ASTM F397-93(1999)

(Test Method)Standard Test Method for Resistivity of Silicon Bars Using a Two-Point Probe

Standard Test Method for Resistivity of Silicon Bars Using a Two-Point Probe

SCOPE

1.1 This test method covers the measurement of the resistivity of single-crystal bars having cross sections that are uniform in area and square, rectangular or round in shape, and having resistivity between 0.0009 and 3000 [omega][dot]cm. The resistivity of a silicon crystal is an important acceptance requirement.

1.2 This test method is intended for use on single crystals of silicon of either n- or p-type for which the uniformity of the crystal cross section is such that the area can be accurately calculated. The specimen cross-sectional area shall be constant to within +1% of the average area as determined by measurements along the crystal axis (see 12.2).

1.3 The ratio of the length to the maximum dimension of the cross section of the specimen shall not be less than 3:1 (see 12.1). The largest diameter tested by round robin was 3.75 cm (1.5 in.), and this is the largest diameter that can be measured by this method. The specimen shall normally have a surface finish of 0.4 [mu]m (16 [mu]in.) rms or less (see ANSI B46). Other surface finishes may be used if mutually acceptable; however, the multilaboratory precision figures of this test (see 16.1) then may no longer apply.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 397 – 93 (Reapproved 1999) DIN 50430

Standard Test Method for

Resistivity of Silicon Bars Using a Two-Point Probe

This standard is issued under the fixed designation F 397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Semiconducting Materials

2.2 Other Standard:

1.1 This test method covers the measurement of the resis-

ANSI B46 Surface Texture

tivity of single-crystal bars having cross sections that are

2.3 SEMI Standard:

uniform in area and square, rectangular or round in shape, and

C1 Specifications for Reagents

having resistivity between 0.0009 and 3000 V·cm. The resis-

tivity of a silicon crystal is an important acceptance require-

3. Terminology

ment.

3.1 Definitions of Terms Specific to This Standard:

1.2 This test method is intended for use on single crystals of

3.1.1 resistivity, r[V·cm]—of a semiconductor, the ratio of

silicon of either n-or p-type for which the uniformity of the

the potential gradient (electric field) parallel with the current to

crystal cross section is such that the area can be accurately

the current density.

calculated. The specimen cross-sectional area shall be constant

to within 61 % of the average area as determined by measure-

4. Summary of Test Method

ments along the crystal axis (see 12.2).

4.1 A direct current is passed through ohmic contacts at the

1.3 The ratio of the length to the maximum dimension of the

ends of a bar specimen and the potential difference is deter-

cross section of the specimen shall not be less than 3:1 (see

mined between two probes placed along the current direction

12.1). The largest diameter tested by round robin was 3.75 cm

(see 7.3.1). The resistivity is calculated from the current and

(1.5 in.), and this is the largest diameter that can be measured

potential values and factors appropriate to the geometry. This

by this method. The specimen shall normally have a surface

test method includes procedures for checking both the probe

finish of 0.4 μm (16 μin.) rms or less (see ANSI B46). Other

assembly and the electrical measuring apparatus.

surface finishes may be used if mutually acceptable; however,

4.1.1 The spacing between the two probe tips is determined

the multilaboratory precision figures of this test (see 16.1) then

from measurements of indentations made on a polished single-

may no longer apply.

crystal surface.

1.4 This standard does not purport to address all of the

4.1.2 The accuracy of the electrical measuring equipment is

safety concerns, if any, associated with its use. It is the

tested by means of an analog circuit containing a known

responsibility of the user of this standard to establish appro-

resistance together with other resistors which simulate the

priate safety and health practices and determine the applica-

resistance at the contacts between the probe tips and the

bility of regulatory limitations prior to use. Specific hazard

semiconductor surface.

statements are given in Section 9.

4.2 Procedures for preparing the specimen, for measuring

2. Referenced Documents its size, and for determining the temperature of the specimen

during measurement are also given. A table of temperature

2.1 ASTM Standards:

3 coefficient of resistivity versus resistivity is included with the

D 1193 Specification for Reagent Water

4 method so that appropriate calculations can be made.

E 1 Specification for ASTM Thermometers

F 42 Test Methods for Conductivity Type of Extrinsic

5. Significance and Use

5.1 This test method is recommended for material accep-

This test method is under the jurisdiction of ASTM Committee F-1 on

tance and manufacturing control of single-crystal bulk silicon.

Electronicsand is the direct responsibility of Subcommittee F01.06 on Silicon

It is also applicable to other semiconductor materials but

Materials and Process Control.

Current edition approved Aug. 15, 1993. Published October 1993. Originally neither the appropriate conditions of measurement nor the

published as F 397 – 74 T. Last previous edition F 397 – 88.

expected precision have been experimentally determined.

DIN 50430 is an equivalent method. It is the responsibility of DIN Committee

NMP 221, with which Committee F-1 maintains close technical liaison. DIN 50430,

Testing Inorganic Semiconductor Materials: Measurement of the Specific Electrical

Resistance of Bar-Shaped Monocrystals of Silicon or Germanium by the Two-Probe Annual Book of ASTM Standards, Vol 10.05.

Direct Current Method is available from Beuth Verlag GmbH, Burggrafenstrasse Available from American National Standards Institute, 11 West 42nd St., 13th

4-10, D-1000 Berlin 30, Federal Republic of Germany. Floor, New York, NY 10036.

3 7

Annual Book of ASTM Standards, Vol 11.01. Available from the Semiconductor Equipment and Materials International, 805

Annual Book of ASTM Standards, Vol 14.03. E. Middlefield Rd., Mountain View, CA 94043.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 397

5.2 This test method assumes no radial resistivity variation their vapors are essential.

in the crystal. If such variations are present in the crystal, this 7.2 Measurement of Cross-Sectional Specimen

method yields an average resistivity of some unknown cross

Geometry—A micrometer or vernier caliper capable of mea-

section of the crystal. In such cases, the resistivity measured on suring the dimensions of square or rectangular bars and circular

a slice cut from the crystal may not correlate with the resistivity

rods with a resolution of 60.05 mm (60.002 in.) or 60.2 %,

measured by this test method for the region about that slice. whichever is smaller.

7.3 Probe Assembly:

6. Interferences

7.3.1 Probes—Either of two shapes may be used:

6.1 Photoconductive and photovoltaic effects can seriously

7.3.1.1 Chisel-shaped voltage probes should preferably be

influence the observed resistivity, particularly with nearly

made from standard tungsten carbide flat tools 0.318 by 0.635

intrinsic material. Therefore, all determinations should be

cm (0.125 by 0.25 in.). The included angle of the chisel should

made in a dark chamber unless experience shows that the

be approximately 45° and the nominal tip radius should be

material is insensitive to ambient illumination.

approximately 0.04 mm (0.0015 in.).

6.2 Spurious currents can be introduced in the testing circuit

7.3.1.2 Conical-pointed voltage probes shall have tungsten

when the equipment is located near high-frequency generators.

carbide or osmium tips with included angle of 45 to 150°. The

If the equipment is located near such sources, adequate

nominal radius of a probe tip should be initially 25 to 50 μm.

shielding must be provided.

7.3.2 Probe Force:

6.3 Minority carrier injection during the measurement can

7.3.2.1 The force on the chisel-shaped probe shall be 8 6 1

occur due to the electric field in the specimen. With material

N when the probes are against the specimen in the measure-

possessing high lifetime of the majority carriers and high

ment position.

resistivity, such injection can significantly influence the results.

7.3.2.2 The force on the conical-pointed probes shall be

Carrier injection can be detected by repeating the measure-

1.75 6 0.25 N when the probes are against the specimen in the

ments at lower current. In the absence of injection no change in

measuring position.

resistivity should be observed. The current level recommended

7.3.3 Insulation—The electrical isolation between a probe

should reduce the probability of difficulty from this source to a

and any other probe or part of the probe assembly shall be at

minimum but in cases of doubt, the measurements of 13.3 to

least 10 V.

13.7 should be repeated at a lower current. If the proper current

7.3.4 Probe Alignment and Separation—The spacing for the

is being used, doubling or halving its magnitude should not

chisel-shaped two-probe shall be nominally 1 cm. The conical

cause a change in observed resistance that is more than 0.5 %.

probe spacing shall have a nominal value of 4.7 mm (0.18 in.).

Minority carrier effects should be most pronounced near

Probe spacing shall be determined in accordance with the

current contacts.

procedure of 11.1 in order to establish the suitability of the

6.4 Semiconductors have a significant temperature coeffi-

probe assembly as defined in 11.1.5. The following apparatus is

cient of resistivity. Consequently, the current used should be

required for this determination:

small to avoid resistive heating. If resistive heating is sus-

7.3.4.1 A chemically polished surface on material charac-

pected, it can be detected by a change in readings as a function

teristic of the specimen to be measured.

of time starting immediately after the current is applied.

7.3.4.2 A toolmaker’s microscope capable of measuring

Resistive heating can also be detected by changing the current

increments of 2.5 μm.

level as in 6.3.

NOTE 1—The nominal spacing for the conical probe configuration is

6.5 Vibration of the voltage probes sometimes causes

arrived at by using the outer-most pins of the “62.5 mil” four-point probe.

troublesome changes in contact resistance. If difficulty is

Four-point probes of other nominal spacing may be used for the purposes

encountered, the apparatus should be shock mounted.

of 7.3.4 by mutual agreement; however, the multilaboratory precision

6.6 Non-catastrophic cracks (not generally visible) or other

figures of 16.1 were arrived at using only the probes specified in 7.3.4.

mechanical damage can give erroneous readings. If visible

7.4 Probe Supports— Jigs must be provided for holding the

cracks are seen, it may be necessary to saw the crystal into

specimen and bringing the probes into contact with the

sections and measure separately.

specimen perpendicular to the specimen surface without lateral

7. Apparatus

movement. Probe positioning must be repeatable within 0.5 %

of the average probe spacing.

7.1 Specimen Preparation:

7.5 End Contacts— Contact to each specimen end should be

7.1.1 Grinding Facilities capable of giving a finish of 0.4

made by metallic fiber mesh (“conductive wool”) or soft plates

μm rms, or less.

large enough to cover the ends of the specimen and made of

7.1.2 Sandblasting Facility that uses aluminum oxide, SiC,

annealed copper or a metal with an equivalent conductivity.

or equivalent abrasive commercially specified as 27 μm.

7.1.3 Triple Beam, Dial, or Trip Balance. Prior to measurement, the ends of the specimen shall be made

ohmic by electroplating or painting with conducting silver

7.1.4 Diamond Abrasive Saw to cut proper specimen shape,

paint.

if not previously done.

7.6 Thermometer— ASTM precision thermometer having a

7.1.5 Chemical Laboratory Apparatus such as plastic bea-

kers, graduates, and plastic-coated tweezers suitable for use range from − 8 to 32°C and conforming to the requirements for

Thermometer 63C as prescribed in Specification E 1.

both with acids (including hydrofluoric) and with solvents.

Adequate facilities for handling and disposing of acids and 7.7 Electrical Measuring Apparatus:

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 397

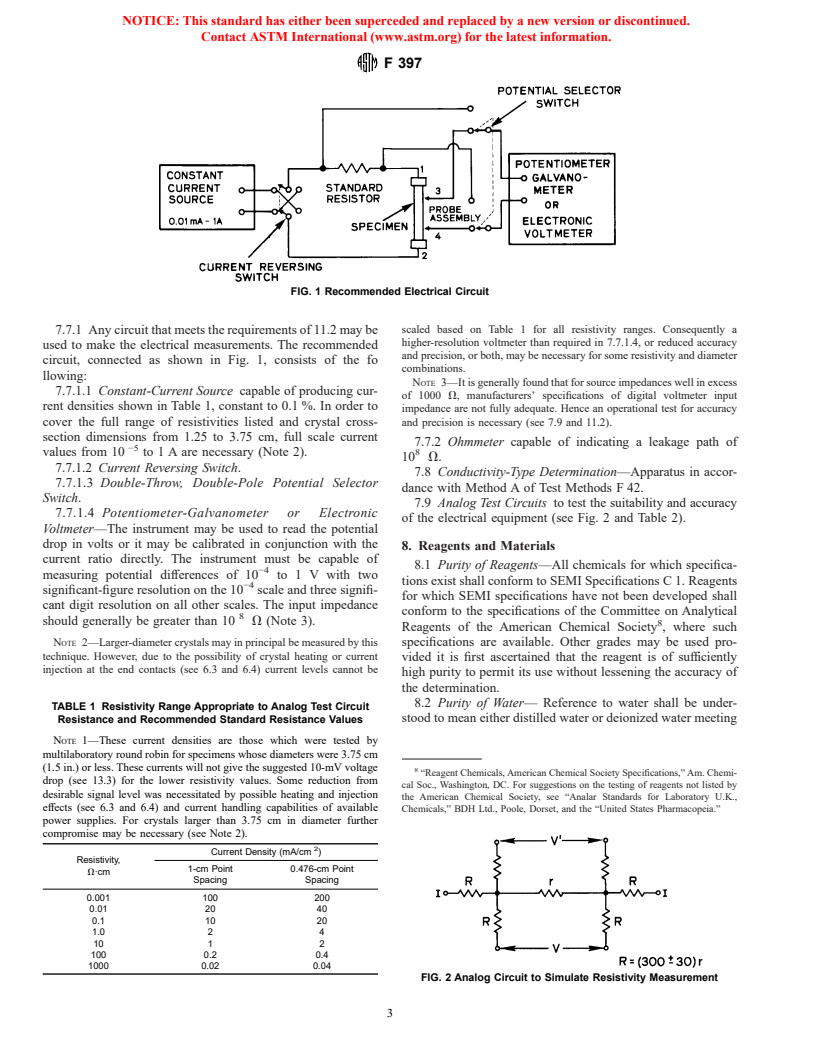

FIG. 1 Recommended Electrical Circuit

scaled based on Table 1 for all resistivity ranges. Consequently a

7.7.1 Any circuit that meets the requirements of 11.2 may be

higher-resolution voltmeter than required in 7.7.1.4, or reduced accuracy

used to make the electrical measurements. The recommended

and precision, or both, may be necessary for some resistivity and diameter

circuit, connected as shown in Fig. 1, consists of the fo

combinations.

llowing:

NOTE 3—It is generally found that for source impedances well in excess

7.7.1.1 Constant-Current Source capable of producing cur-

of 1000 V, manufacturers’ specifications of digital voltmeter input

rent densities shown in Table 1, constant to 0.1 %. In order to

impedance are not fully adequate. Hence an operational test for accuracy

cover the full range of resistivities listed and crystal cross- and precision is necessary (see 7.9 and 11.2).

section dimensions from 1.25 to 3.75 cm, full scale current

7.7.2 Ohmmeter capable of indicating a leakage path of

−5

values from 10 to 1 A are necessary (Note 2).

10 V.

7.7.1.2 Current Reversing Switch.

7.8 Conductivity-Type Determination—Apparatus in accor-

7.7.1.3 Double-Throw, Double-Pole Potential Selector

dance with Method A of Test Methods F 42.

Switch.

7.9 Analog Test Circuits to test the suitability and accuracy

7.7.1.4 Potentiometer-Galvanometer or Electronic

of the electrical equipment (see Fig. 2 and Table 2).

Voltmeter—The instrument may be used to read the potential

drop in volts or it may be calibrated in conjunction with the

8. Reagents and Materials

current ratio directly. The instrument must be capable of

8.1 Purity of Reagents—All chemicals for which specifica-

−4

measuring potential differences of 10 to 1 V with two

tions exist shall conform to SEMI Specifications C 1. Reagents

−4

significant-figure resolution on the 10 scale and three signifi-

for which SEMI specifications have not been developed shall

cant digit resolution on all other scales. The input impedance

conform to the specifications of the Committee on Analytical

should generally be greater than 10 V (Note 3).

Reagents of the American Chemical Society , where such

NOTE 2—Larger-diameter crystals may in principal be measured by this specifications are available. Other grades may be used pro-

technique. However, due to the possibility of crystal heating or current

vided it is first ascertained that the reagent is of sufficiently

injection at the end contacts (see 6.3 and 6.4) current levels cannot be

high purity to permit its use without lessening the accuracy of

the determination.

8.2 Purity of Water— Reference to water shall be under-

TABLE 1 Resistivity Range Appropriate to Analog Test Circuit

stood to mean either distilled water or deionized water meeting

Resistance and Recommended Standard Resistance Values

NOTE 1—These current densities are those which were tested by

multilaboratory round robin for specimens whose diameters were 3.75 cm

(1.5 in.) or less. These currents will not give the suggested 10-mV voltage 8

“Reagent Chemicals, American Chemical Society Specifications,” Am.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.