ASTM D1565-81(1990)

(Specification)Specification for Flexible Cellular Materials-Vinyl Chloride Polymers and Copolymers (Open-Cell Foam) (Withdrawn 1998)

Specification for Flexible Cellular Materials-Vinyl Chloride Polymers and Copolymers (Open-Cell Foam) (Withdrawn 1998)

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1565 – 81 (Reapproved 1990)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Flexible Cellular Materials—Vinyl Chloride

1

Polymers and Copolymers (Open-Cell Foam)

This standard is issued under the fixed designation D 1565; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

This specification was prepared jointly by the American Society for Testing and Materials and the Society of the Plastics Industry.

1. Scope of a helix at a temperature between 18 and 29°C.

3.6 cellular material—a generic term for materials contain-

1.1 This specification covers flexible cellular products con-

ing many cells (either open, closed, or both) dispersed through-

taining interconnecting cells made of a base material known as

out the mass.

poly(vinyl chloride) or copolymers thereof.

1.2 It is intended as a general specification and may need to

4. Classification

be supplemented by detailed specifications or methods of test

4.1 Grades of vinyl foam are designated by letters that

for a particular product, in which case the latter would take

identify the kind of vinyl foam as follows:

precedence. Reference to methods for testing poly(vinyl chlo-

4.1.1 VC—Vinyl foam, cored,

ride) foam products should specifically state the particular test

4.1.2 VU—Vinyl foam, uncored, and

or tests desired.

4.1.3 VO—Vinyl foam, uncored, extra firm.

1.3 This standard does not purport to address all of the

4.2 Digits following the letters indicate the degree of

safety problems, if any, associated with its use. It is the

firmness, the softer grades being identified with the lower

responsibility of the user of this standard to establish appro-

numbers and the firmer grades with the higher numbers (see

priate safety and health practices and determine the applica-

Table 1).

bility of regulatory limitations prior to use.

4.3 Suffıx Letters may be added singly or in combination

2. Referenced Documents after any grade designation to indicate additional requirements

beyond the basic requirements specified in Table 1. The

2.1 ASTM Standards:

approved suffix letters and their significance are as follows:

E 145 Specification for Gravity-Convection and Forced-

2

Suffix Letters

Ventilation Ovens

C—Weather Resistance.*

D—Load Deflection.*

3. Description of Terms Specific to This Standard

E—Oil Resistance.*

F—Low Temperature.*

3.1 vinyl or PVC—abbreviated terms used to designate

G—Tear Resistance.*

poly(vinyl chloride) or copolymers thereof.

H—Flexing Resistance.

3.2 surface skin—the smooth skin on a foam formed during

J—Abrasion Resistance.*

K1—Adhesion to Metal, Made During Moldings.*

manufacture by contact with the mold, cover plate, or air.

K2—Adhesion, Cemented Bond, Made After Molding.*

3.3 mechanically blown foam—a foam made by mechani-

M—Flame Resistance.*

cally mixing a gas into a base material so as to develop a foam

P—Nonstaining.*

P1—Compatibility with Other Materials.*

structure.

R—Resilience.*

3.4 chemically blown foam—a foam made by incorporating

W—Density.

a chemical agent into the base material which on heating

Z—Special Requirements.*

liberates a gas causing foaming of the base materials.

* Test method and values shall be as agreed upon between the purchaser

3.5 flexible—a descriptive term applied to a cellular organic

and the manufacturer.

polymeric material that will not rupture within 60 s when a

specimen 200 by 25 by 25 mm is bent around a 25-mm

5. Manufacture

diameter mandrel at a uniform rate of one lap in5sinthe form

5.1 Foam may be produced in sheet, strip, molded, or

specific shapes. The foam articles may be solid or cored. Size,

1

shape, and distribution of cores, if any, shall be at the option of

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular

the manufacturer, subject to the approval of the purchaser.

Plastics.

Current edition approved Nov. 27, 1981. Published January 1982. Originally

6. Material and Workmanship

published as D 1565 – 58 T. Last previous edition D 1565 – 76.

2

Annual Book of ASTM Standards, Vol 14.02. 6.1 Vinyl foam shall be manufactured from poly(vinyl

1

---------------------- Page: 1 ----------------------

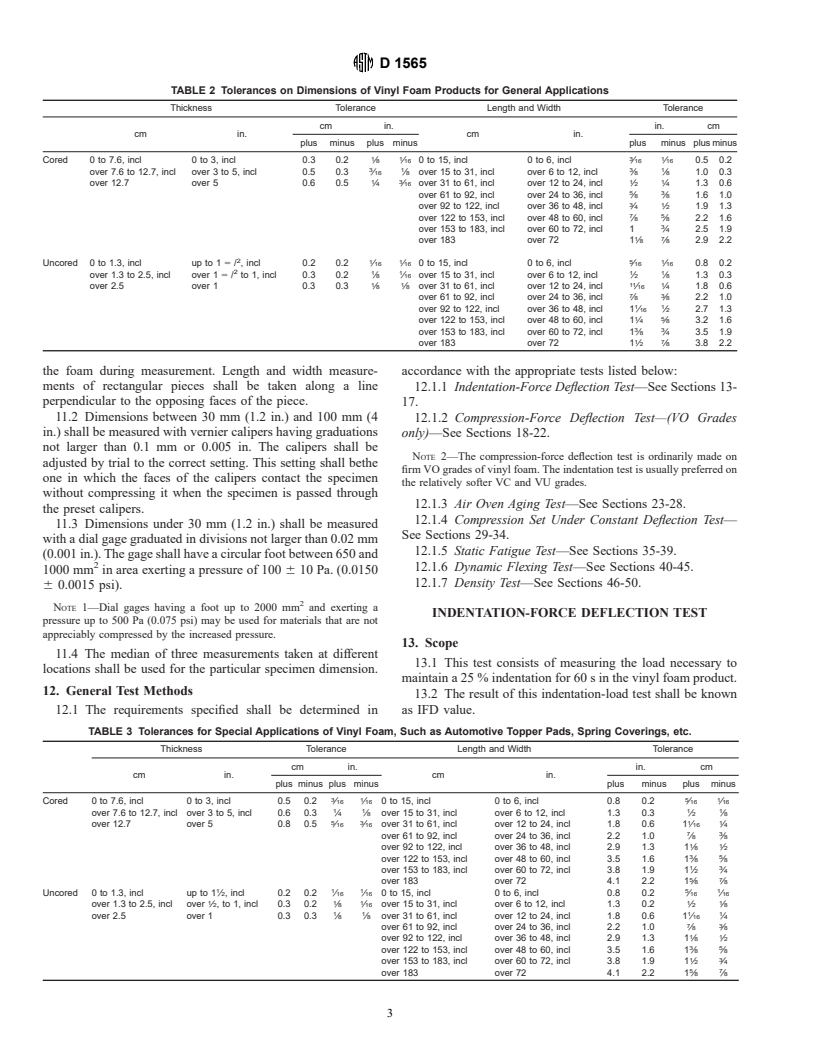

D 1565

TABLE 1 Physical Requirements of Vinyl Foam

Requirements

A

Basic Requirements

Added by Suffix H

Air Oven Aging, 22 h

Force for 25 % indentation Compression Deflection

Compression Set 22 h Dyna

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.