ASTM E345-93(2002)

(Test Method)Standard Test Methods of Tension Testing of Metallic Foil

Standard Test Methods of Tension Testing of Metallic Foil

SIGNIFICANCE AND USE

Tension tests provide information on the strength and ductility of materials under uniaxial tensile stresses. This information may be useful in comparisons of materials, alloy development, quality control, and design.

The results of tension tests from selected portions of a part or material may not totally represent the strength and ductility of the entire end product of its in-service behavior in different environments.

These test methods are considered satisfactory for acceptance testing of commercial shipments since the methods have been used extensively for these purposes.

Tension tests provide a means to determine the ductility of materials through the measurement either of elongation or reduction of area. However, as specimen thickness is reduced, tension tests may become less useful for the determination of ductility. For these purposes Test Method E 796 presents an alternative procedure for measuring ductility.

SCOPE

1.1 These test methods cover the tension testing of metallic foil at room temperature in thicknesses less than 0.006 in. (0.150 mm).

Note 1—Exception to these methods may be necessary in individual specifications or test methods for a particular material.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E345–93(Reapproved 2002)

Standard Test Methods of

Tension Testing of Metallic Foil

This standard is issued under the fixed designation E 345; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 These test methods cover the tension testing of metallic 3.1 The definitions of terms relating to tension testing

foil at room temperature in thicknesses less than 0.006 in. appearing in TerminologyE6 apply to the terms used in these

(0.150 mm). methods of tension testing.

NOTE 1—Exception to these methods may be necessary in individual

4. Significance and Use

specifications or test methods for a particular material.

4.1 Tension tests provide information on the strength and

1.2 The values stated in inch-pound units are to be regarded

ductility of materials under uniaxial tensile stresses. This

as the standard. The SI values in parentheses are for informa-

information may be useful in comparisons of materials, alloy

tion only.

development, quality control, and design.

1.3 This standard does not purport to address all of the

4.2 The results of tension tests from selected portions of a

safety concerns, if any, associated with its use. It is the

part or material may not totally represent the strength and

responsibility of the user of this standard to establish appro-

ductility of the entire end product of its in-service behavior in

priate safety and health practices and determine the applica-

different environments.

bility of regulatory limitations prior to use.

4.3 These test methods are considered satisfactory for ac-

ceptance testing of commercial shipments since the methods

2. Referenced Documents

have been used extensively for these purposes.

2.1 ASTM Standards:

4.4 Tension tests provide a means to determine the ductility

B 193 Test Method for Resistivity of Electrical Conductor

of materials through the measurement either of elongation or

Materials

reduction of area. However, as specimen thickness is reduced,

E4 Practices for Force Verification of Testing Machines

tension tests may become less useful for the determination of

E6 Terminology Relating to Methods of Mechanical Test-

ductility. For these purposes Test Method E 796 presents an

ing

alternative procedure for measuring ductility.

E8 Test Methods forTensionTesting of Metallic Materials

E8M Test Methods for Tension Testing of Metallic Mate-

5. Apparatus

rials (Metric)

5.1 Testing Machines—Machines used for tension testing

E29 Practice for Using Significant Digits in Test Data to

shall conform to the requirements of PracticesE4. The loads

Determine Conformance with Specifications

used in determining tensile strength, yield strength, and yield

E 252 Test Method for Thickness of Thin Foil and Film by

point shall be within the verified loading range of the testing

Weighing

machine as defined in PracticesE4.

E 796 Test Method for Ductility Testing of Metallic Foil

5.2 Gripping Devices:

5.2.1 General—Various types of gripping devices may be

used to transmit the measured load applied by the testing

These test methods are under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and are the direct responsibility of Subcommittee E28.04 on

machine to the test specimen. To ensure axial tensile stress

Uniaxial Testing.

within the gage length, the axis of the test specimen must

Current edition approved Aug. 15, 1993. Published October 1993. Originally

e1 coincide with the center line of the heads of the testing

published as E 345 – 68 T. Last previous edition E 345 – 87 (1992) .

machine. Any departure from this center line may introduce

Annual Book of ASTM Standards, Vol 02.03.

Annual Book of ASTM Standards, Vol 03.01.

bending stresses that are not included in the usual stress

Annual Book of ASTM Standards, Vol 14.02.

computation (load divided by cross-sectional area).

Annual Book of ASTM Standards, Vol 02.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E345–93 (2002)

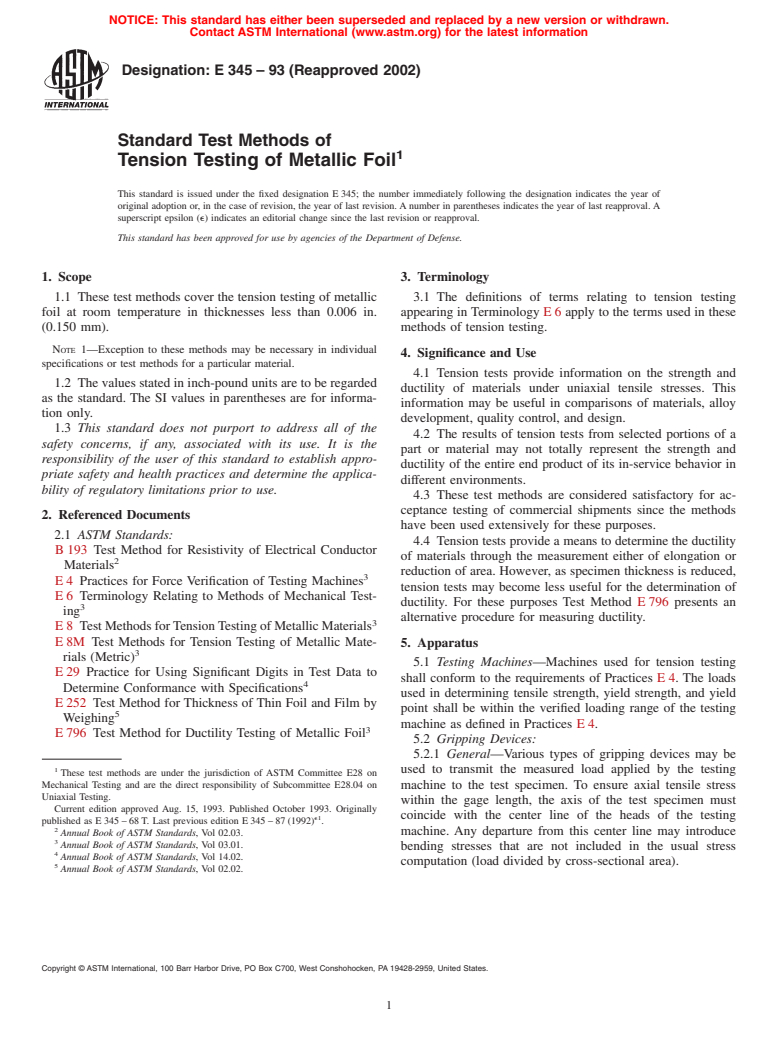

Dimensions

Specimen

Type A Type B

in. mm in. mm

G—Gage length 2.000 6 0.005 50.0 6 0.1 5 125

W—Width 0.500 6 0.010 12.50 6 0.25 0.500 12.5

T—Thickness thickness of foil thickness of foil

R—Radius of fillet, min ⁄4 19 . .

L—Overall Length, min 8 200 9 230

A—Length of reduced section, min 2 ⁄4 60 . .

B—Length of grip section, min 2 50 . .

C—Width of grip section, approx. ⁄4 20 0.500 12.5

NOTE 1—ForTypeAspecimens,theendsofthereducedsectionshallnotdifferinwidthbymorethan0.002in.(0.05mm).Also,theremaybeagradual

decrease in width from the ends to the center, but the width at either end shall not be more than 0.005 in. (0.10 mm) larger than the width at the center.

NOTE 2—The dimension T is the thickness of the test specimen as provided for in the applicable material specifications.

FIG. 1 Foil Tension Test Specimen

5.2.2 Wedge Grips—Testing machines usually are equipped 7. Procedures

with wedge grips. These wedge grips generally furnish a

7.1 Type A Specimen Preparation—The specimens can be

satisfactory means of gripping long specimens of ductile

machined in packs by use of a milling-type cutter. The

materials in the thicker foil gages. If, for any reason, one grip

machined specimens shall be examined under about 203

of a pair advances farther than the other as the grips tighten, an

magnification to determine that the edges are smooth and that

undesirable bending stress may be introduced. When liners are

there are no surface scratches or creases. Specimens showing

used behind the wedges, they must be of the same thickness

discernible scratches, creases, or edge discontinuities shall be

and their faces must be flat and parallel. For proper gripping, it

rejected. The milling cutter shall be sharpened or renewed

is desirable that the entire length of the serrated face of each

when necessary. When machining some thicknesses and tem-

wedge be in contact with the specimen.Abuffer material such

pers of material it may be necessary to interleave the samples

as 320-grit silicon carbide paper may be inserted between the

with hard aluminum sheet, a plastic, or other suitable material.

specimen and serrated faces to minimize tearing of specimens.

For some materials it may be desirable to polish the edges of

5.2.3 Smooth Face Grips—For foils less than 0.003 in.

the specimens, either mechanically or by electropolishing.

(0.076 mm) thickness, it may be desirable that the grips have

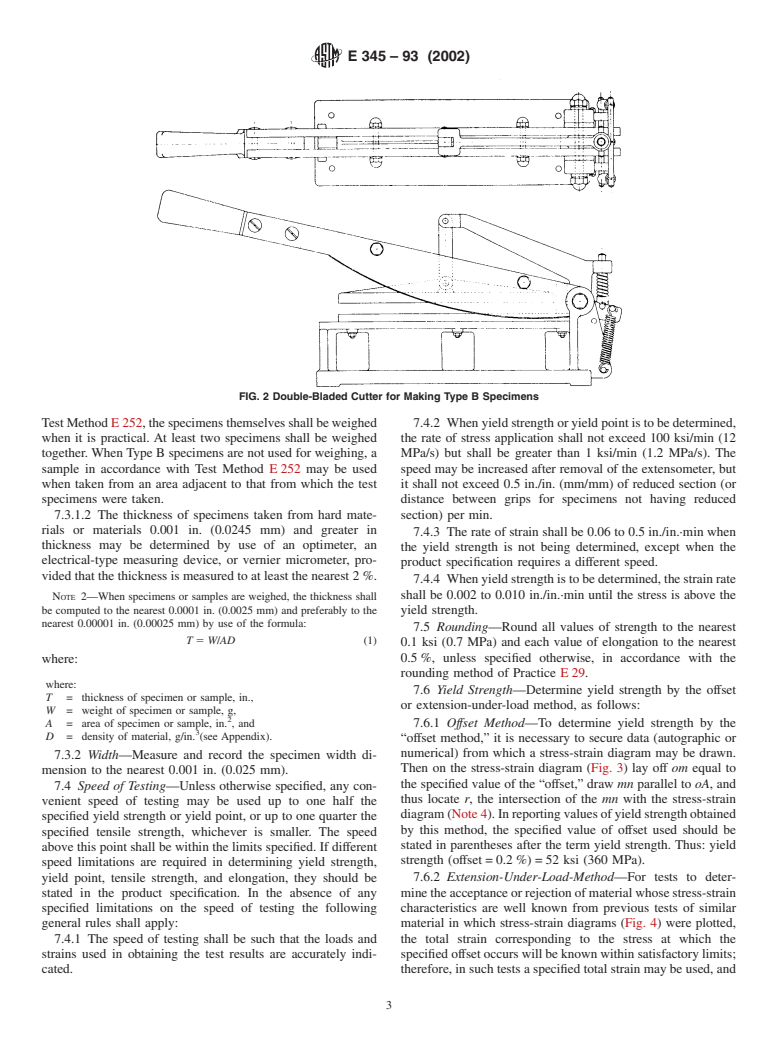

7.2 TypeBSpecimenPreparation—The specimens, particu-

smooth faces and that the gripping pressure be about 100 psi

larly of soft and of thin hard metals, may be prepared by

(0.7 MPa) for each 0.001 in. (0.025 mm) of specimen thick-

shearing, for example, by use of a double-bladed cutter (Fig. 2)

ness. 6

or by slitting. The cutting edges should be lubricated, if

necessary with a material such as stearic acid in alcohol or

6. Test Specimen

another suitable material. The finished specimens shall be

6.1 General—Test specimens shall be prescribed in the

examined under about 203 magnification to determine that the

product specification for the material being tested. If a Type A

edges are smooth and there are no surface scratches or creases.

specimen is used, all specimen dimensions, test procedures,

Specimens showing discernible surface scratches, creases, or

and calculations shall be in compliance with those shown in

edge discontinuities shall be rejected.

Test MethodsE8orE8M.

7.3 Specimen Measurement:

6.2 Type A Specimen—Type A specimens shall be in accor-

7.3.1 Thickness:

dance with the ⁄2-in. (12.5-mm) sheet-type specimen shown in

7.3.1.1 Thicknessofspecimenstakenfromsoftfoilsorfrom

Fig. 1. To avoid lateral buckling in tests of some materials, the

foils 0.002 in. (0.05 mm) and thinner shall be determined to an

minimum radius of the fillet should be ⁄4 in. (19 mm), or the

accuracy of 2 % of the thickness by weighing in accordance

width of the grip ends should be only slightly larger than the

with Test Method E 252 or by measuring devices. When using

width of the reduced section, or both; and the reduced section

should be at least 20 % longer than the gage length.

6.3 Type B Specimens—Type B specimens shall be in

The Thwing-Albert JDC-50 precision cutter available from Thwing-Albert

accordance with the ⁄2-in. (12.5-mm) wide parallel sided

Instrument Co., 10960 Dutton Rd., Philadelphia, PA 19154, has been found to be

specimen shown in Fig. 1. acceptable.

E345–93 (2002)

FIG. 2 Double-Bladed Cutter for Making Type B Specimens

TestMethodE 252,thespecimensthemselvesshallbeweighed 7.4.2 When yield strength or yield point is to be determined,

when it is practical. At least two specimens shall be weighed the rate of stress application shall not exceed 100 ks

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.