ASTM D5400-15(2021)

(Test Method)Standard Test Methods for Hydroxypropylcellulose

Standard Test Methods for Hydroxypropylcellulose

SIGNIFICANCE AND USE

5.1 The results of this test are used for calculating the total solids in the sample; and, by common usage, all materials volatile at this test temperature are designated as moisture.

5.2 Moisture analysis (along with residue on ignition) is a measure of the amount of active polymer in the material and must be considered when determining the amount of hydroxypropylcellulose to use in various formulations.

SCOPE

1.1 These test methods cover the testing of hydroxypropylcellulose.

1.2 The test procedures appear in the following order:

Sections

Moisture

4 – 9

Viscosity

10 – 16

pH

17 – 21

Residue on Ignition

22 – 28

Hydroxypropoxy Content

29 – 36

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 26.6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5400 − 15 (Reapproved 2021)

Standard Test Methods for

Hydroxypropylcellulose

This standard is issued under the fixed designation D5400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Reagents

1.1 These test methods cover the testing of hydroxypropy- 3.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

lcellulose.

all reagents shall conform to the specifications of the Commit-

1.2 The test procedures appear in the following order:

tee onAnalytical Reagents of theAmerican Chemical Society,

Sections

where such specifications are available. Other grades may be

Moisture 4–9

used, provided it is first ascertained that the reagent is of

Viscosity 10–16

pH 17–21

sufficiently high purity to permit its use without lessening the

Residue on Ignition 22–28

accuracy of the determination.

Hydroxypropoxy Content 29–36

3.2 Purity of Water—Unless otherwise indicated, references

1.3 The values stated in SI units are to be regarded as the

to water shall be understood to mean distilled water.

standard. The values given in parentheses are for information

only.

MOISTURE

1.4 This standard does not purport to address all of the

4. Scope

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.1 Thistestmethodcoversthedeterminationofthevolatile

priate safety, health, and environmental practices and deter- content of hydroxypropylcellulose.

mine the applicability of regulatory limitations prior to use.

5. Significance and Use

For specific hazard statements, see 26.6.

5.1 The results of this test are used for calculating the total

1.5 This international standard was developed in accor-

solids in the sample; and, by common usage, all materials

dance with internationally recognized principles on standard-

volatile at this test temperature are designated as moisture.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5.2 Moisture analysis (along with residue on ignition) is a

mendations issued by the World Trade Organization Technical

measure of the amount of active polymer in the material and

Barriers to Trade (TBT) Committee.

must be considered when determining the amount of hydroxy-

propylcellulose to use in various formulations.

2. Referenced Documents

6. Apparatus

2.1 ASTM Standards:

6.1 Oven, gravity convection, capable of maintaining a

D3876Test Method for Methoxyl and Hydroxypropyl Sub-

temperature of 105 6 3°C.

stitution in Cellulose Ether Products by Gas Chromatog-

raphy 6.2 Weighing Dish, glass or aluminum, with cover, 50 mm

E70Test Method for pH of Aqueous Solutions With the

in diameter, 25 mm in height, or equivalent.

Glass Electrode

6.3 Analytical Balance.

7. Procedure

These test methods are under the jurisdiction of ASTM Committee D01 on 7.1 Weigh about5gof sample to the nearest 0.001 g in a

Paint and Related Coatings, Materials, and Applications and are the direct

tared and covered weighing dish.

responsibility of Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved June 1, 2021. Published June 2021. Originally

approved in 1993. Last previous edition approved in 2015 as D5400–15. DOI: ACS Reagent Chemicals, Specifications and Procedures for Reagents and

10.1520/D5400-15R21. Standard-Grade Reference Materials, American Chemical Society, Washington,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

Standards volume information, refer to the standard’s Document Summary page on U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

the ASTM website. copeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5400 − 15 (2021)

7.2 Place it in an oven at 105 6 1°C for 3 h with the cover

removed.

7.3 Removethedishfromtheoven,immediatelyreplacethe

cover, cool in a desiccator, and weigh.

8. Calculation

8.1 Calculate the percent moisture, M, as follows:

M 5 ~A/B! 3100 (1)

where:

A = mass loss on heating, g, and

B = sample used, g.

8.2 Report the moisture content to the nearest 0.1%.

9. Precision and Bias

9.1 Precision—Statistical analysis of intralaboratory test

resultsonsamplescontainingfrom1to6%moistureindicates

a precision of 60.2% absolute at the 95% confidence level.

9.2 Bias—No justifiable statement on bias can be made as

no suitable reference material is available as a standard.

VISCOSITY

10. Scope

10.1 This test method is an arbitrary method of determining

theviscosityofaqueoussolutionsofhydroxypropylcellulosein

the viscosity range of 10 to 16 000 mPa · s (cP) at 25°C.

10.2 The concentration to be used for the test shall be

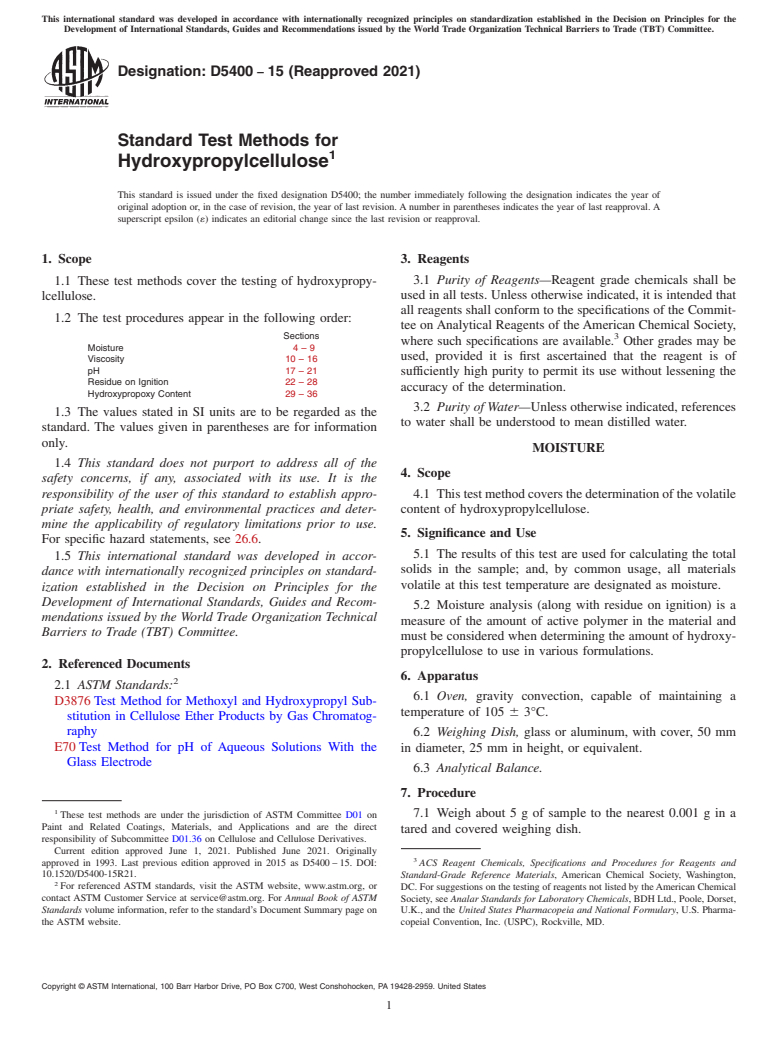

agreed upon between the purchaser and the seller. It shall be FIG. 1 Cylindrical Rotational Elements and Speeds

such that the viscosity of the solution will fall within the range

of this test.

11.2 This test method determines the relative ability of the

polymertothickenaqueoussolutionsandisthereforerelatedto

10.3 The results for the viscosity of hydroxypropylcellulose

the concentration required in various formulations to achieve

by this test method will not necessarily agree with results from

the desired finished product viscosity.

other types of instruments used for viscosity measurement.

10.4 The determinations are run on a calculated dry basis;

12. Apparatus

that is, the amount of hydroxypropylcellulose required for the

12.1 Viscometer, Rotational—The essential instrumentation

desired concentration on a dry basis is calculated from the

required providing the minimum rotational viscometer analyti-

known moisture content.

cal capabilities for this method include:

12.1.1 A drive motor,toapplyaunidirectionaldisplacement

11. Significance and Use

to the specimen at a rate from 0.5 to 60 rev/min constant to

11.1 TherotationalelementsandspeedsgiveninTable1are

within 61%.

recommended for this purpose. Slight deviations from Table 1

12.1.2 A force sensor to measure the torque developed by

may be found convenient for an individual application.

the specimen.

12.1.3 A coupling shaft or other means to transmit the

rotational displacement from the motor to the specimen.

TABLE 1 Cylindrical Rotational Elements and Speeds

(see Fig. 1)

NOTE 1—It is helpful to have a mark on the shaft to indicate the

appropriate level of the specimen.

Torque

Viscosity Range, Diameter (D) Length (L) Speed

Scale

12.1.4 A rotational element, spindle or tool to fix the

(mPa·s) (mm) (mm) (rmin)

Multiplier

specimen between the drive shaft and a stationary position.

10 to 80 19 65 60 1

20 to 160 19 65 30 2

NOTE 2—The rotational element shall be of the immersion type. This

50 to 400 10 54 60 5

standard is not intended for cone-and-plate or parallel plate type viscom-

100 to 800 10 54 30 10

eters.

400 to 1600 5.9 43 60 20

NOTE 3—Each rotational element typically covers a range of about two

800 to 3200 5.9 43 30 40

decades of viscosity. The rotational element is selected so that the

2000 to 8000 3.2 31 60 100

4000 to 16 000 3.2 31 30 200 measured viscosity is between 15 and 95% of the range of the rotational

element.

D5400 − 15 (2021)

12.1.5 A guard to protect the rotational element from A 3100

S 5 (2)

mechanical damage. 100 2 B

12.1.6 A temperature sensor to provide an indication of the

where:

specimen temperature of the range of 20 to 30°C to within

A = desired dry mass of sample, g, and

0.1°C.

B = percent moisture in the weighed sample.

12.1.7 A data collection device, to provide a means of

acquiring, storing, and displaying measured or calculated 13.3 Calculate the mass of water required, W, in grams as

follows:

signals, or both. The minimum output signals required for

rotationalviscometryaretorque,rotationalspeed,temperature,

W 5 250 2 S (3)

and time.

where:

12.1.8 A stand,tosupport,level,andadjusttheheightofthe

S = sample mass, g.

drive motor, shaft, and rotational element.

12.1.9 Container, glass bottle, 350-cm (12-oz) approxi-

13.4 Weighthewaterintotheglassbottleandplaceitonthe

mately64mm(2 ⁄2in.)inoutsidediameterand152mm(6in.)

stirrer,mixingataspeedsufficienttocauseavortexbutnotfast

high.

enough to splash.

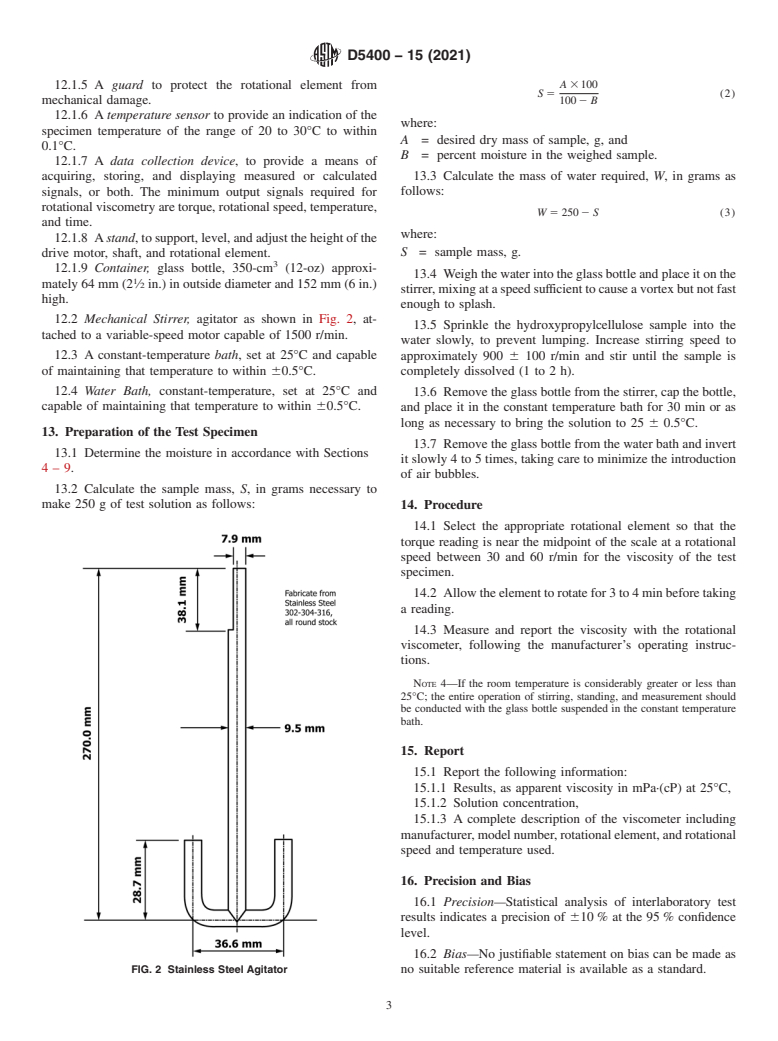

12.2 Mechanical Stirrer, agitator as shown in Fig. 2, at-

13.5 Sprinkle the hydroxypropylcellulose sample into the

tached to a variable-speed motor capable of 1500 r/min.

water slowly, to prevent lumping. Increase stirring speed to

12.3 A constant-temperature bath, set at 25°C and capable

approximately 900 6 100 r/min and stir until the sample is

of maintaining that temperature to within 60.5°C. completely dissolved (1 to 2 h).

12.4 Water Bath, constant-temperature, set at 25°C and

13.6 Removetheglassbottlefromthestirrer,capthebottle,

capable of maintaining that temperature to within 60.5°C. and place it in the constant temperature bath for 30 min or as

long as necessary to bring the solution to 25 6 0.5°C.

13. Preparation of the Test Specimen

13.7 Removetheglassbottlefromthewaterbathandinvert

13.1 Determine the moisture in accordance with Sections

it slowly 4 to 5 times, taking care to minimize the introduction

4–9.

of air bubbles.

13.2 Calculate the sample mass, S, in grams necessary to

make 250 g of test solution as follows:

14. Procedure

14.1 Select the appropriate rotational element so that the

torque reading is near the midpoint of the scale at a rotational

speed between 30 and 60 r/min for the viscosity of the test

specimen.

14.2 Allowtheelementtorotatefor3to4minbeforetaking

a reading.

14.3 Measure and report the viscosity with the rotational

viscometer, following the manufacturer’s operating instruc-

tions.

NOTE 4—If the room temperature is considerably greater or less than

25°C; the entire operation of stirring, standing, and measurement should

be conducted with the glass bottle suspended in the constant temperature

bath.

15. Report

15.1 Report the following information:

15.1.1 Results, as apparent viscosity in mPa·(cP) at 25°C,

15.1.2 Solution concentration,

15.1.3 A complete description of the viscometer including

manufacturer,modelnumber,rotationalelement,androtational

speed and temperature used.

16. Precision and Bias

16.1 Precision—Statistical analysis of interlaboratory test

results indicates a precision of 610% at the 95% confidence

level.

16.2 Bias—No justifiable statement on bias can be made as

FIG. 2 Stainless Steel Agitator no suitable reference material is available as a standard.

D5400 − 15 (2021)

pH 25.2 Hydrofluoric Acid (48%).

17. Scope

26. Procedure

17.1 This test method covers the determination of the pH of

26.1 Weigh, to the nearest 0.0001 g, about1gof hydroxy-

aqueous solutions of hydroxypropylcellulose.

propylcellulose into a tared platinum dish. Using a hot plate,

heat the dish containing the sample (gently at first) until the

18. Significance and Use

sample is thoroughly charred. Cool the dish for several

18.1 This test method determines the relative acidity or

minutes.

alkalinityofaqueoussolutionsofhydroxypropylcellulose.This

26.2 Moisten the residue with about 1 mL of sulfuric acid

must be taken into consideration when determining materials

andheatgentlyonthehotplateuntilwhitefumesarenolonger

of construction for equipment and packaging for handling and

evolved.

storing these solutions. Also, pH may affect suitability for

certain end-use applications.

26.3 Placethedishinamufflefurnaceat800 625°Cfor30

min. Allow the dish to cool.

19. Apparatus

26.4 Repeat 26.2 and 26.3. Cool in a desiccator. Weigh the

19.1 pH Meter, with glass electrodes.

residue (R ).

20. Procedure

26.5 Moisten the residue with up to 1 mL of water and

carefully add about 5 mL of hydrofluoric acid, in small

20.1 Determine the pH of the viscosity solution from 13.5,

usingasuitablepHmeterthathasbeenstandardizedaccording portions. Evaporate to dryness on a hot plate in a fume hood.

Allow the dish to cool.

to Test Method E70.

26.6 Carefully add about 5 mLof hydrofluoric acid and 0.5

21. Precision and Bias

mL of sulfuric acid and evaporate to dryness on a hot plate in

21.1 Precision—Statistical analysis of intralaboratory test

afumehood.(Warning—Hydrofluoricacidisapoisonousand

results on samples with pH values of 4.5 to 8.5 indicates a

extremely hazardous acid because of its ability to cause severe

precision of 65% at the 95% confidence level.

burns that are not immediately painful or visible. Use extreme

21.2 Bias—No justifiable statement on bias can be made as care in handling.)

no suitable reference material is available as a standard.

26.7 Place the dish in a muffle furnace at 1000 6 25°C for

20 min. Allow the dish to cool in a desiccator. Weigh the

RESIDUE ON IGNITION

residue (R ).

22. Scope

27. Calculations

22.1 This test method covers the determination of the

amount of residue left from igniting a sample of hydroxypro- 27.1 Calculate the percent residue on ignition, RI, as fol-

pylcellulose after being moistened first with sulfuric acid and lows:

then with hydrofluoric acid.

RI 5 ~R /S! 3100 (4)

23. Significance and Use

where:

23.1 Excessiveresidueonignitioncanaffectsolutionclarity

R = ash after ignition with hydrofluoric acid, g, and

and film properties. The residue on ignition (along with S = sample used, g.

moisture) is a measure of the amount of active polymer in the

27.2 The percent silica content, Si, may be calculated as

material and must be considered when determining the amount

follows:

of hydroxypropylcellulose to use in various formulations.

Si 5 R 2 R / S 3 100 (5)

~ !

1 2

23.2 Commercially available hydroxypropylcellulose most

where:

often has up to 0.60% silica added as an anti-caking agent.

Therefore, a hydrofluoric acid ashing step is required to

R = ash after ignition with sulfuric acid, g,

R = ash after ignition with hydrofluoric acid, g, and

remove the silica.

S = sample used, g.

24. Apparatus

28. Precision and Bias

24.1 Dishes, platinum, 75-mL capacity.

28.1 Precision—Statistical analysis of intralaboratory test

24.2 Hot Plate.

results on samples

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.