ASTM C351-92b(1999)e1

(Test Method)Standard Test Method for Mean Specific Heat of Thermal Insulation (Withdrawn 2008)

Standard Test Method for Mean Specific Heat of Thermal Insulation (Withdrawn 2008)

SIGNIFICANCE AND USE

Mean specific heat is an essential property of a thermal insulating material when the latter is used under conditions of unsteady or transient heat flow. It is a part of the parameter, thermal diffusivity, which governs the rate of temperature diffusion through insulation. It is a basic thermodynamic property of all substances, the value of which depends upon chemical composition and temperature.

Note 1—Specific heat of insulations, as measured by this test method, using small specimens of a multi-component composite or of a low-density product that has to be highly compressed, may not be directly applicable for use in calculations involving transient thermal response. The applicability of the results will depend upon a system being analyzed, the desired accuracy, and the relative amounts, and specific heats of the various solid or fluid components, or both, of the thermal insulation.

SCOPE

1.1 This test method covers the determination of mean specific heat of thermal insulating materials. The materials must be essentially homogeneous and composed of matter in the solid state.

1.2 This test method employs the classical method of mixtures. This provides procedures and apparatus simpler than those generally used in scientific calorimetry, an accuracy that is adequate for most thermal insulating purposes, and a degree of precision that is reproducible by laboratory technicians of average skill. While this test method was developed for testing thermal insulations, it is easily adaptable to measuring the specific heat of other materials.

1.3 The test procedure provides for a mean temperature of approximately 60°C (100 to 20°C temperature range), using water as the calorimetric fluid. By substituting other calorimetric fluids the temperature range may be changed as desired.

1.4 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of mean specific heat of thermal insulating materials. The materials must be essentially homogeneous and composed of matter in the solid state.

Formerly under the jurisdiction of Committee C16 on Thermal Insulation, this test method was withdrawn in August 2008 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: C 351 – 92b (Reapproved 1999)

Standard Test Method for

Mean Specific Heat of Thermal Insulation

This standard is issued under the fixed designation C 351; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 6.1.3.1 was editorially updated in June 2007.

1. Scope degree, measured as the average quantity over the temperature

range specified. (It is distinguished from true specific heat by

1.1 This test method covers the determination of mean

being an average rather than a point value.) The unit of

specific heat of thermal insulating materials. The materials

measurement is J/kg·K.

must be essentially homogeneous and composed of matter in

3.1.2 thermal capacity—the amount of heat necessary to

the solid state.

change the temperature of the body one degree. For a homo-

1.2 This test method employs the classical method of

geneous body it is the product of mass and specific heat. For a

mixtures. This provides procedures and apparatus simpler than

nonhomogeneous body it is the sum of the products of mass

those generally used in scientific calorimetry, an accuracy that

and specific heat of the individual constituents. Thermal

is adequate for most thermal insulating purposes, and a degree

capacity has the units of J/K.

of precision that is reproducible by laboratory technicians of

3.1.3 thermal diffusivity—the ratio of thermal conductivity

average skill. While this test method was developed for testing

of a substance to the product of its density and specific heat.

thermal insulations, it is easily adaptable to measuring the

Common unit for this property is m /s.

specific heat of other materials.

3.1.4 water equivalent—the mass of water that requires the

1.3 The test procedure provides for a mean temperature of

same amount of heat as the given body in order to change its

approximately 60°C (100 to 20°C temperature range), using

temperature by an equal amount.

water as the calorimetric fluid. By substituting other calorimet-

ric fluids the temperature range may be changed as desired.

4. Summary of Test Method

1.4 The values stated in SI units are to be regarded as the

4.1 Themethodofmixturesusedinthistestmethodconsists

standard.

essentiallyofaddingaknownmassofmaterialataknownhigh

1.5 This standard does not purport to address all of the

temperature to a known mass of water at a known low

safety concerns, if any, associated with its use. It is the

temperature and determining the equilibrium temperature that

responsibility of the user of this standard to establish appro-

results. The heat absorbed by the water and the containing

priate safety and health practices and determine the applica-

vessel can be calculated and this value equated to the expres-

bility of regulatory limitations prior to use.

sion for the heat given up by the hot material. From this

2. Referenced Documents equation the unknown specific heat can be calculated.

2.1 ASTM Standards:

5. Significance and Use

E1 Specification forASTM Liquid-in-Glass Thermometers

5.1 Mean specific heat is an essential property of a thermal

3. Terminology insulating material when the latter is used under conditions of

unsteady or transient heat flow. It is a part of the parameter,

3.1 Definitions:

thermal diffusivity, which governs the rate of temperature

3.1.1 mean specific heat—the quantity of heat required to

diffusion through insulation. It is a basic thermodynamic

change the temperature of a unit mass of a substance one

property of all substances, the value of which depends upon

chemical composition and temperature.

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

NOTE 1—Specific heat of insulations, as measured by this test method,

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

using small specimens of a multi-component composite or of a low-

Measurement.

density product that has to be highly compressed, may not be directly

Current edition approved Aug. 15, 1992. Published October 1992. Originally

approved in 1954. Last previous edition approved in 1999 as C 351 – 92b(1999). applicable for use in calculations involving transient thermal response.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Weber, R. L., Heat and Temperature Measurement, Prentice-Hall, New York,

the ASTM website. NY, 1950.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

C 351 – 92b (1999)

The applicability of the results will depend upon a system being analyzed,

6.1.3.1 A convenient form of electric heater can be con-

the desired accuracy, and the relative amounts, and specific heats of the

structed by covering a 254-mm length of 38-mm diameter

various solid or fluid components, or both, of the thermal insulation.

brass pipe with a thin sheet of nonflammable insulation,

winding about 70 turns of 22-gage (0.64 mm) Nichrome wire

6. Apparatus

overthepaper,andinsulatingtheassemblywith25.4-mmthick

6.1 The typical apparatus is shown schematically in Fig. 1.

pipe insulation. It is necessary that the end turns be closer

It consists of the following:

together than those over the center portion of the heater to

6.1.1 Calorimeter and Accessories—The calorimeter shall

compensate for end heat loss. The heater temperature is

be an unlagged Dewar flask with a maximum capacity of not

controlled by regulating the electric current to the heater with

less than 500 mL nor more than 750 mL. The flask shall have

a variable transformer or resistor.Aconstant voltage source of

an insulated cover or stopper. Other accessories shall include a

powerwithin 61 %maximumvoltagevariationisnecessaryto

magnetic stirrer equipped with a speed-regulating device.

minimize temperature fluctuations.

6.1.2 Differential Temperature Sensor—An appropriate

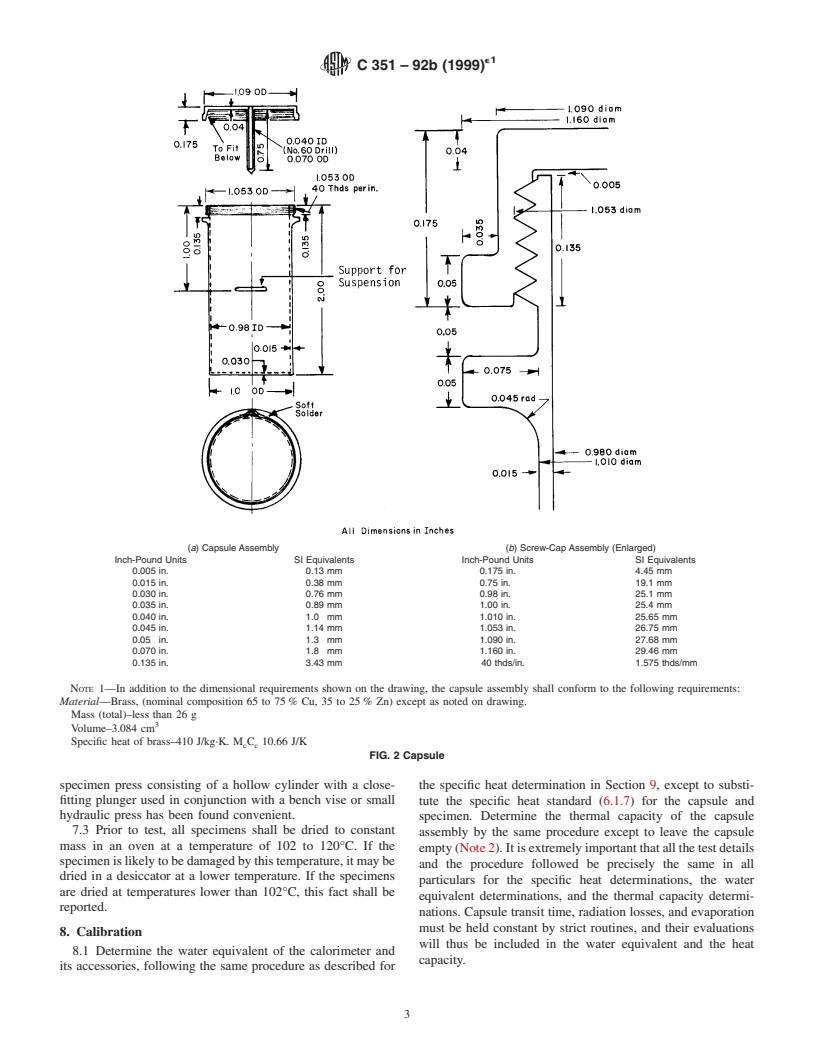

6.1.4 Capsule—The capsule shall comprise a hollow cylin-

temperature difference sensor, such as a Beckmann differential

der of brass approximately 25.4 mm in diameter by 50.8 mm

thermometer or a suitable equivalent, preferably with a mag-

long. It shall have a removable cap and a thermocouple well

nifier, and having a range of at least 5°C and a sensitivity of no

extending into the cavity space to accommodate the tempera-

less than 0.01°C shall be used to determine the rise in

ture sensor. It is imperative that the capsule assembly be

temperature of the calorimetric fluid during test. Where a

absolutely watertight, as no leakage can be tolerated. The

differential thermometer is used, it shall be set with its lowest

completed capsule, including cap, gasket, and suspension loop,

temperaturedivisionattheapproximateroomtemperature,and

shallhaveathermalcapacitynotexceeding10.5J/K.Acapsule

the setting point checked with a precision-type temperature

design meeting the above requirements is shown in Fig. 2.

sensor (such as Thermometer 632C, preferably with a magni-

6.1.5 Temperature Sensor—A suitable, calibrated tempera-

fier, described in SpecificationE1).

turesensorandassociatedread-outequipmentofsuitablerange

6.1.3 Heater—The heater shall be of the open-end radiation

and precision to permit reading temperatures to an accuracy of

typesimilartothecylindricaldeviceshowninFig.1.Itmaybe

0.1°C shall be used. If a thermocouple is used, the wire size

heated by electricity or steam. The relative dimensions of the

should be small to limit the error caused by thermal conduc-

heater and the capsule shall be such that the specimen will be

tance losses along the length. Thermocouples can be made

heated to a uniform and constant temperature as required. A

from any of the standard pairs registered with the National

maximum variation of 6 1°C over the length of the heater is

Institute of Standards and Technology. A particular suitable

permitted. The heater shall be provided with an insulated

thermocouple is chromel/constantan, fabricated from wires

removable top cover designed both to permit passage of the

having a diameter no greater than No. 30 B & S gage (0.265

leadsofthetemperaturesensorandtosuspendthecapsule.The

mm). The pair combines the attributes of reduced heat leakage

bottom shall be closed with a removable insulated cover to

and a higher emf than copper/constantan.

permit free dropping of the capsule. The heater assembly shall

6.1.6 TestRoom—Thetemperatureoftheroominwhichthe

be mounted so it can be swung quickly into place over the

test is conducted shall be reasonably constant during the test

calorimeter.

period. The test room temperature control is satisfactory if the

time-temperature curve is a straight line (within the allowable

experimental error) for a 10-min period before the dropping of

thecapsuleandfora10-minperiodjustpriortothetermination

of the test.

6.1.7 Specific Heat Standard—Electrolytic copper (com-

mercial electrical bus bar copper) shall be used as a specific

heat standard.Astandard specimen as shown in Fig. 3 shall be

used to determine the water equivalent of the calorimeter flask

and its accessories. For the temperature range covered (be-

tween 100 and 20°C) the mean specific heat of copper shall be

taken as 390.0 J/(kg·K).

7. Test Specimens

7.1 Specimens shall be selected at random as required to

provide test material representative of the lot sampled. The

number of specimens may be determined by agreement but

shall be not less than three.

7.2 The specimens shall be tested in the compressed form,

since it is desirable to have as large a mass as possible. A

“Reference Table for Thermocouples,” Circular No. 508, National Institute of

FIG. 1 Specific Heat Calorimeter Standards and Technology, Gaithersburg, MD 20899.

e1

C 351 – 92b (1999)

(a) Capsule Assembly (b) Screw-Cap Assembly (Enlarged)

Inch-Pound Units SI Equivalents Inch-Pound Units SI Equivalents

0.005 in. 0.13 mm 0.175 in. 4.45 mm

0.015 in. 0.38 mm 0.75 in. 19.1 mm

0.030 in. 0.76 mm 0.98 in. 25.1 mm

0.035 in. 0.89 mm 1.00 in. 25.4 mm

0.040 in. 1.0 mm 1.010 in. 25.65 mm

0.045 in. 1.14 mm 1.053 in. 26.75 mm

0.05 in. 1.3 mm 1.090 in. 27.68 mm

0.070 in. 1.8 mm 1.160 in. 29.46 mm

0.135 in. 3.43 mm 40 thds/in. 1.575 thds/mm

NOTE 1—In addition to the dimensional requirements shown on the drawing, the capsule assembly shall conform to the following requirements:

Material—Brass, (nominal composition 65 to 75 % Cu, 35 to 25 % Zn) except as noted on drawing.

Mass (total)–less than 26 g

Volume–3.084 cm

Specific heat of brass–410 J/kg·K. M C 10.66 J/K

c c

FIG. 2 Capsule

specimen press consisting of a hollow cylinder with a close- the specific heat determination in Section 9, except to substi-

fitting plunger used in conjunction wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.