ASTM F2559-06

(Guide)Standard Guide for Writing a Specification for Sterilizable Peel Pouches

Standard Guide for Writing a Specification for Sterilizable Peel Pouches

SIGNIFICANCE AND USE

Medical device peel pouches are universally used by the industry and produced by a myriad of suppliers. They may be constructed of many different materials including films, foils, paper, nonwovens such as Tyvek, and combinations thereof. However, even with the diversity of materials, there are still basic requirements that all pouches should exhibit. Above all, the pouches must contain and protect the device while maintaining sterility during all physical handling.

Pouch requirements may be divided into two categories, initial pouch and material qualification, and routine production and receipt requirements to ensure the purchaser receives exactly what is ordered. While all requirements should be included in the written specification, initial qualification tests may only be needed prior to the first order. Routine production and receipt requirements should be adhered to on every order. Initial qualification requirements are indicated within each clause, where applicable.

This guide provides an understanding of the requirements needed for the manufacture, purchase, and acceptance of a preformed peelable pouch. Appropriate test methods for compliance are also cited.

Note 1—All test methods for a particular requirement may not be cited due to specific or unique circumstances. For additional guidance on applicable methods, refer to Guide F 2097.

The specification and its requirements should be mutually agreed to by the supplier and purchaser of pouches. This helps ensure that pouches will comply to specified requirements.

SCOPE

1.1 This guide defines the requirements and considerations for flexible peel pouches with one open, unsealed end that are intended to be sterilized containing medical devices. These are also known as preformed sterile barrier systems.

1.2 Pouch styles are categorized as chevron, header, and corner peel. These pouches are typically manufactured by heat sealing, or in some cases, by cohesive cold sealing. The sealing bond is intended to be peeled open to aseptically dispense the contents.

1.3 Pouch materials may be either porous, nonporous, or any combination of the two.

1.4 This guide addresses some critical printing requirements on the pouch.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2559 – 06

Standard Guide for

Writing a Specification for Sterilizable Peel Pouches

This standard is issued under the fixed designation F2559; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F2097 Guide for Design and Evaluation of Primary Flexible

Packaging for Medical Products

1.1 This guide defines the requirements and considerations

F2203 Test Method for Linear Measurement Using Preci-

for flexible peel pouches with one open, unsealed end that are

sion Steel Rule

intended to be sterilized containing medical devices. These are

F2250 Practice for Evaluation of Chemical Resistance of

also known as preformed sterile barrier systems.

Printed Inks and Coatings on Flexible Packaging Materials

1.2 Pouch styles are categorized as chevron, header, and

F2475 Guide for Biocompatibility Evaluation of Medical

corner peel. These pouches are typically manufactured by heat

Device Packaging Materials

sealing, or in some cases, by cohesive cold sealing.The sealing

2.2 TAPPI Standards:

bond is intended to be peeled open to aseptically dispense the

T437 Dirt in Paper and Paperboard

contents.

1.3 Pouch materials may be either porous, nonporous, or

3. Terminology

any combination of the two.

3.1 Definitions—For definitions and terms used in this

1.4 Thisguideaddressessomecriticalprintingrequirements

guide, see Terminology F17.

on the pouch.

3.2 Definitions of Terms Specific to This Standard:

1.5 This standard does not purport to address all of the

3.2.1 pouch, n—a flexible package constructed of one or

safety concerns, if any, associated with its use. It is the

more materials sealed together to form a preformed sterile

responsibility of the user of this standard to establish appro-

barrier system. When purchased, one end or side is open to

priate safety and health practices and determine the applica-

allow for product loading and final sealing.

bility of regulatory limitations prior to use.

3.2.2 specification, n—an explicit set of requirements to be

2. Referenced Documents satisfied by a material, product, system, or service. Examples

of specifications include, but are not limited to, requirements

2.1 ASTM Standards:

for; physical, mechanical, or chemical properties, and safety,

E122 Practice for Calculating Sample Size to Estimate,

quality, or performance criteria. A specification identifies the

With Specified Precision, the Average for a Characteristic

test methods for determining whether each of the requirements

of a Lot or Process

is satisfied.

F17 Terminology Relating to Flexible Barrier Packaging

F88 Test Method for Seal Strength of Flexible Barrier

4. Summary

Materials

4.1 This guide provides guidance for writing a peel pouch

F1140 Test Methods for Internal Pressurization Failure

material specification. Materials, method of manufacture,

Resistance of Unrestrained Packages

physical properties, performance requirements, dimensioning,

F1886 Test Method for Determining Integrity of Seals for

appearance, and printing are all issues that need to be ad-

Medical Packaging by Visual Inspection

dressedinapeelpouchspecification.Appropriaterequirements

F2054 Test Method for Burst Testing of Flexible Package

and test methods are suggested for preparing a specification.

Seals Using Internal Air Pressurization Within Restraining

Plates

5. Significance and Use

5.1 Medical device peel pouches are universally used by the

industry and produced by a myriad of suppliers. They may be

This guide is under the jurisdiction of ASTM Committee F02 on Flexible

constructed of many different materials including films, foils,

Barrier Packaging and is the direct responsibility of Subcommittee F02.50 on

paper, nonwovens such as Tyvek, and combinations thereof.

Package Design and Development.

Current edition approved Nov. 1, 2006. Published November 2006. DOI:

10.1520/F2559-06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

Standards volume information, refer to the standard’s Document Summary page on 15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

the ASTM website. In accordance with ASTM International Form and Style for ASTM Standards.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2559 – 06

However, even with the diversity of materials, there are still

basic requirements that all pouches should exhibit. Above all,

the pouches must contain and protect the device while main-

taining sterility during all physical handling.

5.2 Pouch requirements may be divided into two categories,

initial pouch and material qualification, and routine production

and receipt requirements to ensure the purchaser receives

exactly what is ordered. While all requirements should be

included in the written specification, initial qualification tests

may only be needed prior to the first order. Routine production

and receipt requirements should be adhered to on every order.

Initial qualification requirements are indicated within each

clause, where applicable.

5.3 This guide provides an understanding of the require-

ments needed for the manufacture, purchase, and acceptance of

a preformed peelable pouch. Appropriate test methods for

compliance are also cited.

FIG. 2 Header Bag

NOTE 1—All test methods for a particular requirement may not be cited

due to specific or unique circumstances. For additional guidance on

NOTE 2—There are numerous test methods associated with determining

applicable methods, refer to Guide F2097.

physical and chemical properties of flexible materials used in the

5.4 The specification and its requirements should be mutu-

fabrication of pouches. Care should be taken in selecting the most

appropriate test for the user’s particular application and use. For guidance

ally agreed to by the supplier and purchaser of pouches. This

in determining which methods to use, refer to Guide F2097.

helps ensure that pouches will comply to specified require-

ments.

6.2.2 The ability of the materials to demonstrate compliance

with predetermined requirements may be addressed by either

6. Specification

the certification from raw or component materials supplier or

6.1 Classification:

by actual testing performed by the pouch manufacturer in

6.1.1 Style:

compliance with quality systems.These requirements are often

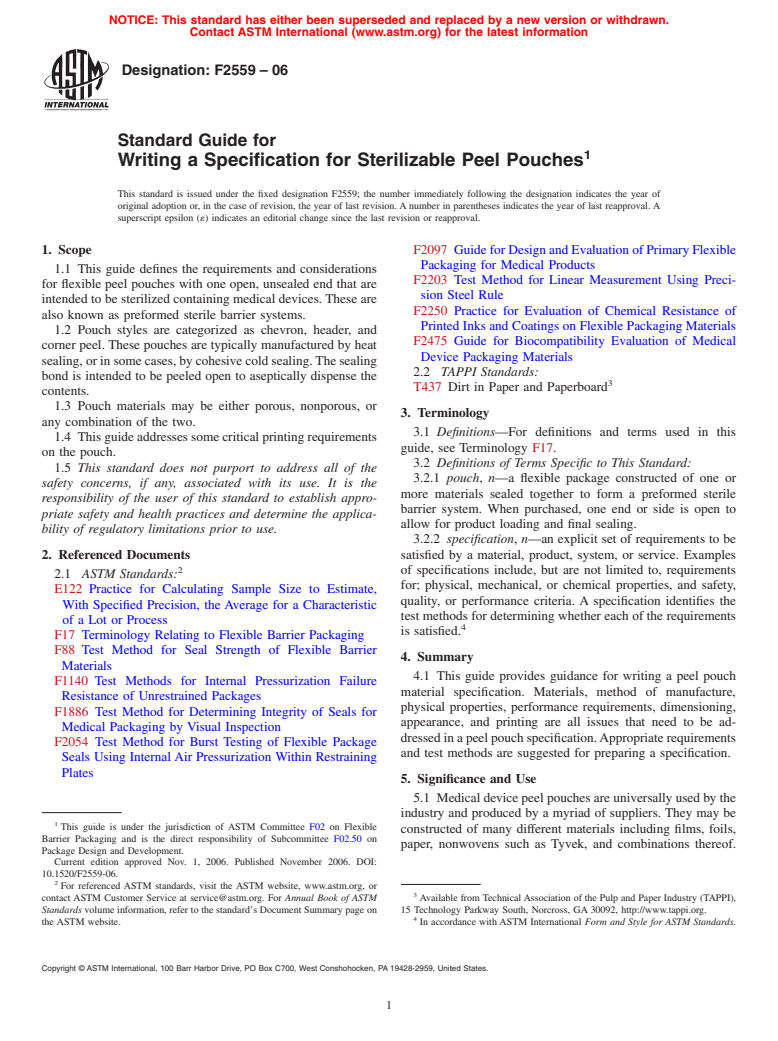

6.1.1.1 Chevron pouch (see Fig. 1),

evaluated during the initial package qualification and not

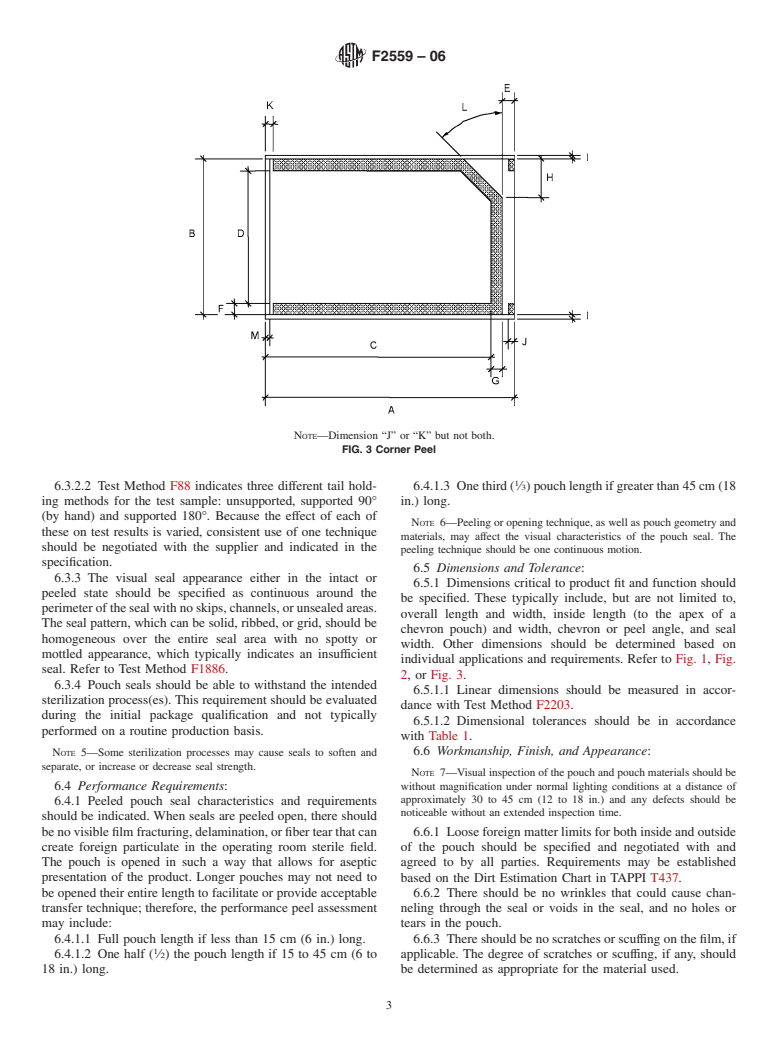

6.1.1.2 Corner peel pouch (see Fig. 2), and

typically performed on a routine production basis.

6.1.1.3 Header bag (see Fig. 3).

6.2.3 Pouches should be manufactured within a formal

6.2 Materials and Manufacture:

quality system.

6.2.1 Materials used in the construction of medical device

6.2.4 The process of converting materials into pouches

peel pouches should be specified as non-toxic, providing a

should be validated to demonstrate it is capable of consistently

microbial barrier and any other appropriate physical barrier

producing a product that complies with predetermined require-

(oxygen, water vapor, light, and so forth), and being compat-

ments such as dimensions, quality attributes, seal strength and

ible with the intended sterilization process.These requirements

seal integrity.

shouldbeevaluatedduringtheinitialpackagequalificationand

6.3 Physical Properties:

are not typically performed on a routine production basis.

6.3.1 The critical physical property for a peel pouch is how

well the seal is fabricated and how well it will stand up to the

stresses of sterilization, distribution, storage, and handling

environments.

6.3.2 A seal strength should be specified. This requirement

may be a minimum or maximum value, or both, the user has

qualified, or it may be an average or range value based on the

sealing process capability.

NOTE 3—Minimum seal strength is typically that which maintains

package integrity through the processing, sterilization, handling, and

distribution systems. Maximum seal strength is that which, if exceeded,

mayresultintheperceptionthatthepouchistoodifficulttoopenorcauses

fiber tear or delamination between one or more of the bonded substrates.

6.3.2.1 Seal strength is measured using a tensile test method

suchasTestMethodF88orbursttestusingTestMethodF2054

or Test Method F1140.

NOTE 4—Burst testing is more commonly used for in-process testing

rather than acceptance testing. If burst strength is to be used for in-process

NOTE—Dimension “I” or “J” but not both. control, then concurrent tensile and burst testing should be performed at

FIG. 1 Chevron Pouch the time of validation.

F2559 – 06

NOTE—Dimension “J” or “K” but not both.

FIG. 3 Corner Peel

6.3.2.2 Test Method F88 indicates three different tail hold- 6.4.1.3 Onethird( ⁄3)pouchlengthifgreaterthan45cm(18

ing methods for the test sample: unsupported, supported 90° in.) long.

(by hand) and supported 180°. Because the effect of each of

NOTE 6—Peeling or opening technique, as well as pouch geometry and

these on test results is varied, consistent use of one technique

materials, may affect the visual characteristics of the pouch seal. The

should be negotiated with the supplier and indicated in the

peeling technique should be one continuous motion.

specification.

6.5 Dimensions and Tolerance:

6.3.3 The visual seal appearance either in the intact or

6.5.1 Dimensions critical to product fit and function should

peeled state should be specified as continuous around the

be specified. These typically include, but are not limited to,

perimeterofthesealwithnoskips,channels,orunsealedareas.

overall length and width, inside length (to the apex of a

The seal pattern, which can be solid, ribbed, or grid, should be

chevron pouch) and width, chevron or peel angle, and seal

homogeneous over the entire seal area with no spotty or

width. Other dimensions should be determined based on

mottled appearance, which typically indicates an insufficient

individual applications and requirements. Refer to Fig. 1, Fig.

seal. Refer to Test Method F1886.

2,or Fig. 3.

6.3.4 Pouch seals should be able to withstand the intended

6.5.1.1 Linear dimensions should be measured in accor-

sterilization process(es). This requirement should be evaluated

dance wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.