ASTM D7539-10(2015)

(Practice)Standard Practice for Using a Test Chamber for Humidity Conditioning of Test Panels of Pavement Marking Paints

Standard Practice for Using a Test Chamber for Humidity Conditioning of Test Panels of Pavement Marking Paints

SIGNIFICANCE AND USE

5.1 The drying rate of organic coatings varies with changes in temperature, air flow, and relative humidity. In particular, the drying rate of waterborne paints depends on the evaporation of water and thus is much more dependent on relative humidity than are solvent based paints or paints that are 100 % solids. Measurement of the rate of drying of waterborne paints under ambient conditions in laboratories cannot be adequately replicated without some control of the drying conditions. A test chamber will be described that provides a means of controlling relative humidity above ambient humidity and minimizing the effects of air flow variability at ambient room temperatures. If desired, the test chamber without water in it and with vents wide open can be placed in a temperature and humidity controlled room to test dry speed at various temperatures as well as humidity while using the chamber to minimize the effect of air flow.

5.2 This practice is particularly useful for testing the drying rate of waterborne pavement marking (traffic) paints where fast dry at elevated ambient humidity is an important feature. For waterborne traffic paints, the test chamber can be used to evaluate dry to no-pick-up (Test Method D711) and water wash-off resistance (Practices D7377 and D7538) at elevated ambient humidity.

SCOPE

1.1 Specification D3924 defines a standard environment of 23 ± 2°C and 50 ± 5 % relative humidity and free from drafts for normal conditioning and testing of paint, varnish, lacquer, and related materials. This practice describes a test chamber that allows for control of relative humidity above the ambient relative humidity and minimization of air flow for conditioning of test panels at elevated relative humidity and room temperatures.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7539 − 10 (Reapproved 2015)

Standard Practice for

Using a Test Chamber for Humidity Conditioning of Test

Panels of Pavement Marking Paints

This standard is issued under the fixed designation D7539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standard:

TT-P-1952E Federal Specification for Paint, Traffic and

1.1 Specification D3924 defines a standard environment of

Airfield Marking, Waterborne (10 July 2007)

23 6 2°C and 50 6 5 % relative humidity and free from drafts

for normal conditioning and testing of paint, varnish, lacquer,

3. Terminology

and related materials. This practice describes a test chamber

3.1 Definitions:

that allows for control of relative humidity above the ambient

3.1.1 test chamber, n—a cabinet or box, preferably made of

relative humidity and minimization of air flow for conditioning

transparent, waterproof material, such as clear acrylic plastic,

of test panels at elevated relative humidity and room tempera-

with panel supports and holes (ports) that can be partially to

tures.

fully opened to mix outside ambient air with humidified air in

1.2 The values stated in inch-pound units are to be regarded

the chamber or some other means to provide humidified air

as standard. The values given in parentheses are mathematical

with minimal air flow.

conversions to SI units that are provided for information only

3.1.1.1 Discussion—Also commonly referred to as a humid-

and are not considered standard.

ity box or humidity chamber, as in Federal Specification

1.3 This standard does not purport to address all of the

TT-P-1952E.

safety concerns, if any, associated with its use. It is the

3.1.2 waterborne pavement marking (traffıc) paint, n—an

responsibility of the user of this standard to establish appro-

aqueous paint used for marking pavements.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Practice

4.1 Atest chamber is described that allows for the control of

2. Referenced Documents

relative humidity above ambient relative humidity and the

2.1 ASTM Standards: minimization of air flow variability at ambient room tempera-

D711 Test Method for No-Pick-Up Time of Traffic Paint

tures.

D1640 Test Methods for Drying, Curing, or Film Formation

5. Significance and Use

of Organic Coatings

D3924 Specification for Standard Environment for Condi-

5.1 The drying rate of organic coatings varies with changes

tioning and Testing Paint, Varnish, Lacquer, and Related

intemperature,airflow,andrelativehumidity.Inparticular,the

Materials

drying rate of waterborne paints depends on the evaporation of

D7377 Practice for Evaluating the Water Wash-Off Resis-

water and thus is much more dependent on relative humidity

tance of Traffic Paints using a Water Faucet

than are solvent based paints or paints that are 100 % solids.

D7538 Practice for Evaluating the Water Wash-Off Resis-

Measurement of the rate of drying of waterborne paints under

tance of Traffic Paints Using an Atomizing Spray Device

ambient conditions in laboratories cannot be adequately repli-

cated without some control of the drying conditions. A test

chamber will be described that provides a means of controlling

1 relative humidity above ambient humidity and minimizing the

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

effects of air flow variability at ambient room temperatures. If

Subcommittee D01.44 on Traffic Coatings.

desired, the test chamber without water in it and with vents

Current edition approved June 1, 2015. Published June 2015. Originally

wide open can be placed in a temperature and humidity

approved in 2010. Last previous edition approved in 2010 as D7539 – 10. DOI:

10.1520/D7539-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from General Services Administration, Federal Supply Service,

Standards volume information, refer to the standard‘s Document Summary page on Specification Section, Suite 8100, 470 L’Enfant Plaza, SW, Washington DC 20407,

the ASTM website. http://www.gsa.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7539 − 10 (2015)

controlled room to test dry speed at various temperatures as 8.1.3 Establish the desired relative humidity by opening and

well as humidity while using the chamber to minimize the closing the ports on the sides of the chamber, preferably so that

effect of air flow. the size of the port openings are about the same on both sides

of the chamber to equalize the air circulation in the chamber.

5.2 This practice is particularly useful for testing the drying

Therelativehumidityinthetestchamberwillstabilizeoncethe

rate of waterborne pavement marking (traffic) paints where fast

port openings are established. Occasional slight adjustments in

dry at elevated ambient humidity is an important feature. For

the side port openings may be required if the ambient humidity

waterborne traffic paints, the test chamber can be used to

in the room changes significantly during testing.

evaluate dry to no-pick-up (Test Method D711) and water

8.1.4 Target test relative humidity must be above the ambi-

wash-off resistance (Practices D7377 and D7538) at elevated

ent humidity in the room. It is best to use the chamber in a

ambient humidity.

conditioned room at a controlled temperature (23 6 2°C) and

humidity (50 6 5 % relative humidity) as described in Speci-

6. Apparatus and Equipment

fication D3924.

6.1 Test Chamber—The required elements of the test cham-

8.2 Calibration and Standardization—When using the test

ber are listed below. (Manufacturing details and a photograph

chamber to determine drying rates, the initial

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7539 − 10 D7539 − 10 (Reapproved 2015)

Standard Practice for

Using a Test Chamber for Humidity Conditioning of Test

Panels of Pavement Marking Paints

This standard is issued under the fixed designation D7539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Specification D3924 defines a standard environment of 23 6 2°C and 50 6 5 % relative humidity and free from drafts for

normal conditioning and testing of paint, varnish, lacquer, and related materials. This practice describes a test chamber that allows

for control of relative humidity above the ambient relative humidity and minimization of air flow for conditioning of test panels

at elevated relative humidity and room temperatures.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D711 Test Method for No-Pick-Up Time of Traffic Paint

D1640 Test Methods for Drying, Curing, or Film Formation of Organic Coatings

D3924 Specification for Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials

D7377 Practice for Evaluating the Water Wash-Off Resistance of Traffic Paints using a Water Faucet

D7538 Practice for Evaluating the Water Wash-Off Resistance of Traffic Paints Using an Atomizing Spray Device

2.2 Other Standard:

TT-P-1952E Federal Specification for Paint, Traffic and Airfield Marking, Waterborne (10 July 2007)

3. Terminology

3.1 Definitions:

3.1.1 test chamber, n—a cabinet or box, preferably made of transparent, waterproof material, such as clear acrylic plastic, with

panel supports and holes (ports) that can be partially to fully opened to mix outside ambient air with humidified air in the chamber

or some other means to provide humidified air with minimal air flow.

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

Current edition approved July 1, 2010June 1, 2015. Published July 2010June 2015. Originally approved in 2010. Last previous edition approved in 2010 as D7539 – 10.

DOI: 10.1520/D7539–10.10.1520/D7539–10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard‘s Document Summary page on the ASTM website.

Available from General Services Administration, Federal Supply Service, Specification Section, Suite 8100, 470 L’Enfant Plaza, SW, Washington DC 20407,

http://www.gsa.gov.

3.1.1.1 Discussion—

Also commonly referred to as a humidity box or humidity chamber, as in Federal Specification TT-P-1952E.

3.1.2 waterborne pavement marking (traffıc) paint, n—an aqueous paint used for marking pavements.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7539 − 10 (2015)

4. Summary of Practice

4.1 A test chamber is described that allows for the control of relative humidity above ambient relative humidity and the

minimization of air flow variability at ambient room temperatures.

5. Significance and Use

5.1 The drying rate of organic coatings varies with changes in temperature, air flow, and relative humidity. In particular, the

drying rate of waterborne paints depends on the evaporation of water and thus is much more dependent on relative humidity than

are solvent based paints or paints that are 100 % solids. Measurement of the rate of drying of waterborne paints under ambient

conditions in laboratories cannot be adequately replicated without some control of the drying conditions. A test chamber will be

described that provides a means of controlling relative humidity above ambient humidity and minimizing the effects of air flow

variability at ambient room temperatures. If desired, the test chamber without water in it and with vents wide open can be placed

in a temperature and humidity controlled room to test dry speed at various temperatures as well as humidity while using the

chamber to minimize the effect of air flow.

5.2 This practice is particularly useful for testing the drying rate of waterborne pavement marking (traffic) paints where fast dry

at elevated ambient humidity is an important feature. For waterborne traffic paints, the test chamber can be used to evaluate dry

to no-pick-up (Test Method D711) and water wash-off resistance (Practices D7377 and D7538) at elevated ambient humidity.

6. Apparatus and Equipment

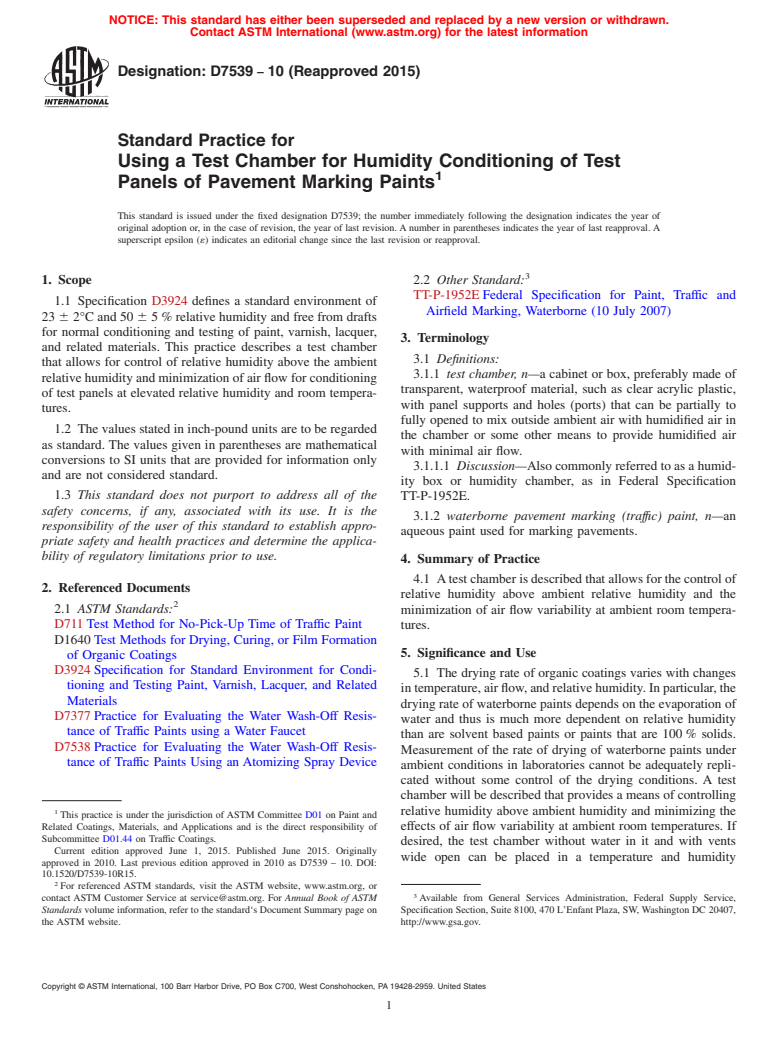

6.1 Test Chamber—The required elements of the test chamber are listed below. (Manufacturing details and a photograph of a

suitable test chamber are shown in Appendix X1.)

(1) Manufactured from transparent material to allow for visual monitoring of relative humidity and dry time test progress inside

of the chamber.

(2) Horizontal support for coated test panels within the chamber that is perforated to allow circulation of humidified air.

(3) A door in the front of the chamber for taking test panels in and out of the chamber.

(4) Control of relative humidity above the ambient relative humidity and minimization of air flow.

6.2 Hygrometer—placed in the test chamber in full view of the operator to monitor the relative humidity inside of the chamber.

This hygrometer should be accurate within 63 % relative humidity and provide

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.