s at 25°C.

10.2 The concentration to be used for the test shall be agreed upon between the purchaser and the seller. It shall be such that

the viscosity of the solution will fall within the range of this test.

10.3 The results for the viscosity of hydroxypropylcellulose by this test method will not necessarily check with results from

other types of instruments used for viscosity measurement.

10.4 The determinations are run on a calculated dry basis; that is, the amount of hydroxypropylcellulose required for the desired

concentration on a dry basis is calculated from the known moisture content.

A

TABLE 1 Brookfield Viscometer Spindle and Speed

Combinations

Viscosity Range, Spindle Speed,

Scale Factor

cP Number r/min

10–80 1 60 100 1

20–160 1 30 100 2

50–400 2 60 100 5

100–800 2 30 100 10

400–1600 3 60 100 20

800–3200 3 30 100 40

2000–8000 4 60 100 100

4000–16 000 4 30 100 200

A 54

Brookfield Viscometer, Model LVF .

D 5400 – 03 (2008)

11. Significance and Use

11.1 This test method is intended for referee purposes. The Brookfield spindles and speeds given in Table 1 are recommended

for this purpose, but slight deviations from Table 1 may occasionally be found convenient for individual application.

11.2 This test method determines the relative ability of the polymer to thicken aqueous solutions and is therefore related to the

concentration required in various formulations to achieve the desired finished product viscosity.

12. Apparatus

12.1 Viscometer, Brookfield Type.

, glass bottle, 350-cm

12.2 Container, glass bottle, 12-oz (350-cm ) approximately 2 ⁄2 in. (64 mm) in outside diameter and 6 in. (152

mm) high. (12-oz) approximately 64 mm (2 ⁄2 in.) in outside diameter and 152 mm (6 in.) high.

12.3 Mechanical Stirrer, agitator as shown in Fig. 1, attached to a variable-speed motor capable of 1500 r/min.

12.4 Water Bath, constant-temperature, set at 25°C and capable of maintaining that temperature to within 60.5°C.

13. Procedure

13.1 Determine the moisture in accordance with Sections 4-9.

13.2 Calculate the sample mass, S , in grams necessary to make 250 g of test solution as follows:

A 3 100

S 5 (2)

100 2 B

where:

A = desired dry mass of sample, g, and

B = percent moisture in the weighed sample.

13.3 Calculate the mass of water required, W, in grams as follows:

Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

Model LVF, available from Brookfield Engineering Laboratories, Inc., Stoughton, MA has been found satisfactory for this purpose.

FIG. 1 Stainless Steel Agitator

D 5400 – 03 (2008)

W 5 250 2 S (3)

where:

S = sample mass, g.

13.4 Weigh the water into the glass bottle and place it on the stirrer, mixing at a speed sufficient to cause a vortex but not fast

enough to splash.

13.5 Sprinkle the hydroxypropylcellulose sample into the water slowly, to prevent lumping. Increase stirring speed to

approximately 900 6 100 r/min and stir until the sample is completely dissolved (1 to 2 h).

13.6 Remove the glass bottle from the stirrer, cap the bottle, and place it in the constant temperature bath for 30 min or as long

as necessary to bring the solution to 25 6 0.5°C.

13.7 Remove the glass bottle from the water bath and invert it slowly 4 to 5 times, taking care to minimize the introduction of

air bubbles.

13.8 Measure the viscosity with the Brookfield viscometer, following the manufacturer’s operating instructions. Select the

proper spindle and speed from Table 1. Allow the spindle to rotate for 3 min before taking the reading. Use the spindle guard.

NOTE 1—If the room temperature is considerably greater or less than 25°C; the entire operation of stirring, standing, and measurement should be

conducted with the glass bottle suspended in the constant temperature bath.

14. Calculation

14.1 Calculate the viscosity, V, in centipoises as follows:

V 5 r 3 f (4)

where:

r = scale reading and

f = factor from Table 1.

15. Report

15.1 Report the following information:

15.1.1 Results, as Brookfield viscosity at 25°C,

15.1.2 Solution concentration,

15.1.3 Spindle used, and

15.1.4 Speed used.

16. Precision and Bias

16.1 Precision—Statistical analysis of interlaboratory test results indicates a precision of 610 % at the 95 % confidence level.

16.2 Bias—No justifiable statement on bias can be made as no suitable reference material is available as a standard.

pH

17. Scope

17.1 This test method covers the determination of the pH of aqueous solutions of hydroxypropylcellulose.

18. Significance and Use

18.1 This test method determines the relative acidity or alkalinity of aqueous solutions of hydroxypropylcellulose. This must

betakenintoconsiderationwhendeterminingmaterialsofconstructionforequipmentandpackagingforhandlingandstoringthese

solutions. Also, pH may affect suitability for certain end-use applications.

19. Apparatus

19.1 pH Meter, with glass electrodes.

20. Procedure

20.1 Determine the pH of the viscosity solution from 13.5, using a suitable pH meter that has been standardized according to

Test Method E 70.

21. Precision and Bias

21.1 Precision—Statistical analysis of intralaboratory test results on samples with pH values of 4.5 to 8.5 indicates a precision

of 65 % at the 95 % confidence level.

21.2 Bias—No justifiable statement on bias can be made as no suitable reference material is available as a standard.

RESIDUE ON IGNITION

22. Scope

22.1 This test method covers the determination of the amount of residue left from igniting a sample of hydroxypropylcellulose

D 5400 – 03 (2008)

after being moistened first with sulfuric acid and then with hydrofluoric acid.

23. Significance and Use

23.1 Excessive residue on ignition can affect solution clarity and film properties. The residue on ignition (along with moisture)

is a measure of the amount of active polymer in the material and must be considered when determining the amount of

hydroxypropylcellulose to use in various formulations.

23.2 Commercially available hydroxypropylcellulose most often has up to 0.60 % silica added as an anti-caking agent.

Therefore, a hydrofluoric acid ashing step is required to remove the silica.

24. Apparatus

24.1 Dishes, platinum, 75-mL capacity.

24.2 Hot Plate.

24.3 Muffle Furnace, capable of reaching 1000 6 25°C.

25. Reagents

25.1 Sulfuric Acid, (sp gr 1.84) —concentrated sulfuric acid (H SO ).

2 4

25.2 Hydrofluoric Acid (48 %).

26. Procedure

26.1 Weigh, to the nearest 0.0001 g, about1gof hydroxypropylcellulose into a tared platinum dish. Using a hot plate, heat the

dish containing the sample (gently at first) until the sample is thoroughly charred. Cool the dish for several minutes.

26.2 Moisten the residue with about 1 mL of sulfuric acid and heat gently on the hot plate until white fumes are no longer

evolved.

26.3 Place the dish in a muffle furnace at 800 6 25°C for 30 min. Allow the dish to cool.

26.4 Repeat 26.2 and 26.3. Cool in a desiccator. Weigh the residue (R ).

26.5 Moisten the residue with up to 1 mL of water and carefully add about 5 mL of hydrofluoric acid, in small portions.

Evaporate to dryness on a hot plate in a fume hood. Allow the dish to cool.

26.6 Carefully add about 5 mL of hydrofluoric acid and 0.5 mL of sulfuric acid and evaporate to dryness on a hot plate in a

fume hood.

NOTE2—Precaution:Hydrofluoric (Warning—Hydrofluoric acid is a poisonous and extremely hazardous acid because of its ability to cause severe

burns that are not immediately painful or visible. Use extreme care in handling.)

26.7 Place the dish in a muffle furnace at 1000 6 25°C for 20 min. Allow the dish to cool in a desiccator. Weigh the residue

(R ).

27. Calculations

27.1 Calculate the percent residue on ignition, RI, as follows:

RI 5 ~R /S! 3 100 (5)

where:

R = ash after ignition with hydrofluoric acid, g, and

S = sample used, g.

27.2 The percent silica content, Si, may be calculated as follows:

Si 5 [R 2 R !/S 3 100 (6)

1 2

where:

R = ash after ignition with sulfuric acid, g,

R = ash after ignition with hydrofluoric acid, g, and

S = sample used, g.

28. Precision and Bias

28.1 Precision—Statistical analysis of intralaboratory test results on samples containing 0.00 to 0.30 % residue on ignition

indicates a precision of 610 % at the 95 % confidence level.

28.2 Bias—No justifiable statement on bias can be made as no suitable reference material is available as a standard.

,

5 6

HYDROXYPROPOXY CONTENT

29. Scope

29.1 This test method covers the determination of the hydroxypropoxy content of hydroxypropylcellulose.

Model LVF, available from Brookfield Engineering Laboratories, Inc., Stoughton, MA has been found satisfactory for this purpose.

D 5400 – 03 (2008)

30. S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.